Student scientific-technical conference of faculty road cars of the Moscow motor-road University this year attracted the attention not only of students and teachers, but also industry representatives. Still, many reports of young researchers it was about issues of importance to the national economy.

Student scientific-technical conference of faculty road cars of the Moscow motor-road University this year attracted the attention not only of students and teachers, but also industry representatives. Still, many reports of young researchers it was about issues of importance to the national economy.

As, for example, the theme of undergraduate Eugene Frolov: “the Study of the bulldozer exposed the middle knife in the construction of highways”, or his classmate Vladimir Bogatyrev: “the Study of models heavy scraper with a gas-dynamic intensifier”. Scientific Director of both researchers Professor, doctor of technical Sciences Vladilen Ivanovich Balovnev, head of Department of operation of road machines, were satisfied: the two reports aroused great interest. Although students Frolov and Bogatyrev make the first independent steps, their studies were awarded diplomas of the Moscow city Committee of the Komsomol and the Moscow city Council for the research work. After all, it was about the intensification of the most time consuming — digging.

Our homeland — a country-building. One after another new towns, giant industrial complexes, dams, canals, Railways and roads. And at the heart of each construction is the so-called zero cycle. How to speed up, to intensify the process of excavation and movement of earth?

What if, for example, working on earth moving machines to do not a solid as it is now, but composite? For example, the dozer blade can not immediately move the layer of soil over the entire surface. Then forward, like a knife edge, comes out the middle part of the blade and shifts the narrower part of the land — the rest will be cut off for easier. You can give the blade though not quite normal, but perfectly fitted for the soil form. This issue was dedicated to one of the reports.

There are other ways. And they all stem from one problem: to reduce the friction between the removable layer of the earth and work on the car. To overcome this friction, the machine consumes 30 to 60% of capacity. And it is easy to imagine what a huge gain in performance will be obtained if this task can be solved at least partially.

Maybe to cover the working body of the machine is well sliding, anti-friction material such as Teflon? This use of achievements of modern chemistry of polymers reduces the loss of power almost to 40%. But… the Teflon coating wears out quickly, and the more persistent chemicals are still not offered.

Electro-osmosis is the penetration of electrically charged particles through the layer of solids — can also be used. If to stick in damp ground conductor, and the other will be a working body of the machine, droplets of subsurface water will spread invisible capillary passages and to Moisten the working body. Experiments showed that when using this method, the coefficient of friction between the blade (or bucket) and soil in some cases was reduced by 80%. A striking result! But, first, the case is very thin and requires greater study, and secondly, this method is not applicable for the dry soils.

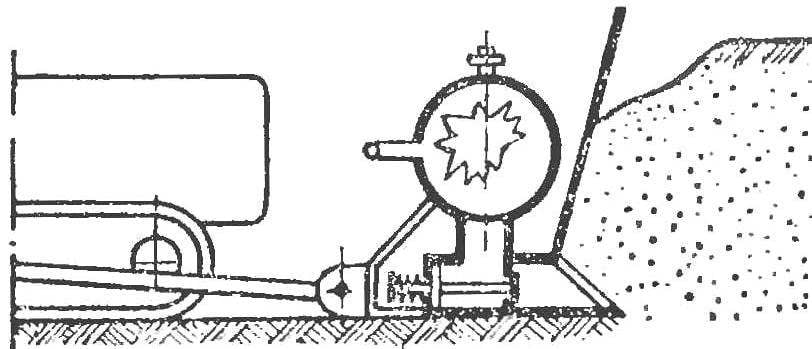

And if you use the principle of air cushion? Today it finds wide application in the transport technology. What happens if the dozer blade apply compressed air? Between it and the layer of the earth is formed air cushion. Then the friction will decrease sharply. According to the Kharkiv automobile and road Institute, in some cases, resistance to the dozer blade will be reduced by 30%. The same effect, the scraper (Fig. 1).

