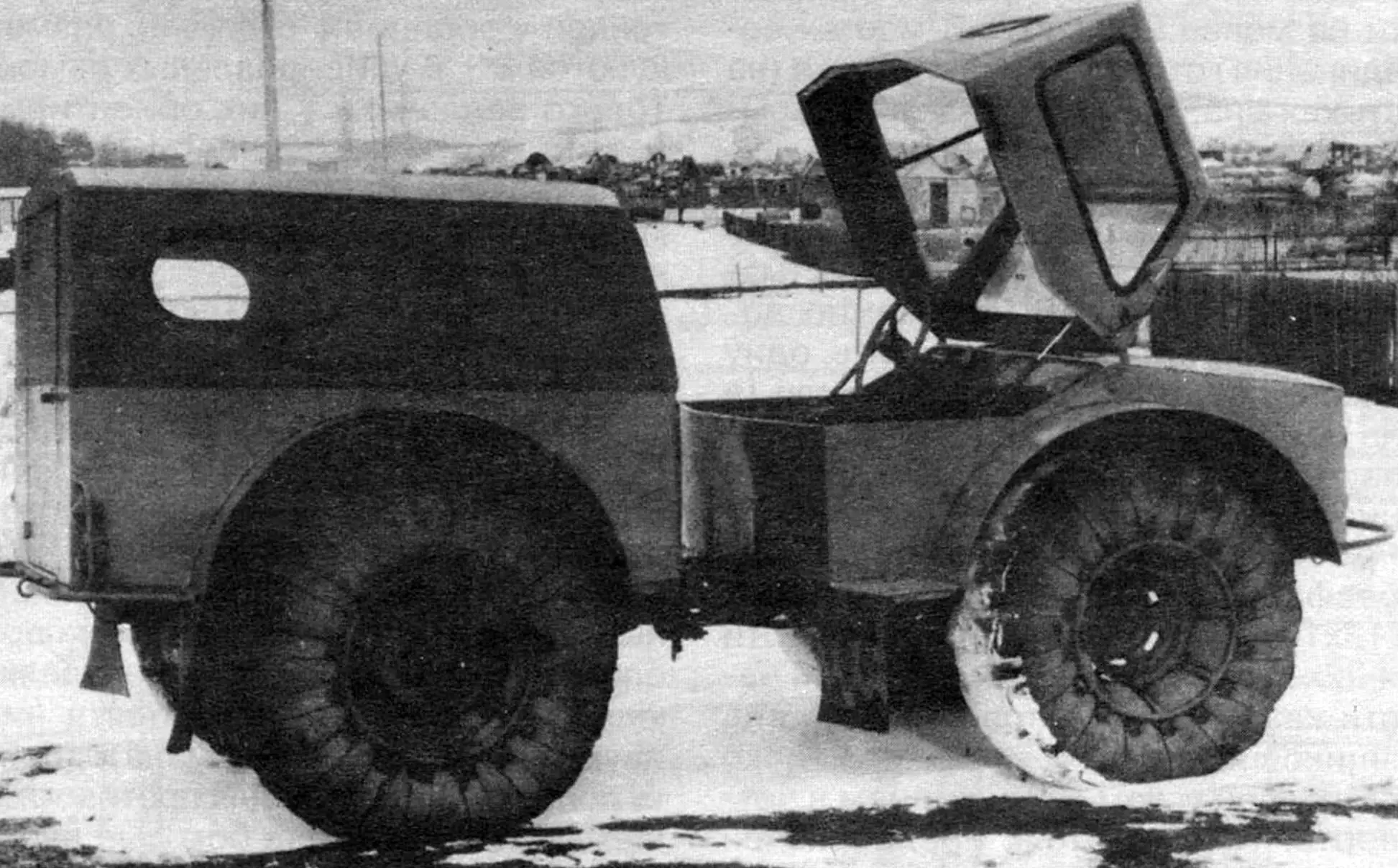

In the taiga regions, it’s not easy to get by without an off-road vehicle. That’s why all-terrain vehicles are always held in high regard here. I, for example, drive mine both in summer and winter. And it helps not only me.

Once I went winter fishing. A steep bank about two meters high on the river side was covered with snow, forming a sort of descent. My vehicle easily drove down at this spot onto the ice, where the snow depth was more than half a meter, and continued on.

After fishing, I was returning along my tracks. Reaching the bank, I saw a thoroughly stuck “Niva” there. The driver and passenger were digging it out, trying to free it from the snow. It turned out: the driver, seeing the wide track, thought that a large and heavy vehicle had left it, and followed the track… My all-terrain vehicle had pressed the snow to a depth of only 10 cm. The “Niva” immediately sank to the bottom.

I and my all-terrain vehicle had to help pull it out.

