“Indoor model — on the lunge, even with the Microdrive! It can’t be!” — you might say. And if you add that it starts in the school hall, the question will arise even more. Because the noise model airplane engine, even the smallest volume of 0.3 cm3 is unacceptable in the school hall.

“Indoor model — on the lunge, even with the Microdrive! It can’t be!” — you might say. And if you add that it starts in the school hall, the question will arise even more. Because the noise model airplane engine, even the smallest volume of 0.3 cm3 is unacceptable in the school hall.

However, it may be otherwise. One on the oldest Leningrad modelers, master of sports A. A. Erler, and his circle of model airplanes-students adapted the motor from a model of an electric cord for models with external power supply “Electrics”, built by one of the pupils of A. A. Erler. Sergey Petrakov, not flown in the halls of the Palace of pioneers and produced a constant effect.

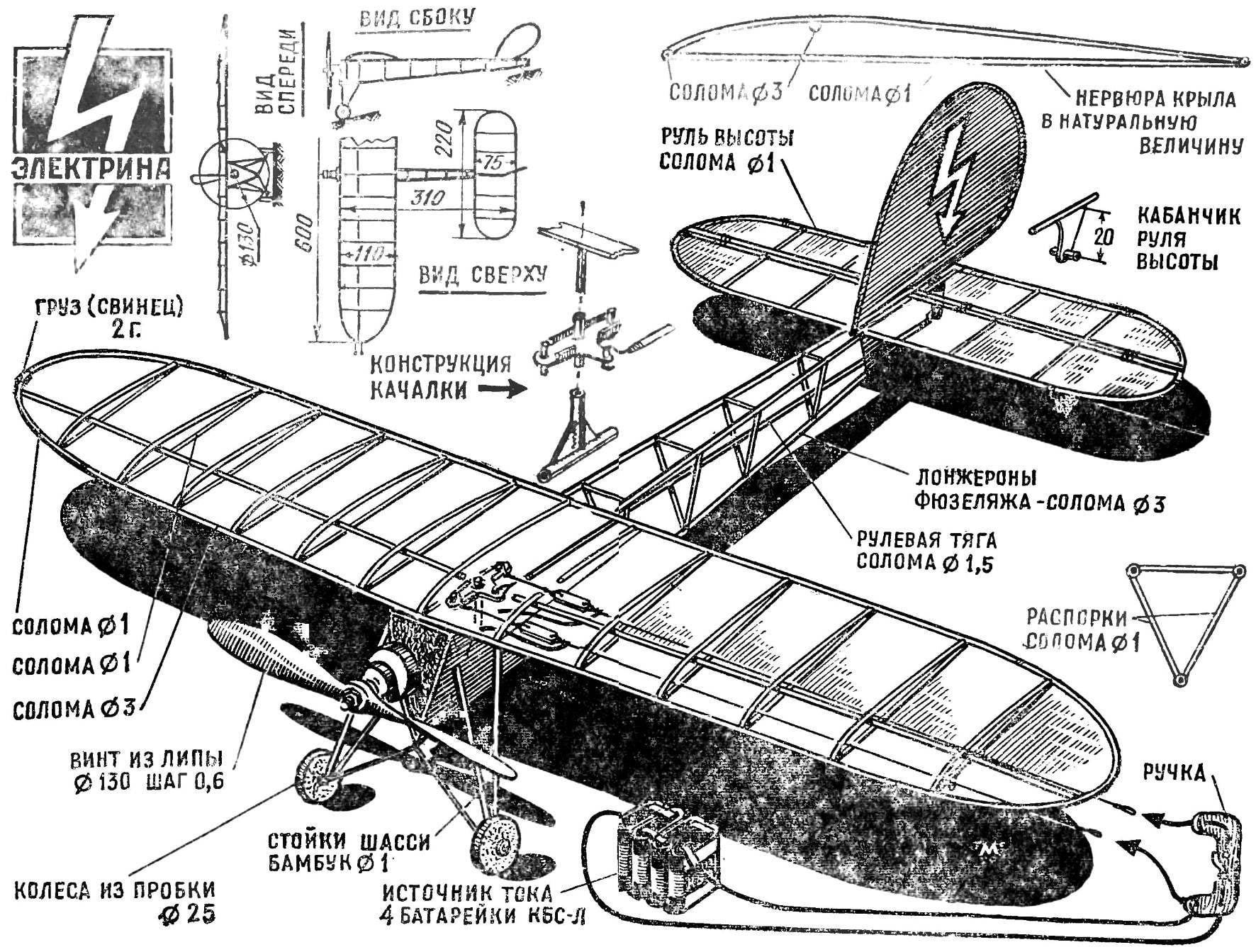

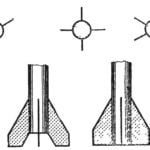

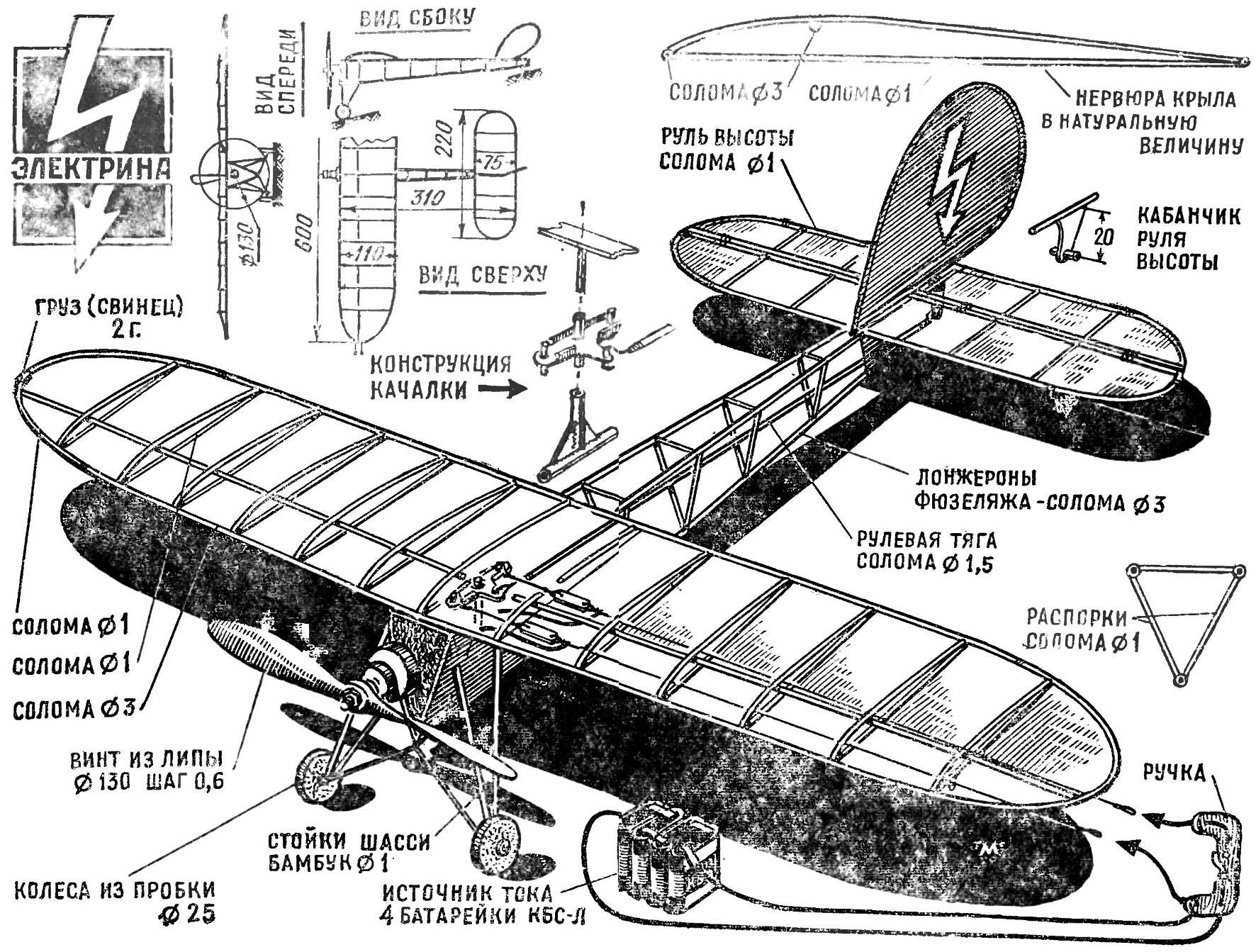

The NT model is made of straw. Flying weight is 20 g. its design is a cantilever high-wing aircraft with a fuselage of triangular section. The main working element of the fuselage — nose bulkhead-boss. Fabricate it from a piece of cork or balsa in the form of an isosceles triangle with a thickness of about 10 mm. In it cut a slit under the motor where it needs tight log. Use the motor from a toy electric locomotive type “Pico” (made in GDR) with a gauge of 12 mm. Further secure the motor with tape. Terminals must be outside for just connect the pins from the cord.