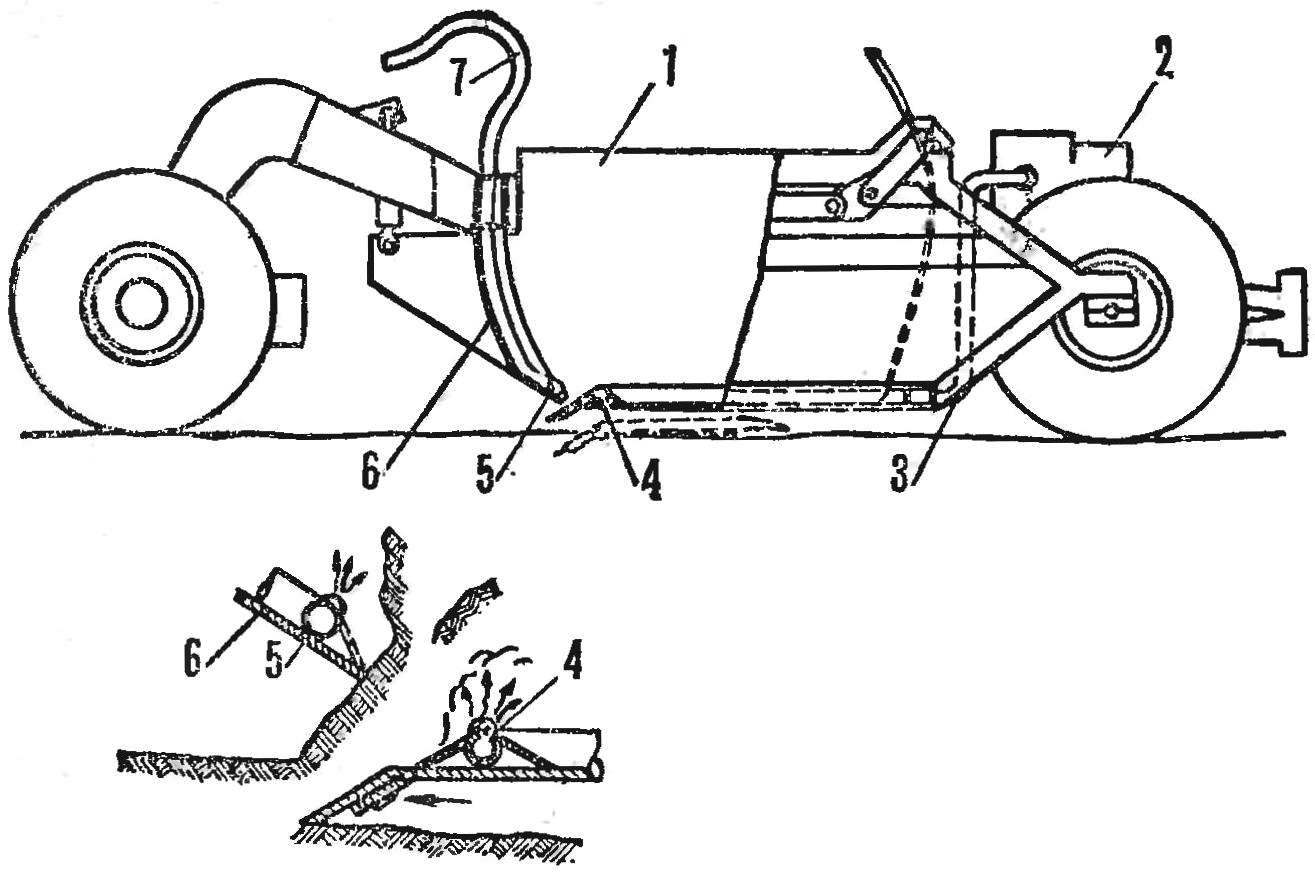

Fig. 1. Scraper with gas-dynamic effects on the soil:

1 — bucket; 2 — source of compressed gas; 3 — gas pipe to the bucket; 4 — exhaust holes in the bucket; 5 — exhaust nozzle at the valve; 6 — valve; 7 — pipeline to the flap.

