We continue the story about machines and mechanisms built by V.A. SVERBIL — an amateur designer from the village of Zelenchukskaya in the Karachay-Cherkess Republic. In the publication “Walk-behind tractor — nothing superfluous” (“Modelist-Konstruktor” No. 2’98), his faithful garden helper “Elektronik” was described. Now we offer to familiarize yourself with the design of a cargo cart for this walk-behind tractor.

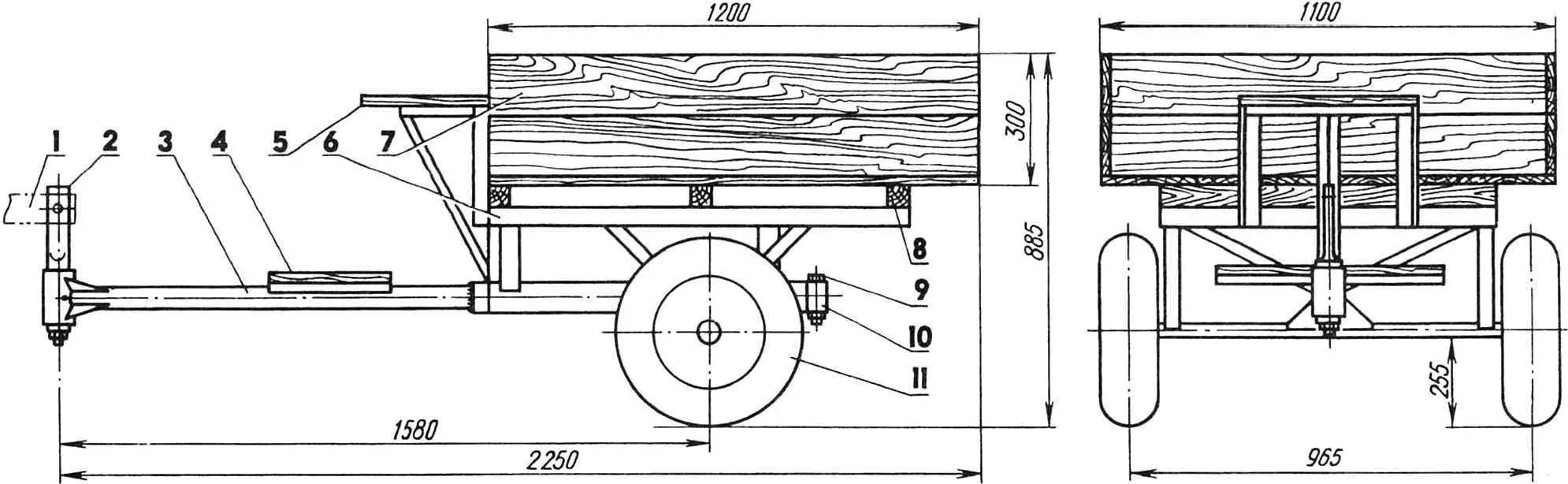

Since V. A. Sverbil uses his “Elektronik” mainly for growing potatoes, the cargo cart for the walk-behind tractor primarily transports this agricultural product. And in quite large quantities: the cart holds six bags of potatoes, plus the driver’s weight — a total of about four hundred kilograms. Hence the design features of the cart: a sturdy drawbar, a powerful frame, a spacious body, reliable wheels. The listed units and assemblies will be considered in this sequence.