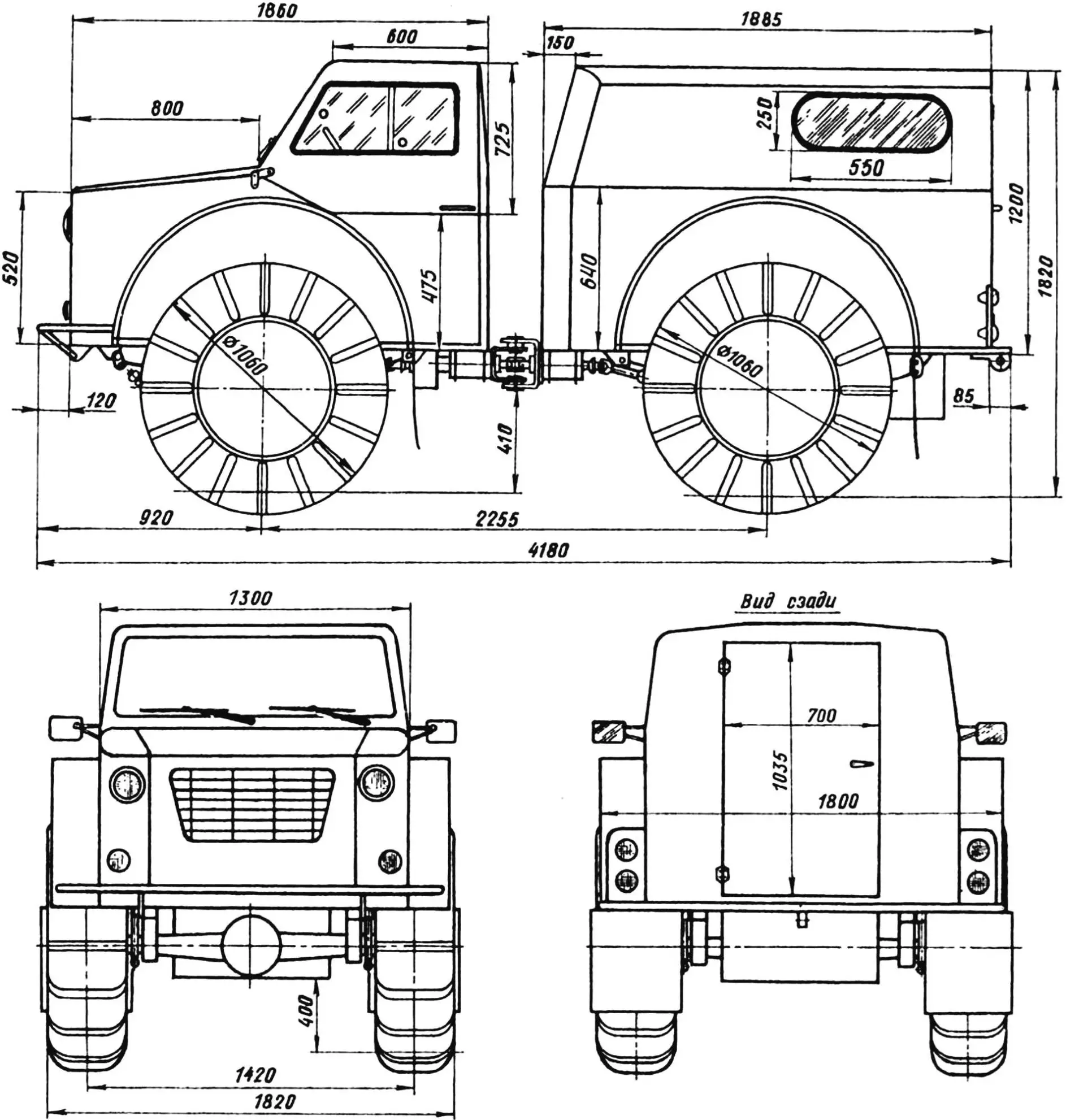

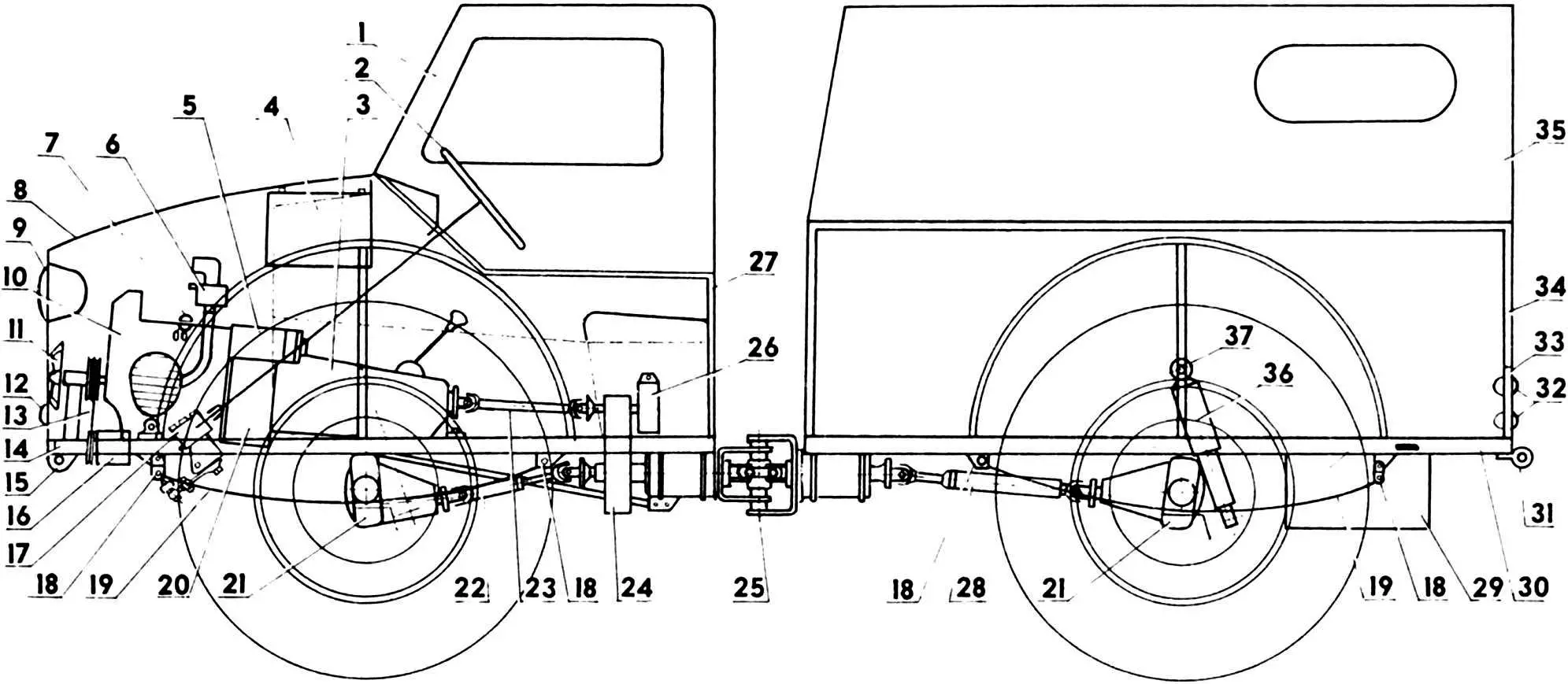

The all-terrain vehicle is a design with a “breaking” frame. On the front part of the frame, conventionally called the engine frame, are located the power unit and the control cabin.

