Creating some kind of mechanism or tool, the person usually by its name defines its main functional purpose. So, saw, saws, drill — sowing, the hole punch punch holes, and, say, a wrench used for screwing or unscrewing the nuts.

Creating some kind of mechanism or tool, the person usually by its name defines its main functional purpose. So, saw, saws, drill — sowing, the hole punch punch holes, and, say, a wrench used for screwing or unscrewing the nuts.

The same can be said about the machines: milling, surface grinding, turning, planing or boring — in fact the aircraft is performed technological operations.

However, visitors to the Central exhibition NTTM-78 inevitably wrong, coming up with a familiar yardstick to the lathe with a fixture designed by the innovators of the Mogilev plant “Strommashina”. This little attachment turns lathe… grinding.

The need for this arose in connection with the need to grind such a difficult item, such as shaft. Special equipment on the company for this operation was not. Then was born the idea to use the capabilities of the lathe is attached to this shaft could be rotated uniformly polishing the surface. And in order to expedite this operation, it is sufficient to introduce an additional counter-rotating grinding tool.

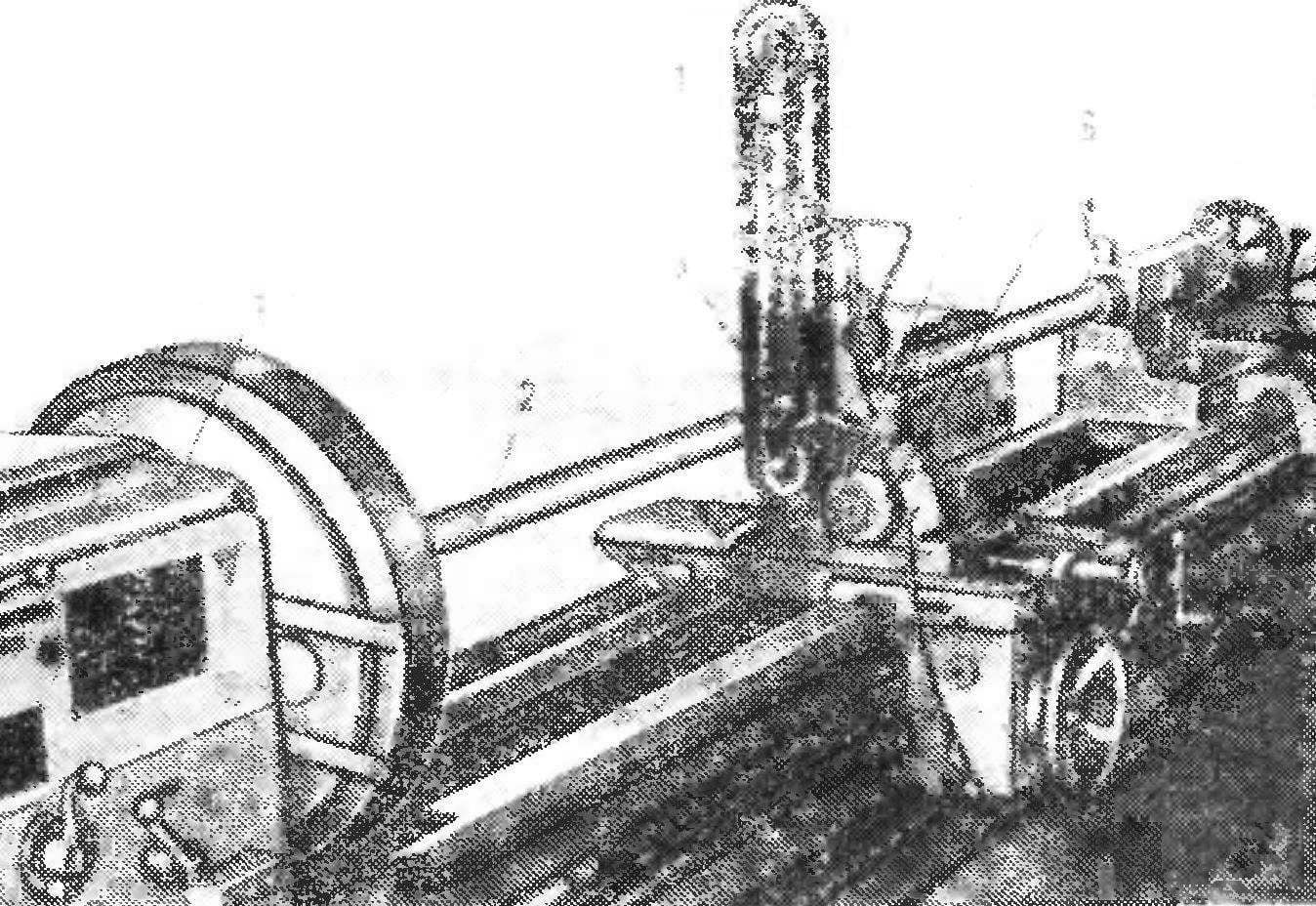

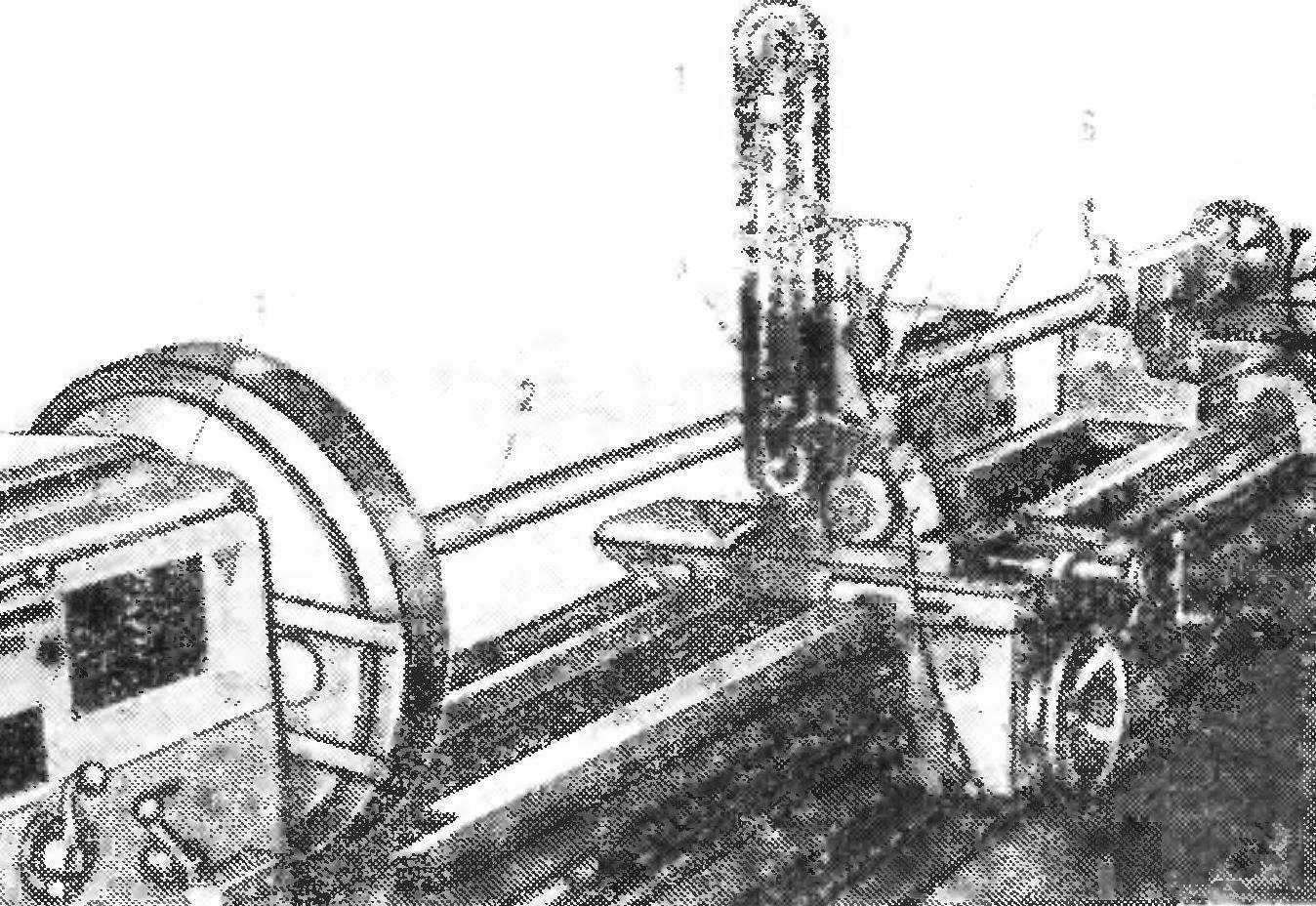

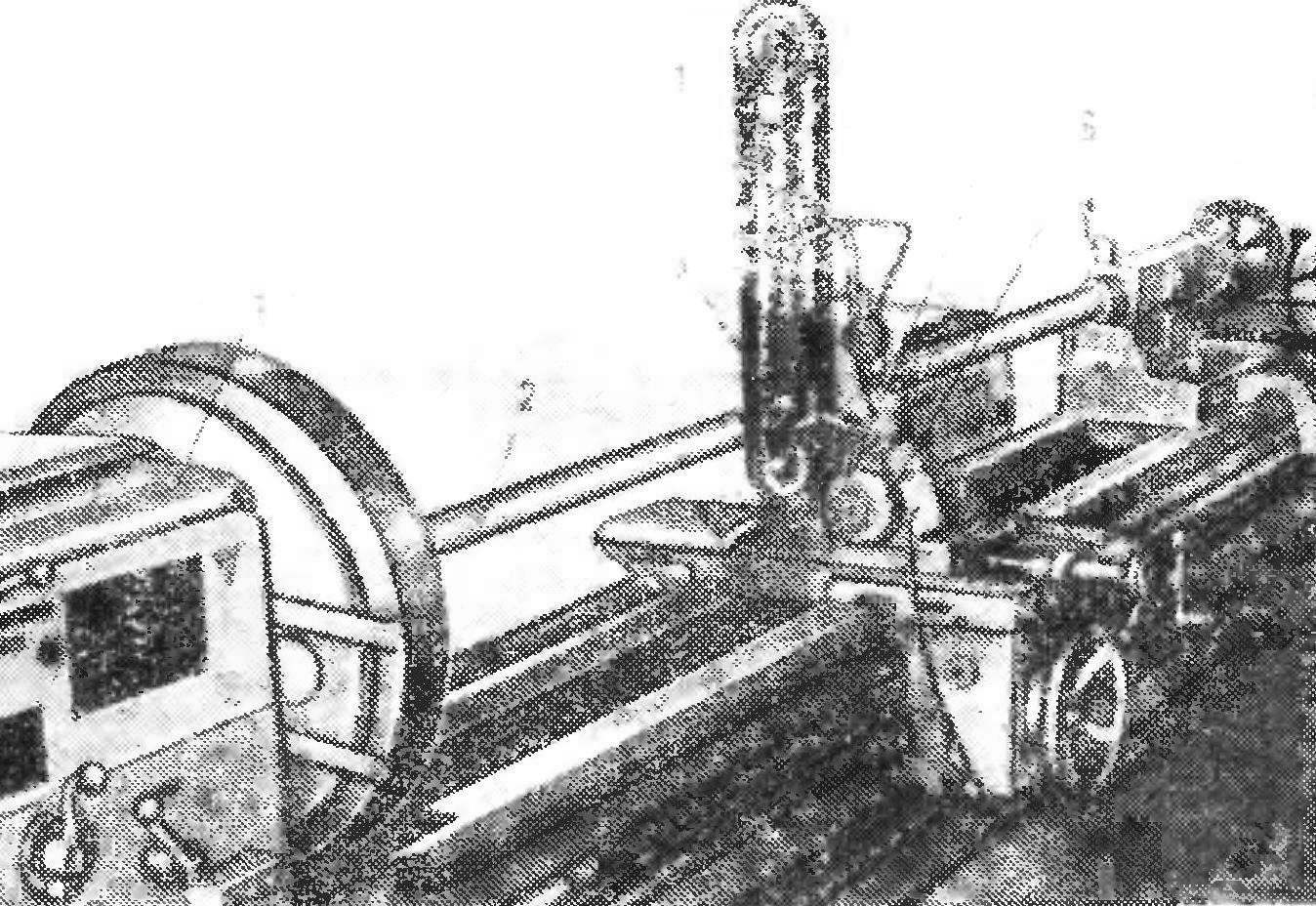

Grinding attachment:

1 — lathe 2 — treated shaft 3 to the abrasive tape, 4 — hour (rolling pin) with pulleys, 5 — tool post machine, 6 — motor consoles

The result is a simple device, resembling upright saw “Friendship”, only with electric motor and abrasive belt instead of a cutting chain. Through V-belt transmission from motor to the lower rubber-coated pulley driven over it and a second, upper pulley annular strip of abrasive. Being pinned to the shaft, skin polishing or polishing it. The last depends on where they are in contact: if the clamping is carried out at the pulley on the work shaft is transmitted great effort is sanding; the higher pulley tape has a “softer” polishing surface.

The necessary vertical or horizontal movement grinding head is achieved by fixing it in the tool post. Stand with pulleys to adjust the tension of the abrasive belt. The device allows processing the surface of the rollers to clean the 8-10 class.