For bending metal rods and pipes there are many ways and devices. Most often this operation is performed on the bending. But not everyone (even of the workman person) he has. The easiest method is when one end of the workpiece is securely fixed in a suitable place (e.g. in a vise), and holding the other bend If bend the end of the short, he put on a corresponding segment of the pipe, using it as a grip and lever. But this method does not provide either the quality or the accuracy of the bend radius.

For bending metal rods and pipes there are many ways and devices. Most often this operation is performed on the bending. But not everyone (even of the workman person) he has. The easiest method is when one end of the workpiece is securely fixed in a suitable place (e.g. in a vise), and holding the other bend If bend the end of the short, he put on a corresponding segment of the pipe, using it as a grip and lever. But this method does not provide either the quality or the accuracy of the bend radius.

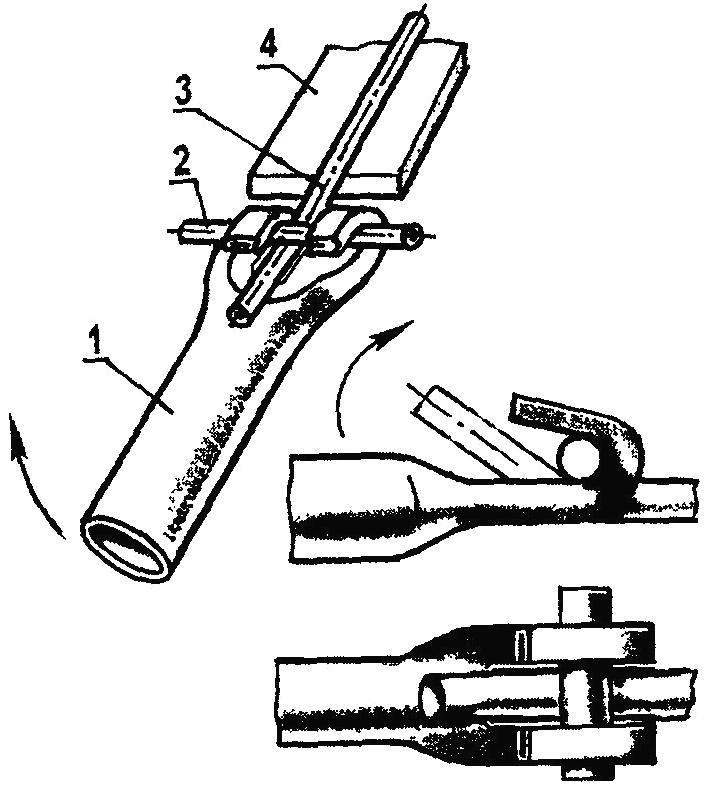

If you have to bend a significant number of the same pieces of pipe, without compromising the specified radius and place of its execution, you can make a simple fixture It will not only greatly facilitate the work, but will allow you to bend the workpiece at a small radius comparable to its transverse size.

To fit any desired diameter and length cut thick-walled tube and a piece “is” the radius corresponding to the bending parts (can be taken from the same pipe or workpiece) Diameter of the lever of the fixture depends on the cross section of the bent parts, preferably 2 (or more) times the thickness of the workpiece.

One end of the pipe is flattened in a Vice or with a hammer on a length constituting roughly about six diameters “is” (the size of the throat of the hook the future). This place is cut median longitudinal groove of a width slightly greater than the cross section of the workpiece and a length slightly smaller than the formed plane.

The fixture is a length of flexible tubes and bars:

1 — arm (a thick-walled steel pipe), 2 — “is”-bar, 3 — workpiece, 4 — emphasis

The sidewall tapered end (horns formed fork) are bent at 165 — 170° stashed “kruglyashi” that will be used in the fixture as a mandrel So the angle will allow, if necessary, to insert “is” in diameter and more, i.e. to increase the bend radius of the workpiece cross-Section of the workpieces is limited to cross-sectional dimension of the groove and a clearance between its rear edge and the side surface of the mandrel To facilitate the bending process carried out by the local heating of billets in the flame of a blowtorch, gas burner, etc., and the device at this time used as a holder.

To prevent collapse of tubes with a small bend radius is used a known method, their internal cavity pre-filled with sand, and in the end holes hammered wooden plugs.

Before each operation, all rubbing places pieces and parts fit abundantly lubricated with engine oil — pretty good and spent.

A. somewhere behind the house Anna