The power unit includes an engine with a power of 26 hp and a displacement of 746 cm3 from a K-750 motorcycle, a clutch mechanism and starter — from ZAZ-965A, a generator and gearbox — from VAZ-2101.

The engine is slightly modified. First, it’s equipped with a forced air cooling system — an extension with a two-groove pulley is fitted on the crankshaft at the front. From it, rotation is transmitted by belts to two fan impellers that blow air over each engine cylinder, as well as to the generator.

Second, it’s fitted with a fuel pump from ZAZ-965A, which is located on the oil pump drive cover and connected to its shaft. Fuel is supplied from a 30-liter tank suspended under the body frame behind the rear axle.

Third, a K-127 carburetor and ZAZ-965A air filter are installed.

And finally, fourth, the gear ring is mounted on the flywheel through an adapter, and the clutch disc hub is replaced with a “Zhiguli” one.

1 — cabin (folding part); 2 — steering wheel (from ZAZ-965A car, steering column — from VAZ-2101); 3 — gearbox (from VAZ-2101); 4 — battery; 5 — starter (from ZAZ-965A); 6 — air filter (from ZAZ-968, conditionally not shown) and carburetor (from ZAZ-965A); 7 — fuel pump (from ZAZ-965A); 8 — engine hood; 9 — headlight (2 pcs.); 10 — engine (from K-750 motorcycle); 11 — fan impeller (2 pcs.); 12 — side lights (2 pcs.); 13 — belt drive (2 pcs.); 14 — engine frame; 15 — front bumper bracket (2 pcs.); 16 — generator (from VAZ-2101); 17 — steering mechanism (from VAZ-2101); 18 — spring brackets and shackles; 19 — springs (from “Moskvich-412”); 20 — clutch mechanism (from ZAZ-965A); 21 — axles (rear axles from “Moskvich-412” cars); 22,23,28 — driveshafts; 24 — transfer case; 25 — joint unit; 26 — hand brake drive; 27 — lower cabin frame; 29 — fuel tank (30 l capacity); 30 — body frame; 31 — towing eye; 32 — rear light block (2 pcs.); 33 — light block frame (2 pcs.); 34 — body frame; 35 — body; 36 — shock absorber (rear from “Moskvich-412”, 4 pcs.); 37 — shock absorber mounting pin (4 pcs.).

The power unit is covered with a hood made of 0.7 mm thick galvanized steel sheet. Cooling air access — from the front through a grille. The hood frame is combined with the lower cabin frame and made from 25×25 mm section tubes and 25×25 angle.

The top of the cabin, designed for two people, for boarding the driver and passenger, folds onto the hood and is held in this position by two shock absorbers from the “third” door of the “Niva”.

The cabin is equipped with rearview mirrors, “wipers” (not yet in the photo), a homemade instrument panel, and is insulated — warm air comes from the muffler. Its sheathing is also made of galvanized steel. The front glass — from SZA motorized wheelchair, the right one — “Zaporozhets”, the left one with a sliding vent and the rear — homemade (from plexiglass).