To the corners of the nose frame-boss attach of thread and glue to the longitudinal elements of the fuselage spar of straw stalks of Ø 3 mm. Connect them in the rear on a small boss, also carved out of cork or balsa. All spars in the appropriate places with a knife make punctures and set between them on each side with six bars of dry stalks of injury Ø 1 mm. the ends of the struts pre-focus.

The skeleton of the fuselage assembled. Check whether it is symmetrical when viewed from above. If not, then straighten over the stove, twisting the fuselage in the opposite direction. When symmetry is achieved, the joints between the longerons with struts lubricate emalita or nitrocream.

Of paper make a rocking chair of management, the edges of the fold to reinforce the structure in four holes: glue the tube of straw. In the Central hole — tube height of 10 mm and three 8 mm. the Axis of the tubes shall be perpendicular to the plane of rocking.

Now do to the control arms of a nest of straw Ø 3 mm and attach it to the lower longeron of the fuselage on the square of paper. For a square cut a slit in the side member, which will secure it in the glue; the upper part of a square to glue to the tube of the straw. Insert the Central tube rocking in the slot: it should rotate freely. Further, from pine or basswood cut stand for the control arms of a round rod which must be free to enter into the Central tube of the swing and rests in the slot. The upper end of the rod stick to the balsa or cork resistant plate with a thickness of 3 and a width of 8 mm. Then glue it to the top of the toe of the fuselage between the nose bulkhead is a boss and first spacer.

One-piece wing, made from dry straw. Its front and rear edges, and a longitudinal straw Ø 1 mm; chamfer and rib — straw Ø 1 mm. the Last curve by drawing over steam or electric stove. The wing has no transverse “V”. The ribs are connected with edges “itroll”, ending with edges — pipe-i.e. the pipe of smaller diameter is inserted into a large. Each rib has a straight shelf.

Stabilizer and Elevator all-in-one. They are made of dry grass stems Ø 1 mm in the same way as the wing, only the ribs of the horizontal tail flat. The keel also has a bend from grass stems Ø 1 mm. Fuselage, wing, stabilizer and fin are covered with tissue or condenser paper. Wing and keel are tight on both sides.

The Elevator is suspended from the stabilizer at two points on the hinges of a harsh thread. It is managed by traction from the grass stem Ø 1.5 mm, the ends of which are inserted on glue cork pine. They secure the wire hooks, l-shaped. One end of the pull rod, insert into the tube of the swing, opposite — tube of the rocking of the Elevator. The latter is made of celluloid of a thickness of 1 mm. It is secured with thread n glue to the rib of the Elevator.

Chassis model consists of six bamboo stands Ø 1 mm, the ends of which thread and attached with glue, wire axles and wheels of the tube. In the center of the wheels inserted tubes made of caps from bottles of kefir or milk. Landing gear on glue insert into the frame-boss. All dimensions of the chassis visible from the drawing. Propeller Ø 130 mm with a step of 0.6 relative cut of lime.

Using the cord, you can control the model, and it is current to the motor. For cord better to use a single wire Ø 0,25 mm enameled covering a length of 4 m (one lived). Cords tie it to the handle of plywood thickness of 5 mm n plug to four series-connected flat cells. Battery during the flight you can put in your pocket or clipped to a belt. On the handle install a miniature switch or spring contact made of brass of thickness 0,25 mm. cords Then pass through two loops, curved wire and attached with thread and glue to the shelf from below the last rib. Through the two insulating plates of celluloid of a thickness of 1 mm, they are attached to the bridles, attached to the round dowels made of pine, freely within extreme tube rocking. Before the point of attachment to the insulating plates, strip the cords from the insulation and solder electrodes of a thin stranded wire to the motor.

For better stability of the model in flight trailing edge of the keel is offset to the right by about 10 mm. in addition, on the right wing at the end of the rounded thread and glue, attach a lead weight weighing 2 g. the Model flies in a room that is at least 10X10 m with a speed of 2-3 m/s and freely flies up from the floor.

The most advantageous length cord to run “Electrify”—4—7 m Before the flight in the school hall, if it has no marking necessary on the floor to draw a chalk circle, within which the person operating the model. It is necessary that the model in flight, did not hit the wall or any other obstacle.

A. TRLER, master of sports of the USSR