metal rod Ø 6 mm, matting or Mat, a thin soft wire, lacquer furniture, small for metal.

TOOL: hacksaw, file, sandpaper, scissors, meter, brush, hammer, vise.

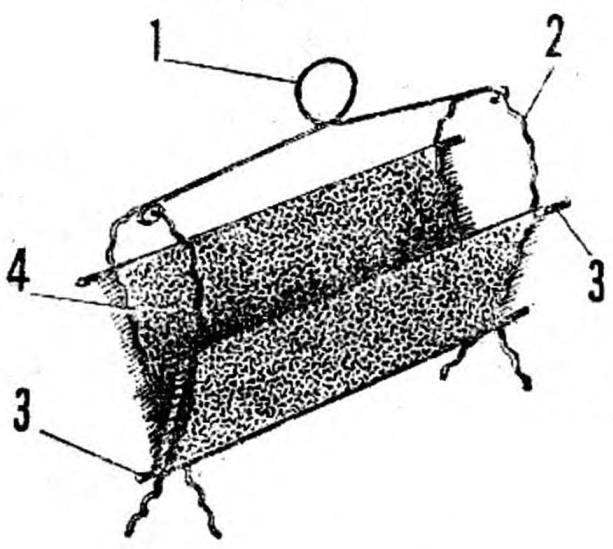

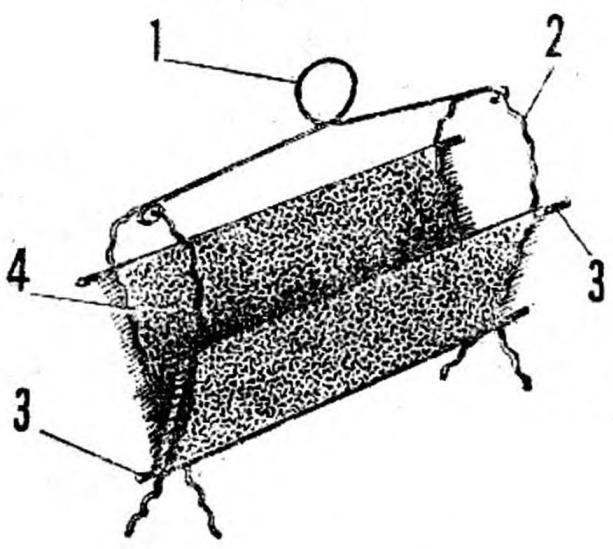

MANUFACTURER. Of a rod with a length of about 820 mm vygeboom detail 1: first, using a hammer and vise end “hooks” to bond with the workpiece 2, and then on any handy blank (round the block a little pipe of suitable diameter) — the ring-pen.

In the same way receive the items 2, performing the role of racks. The last processing, part 3 — the straight cut rod with a length of 520 mm (required three pieces).

Metal stand to make the product more artistry can be further bent (zigzag). All end plane of the processed file, the rest of the surface is sandpaper.

ASSEMBLY. First, parts 1 and 2, which arc vertices stands will enter the hooks of the handle and finally Zagam them with a hammer grip.

Now one of the crossbars 3 put the crosshair on legs racks and fasten them with wire. Likewise fastened on the side stands the other two arcs cross. Remains of mats or Mat to carve out a rectangle the width between the uprights (with a small allowance for “fringe”) and length, which would pass it under the lower crossmember and put edges on the side to secure the thread here or the same wire. However, before this metal frame should be painted with enamel, and packing-billet cover with a colourless furniture Polish.

Recommend to read THE RETURN OF THE MINI FRONT-WHEEL DRIVE MINI COOPER S 2002 ISSUE. Until now, the main trend of the world design was the desire to create a car that did not create one. The designers were looking for new... CONTACT — THE CONTACT! Motorists know that if a car a long time not to use the battery terminals to prevent oxidation must be removed, and the open contact of the battery terminals to isolate. The easiest way...  MATERIAL: metal rod Ø 6 mm, matting or Mat, a thin soft wire, lacquer furniture, small for metal.

MATERIAL: metal rod Ø 6 mm, matting or Mat, a thin soft wire, lacquer furniture, small for metal.