Good locksmith tool produced by students of the Moscow school № 787 on the lessons of labour from scraps of reinforcing steel and other metal waste. After heat treatment, its strength is not inferior to the factory.

Good locksmith tool produced by students of the Moscow school № 787 on the lessons of labour from scraps of reinforcing steel and other metal waste. After heat treatment, its strength is not inferior to the factory.

Below are a few samples of such a tool that can serve in schools, clubs syut, clubs of young technicians, and just the tinkerers: the tool can be made from scratch and tailored to the individual wishes of each.

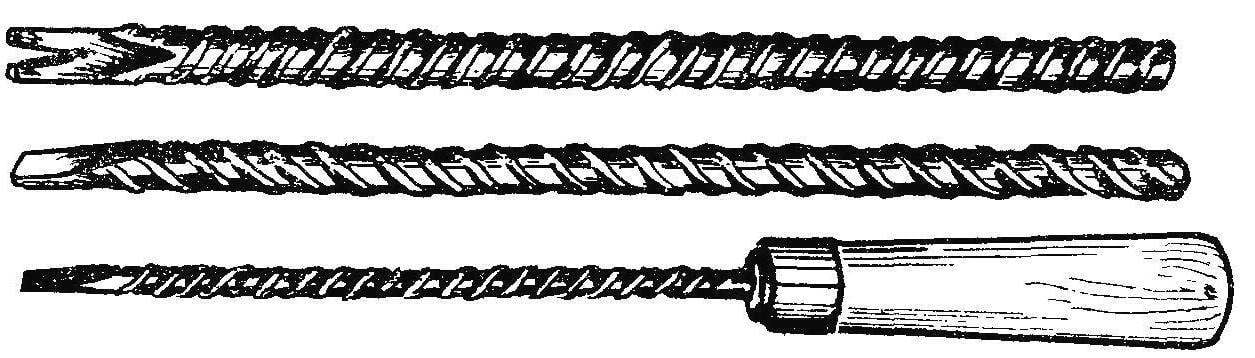

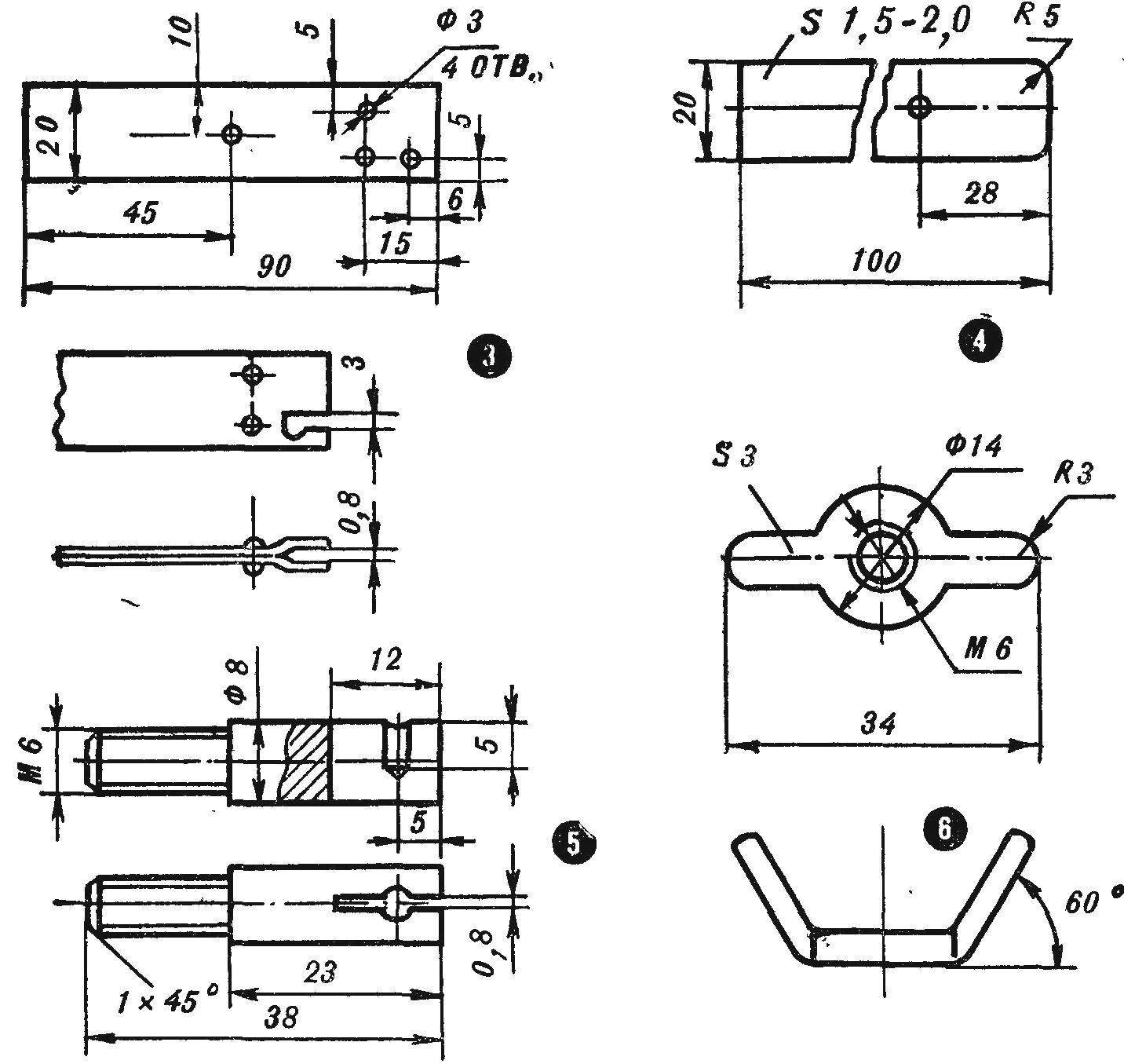

Locksmith tool (Fig. 1) — screwdriver, chisel, punch — made from scraps of reinforcing steel with subsequent thermal treatment (quenched and tempered).

