Nowadays, you can buy any tool, any mechanism. However, all of this costs a considerable amount of money.

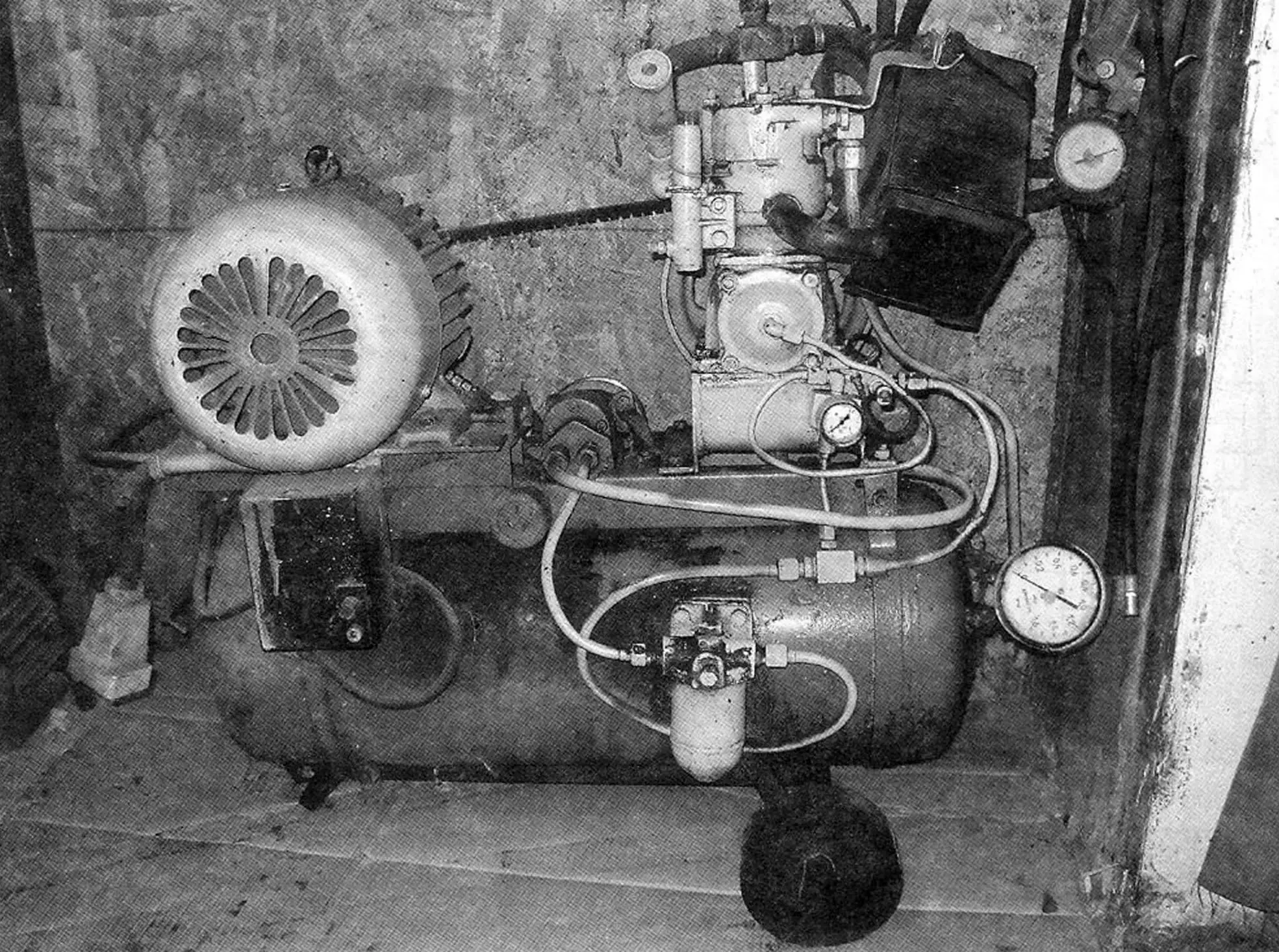

For the maintenance needs of the technical school where I teach, a compressor was needed. But the price range for compressors of Chinese manufacture (far from the best quality) started at eight thousand rubles and increased depending on the improved technical characteristics of the unit.