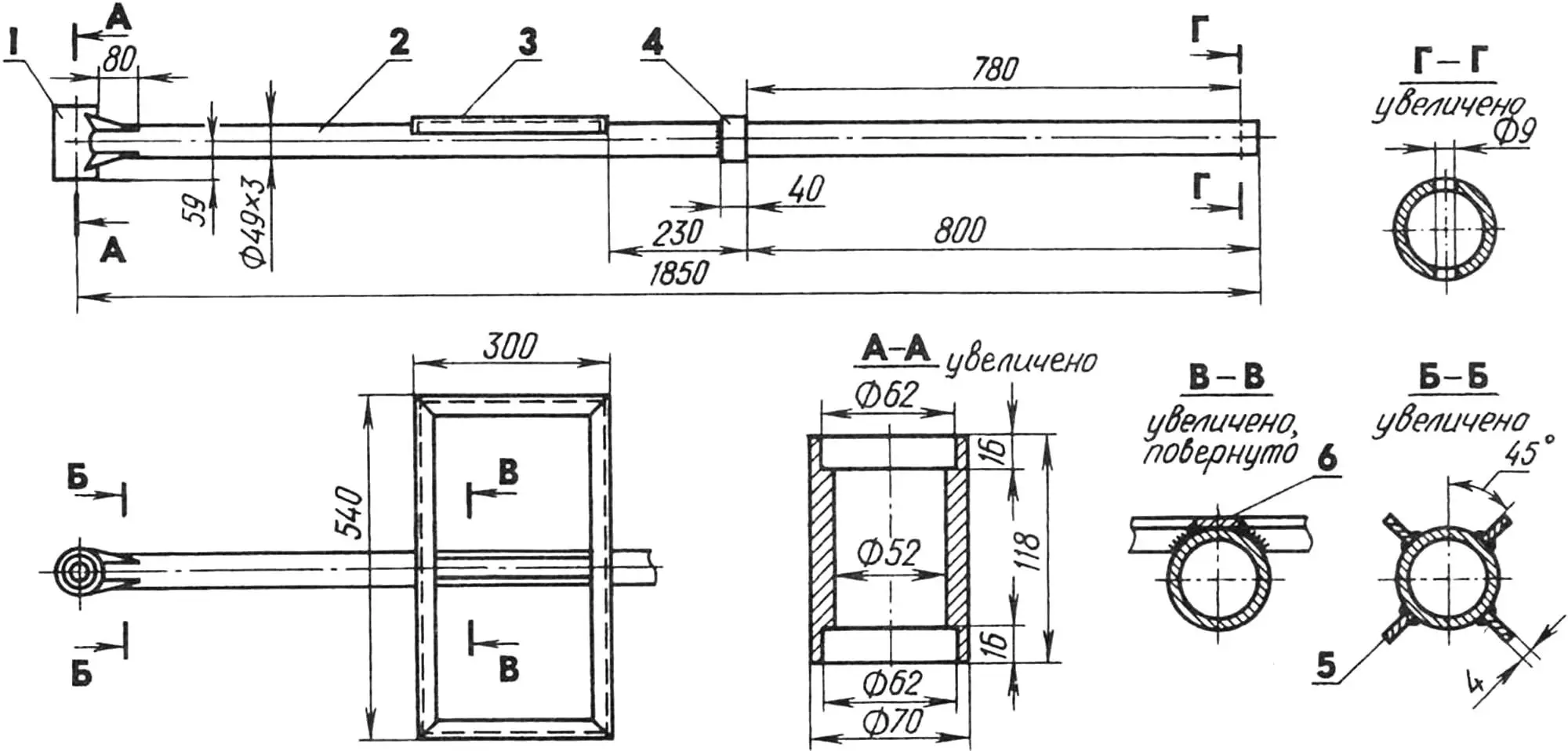

The drawbar consists of just a few parts connected by electric welding. The most loaded place here is the joint of the steering unit housing and the drawbar. Therefore, it is reinforced with four stiffening ribs.

1 — attachment bracket of the “Elektronik” walk-behind tractor, 2 — console, 3 — drawbar, 4 — footrest (board s20), 5 — driver’s seat (board s20), 6 — frame, 7 — body (board s20), 8 — support beam (timber 50×50, 3 pcs.), 9 — bolt M8, 10 — stop ring (tube 58×4), 11 — wheel (from SZD motorized wheelchair, 2 pcs.).