And even more scientific advances come to the aid of the traditional shovel. Experiments on the destruction of the heavy-duty soils and even rocks by jetting high-pressure: 7000 kgf/cm2, a huge initial speed of the jet, pulsating with a frequency of 5 shots per second. This is something that can give current hydraulics. But quantum physics offers laser beams, plasma. In the press there were messages about the electron beam device for cutting frozen soil and rock.

At the Leningrad mining Institute created a laboratory of destruction of rocks Electromechanical method. It uses the currents of ultra-high frequency: up to 2400 MHz. For example, one of the designs proposed by scientists of the Leningrad (copyright certificate № 319225). With a conventional bulldozer frame is connected, moving ahead of him. Pivotally attached to the frame that moves on the earth ligaabrama steel electrodes. Currents the microwave warm up the soil, and the bulldozer bucket cutting it. Independent suspension allows the skis to follow the contours of the developed array.

But you can do without a frame by placing electrodes directly in the excavator bucket or bulldozer blade (copyright certificate № 378598). The microwave generator is also in the bucket. He fenced off the extra wall and is only activated when the resistance of the frozen soil cutting edges of the teeth. The ground in front of the teeth while instantly loses its strength. All of this means that is born of a fundamentally new class of earth-moving machinery.

But perhaps the most advanced scientists and engineers in the creation of machines where the soil is removed not with a knife, and… explosion. So what? — some might say. Long been known a method in which dense soils first blow, and then moves the earthmoving machine. This is true, but here we are talking about something else entirely. The explosive device is located on the work machine on the dozer blade, bucket, etc.

