Yes, this oven lay on the wood, and… motors that require repair. “Burn” them in her invited young innovators Omsk CHPP-4, participants NTTM-78. It is easy to imagine how much work and time consuming in the repair of electric motors, the extract from the grooves of the rotor and stator are tightly Packed windings with insulating filling. In furnace insulation under high temperature burns, its volume is reduced by more than a third, and the wire is easily removed.

Yes, this oven lay on the wood, and… motors that require repair. “Burn” them in her invited young innovators Omsk CHPP-4, participants NTTM-78. It is easy to imagine how much work and time consuming in the repair of electric motors, the extract from the grooves of the rotor and stator are tightly Packed windings with insulating filling. In furnace insulation under high temperature burns, its volume is reduced by more than a third, and the wire is easily removed.

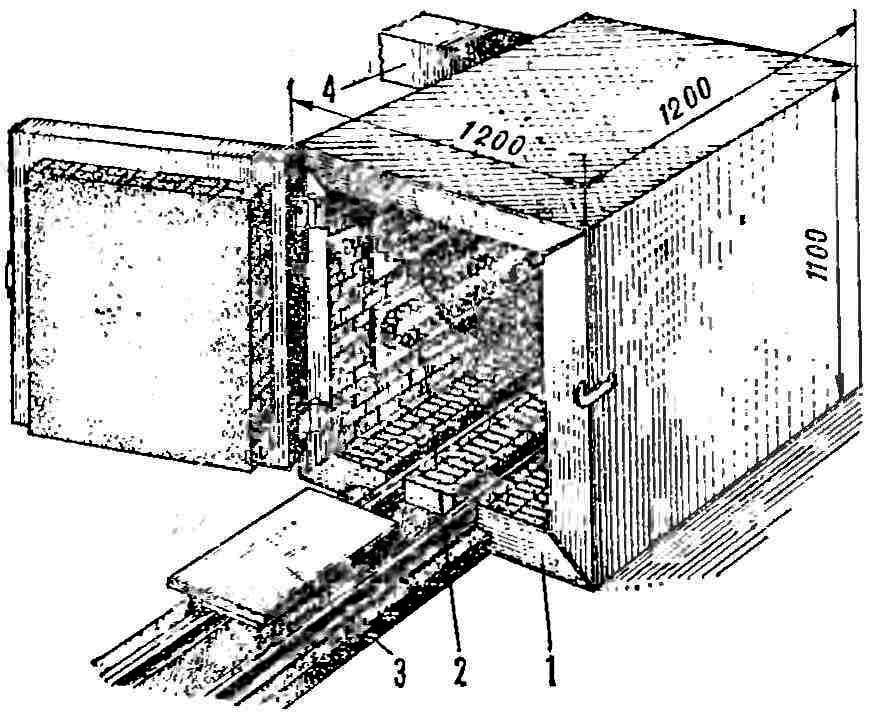

Camera for annealing of the windings is a steel case lined inside with refractory bricks. Inside the oven in her wall mounted electric heating coils, raising the temperature to 300°. The motor is loaded in the camera on a special rail wagon. The products of combustion are discharged through the exhaust vent without polluting the air.

Camera for annealing

1 — body, 2 spiral heating elements, 3 — trolley for the feed motor 4 and exhaust ventilation.

The introduction of such a furnace provides a considerable economic effect — more than 1000 rubles per year. Labour productivity during the disassembly of the windings, processed in the cell increases 10 times.