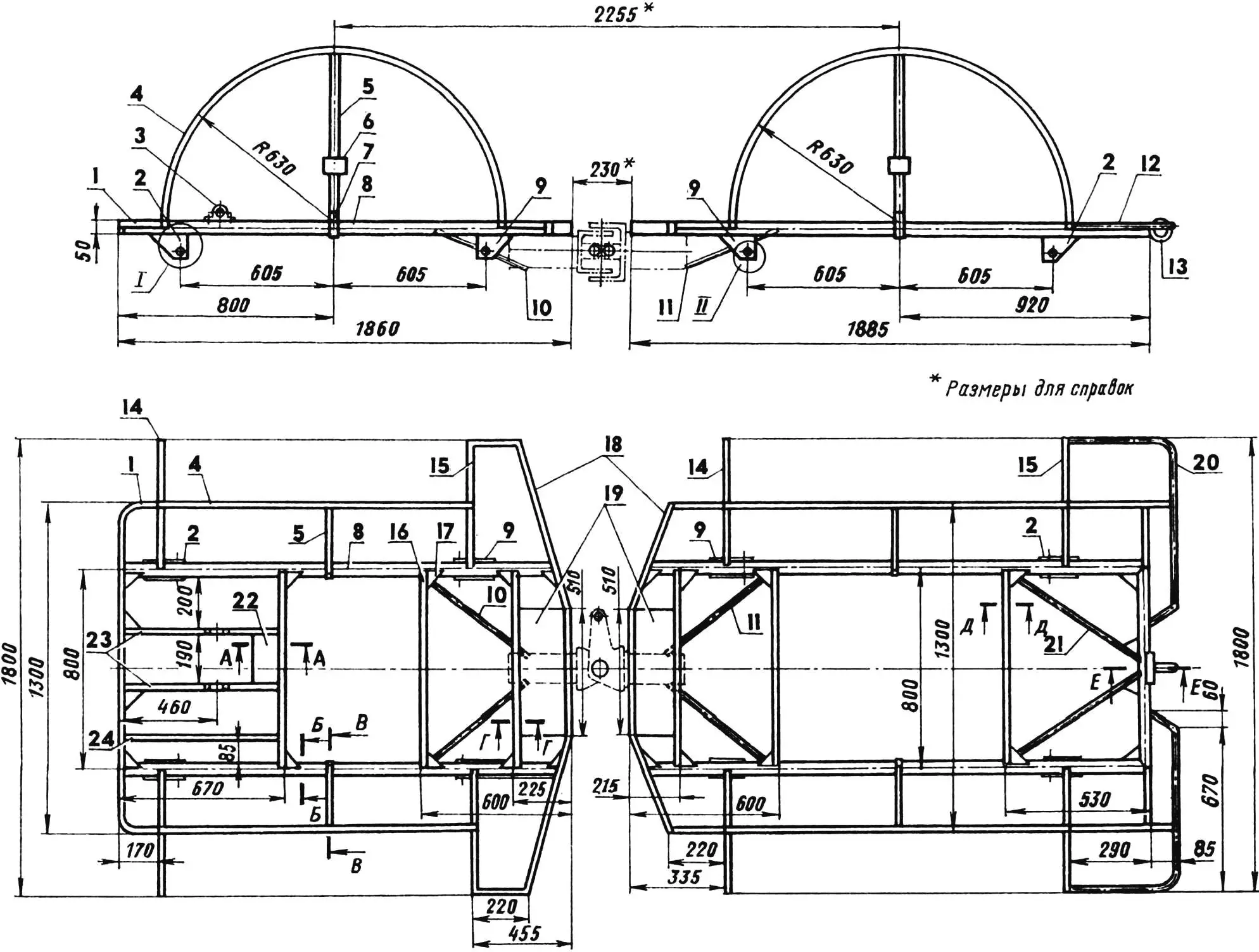

1 — corner fairings (angle 15x15x2); 2 — spring brackets (for shackle); 3 — engine mounting bracket (2 pcs.); 4 — fender arches (tube 25×25, 4 pcs.); 5 — fender posts (tube 25×25, 4 pcs.); 6 — shock absorber pin mounting bracket (steel, sheet s3, 4 pcs.); 7 — band (steel, strip 20×3, 4 pcs.); 8 — side members (tube 50×2.5, 4 pcs.); 9 — spring brackets (for pin); 10,11 — joint unit braces (tube 22×3); 12,20 — rear bumper halves (tube 22×3); 13 — towing eye (steel, rod Ø12); 14,15 — fender supports (tube 25×25, 8 pcs.); 16 — cross member (tube 50×25, 6 pcs.); 17 — gusset (steel, sheet s3, 24 pcs.); 18 — end caps (tube 50×25); 19 — spacers (steel, sheet s3); 21 — towing eye brace (tube 22×3, 2 pcs.); 22 — shelf (steel, sheet s3); 23 — engine support beams (tube 50×25); 24 — diagonal brace (tube 50×25); 25 — socket for rubber bushings of spring eyes (4 pcs.); 26 — shock absorber pin M12x1.25.

On the rear part of the frame, conventionally called the body frame, is installed, naturally, a body with entry through the rear door. In the construction of its walls, the same 25×25 mm section tubes, galvanized steel, and plexiglass are used; the top is made from the roof of an old VAZ-2102, and the bottom — from varnish-impregnated 12 mm thick plywood. The body can carry passengers or cargo weighing up to 300 kg.

Both parts of the all-terrain vehicle frame are made and welded from 50×2.5 and 22×3 mm diameter water and gas pipes, as well as 50×25 and 25×25 mm section tubes. The design of these parts is shown in simplified form in the drawing and needs no special explanation.