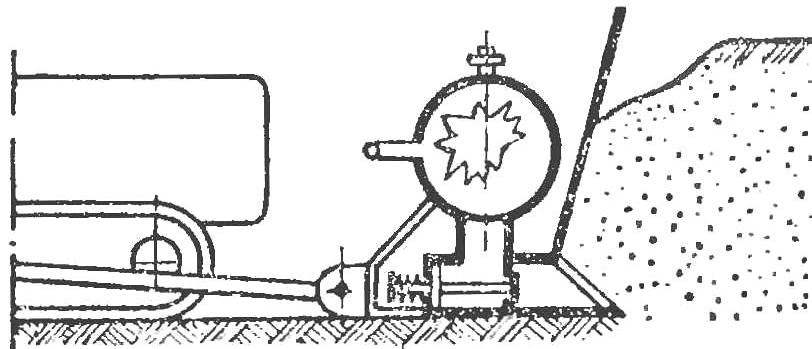

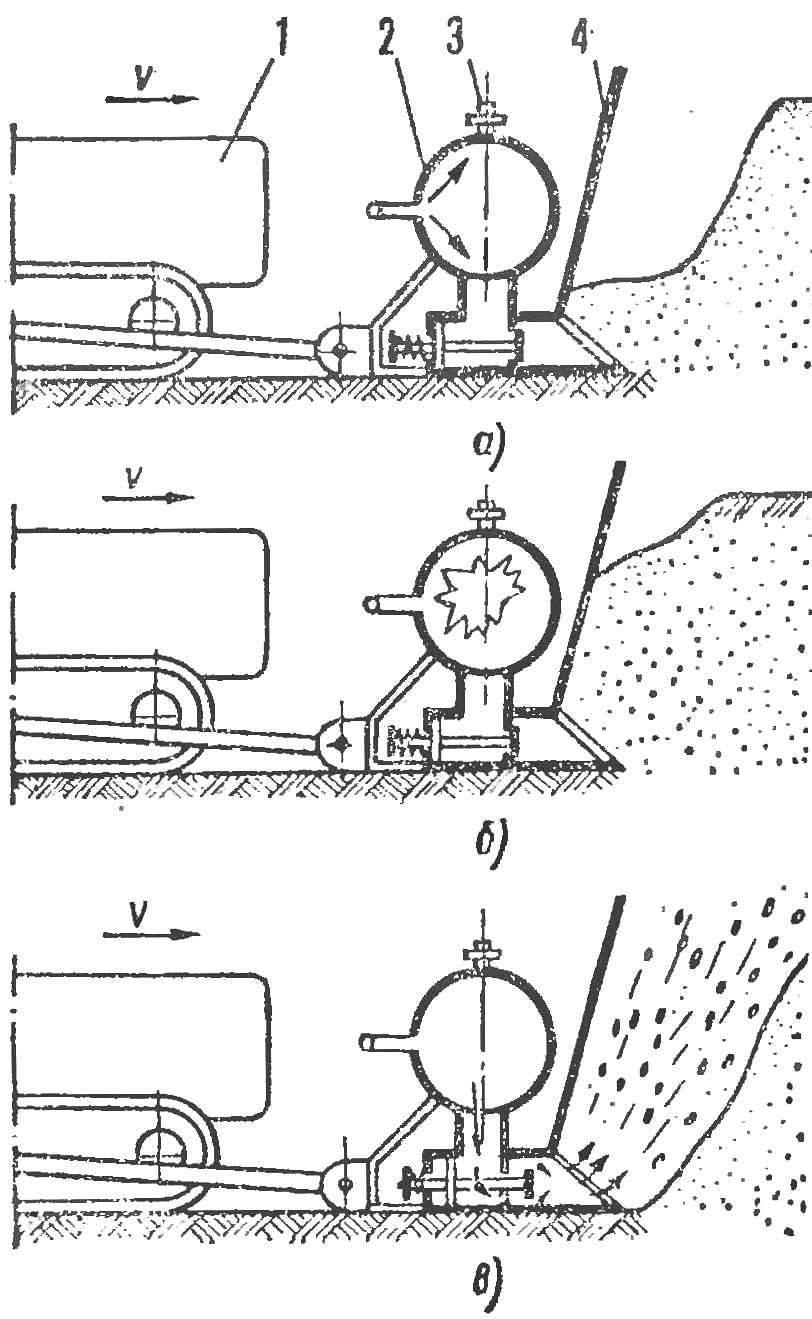

Fig. 2. The scheme of the explosive device:

1 — machine base; 2 — combustion chamber; 3 — spark ignition; 4 — Talnoe device: a) the blade is embedded in the ground, in the combustion chamber is fed fuel and air; b) the mixture in the chamber is ignited; b) — gases, breaking through the holes in the blade, kill the earth and clearing the path of the blade for the next movement.

The word “explosion” in our minds is associated exclusively with the energy of destruction, using for this purpose a special substances. And inadvertently forget that operation of any automotive engine is, in essence, a series of successive explosions In the cylinders explodes the working mixture, consisting of fuel and air. The gases formed at the same time, pushing the piston. What if the piston is not? Then the gas jet will break out with force enough to loosen even hard as a rock, the earth. This is the method and adopted by scientists and engineers for the development of solid ground.

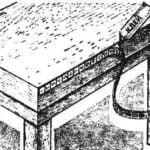

The principle of the device is as follows (Fig. 2): the working body of the machine 1 is placed an explosive device — something like a internal combustion engine, where the cylinder and piston no. Camera 2 (cylinder) charging a mixture of fuel and compressed air. Spark plug 3 ignites the mixture. Everything goes the usual way: in the chamber increases the gas temperature and its pressure. Open exhaust valves; gases with a power rush out through the hole in the lower part of the working body 4 (blade, bucket, etc.). The soil thus loosened, and working on much easier to move it to the side.