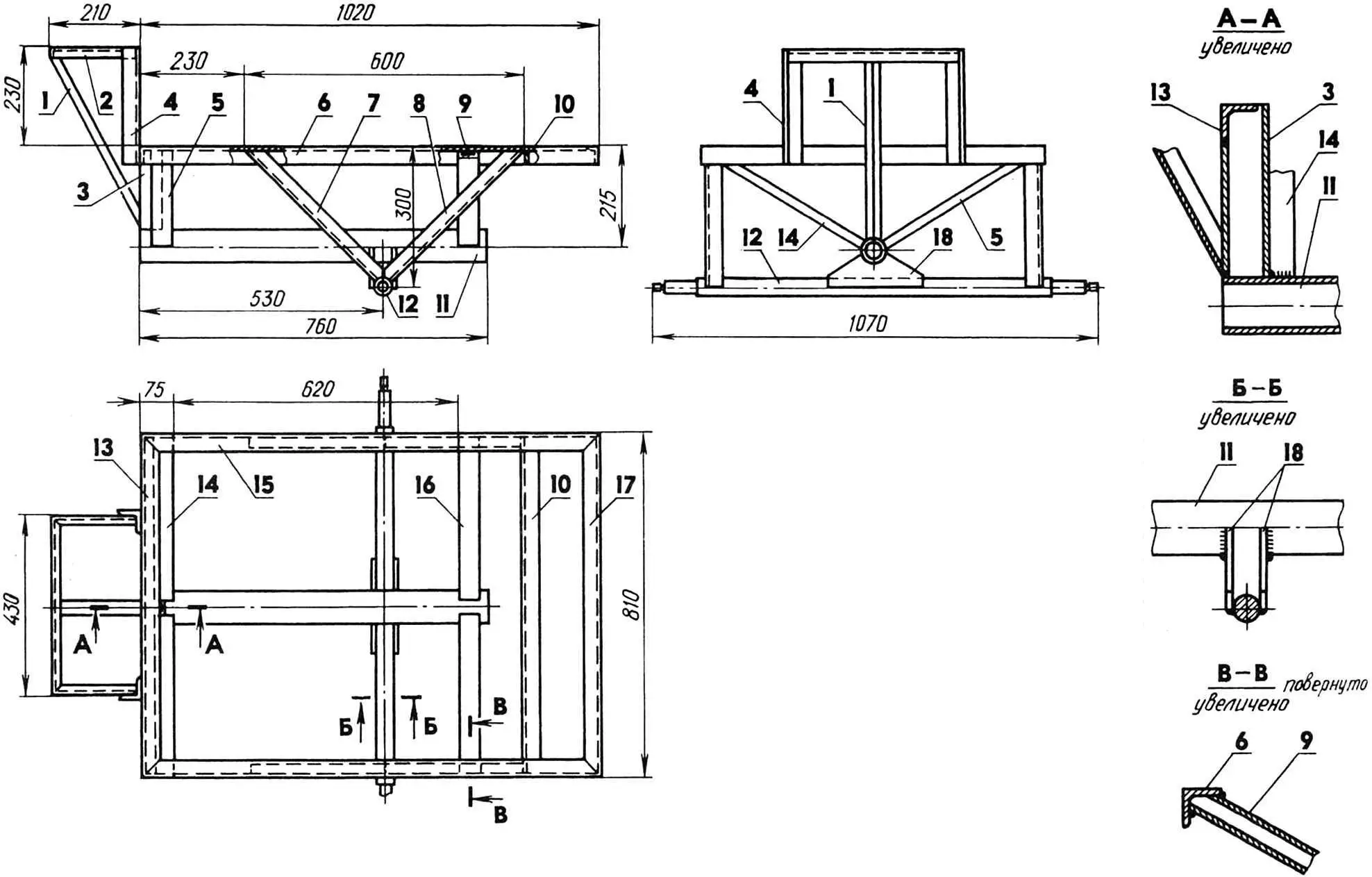

The frame is made from a set of steel elements: angles, rods, round and rectangular section tubes. They are welded into a structure, the somewhat intricate nature of which is due to the cart’s operation on terrain abundant with uneven terrain, scattered stones and boulders: operational loads here are very high.

A steel rod with a diameter of 30 mm is used as the wheel axle, connected by angle supports and gussets to the side members and the longitudinal hinge housing using electric welding. The rod length is chosen so that the wheels do not protrude beyond the body contours.

1 — steering unit housing, 2 — drawbar (tube 49×3, L1820), 3 — footrest frame (angle 25x25x4), 4 — stop (tube 58×4), 5 — stiffening rib (s4), 6 — overlay (strip 25×4).