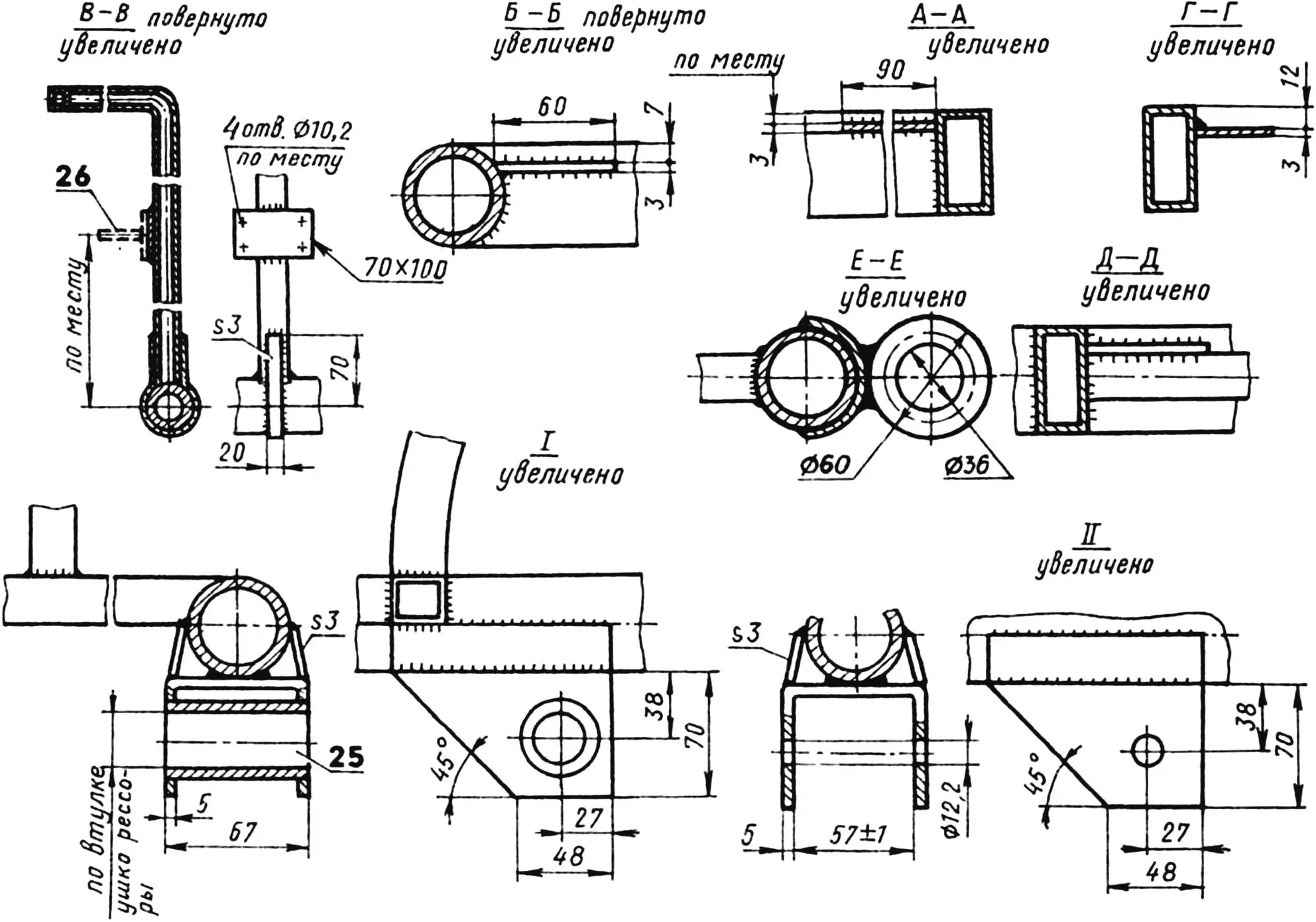

The running gear of the all-terrain vehicle is from two “Moskvich-412” cars: axles (rear) with rewelded spring mounting points (the distance between them is reduced), the springs themselves with mounting parts, shackles and stirrup pads, rear hydraulic shock absorbers. Thanks to this combination, the vehicle’s ride turned out so soft that the maximum suspension oscillation amplitude had to be limited with belt loops fitted on the fender posts and axles.

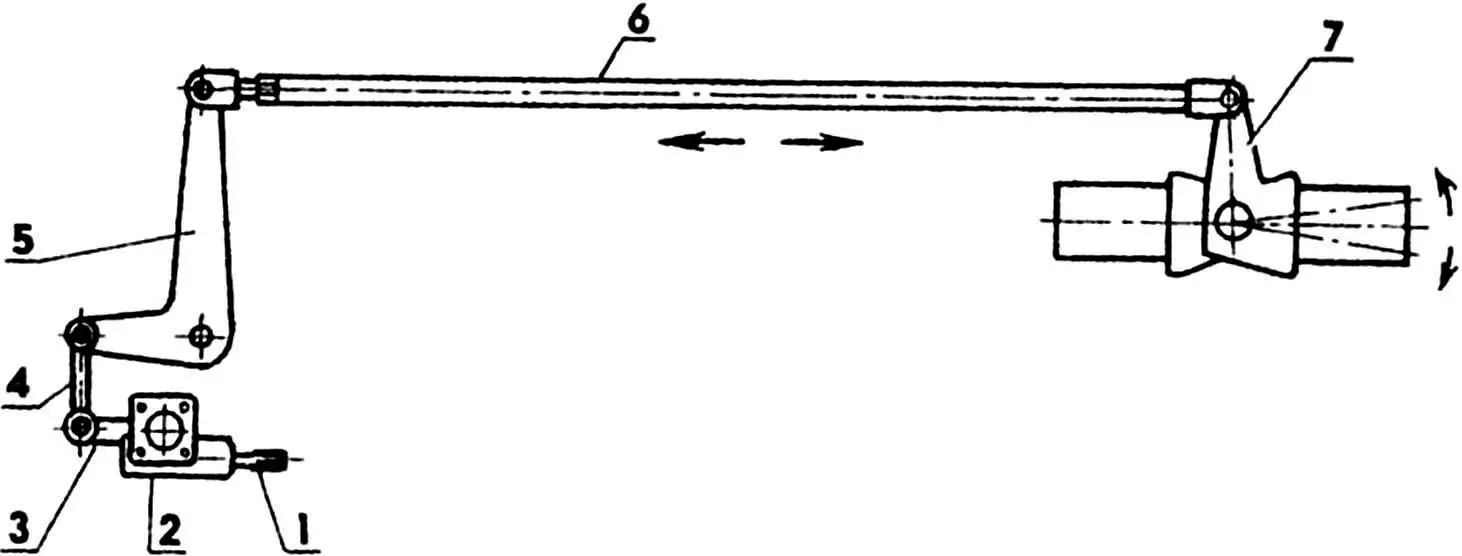

1 — steering mechanism worm shaft; 2 — steering mechanism; 3 — steering arm; 4 — intermediate rod; 5 — rocker; 6 — adjustable rod; 7 — rear fork lever of joint unit.

The all-terrain vehicle is controlled like a regular car. The steering wheel “spinner” is from a “Zaporozhets”, the column and steering mechanism — from “Zhiguli”. The only difference is that the impulse from the steering mechanism is transmitted not to the front wheels, but through additional elements (rocker and adjustable rod) — to the joint unit that “breaks” the frame. I wouldn’t say that this requires increased driver effort. Nevertheless, on a long journey, the arms get tired. To reduce the load on them, I plan to eventually introduce a power hydraulic cylinder with a spool device into the control system.

Lighting and signaling on the all-terrain vehicle are also automotive. There are headlights, side lights, clearance lights, “turn signals” and reflectors.

The brake with pedal drive on all wheels is hydraulic. The hand parking brake is mechanical, acting on a drum attached to the transfer case primary shaft flange.