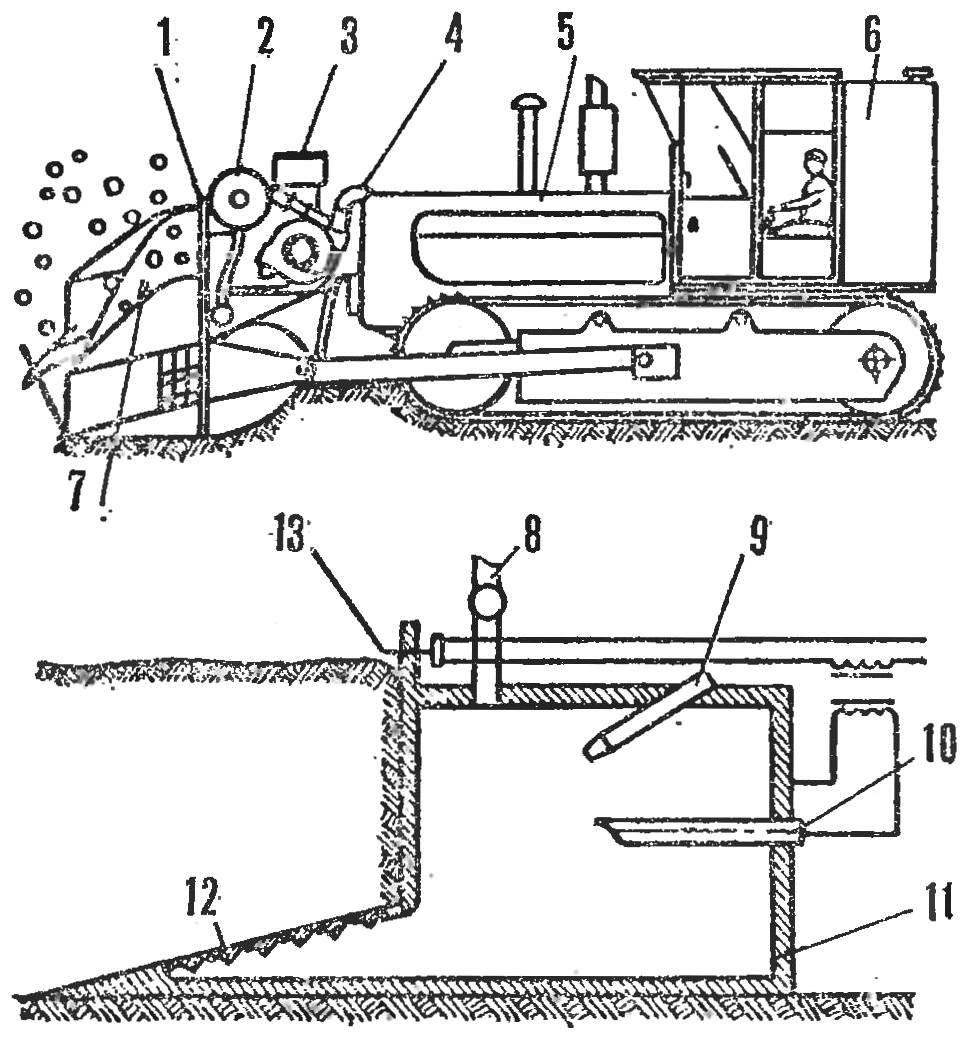

As figure 3 shows, new bulldozer, equipped with a installation. Experiments on models of n prototypes has shown that the ‘machine of this type, manufactured on the basis of an ordinary crawler tractors, can have a capacity of 15-20 times greater than the existing bulldozers of the same class. Here’s an example: the prototype of bulldozer with an explosive device tossed at the hour of 11 500 m3 of soil; regular heavy bulldozer in the same time to cope with only 500 m3 of soil. A trench width of 3 m and a depth of 1.5 m dozer, equipped with an explosive device that digs at a speed of 3.2 km/h.

But trials have shown serious shortcomings of the new method: the bulldozer in the explosions leads to the side, you need some way to change the design of the working body of the blade; a large jet impact force of the explosion; it is difficult to provide the combustion chamber with compressed air for purging and charging them with fresh mixture, this requires a high-performance compressor with 30 to 40 m3/min working otherwise the machine speed will decrease. The solution to all these problems and started researchers.