So we, the guys from the “Technical Creativity” club, set ourselves the goal of constructing this unit with minimal costs, using available materials.

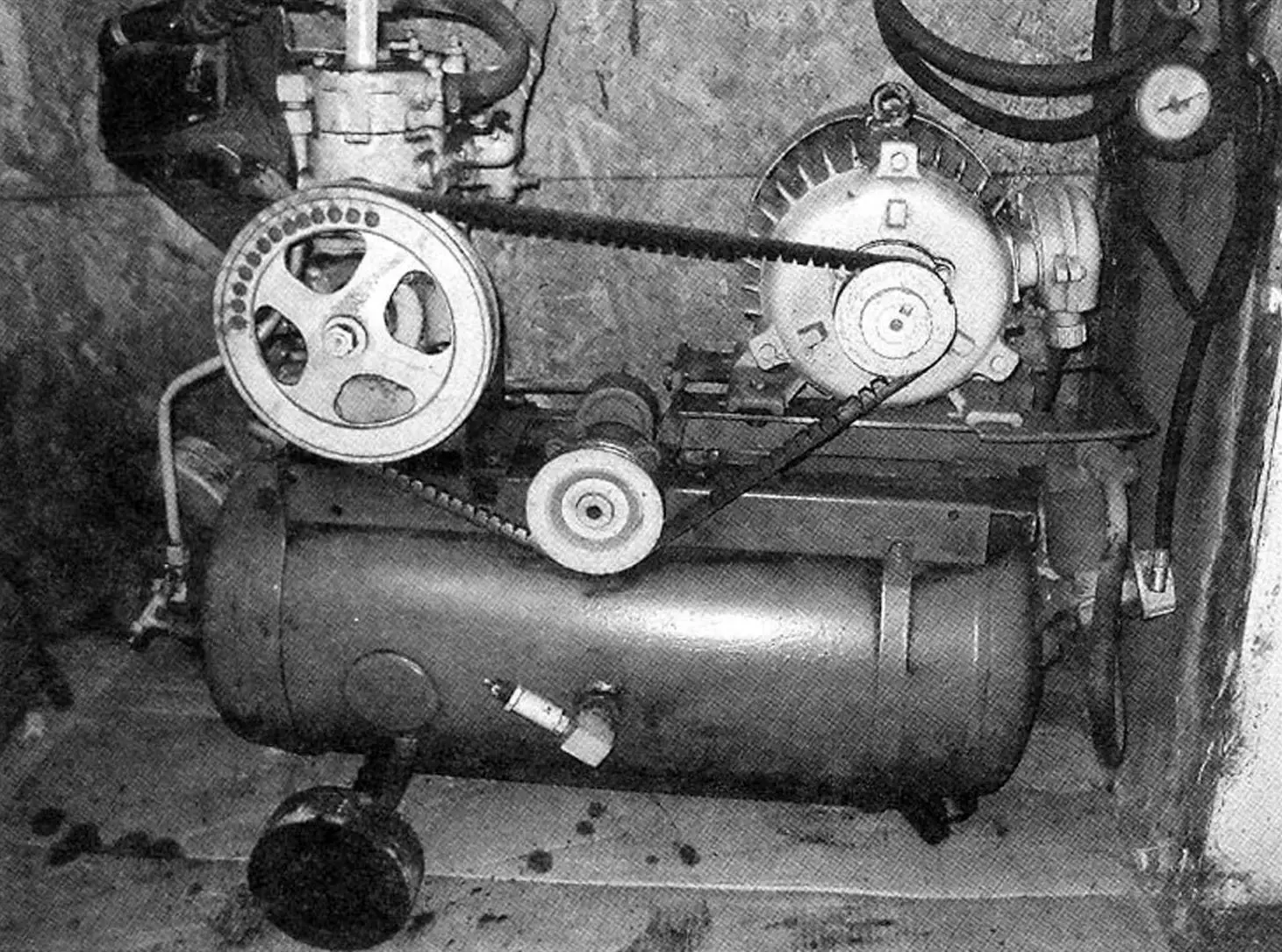

As a basis, we took a two-cylinder air pump-compressor from a decommissioned ZIL-130 truck. Other components were used from various decommissioned equipment. A 60-liter receiver – from an IFA truck (there was such a model, produced in the GDR). A 3 kW electric motor with 1500 rpm – from a pumping station.

