Even the person far from technicians, often have to Unscrew-screw the screws, bolts, nuts (hardware — so often referred to in abbreviated form these metal products) are designed for this tool — a wrench. Each key caused the size of its working parts, simply — throat. But the corresponding value is the size of the key — referred to in the technical handbooks by the letter S (the distance between the opposite parallel faces on a nut, bolt head or screw), is not listed on any of the fasteners. No, as a rule, these data and the attached to any technology operating instructions and repair even in the notation and in the drawings, although other information about fasteners in them abound: specify thread size, and her step sometimes the length and even the type of heat treatment, often tightening torque. But most of these data — structural, and they need to manufacture parts. When the adjustment, repair or Assembly work of the above settings thread, except the last one are not in demand. For a mechanic it is much more important to know what size front axle you need a key for the head of one or the other of the screw or bolt and nut (or, as professionals say, “the key is how much”).

Even the person far from technicians, often have to Unscrew-screw the screws, bolts, nuts (hardware — so often referred to in abbreviated form these metal products) are designed for this tool — a wrench. Each key caused the size of its working parts, simply — throat. But the corresponding value is the size of the key — referred to in the technical handbooks by the letter S (the distance between the opposite parallel faces on a nut, bolt head or screw), is not listed on any of the fasteners. No, as a rule, these data and the attached to any technology operating instructions and repair even in the notation and in the drawings, although other information about fasteners in them abound: specify thread size, and her step sometimes the length and even the type of heat treatment, often tightening torque. But most of these data — structural, and they need to manufacture parts. When the adjustment, repair or Assembly work of the above settings thread, except the last one are not in demand. For a mechanic it is much more important to know what size front axle you need a key for the head of one or the other of the screw or bolt and nut (or, as professionals say, “the key is how much”).

When the nut or bolt head is visible and easily accessible, to determine “how much” require a key, is not difficult — the skilled technician will recognize it at a glance, and one can “calculate” with calipers or through the selection keys: two or three times is usually unable to do.

If fastener is difficult to reach, but still “behind the eyes” (which happens very often), then determine the size of the head of the fastener “turnkey” necessary to the touch, when even a professional can easily make a mistake. The troubles will not happen if the wizard will attempt to work with a key less — that simply will not fit on the head. If the same key would be great, then “cut” them to the edges of the head, as they say, a piece of cake. In addition, the item will be irreparably damaged, then the unscrewing of the fastener, even with a special tool will be a major problem.

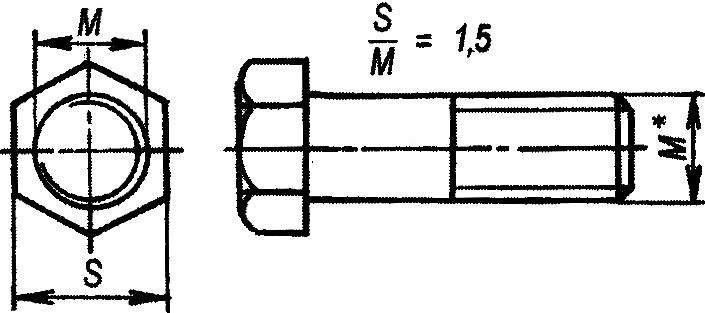

Standard bolt (screw).

