Existing jigsaw has a number of disadvantages. Minor fluctuations in the amplitude of the nail (5 mm) does not allow to increase the speed of cutting both thin and thick plywood. Machine heats up quickly and breaks down. How to increase the amplitude of its oscillations? Indeed, in this case, the cutting speed is the magnitude of the advancing nail the plywood in one pass. The exit is found.

Existing jigsaw has a number of disadvantages. Minor fluctuations in the amplitude of the nail (5 mm) does not allow to increase the speed of cutting both thin and thick plywood. Machine heats up quickly and breaks down. How to increase the amplitude of its oscillations? Indeed, in this case, the cutting speed is the magnitude of the advancing nail the plywood in one pass. The exit is found.

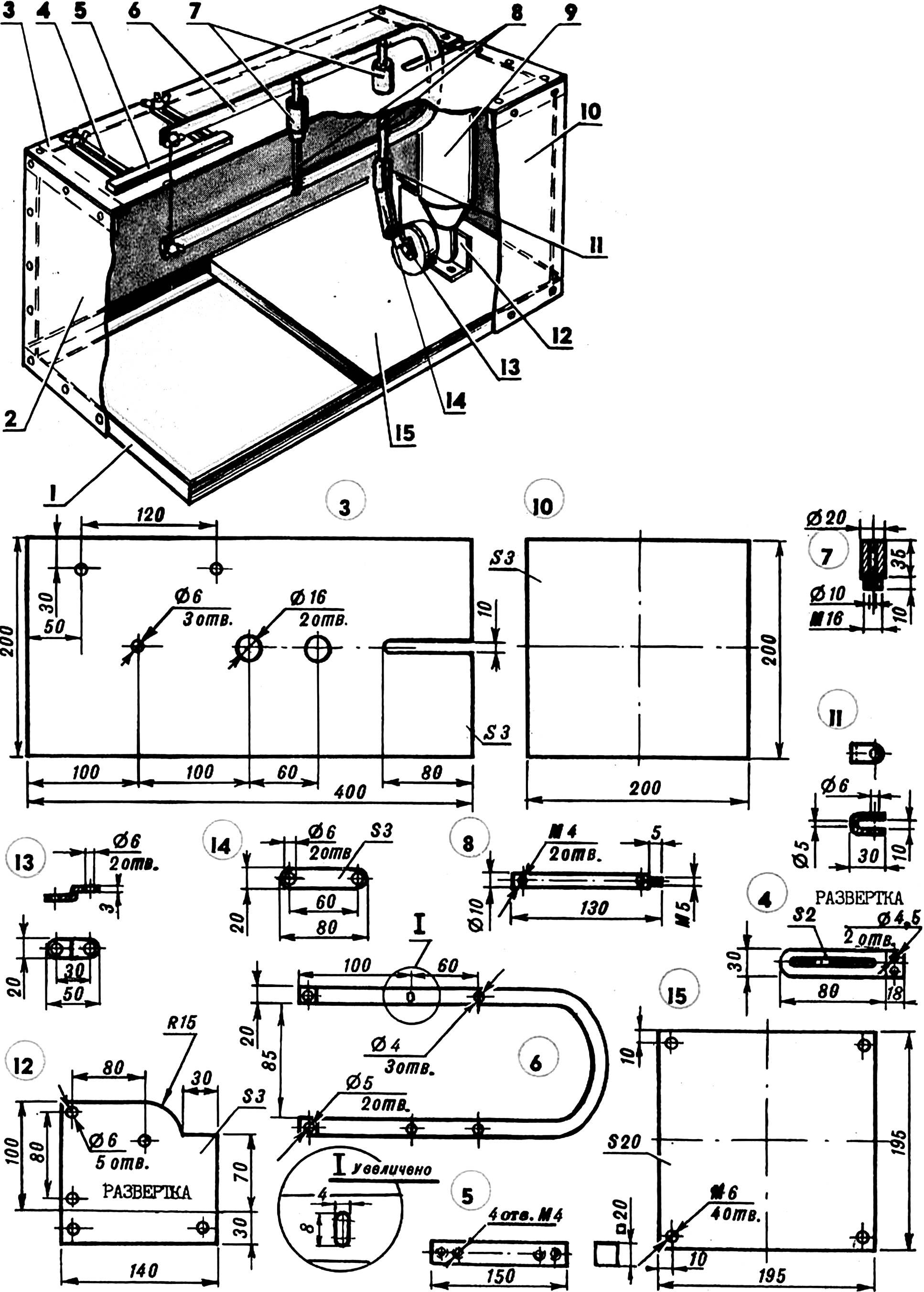

This should be purchased in the shop “auto Parts” windshield wiper motor. It is powered by a battery voltage of 12 and 6 In that allows you to have two speeds: for cutting both thin and thick plywood, and foam. A fret saw with this motor is safe to use in school workshops, through a rectifier, and in the woods and on the beach — from the car. To make the frame of the jigsaw first of all you need metal corner 20X20 mm. the Frame comprises a lower frame size of 400X200 mm and the same upper connected with rivets uprights with a length of 200 mm. To the frame attached made of sheet metal or PCB front wall with a size of 200X200 mm, two side walls of the same size and the rear size 400X200 mm. On the front side are the connector for connecting the cord, pilot light and switch. On top of the frame is fixed on the tabletop. It sets guides are made of aluminum rod Ø 20 mm, and the emphasis for cutting thin strips, or foam. At the end of the table has a slot length of 80 mm and a width of 10 mm for the passage of jigsaw. At the bottom of the frame on the four M6 screws to a metal plate (for stability of the jigsaw). Thereto by plates fastened to the gear motor. Greater speed gives 60 movement of the jig saw in a minute that complies with the rhythm of the human hand, and small — half.

The design of the jigsaw:

1 — frame, 2 — side wall 3 — top, 4 — adjustment of the stop, 5 — stop, 6 — frame, jig saw, 7 — directing, 8 — pusher, 9 — electric motor; 10 — front side, 11 — clip 12 — base plate, 13 is a small pull, 14 — connecting rod, 15 — steel plate.