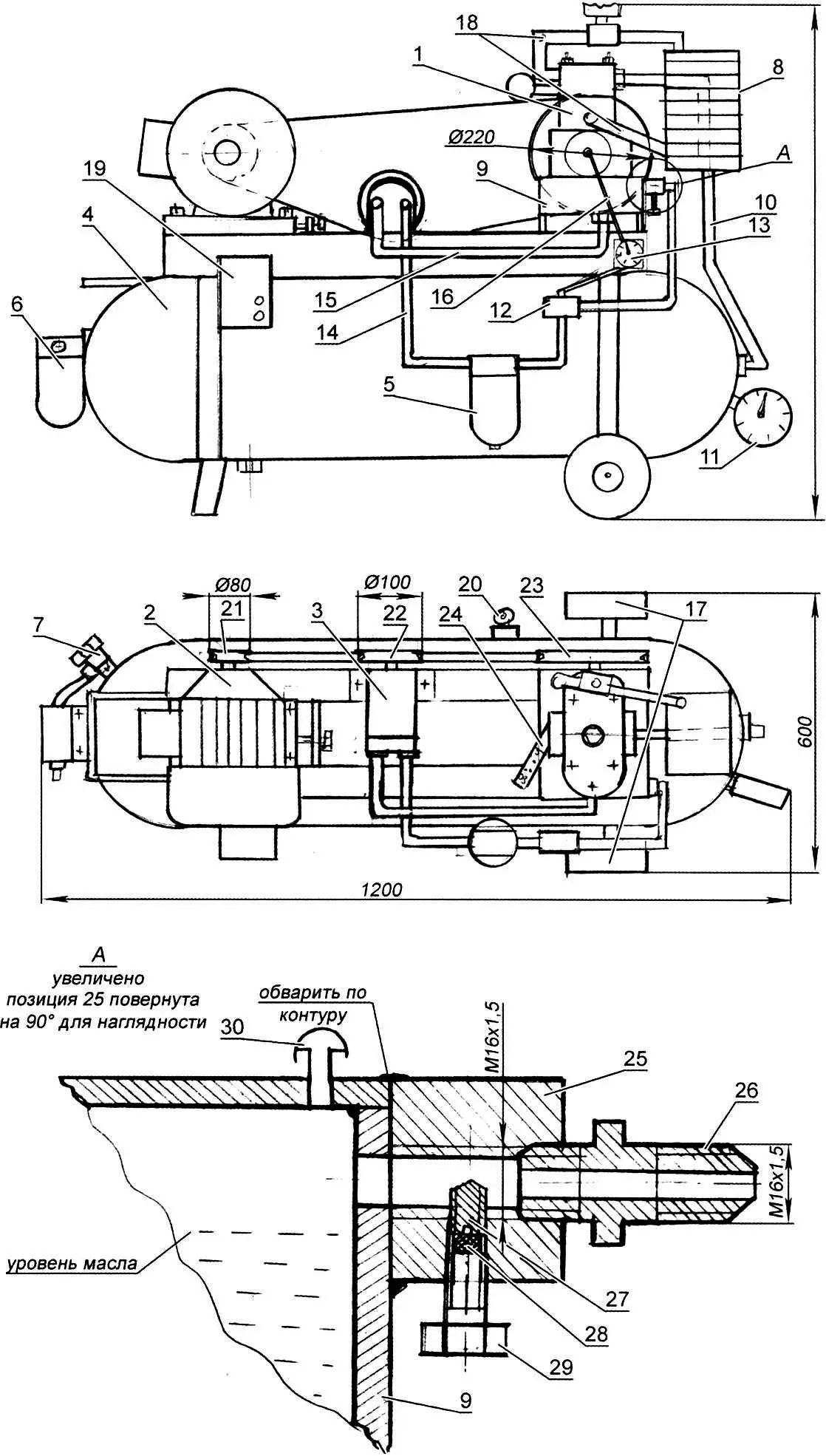

1 – air pump-compressor (from ZIL-130 truck); 2 – electric motor (from metal-cutting machine, N=3 kW, n=1500 rpm); 3 – oil pump (from metal-cutting machine); 4 – receiver (from IFA truck, V=60 L); 5 – oil filter (from T-150 tractor); 6 – air filter-separator; 7 – valve; 8 – oil cooling radiator (from ZIL-130 truck); 9 – compressor crankcase; 10 – air line; 11 – air pressure gauge; 12 – tee; 13 – oil pressure gauge; 14 – oil line; 15 – return line; 16 – oil line to compressor; 17 – wheel (2 pcs.); 18 – inlet and outlet hoses to cooling radiator; 19 – AP circuit breaker; 20 – pressure regulator; 21 – drive pulley (electric motor); 22 – driven pulley (pump); 23 – driven pulley (compressor); 24 – air filter; 25 – oil distributor; 26 – oil line fitting; 27 – adjusting screw M8x1; 28 – gasket (rubber); 29 – lock screw M8x1; 30 – breather

For oil cleaning, an oil filter was used, which was installed on a T-150 tractor engine.