The stronger the resistance to explosion, the more destructive its action: this means that the blade is tightly embedded in the ground. Then the earth is solid the tubes will clog the nozzle. All-Union scientific-research Institute of construction and road machinery proposed construction of the dozer blade to which are attached additional front wedge (and. S. 253627). The wedge pushes soil so that it is compacted just before the exhaust holes ia the dump.

To eliminated the need for the compressor, MADI offers the design of the combustion chamber, equipped with a piston. So on the dozer blade turns out like a proper little engine. With the help of this piston and is compressed in the combustion chamber air (and. S. 379749).

In short, the constructive variants are many, because the search in this direction is intensive. And no wonder: it is estimated that the savings from the work of one bulldozer, equipped with an explosive device is up to 700 thousand rubles per year.

Well, worse than the scraper bulldozer? Even his work will help the explosion. The only difference is that here it is necessary not to throw soil to the side, but rather to throw it into the bucket. The explosion is and does. And the digging force is sharply reduced, additional tractor pushing the scraper behind it is unnecessary; useful volume of the bucket can be increased.

In No. 2 “M-K” this year in the article “Planer for the planet” talked about the biggest in our country, the scraper bucket capacity of which is equal to 26 m3. Remember the drawing? Giant machine under the bucket which can pass a car. Now designers are working to create scrapers with buckets with a volume of 40-60 m3. What the giants should be the machine?!

Studies at the Moscow automobile and road Institute showed that the use of blast gas-dynamic intensification increases the productivity of scrapers by 10-15 percent or more. This issue was dedicated to the report of the student Bogatyrev.

Fig. 3. Bulldozer, equipped with an explosive device (bottom — cut):

1 — blade; 2 — compressor; 3 — engine; 4 — the lifting mechanism of the working equipment 5 — towing; 6 — fuel tank; 7 — guides plastuny to drop soil in the direction; 8 — air supply, 9 — a fuel supply system; 10 — ignition plug; 11 — chamber; 12 — exhaust holes for gas outlet; 13 — sensor switching on the ignition.

But such scrapers and bulldozers have not yet reached beyond the laboratories of n test sites. The experimental sample of new cars, build channels using explosion, tested this year in Moldova.

It turned out that all the standard commercially available excavation equipment is best suited for use of energy of explosion plough canadacapoten. And here’s why. Working on this machine has the shape of a wedge, which doing in the land of deep V-shaped furrow. Once more — and ready drainage channel of the desired depth and profile. The combustion chamber, or as it is called, the pulse generator, can be placed between the planes of the wedge without any it modifications. Only planes need to drill holes to through them into the ground pulled out of Gaza.

And another advantage. When gases explode in the ground, formed V-shaped recesses. For bulldozer it’s bad: it should give a smooth surface. He has the gouges smoothed out. And for canlocate good drainage channel should have such a profile.

The new machine, designed at the Moscow engineering-construction Institute, named HPC-1, which means canadacapoten explosive action, and why the first, no need to explain.

KVD-1 was also constructed using the previous nodes. Same chassis, same working body. Only between planes it placed pulse generator. It works in normal mode a normal combustion of the working mixture. So named by IGN — pulse generator normal combustion. Combustion chamber — the part of the generator — communicates with the discharge openings in the leading edge of the wedge.

KVD-1 differs from the standard canlocate unit, located in front of the traction frame. It includes the compressor, the nodes of the power supply system and ignition, and a winch for lifting the working body. Traction is reduced in two or three times.

Ninth five-year plan finishes. The country is preparing to celebrate the XXV party Congress, which will outline the borders of the new five-year plan. Its a giant program will be provided and construction of new roads, canals, industrial enterprises. To fulfill this volume will become much easier with the help of earth-moving vehicles ahead of which is a blast.

R. YAROV, engineer