Cut the pipe threads have not only a plumber. Many people today are forced to learn the profession of home wizard.

Cut the pipe threads have not only a plumber. Many people today are forced to learn the profession of home wizard.

But in each case there are certain difficulties, to overcome which requires skills, otherwise much time will be spent in vain, and materials in waste. For threading the plane of the die must be strictly perpendicular to the axis of the part. However, the more dice, the harder it is to fulfill this condition, especially at the beginning of operation when most needed, because plasmodesmatal not to need much pressure.

Usually of the situation out as follows: plasmodesmatal bottom and welded a section of pipe with an inner diameter equal to the outer diameter of the die. Such a guide wire is loose on the pipe and the desired accuracy does not. Weld the piece of pipe of suitable diameter more directly to the die does not rise hand-in — wonder tool to ruin.

Our Director much easier. It is a steel cylindrical stepped rod. On the short end of it is cut several strands of a corresponding thread, and the other protectives to the hole diameter of the pipe.

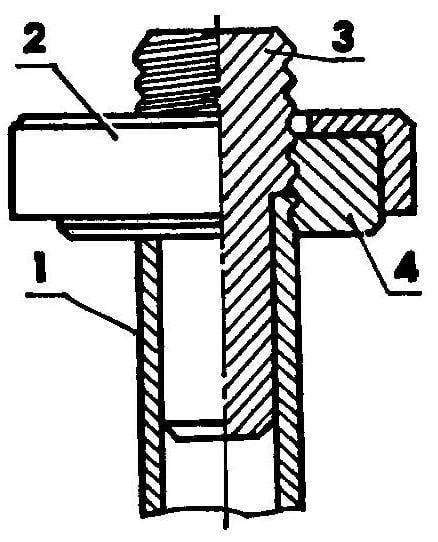

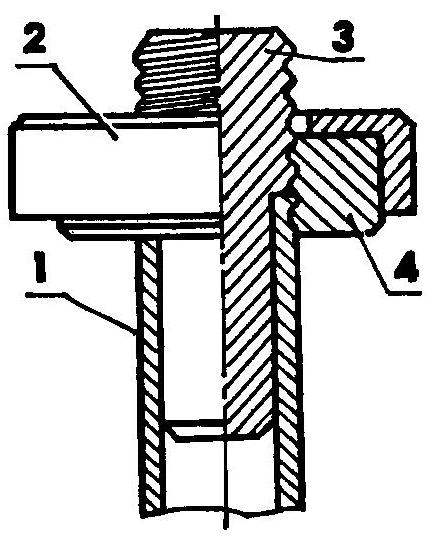

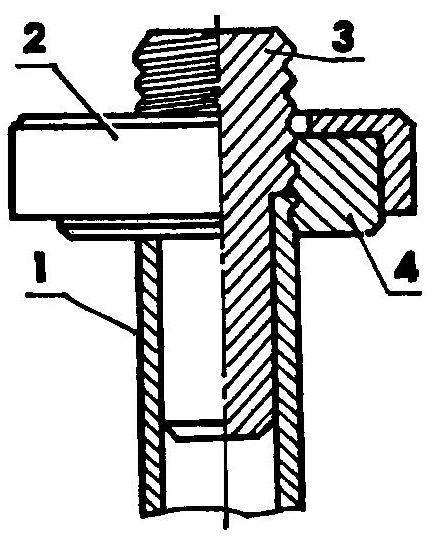

The threading on the pipe using the guide:

1 — pipe; 2 — plasmaterial; 3 — guide; 4 — die

Before working threaded part of the fixture screwed into the plate, and the guide end is inserted into the pipe. Once the dispensing portion of the die starts to cut into the pipe, the guide wire vivenciada of dies up for further work it is no longer needed.

This simple device is easy to manufacture on a conventional lathe.

R. KRAVTSOV, E y K, Rostov region.