This machine will become your assistant if you are engaged in modeling or simply love to tinker.

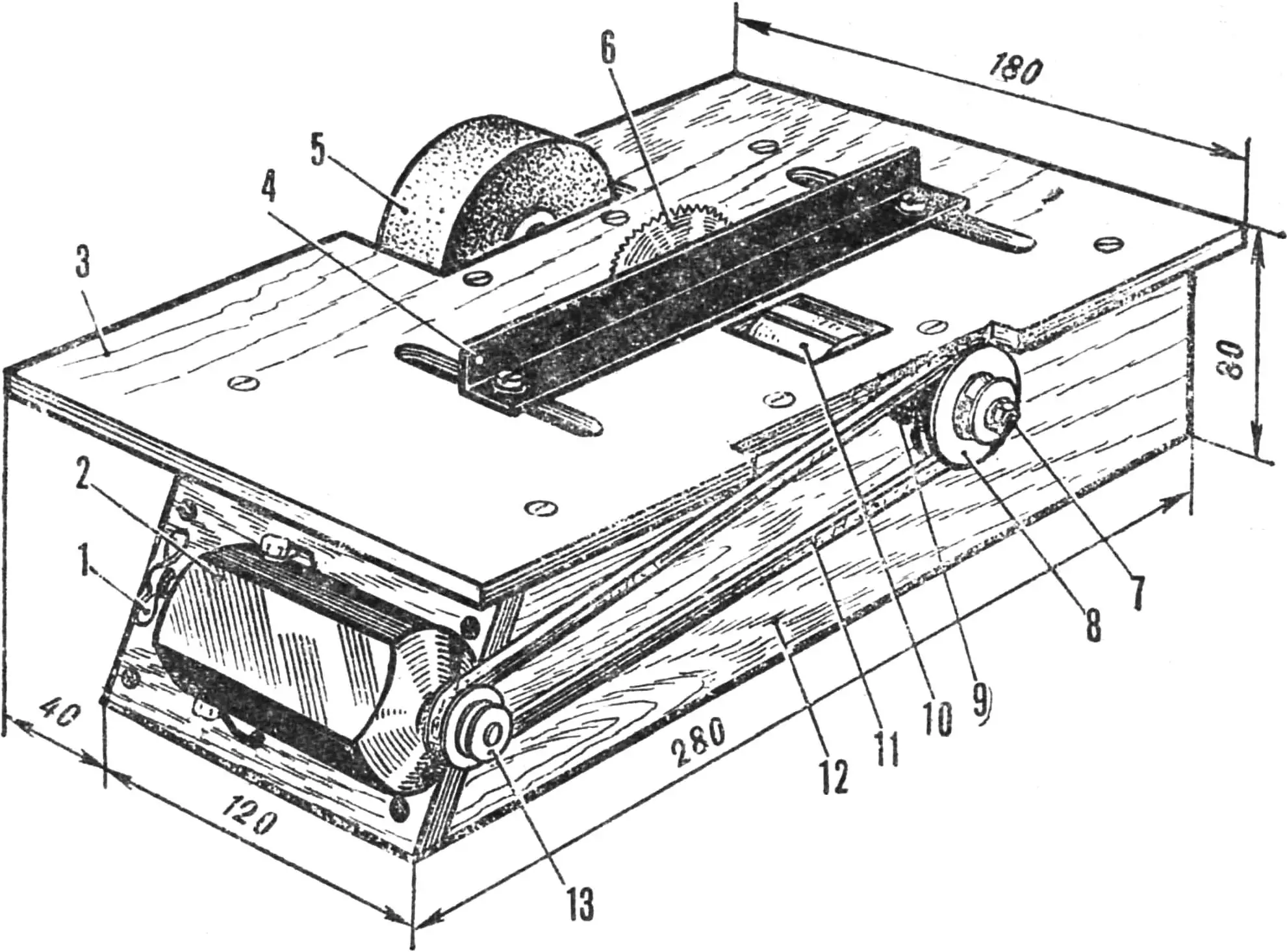

Even at home, there is often a need to cut a rail and plane it or sharpen a tool — all these operations are “within the power” of the machine I made. It is small — dimensions 80Х180X360 mm, so it is convenient to store even in an apartment.

The machine body is assembled from plywood. The side walls are made of ten-millimeter plywood, the front one (to which the electric motor is attached) is 16 mm thick, and the rear one is made of a four-millimeter sheet. To be able to tension the drive belt by moving the electric motor, I made the front wall inclined (at an angle of 60° to the base). The machine table is also plywood — made from a 4 mm thick sheet. All body parts are fastened with screws.