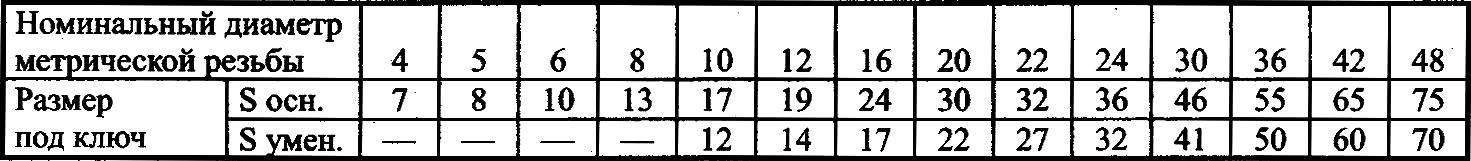

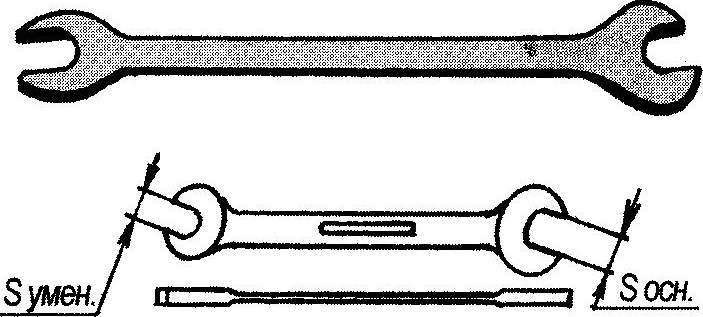

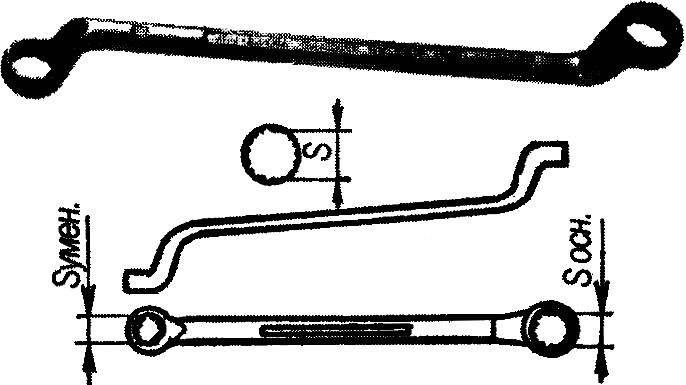

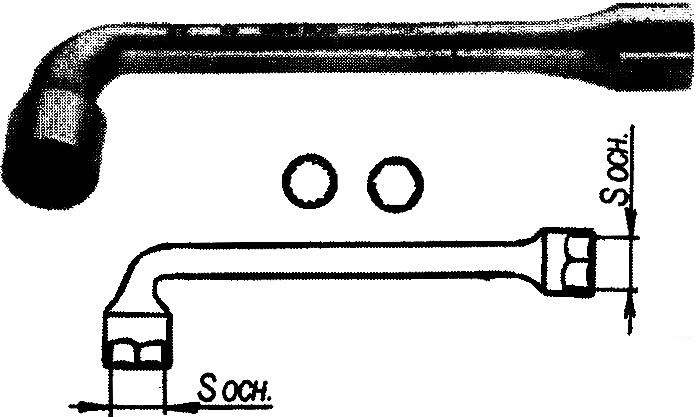

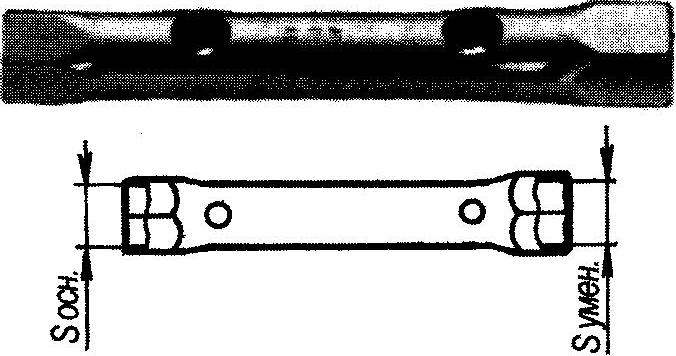

To determine the size of the “turnkey” “for the eyes” it makes sense to refer to the information about threaded fasteners specified in the regulations. Because according to GOST, each thread correspond to two close head size fasteners “turnkey”: the basic and reduced, and the difference in their values is small. On the average the size of the “turnkey” is about 1.5 times larger than the outer thread diameter (see table 1) and it is already possible to navigate. And although it reduced the size of the key is designers less than basic, try remove hardware “for the eyes” it is necessary for the above reasons, still less the key: if it didn’t fit, then you can safely work key corresponding basic size — it will not break (of course, assuming that the fastener is not rusted). The keys are usually also made on the same principle: on the one end the mouth of the (outdoor — carob, closed — end and ring key) is the basic size of the head of the fastener, the other reduced. This series falls just a combination of keys, which at both ends of the throat of the same size, only one open and the other closed (circular), adjustable wrenches.

Table 1. The matching of sizes of the fasteners are “turnkey” and its nominal diameter of metric threads

Double open-end wrench.

Double ring (ring) curved key.

Double end curved wrench.

When working with fasteners for their preservation tool is essential, therefore, to use should only serviceable keys: Zev they should not be extended, and lips crumpled. The keys with such defects should be removed from the working set. Moreover, seemingly similar tools vary considerably in quality metal, the profile of the jaws. The last condition directly affects the distribution of forces on the faces and edges of the hardware.

Fasteners are designed for a certain torque when assembling. Often, however, efforts during disassembly, especially the “stuck” or rusted threaded connections repeatedly exceed it. In these cases it is better to use the appropriate socket or ring (professionals call them ring) keys, and not carob. Especially it is impossible to use a wrench, as in loosening a small (less than S10) nuts, bolts and screws.