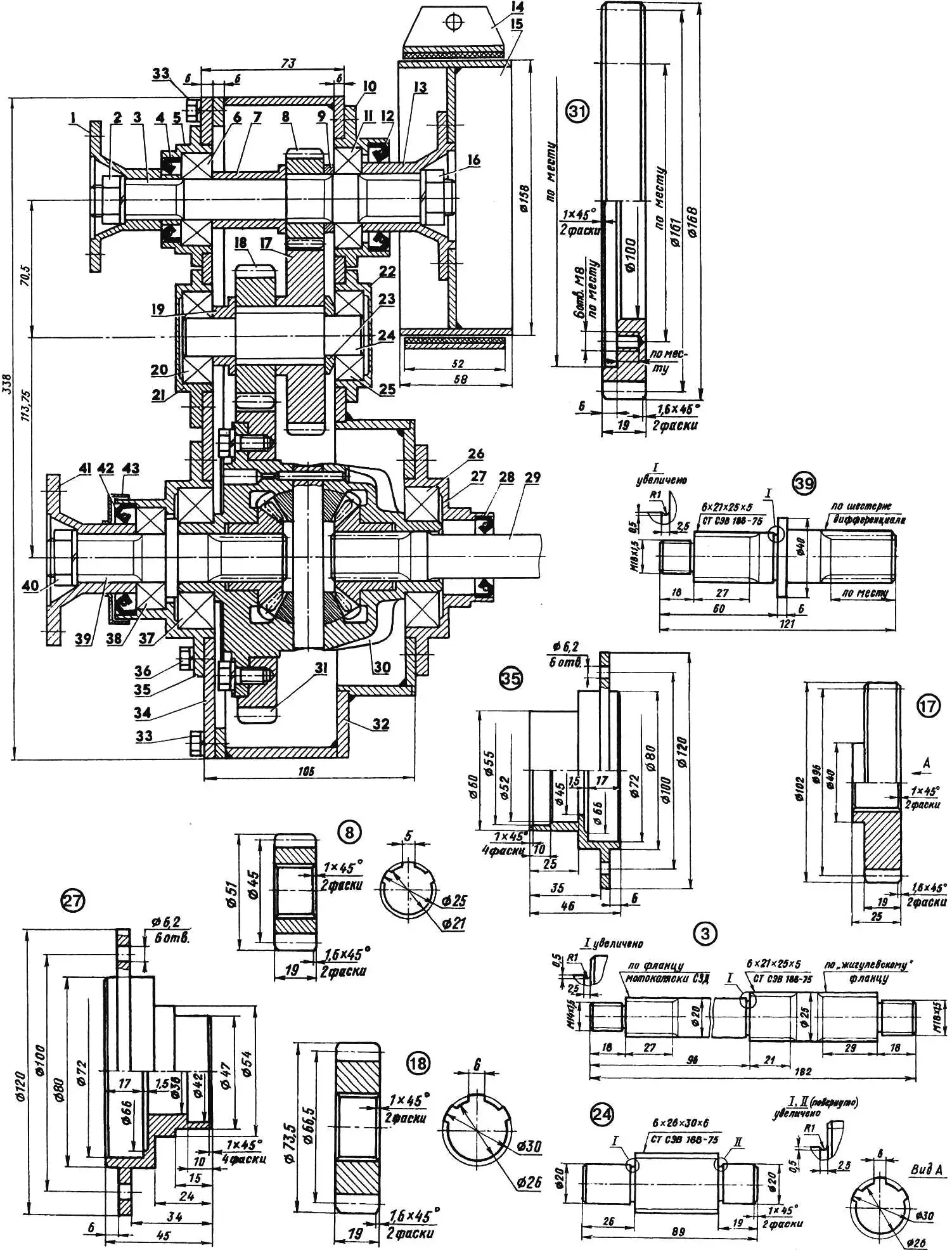

The transfer case (TC) is homemade and quite original, since a differential (from “Moskvich-412”) is included in its design. The housing of this box has a simple shape (parallelepiped), so its drawing is not provided here. All TC shafts are turned from old truck half-axles, while the gears and gear wheel are cut from 40Kh steel blanks. Both are hardened to HRC 46—50.

1,13,41 — flanges; 2 — nut M14x1.5; 3 — primary shaft; 4,28 — seals 42x25x10; 5,10,21,22,27,35 — bearing housings; 6,20,25 — bearings 204; 7,9,19,23 — spacer bushings; 8 — primary shaft gear (z = 15, m = 3); 11,38 — bearings 205; 12,42 — seals 55x36x10; 14 — hand brake drive; 15 — hand brake drum; 16,40 — nuts M18x1.5; 17,18 — intermediate shaft gears (z = 32, m = 3 and z = 19, m = 3.5); 24 — intermediate shaft; 26,37 — bearings 207; 29 — transfer shaft; 30 — differential; 31 — gear wheel (z = 46, m = 3.5); 32 — transfer case housing; 33 — housing cover mounting bolts M8 (around cover perimeter, pitch 45 mm); 34 — housing cover; 36 — bearing housing mounting bolt M6 (34 pcs. total); 39 — front axle drive shaft; 43 — dust cover.

The transfer case is attached to the engine frame with four M10 bolts. It’s connected to the gearbox (GB) by a driveshaft (later I introduced a rubber coupling here). To the primary shaft, as mentioned, the hand brake drum is attached. I’ll only add that the drum is made from a 6-inch diameter water pipe.