To do this, in a muffle furnace or a furnace heated to the working part of the rod to a red glow (700-750°), and then a hammer on the anvil, give it the desired shape. Thereafter, the blank chisels, screwdrivers, punch finally treated with a file or emery stone. And in the swage to additionally rivets on the end is drilled a shallow hole, which then finally brought a drill with round shank for receiving the spherical depression.

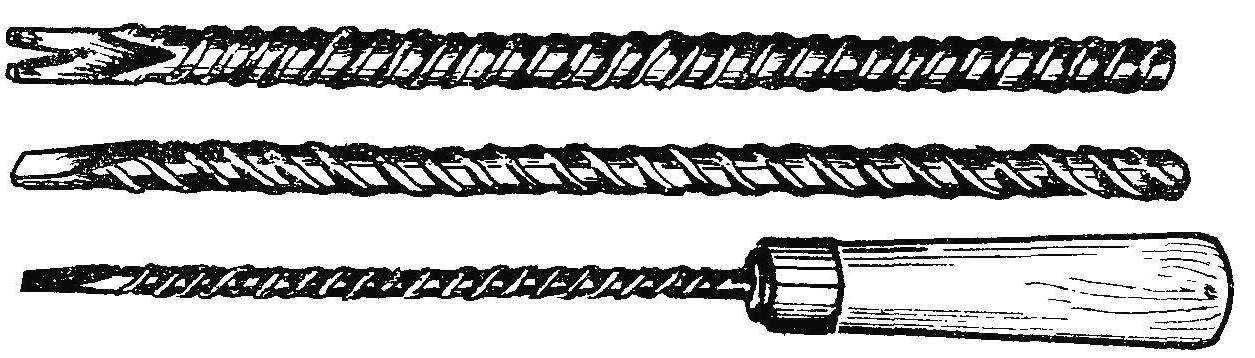

Fig. 1. Tool kit:

1 — piece, 2 — a chisel with a special, 3 — screwdriver 4 — swage for rivets, 5 — spades, 6 — core, 7 — hole punch.

Further, it is necessary to strengthen the working part of the tool, heating it to a temperature of 830° (light red glow). Cooling in water at room temperature, and immersing the working edge of the tool for 2-3 s. Then, taking the working part of the water, quickly strip the control strip on hardened location with emery paper or abrasive wheel. Wait for the ka it has a tint of light yellow color (220°), re-dip the product in water. This treatment with a partial re-release makes the working edge less fragile.