Double end tubular key.

Combo (horn and cap) key.

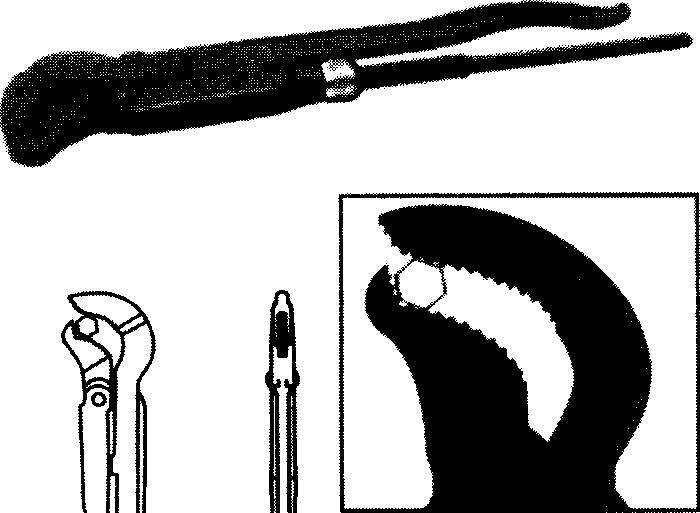

Combined pipe wrench.

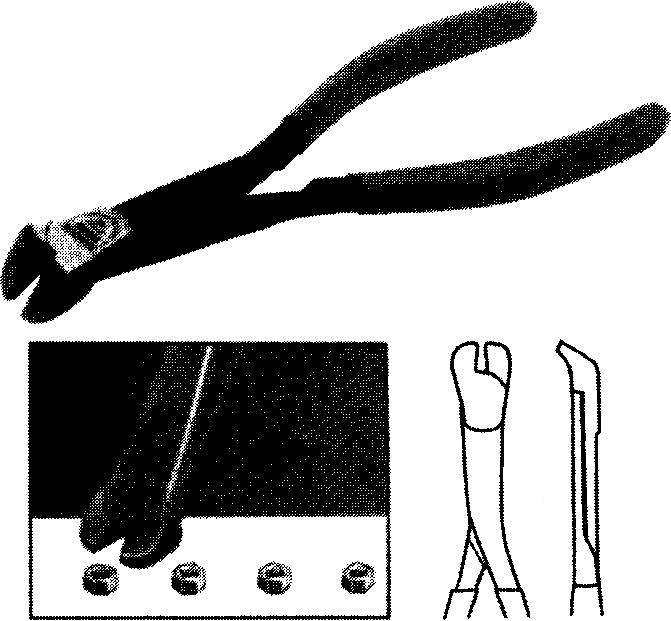

If the rib fasteners are badly corroded or for some reason were “rolled-up”, in order to still pull it back, it is necessary to whittle down the verge for the key “number” is less. Then, saturate the threaded joint with a special fluid (or, in a pinch, kerosene) to soften the rust and after a suitable interval, again try to Unscrew the part. Another way (but not last) remove a bolt or a screw with a damaged head is to make the slot between opposite faces under a strong screwdriver and try to Unscrew fasteners with this tool. And finally, to use this pipe wrench. By the way, the range of the latter have now and those that do not damage the faces and edges of the fasteners, even with large moments of loosening. For small screws, you can use the special pliers.

Pliers for small nuts.

When adjusting and repair of the same equipment (e.g., personal car) have to do regularly, it would be useful to make a table of sizes under the key fasteners of major regulated sites, devoting special time or as treatment for adjustment of a mechanism or Assembly.