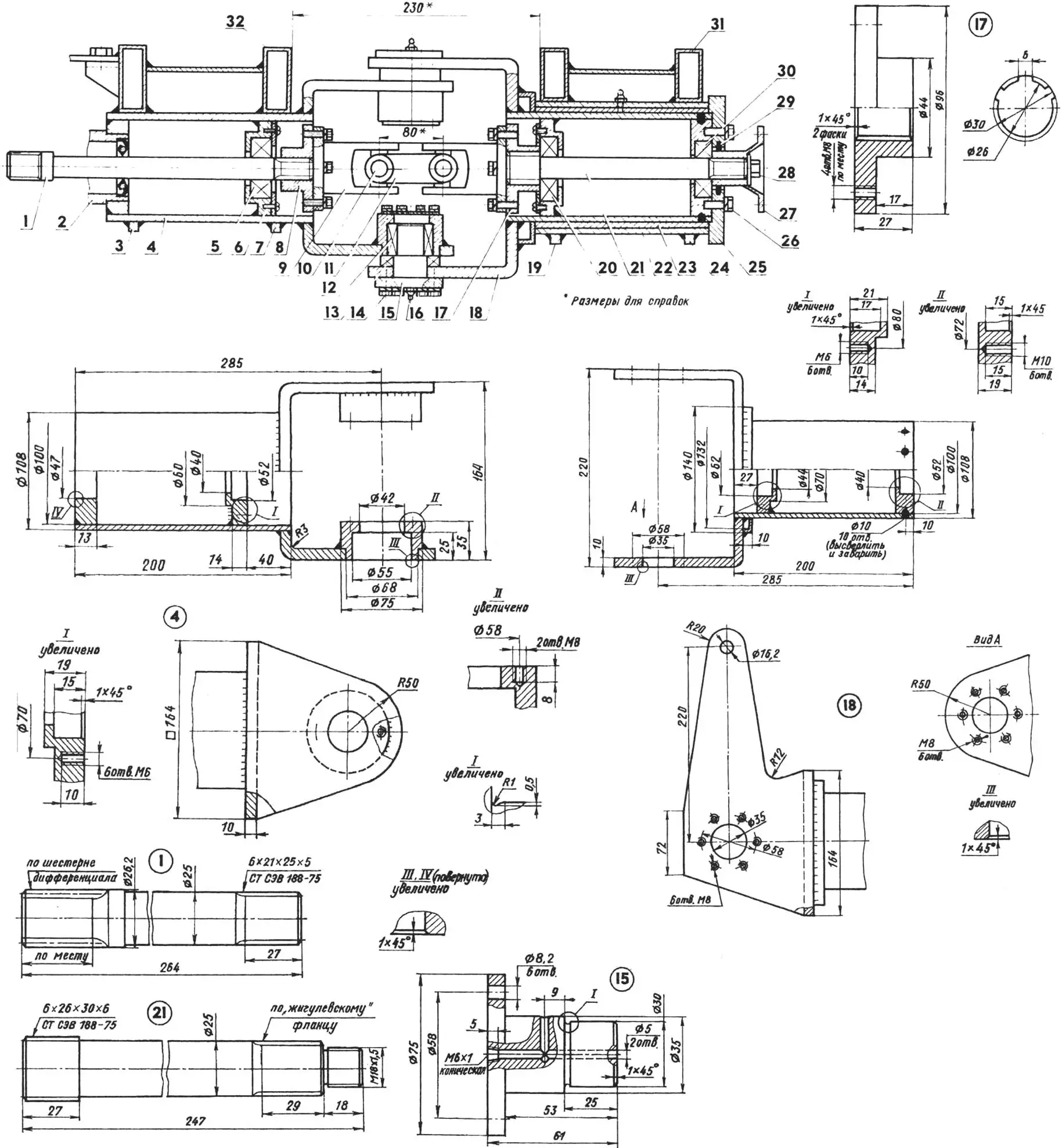

The transfer case (TC) with the front axle of the all-terrain vehicle, and the joint unit (JU) with the rear are connected by driveshafts assembled from driveshafts of various passenger cars. The TC and JU are connected to each other by a transfer shaft — a modified ZIL car half-axle.

The joint unit is also homemade. It consists of forks — front and rear, welded from parts of various configurations. The forks themselves can be made from angles of suitable sizes, as I had in the first version of the unit. The JU design is shown, I think, quite in detail, so I won’t dwell on it. I’ll only say that the joint sliding bearing is best made from a cast iron cylinder liner from a truck engine. It’s lubricated with “TSIATIM-201” through a grease fitting with a syringe. The other bearings are packed with grease once every three years.

1 — transfer shaft; 2 — transfer case; 3,7 — front fork mounting gussets to engine frame; 4 — front fork; 5,30 — bearings 205; 6 — screw M6 (12 pcs.); 8 — joint flange, front; 9 — universal joint fork (2 pcs.); 10 — cross (2 pcs.); 11 — connecting shackle (2 pcs.); 12 — needle bearing 4074106 (2 pcs.); 13 — thrust bearing 8207; 14 — screw M8 (for wrench, 24 pcs.); 15 — joint trunnion (2 pcs.); 16 — grease fitting (3 pcs.); 17 — joint flange, rear; 18 — rear fork; 19,24 — housing mounting gussets to body frame; 20 — bearing 305; 21 — rear axle drive shaft; 22 — housing; 23 — sliding bearing (cast iron, tube 120×6); 25 — end cover; 26 — screw M8 (6 pcs.); 27 — output flange; 28 — nut Ml8x1.5; 29 — seal ring 48x35x5.0; 31 — body frame; 32 — engine frame.

The universal joint forks and crosses for the JU are taken from “Moskvich-402”, the splined connections — from a KamAZ truck.

The halves of the unit are welded to the engine and body frames using four transverse trapezoidal gussets made of 3 mm thick steel sheet, fitted two each on the cylindrical parts of the halves. In addition, for more uniform load transfer to the frames, the JU mounting is reinforced with four braces made of 22×3 tube.