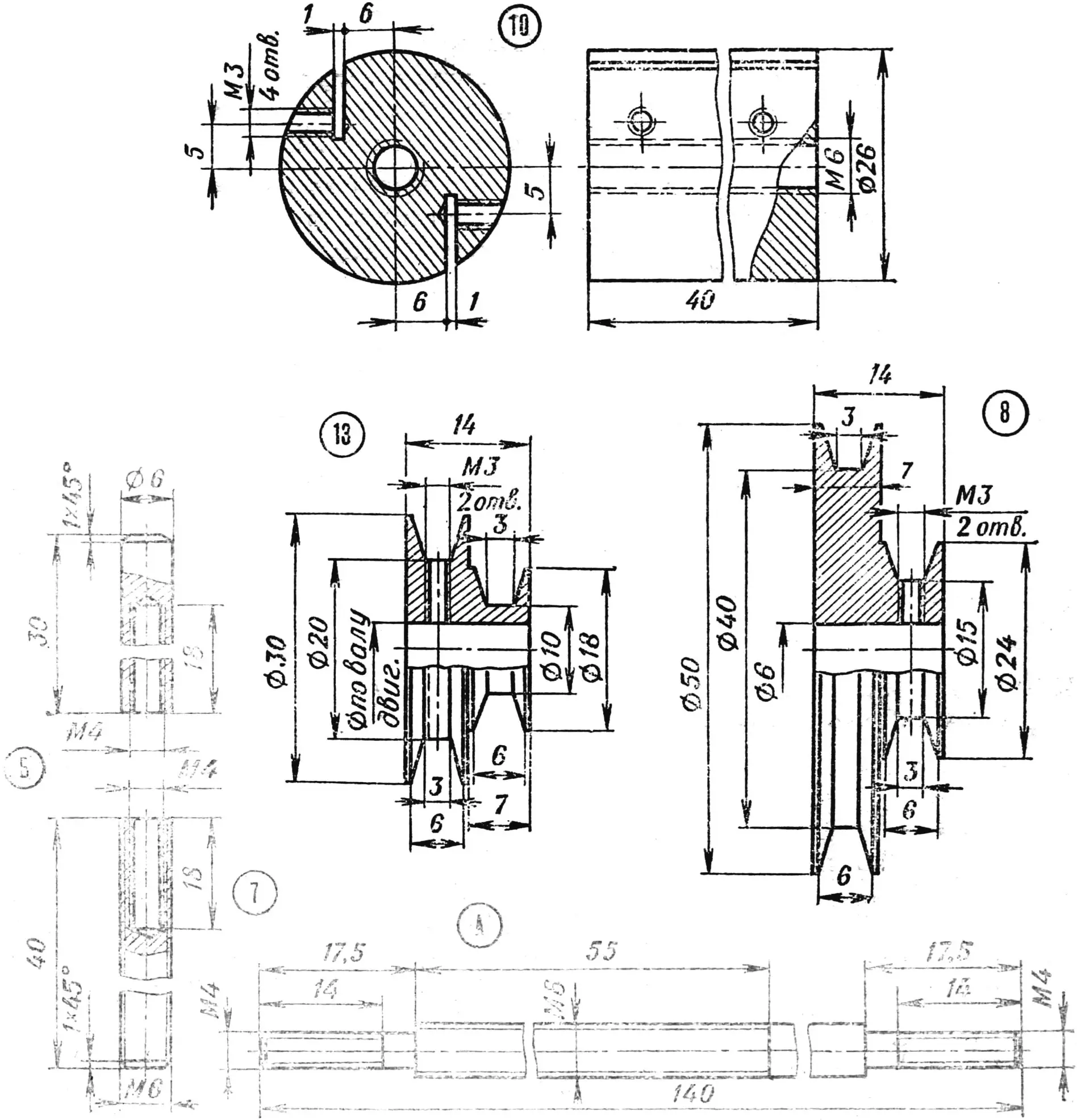

The driving and driven pulleys are turned on a lathe from duralumin. On the axles, they are fixed with two M3 screws each. The machine spindle consists of three parts — central and two side ones. All of them are made of steel rod Ø 6 mm. The spindle rotates in two bearings with an inner ring diameter of 4 mm.

1 — fan impeller, 2 — electric motor, 3 — table, 4 — guide, 5 — abrasive wheel, 6 — saw blade, 7 — machine spindle (A — central part, B — side parts), 8 — driven pulley, 9 — bearing, 10 — planer drum, 11 — drive belt, 12 — side wall, 13 — driving pulley.

I cut the saw blade from the blade of an old wood saw. The technology of its manufacture is simple. With a marking compass, I drew two circles on the blade — one Ø 60 mm (outer diameter of the disk), and the second Ø 56 mm (circle of tooth depressions). After processing the disk along the outer contour with a triangular file, I cut the teeth and set them exactly the same way as it is done on a saw for cutting wood.

The abrasive wheel that came into my possession had an inner diameter of 13 mm, so it had to be mounted on the machine spindle using an intermediate bushing. It should be borne in mind that there are a great many sanding wheels, so the dimensions of the bushing should be determined according to the one you have. Just try to make sure that its outer diameter does not exceed 60 mm.

The machine motor is from an electric sewing machine, its operating voltage is 220 V, power is 20 W and rotation speed is 4550 rpm. In order for the motor not to overheat during prolonged operation, it is useful to mount a small impeller-fan on the free end of the shaft.

The mechanical planer is a steel drum Ø 26 mm with an inner hole M6. Slots 1 mm wide are milled in the drum. Without overthinking, I took knives for it from pencil sharpeners — they were quite suitable for this purpose. In the drum, they are fixed with two M3 screws each.

S. STANYUTIN