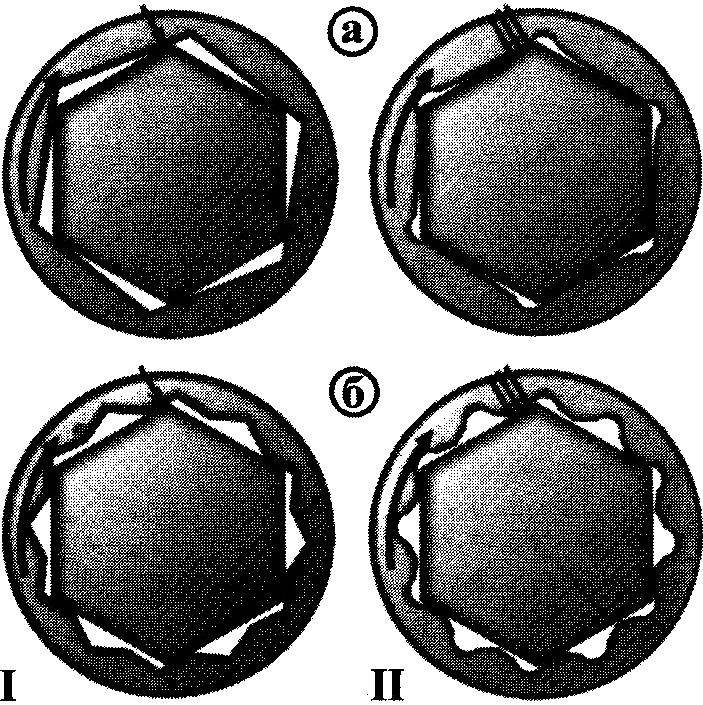

Regular head keys:

Head keys with dynamic profiles:

a — Allen; b — ring.

Efforts on the faces and edges of the fastening screw parts from mechanical (a) and cap (b) keys with different internal profiles:

I — concentrated; II — distributed.

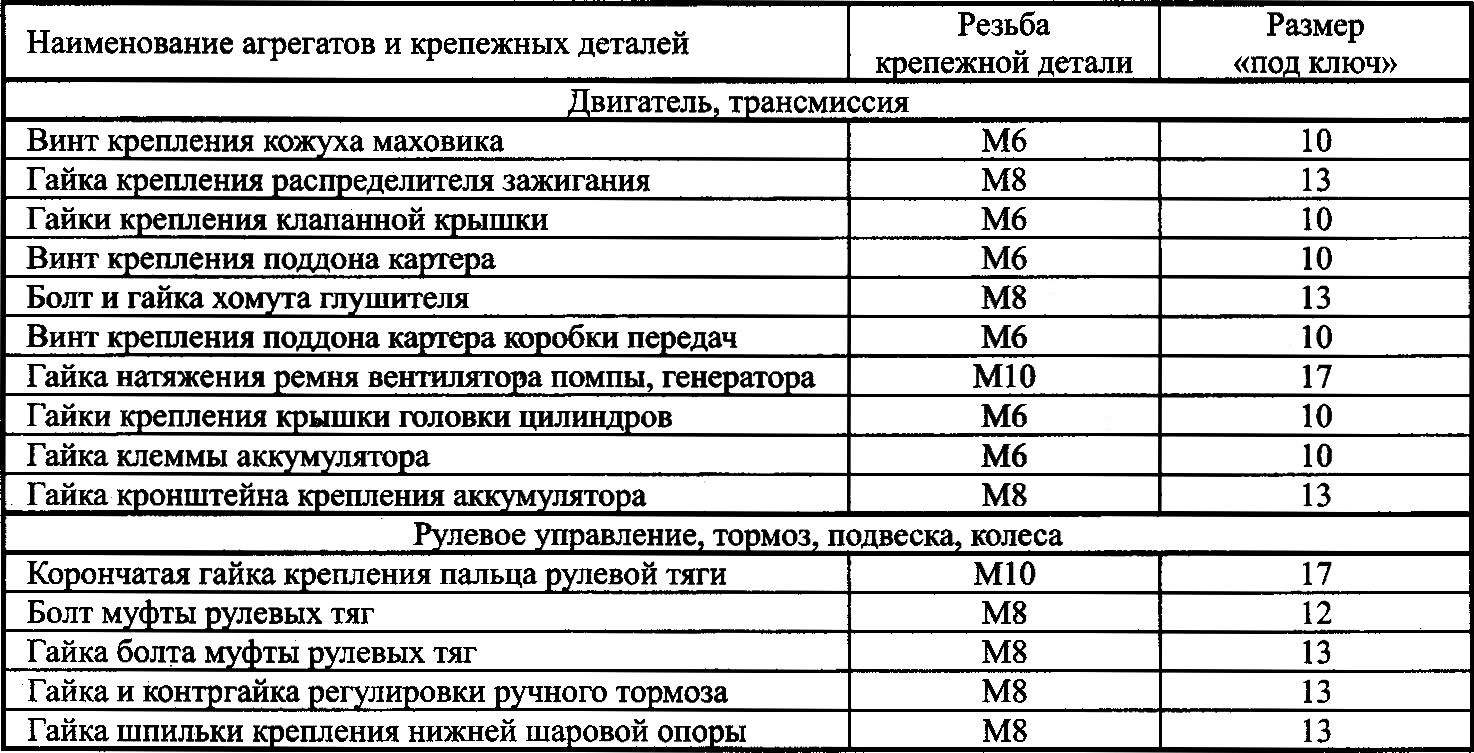

Table 2 lists the dimensions under the key key and the adjusting threaded joints for VAZ-2105.