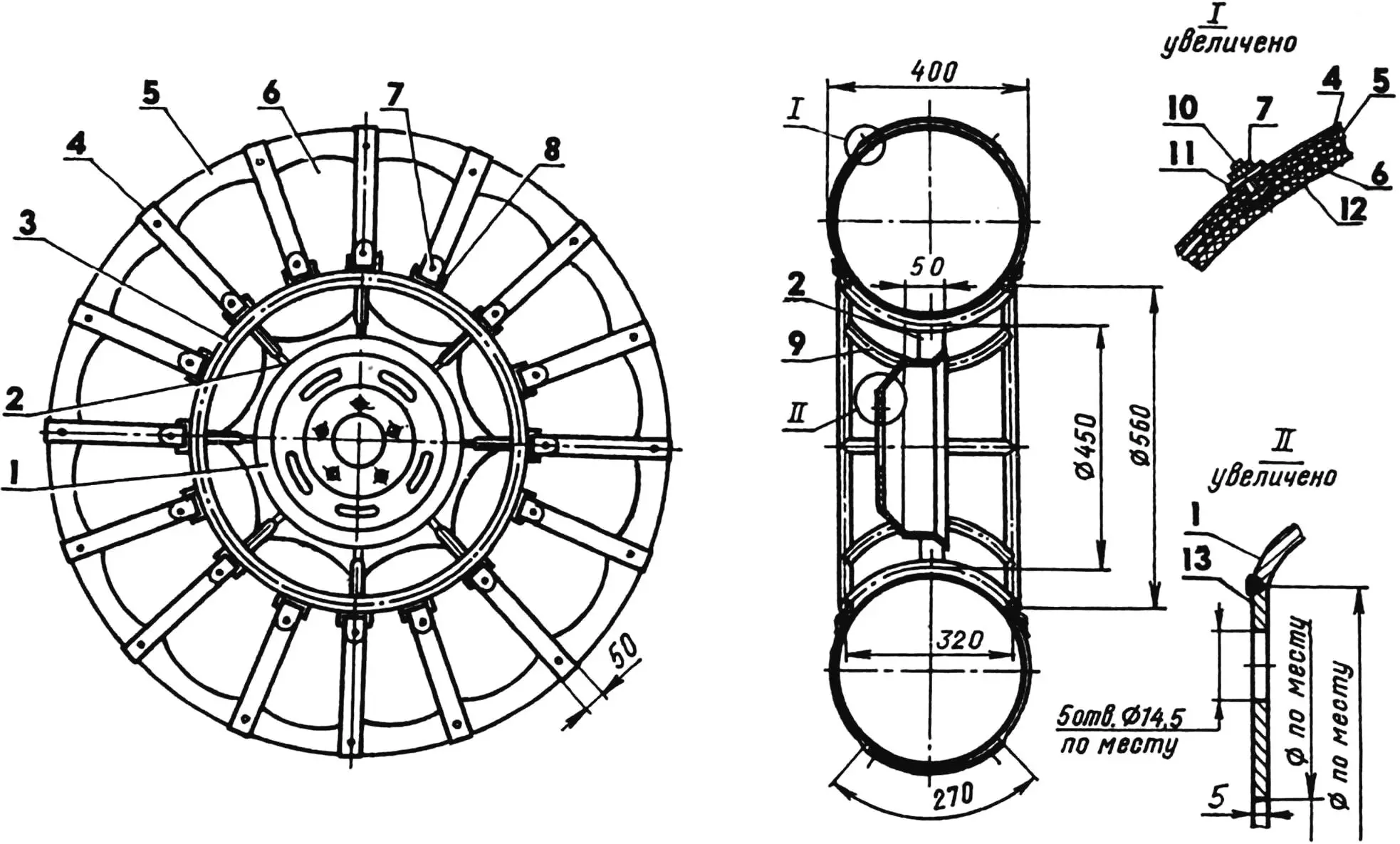

The all-terrain vehicle wheels have a diameter of 1060 mm. The disc of each wheel is cut from a “Zhiguli” one, and to it on eight short spokes made of 50×5 steel strip, a rim made of 22×3 mm tube is welded.

1 — disc (from VAZ-2101, cut); 2 — spoke (steel, strip 50×5, 8 pcs.); 3 — rim (tube 22×3, 2 pcs.); 4 — band (belt 50×5, 16 pcs.); 5 — tread (conveyor belt 270×5); 6 — outer tube (1065x457x420); 7 — nut M8 (64 pcs.); 8 — loop (rod Ø8, 32 pcs.); 9 — support (tube 22×3, 8 pcs.); 10 — bolt M8 (64 pcs.); 11 — washer (64 pcs.); 12 — inner tube (1120x450x380); 13 — adapter (steel, sheet s5).

The center of the disc is cut out, and an adapter — a washer made of 5 mm thick steel sheet with one central and five radial holes for wheel mounting studs — is welded into the resulting window. By the way, the standard M12 studs are replaced here with M14.

As tires, tubes inserted one into another are used: inner — size 1120x450x380 (from aircraft landing gear) and outer — size 1065x457x420 mm (from GAZ-66 truck or tractor cart). A tread — a ring made of 270 mm wide and 5 mm thick conveyor belt, pulled to the rim loops with belts — is fitted on each tire.

Wheels of this design allow the all-terrain vehicle to easily move over almost any plowed field, mud, or swamp. Even in snow up to 70 cm deep, it doesn’t get stuck. And it doesn’t slip on bare ice, although there’s no wheel lock, thanks to spikes made of bolts connecting the tread to the belts. In principle, the all-terrain vehicle could float if the front wheels were doubled.

The most significant drawback of my vehicle is its increased fuel consumption. However, this can be eliminated if the engine power is slightly increased.

All-terrain vehicle technical data

Length, mm … 4180

Width, mm … 1820

Height, mm … 1820

Wheelbase, mm … 2255

Ground clearance, mm … 400

Dry weight, kg … 610

Payload, kg … 450

Maximum speed with driver and passenger, km/h … 45

Fuel consumption, l per 100 km … 18

Brakes:

service … hydraulic, with drive to all wheels,

parking … mechanical, band.

B. RYZHOV