Matching the powerful frame is a sturdy body, assembled from 20-mm thick boards and reinforced at the corners with metal overlays. It is attached to the frame by means of bolts and three powerful support beams made of 50×50 mm timber. The body is loaded, like any single-axle carts — the center of gravity of the load should be located closer to the front side and not extend beyond the wheel rotation axis.

Since the cart is intended mainly for transporting bags of potatoes, the body is made with non-folding sides. For moving bulk cargo, the cart is rarely used.

1 — brace (angle 21×21х3), 2 — seat frame (angle 21x21x3), 3 — upright (tube 50x25x4), 4 — seat posts (angle 40x40x4), 5, 14 — front struts (tube 50×25), 6, 15 — longitudinal side members (angle 40x40x4), 7,8 — right wheel axle supports (angle 32x32x4), 9, 16 — rear struts (tube 50×25), 10 — reinforcing cross member (angle 40x40x4), 11 — longitudinal hinge housing (tube 58×4), 12 — wheel axle (rod Ø 30), 13, 17 — transverse side members (angle 40x40x4), 18 — gussets (s4).

The wheels are borrowed from a long-popular object among DIY enthusiasts — the SZD motorized wheelchair: the front ones are used, with hubs assembled. At the same time, the ends of the rod — the wheel axle — are turned to fit the mounting diameters of the standard hub bearings. Years of cart operation practice have shown that these wheels are the most suitable.