Table 2. Some fasteners and their sizes “turnkey” VAZ

Since we are talking about cars, it is worth noting that in a special account in the tool kit “Zhiguli” (and other machines), so-called “balloon” “19” “candle” “21” keys.

The first is made quite distinctive and stands out from the entire set of keys. It finds out even those who are not familiar with the technique: he cap, with the bent arm-lever, the end of which is made in the form of soldering tip screwdriver. Once this key is removed chrome hubcaps wheels, which on modern machines already do not put. It would be appropriate to sharpen it a bit and thus have included strong screwdriver. In addition to the loosening-tightening bolts, this key can be used with other appropriate fasteners. If necessary, the wheel bolts can loosen and conventional (ring and even carob) key “on 19”.

The second “candle” key looks similar to the end of such tubular keys with the same diametrical hole for the knob. It even saved ratio of 1.5 the diameter of the turns of the thread (14 mm) to the distance between opposite faces of the key (21 mm). If we again turn to table 2, it becomes clear that the key non-standard and special, and other key with the same size kit no. The thread on the candle although standard (14×1,25), but is deprecated.

And another key — the usual carob “10”. This key, like a fire extinguisher, it is always better to keep “at hand” — as they turn away nuts of the battery terminals. After all, if necessary, for example, if a short circuit in the electrical circuit or (which now also has become the actual) to turn off for no reason of alarm (a keychain if it does not “obeys”), this must be done very quickly.

It should be noted that in the automotive tool set is supplied with the keys not under all sizes of fasteners. So if you want to go under the car (in the pit or overpass), not the superfluous will check whether all necessary tools are stuck with it, otherwise you’ll have to get out from under her with nothing. The same should be done if you are going to disassemble for repair or prevent some node or unit. In addition, very often for disassembly of the units without damage requires some sort of universal and special fixtures. If none of this, disassembly may not be possible or even vain.

Another notable point: the fasteners with a size of “turnkey” “13” appeared in our country with the car “Lada”, the prototype of which, as we know, was the Italian FIAT 124. Their appearance has lost its position as the fasteners with the size of the “turnkey” “12” and “14”.

A. POLYANSKIY

Recommend to read

FENCE — PORCH

FENCE — PORCH

A kind of gate on the porch of the cottage block the entrance while the plot owners. And with their arrival it was as if she climbs the steps, becoming an ornamental fence and handrail... JEEP FOR TEENAGERS

JEEP FOR TEENAGERS

In the environment of Russian Amateur designers a lot of those who gladly builds original cars, not only for themselves but also for their children. The website "Modelstructure"...

Even the person far from technicians, often have to Unscrew-screw the screws, bolts, nuts (hardware — so often referred to in abbreviated form these metal products) are designed for this tool — a wrench. Each key caused the size of its working parts, simply — throat. But the corresponding value is the size of the key — referred to in the technical handbooks by the letter S (the distance between the opposite parallel faces on a nut, bolt head or screw), is not listed on any of the fasteners. No, as a rule, these data and the attached to any technology operating instructions and repair even in the notation and in the drawings, although other information about fasteners in them abound: specify thread size, and her step sometimes the length and even the type of heat treatment, often tightening torque. But most of these data — structural, and they need to manufacture parts. When the adjustment, repair or Assembly work of the above settings thread, except the last one are not in demand. For a mechanic it is much more important to know what size front axle you need a key for the head of one or the other of the screw or bolt and nut (or, as professionals say, “the key is how much”).

Even the person far from technicians, often have to Unscrew-screw the screws, bolts, nuts (hardware — so often referred to in abbreviated form these metal products) are designed for this tool — a wrench. Each key caused the size of its working parts, simply — throat. But the corresponding value is the size of the key — referred to in the technical handbooks by the letter S (the distance between the opposite parallel faces on a nut, bolt head or screw), is not listed on any of the fasteners. No, as a rule, these data and the attached to any technology operating instructions and repair even in the notation and in the drawings, although other information about fasteners in them abound: specify thread size, and her step sometimes the length and even the type of heat treatment, often tightening torque. But most of these data — structural, and they need to manufacture parts. When the adjustment, repair or Assembly work of the above settings thread, except the last one are not in demand. For a mechanic it is much more important to know what size front axle you need a key for the head of one or the other of the screw or bolt and nut (or, as professionals say, “the key is how much”).