The quenching and tempering handmade can be divided without two operations: after heating and full cooling, the product is re-heated to the tempering temperature of and again cooled in water.

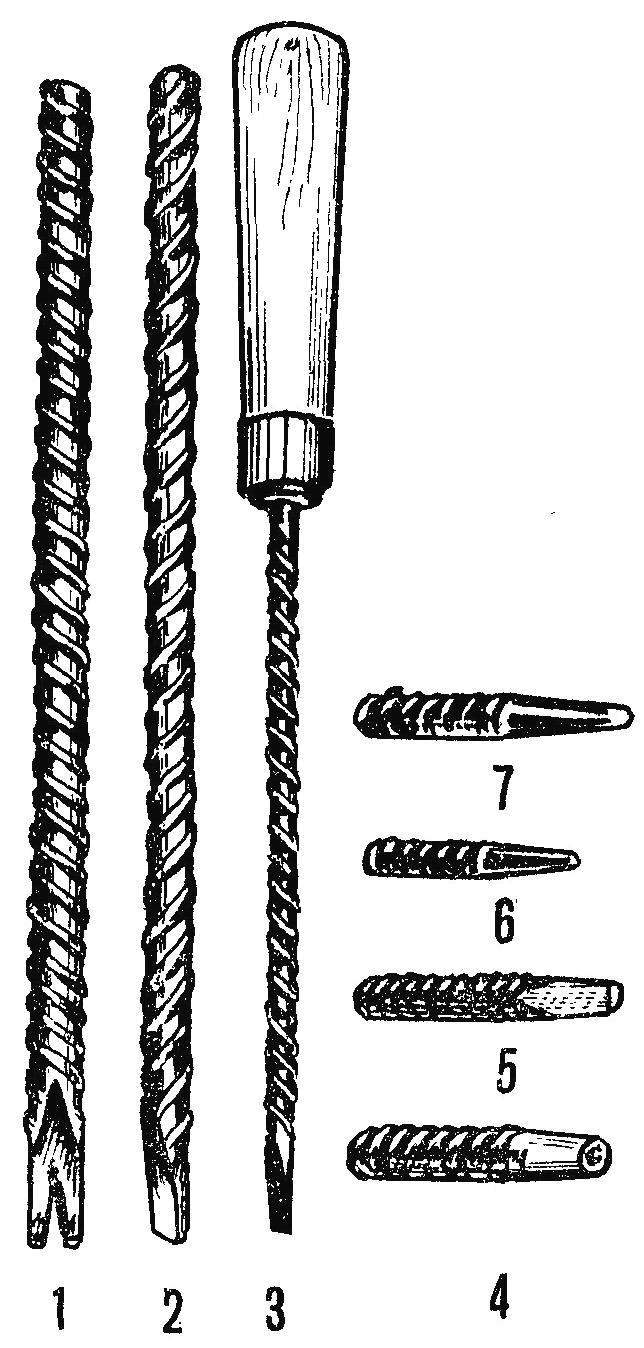

Amateur hacksaw (Fig. 2). The main longitudinal strap saw blade of the machine is made from steel strip 3×20 mm, and the brackets and the handle is made of blanks with thickness of 1.5–2 mm.

Fig. 2. Saw blade machine:

1 — front bracket, 2 — the main strap, 3 — rear bracket, 4 — handle, 5 — natina screw, 6 — shearling.

For the front bracket does the billet size 190Х20Х1,5 mm, bent in half and crimped in place bend the round rod Ø 8 mm. the Rear bracket is assembled from two plates of size 90X20X1,5 mm. the two halves of each bracket are joined with rivets Ø 3 mm (see Fig. 2). The ends of the brackets on one side of RA will be jammed and tightly crimped on the longitudinal main plate.

Similarly, you blank for the handle. For its manufacturing take two plates of size 100X20X1,5 mm and connect in the middle of the countersunk rivet Ø 3 mm.

For mounting the brackets to the main bracket they are placed on a square, clamped in a vise and drill Assembly. After a riveting and remove the excess metal and clean the edges. The handle riveted plastic or plywood overlays.

The tension screw is done on a lathe of suitable material and according to the drawing, and the thread is cut die М6Х1. The production of lamb is self-explanatory.

Yuri ZHDANOV, teacher