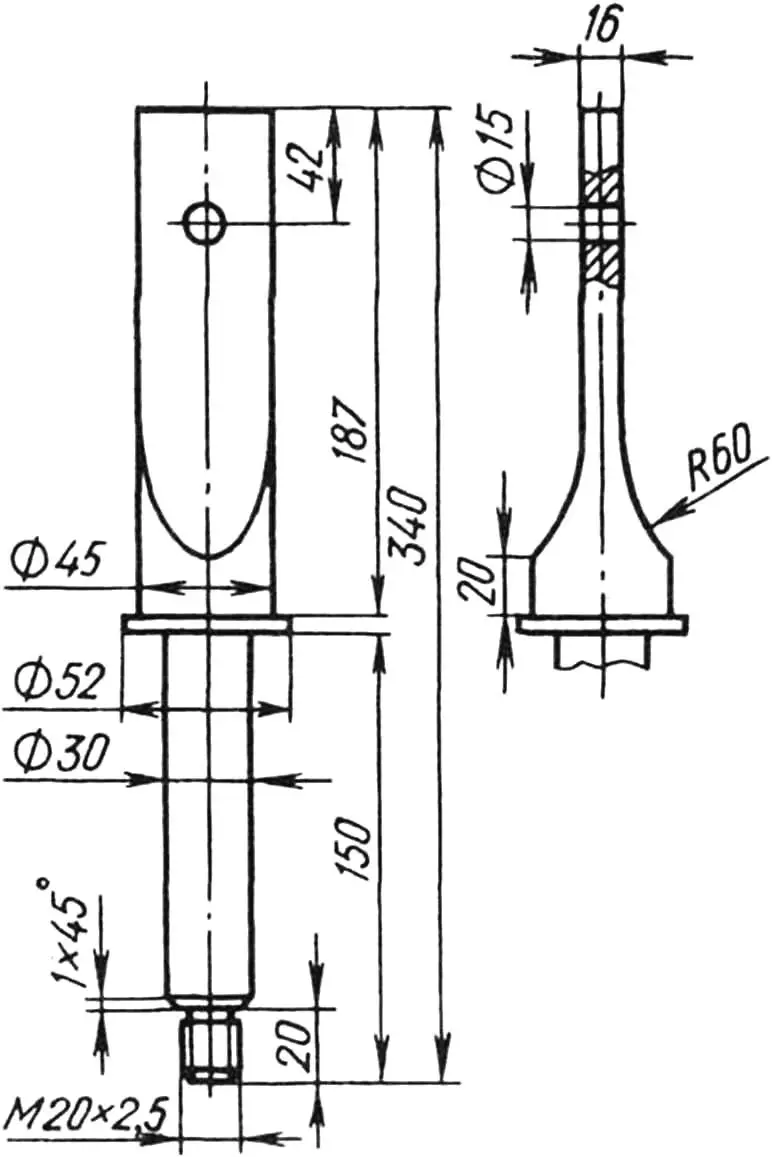

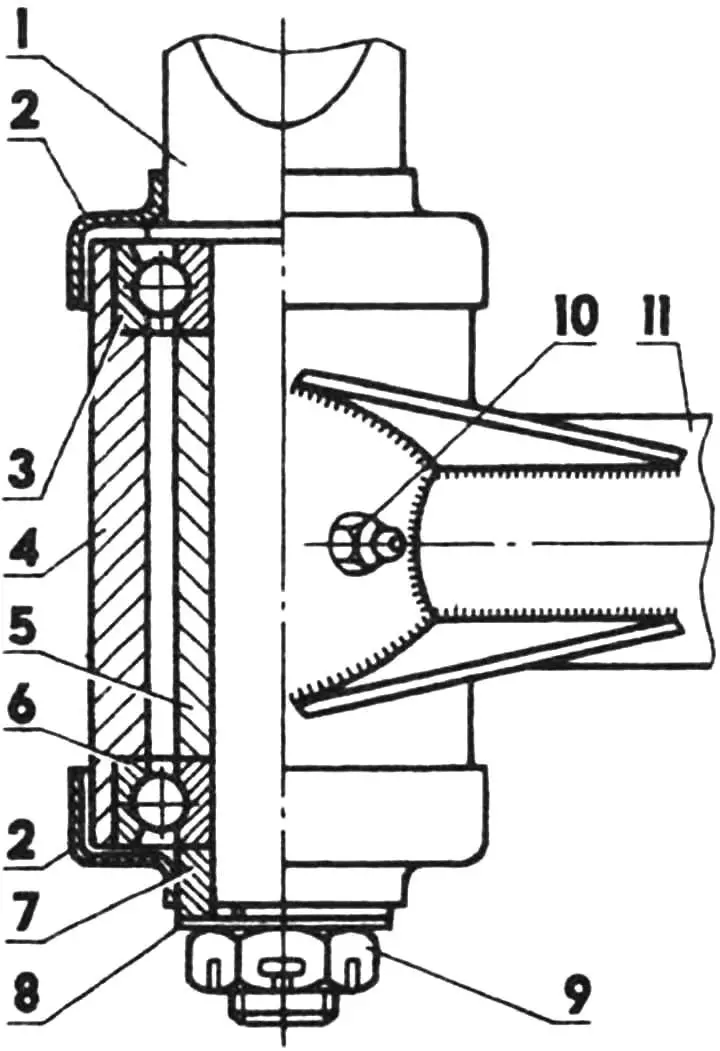

The cart is connected to the walk-behind tractor using a console, the upper part of which repeats the contours of the handle of the same hiller, since it is inserted into the standard attachment bracket, and the lower part is an axis around which the drawbar’s steering unit rotates in two radial-thrust bearings. The space between the bearings is filled with grease and covered with dust caps.

The drawbar is connected to the cart frame by a hinge — the drawbar is inserted into the tubular housing of the longitudinal hinge, and a stop ring is put on its end and fixed with an M8 bolt. This connection allows the cart wheels to be independent of the walk-behind tractor wheel position on road irregularities.

The driver controls the walk-behind tractor—cart combination, positioned on a wooden seat in front of the body. With his hands he holds the control levers, and with his feet he rests on a wooden footrest attached to a special frame on the drawbar.

1 — console, 2 — dust caps, 3, 6 — bearings 36206, 4 — housing, 5 — spacer bushing, 7 — distance bushing, 8 — washer, 9 — nut M20х2.5, 10 — grease fitting, 11 — drawbar.

In a small publication, of course, it is impossible to present all the details of the design. In the drawings, for example, such small details as side loops with straps for securing the transported cargo are not shown. A soft cushion on the seat is not depicted, without which any trip would be a trial for the driver. It is thought that the amateur designer will equip his product with these and other elements independently.

A. TIMCHENKO