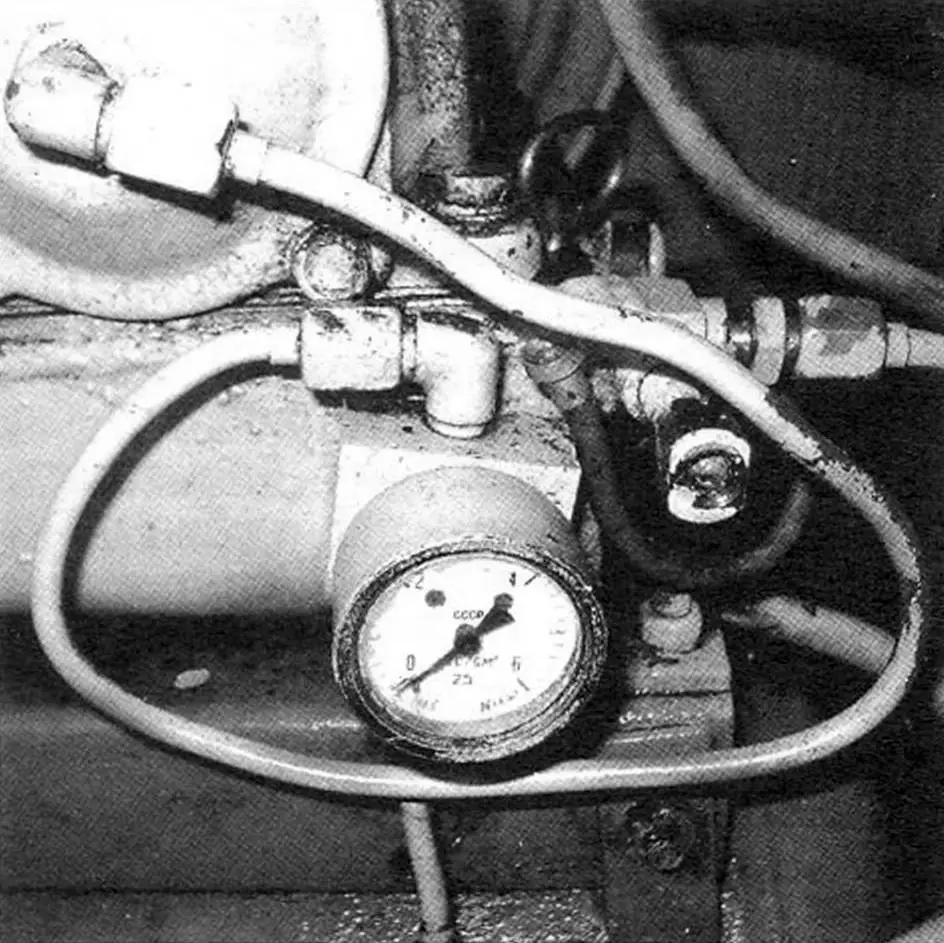

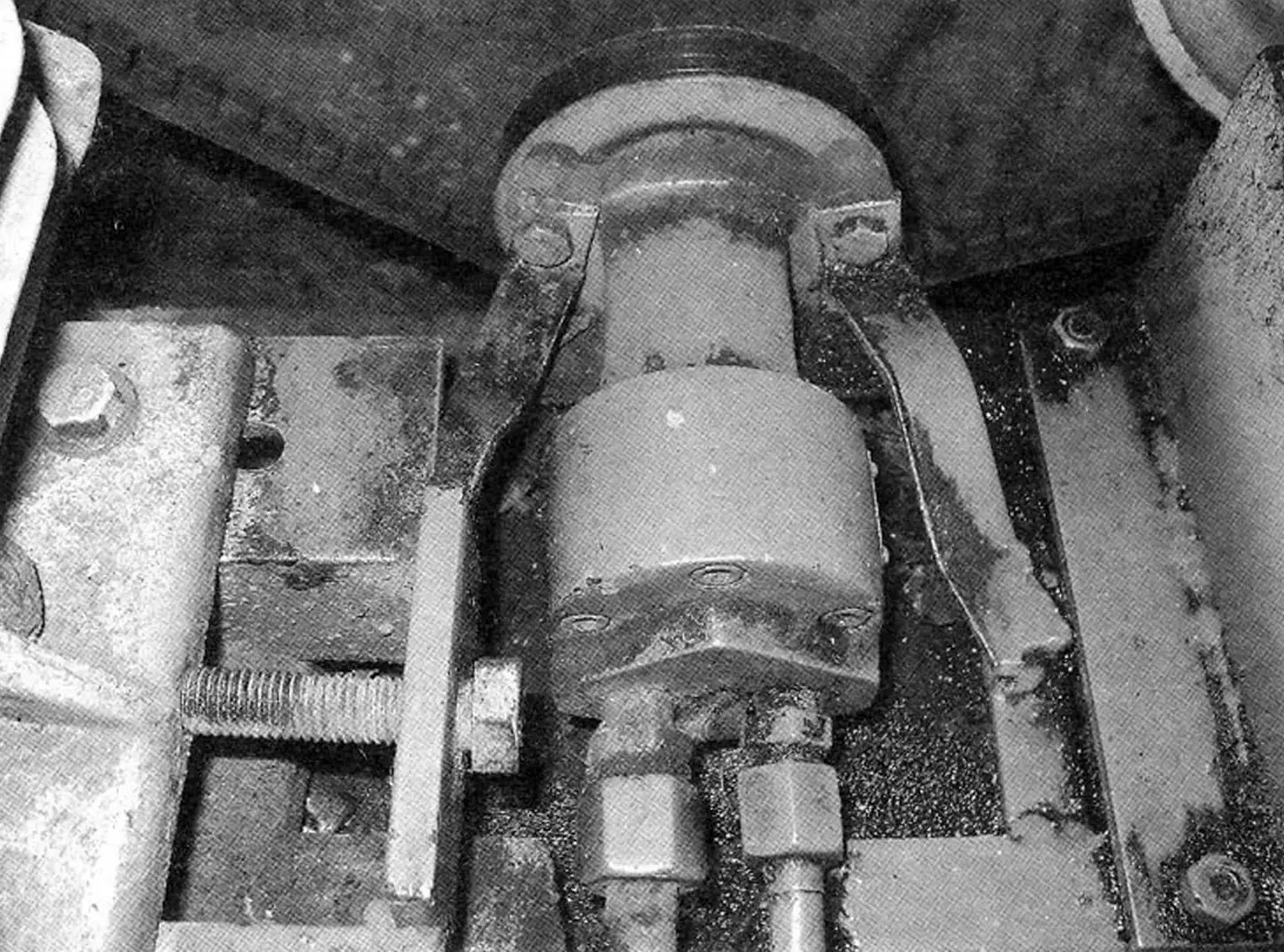

The drive of the oil pump and the crankshaft of the air pump (compressor) is carried out by means of a V-belt drive. The toothed belt and pulley grooves have profile A. As is known, the ZIL-130 compressor is lubricated and cooled from the corresponding systems of the truck engine, and therefore we needed to solve two problems: autonomously “lubricate” and “cool” the air pump-compressor. For lubrication, we installed a gear pump from the emulsion supply station of a lathe. But since this pump has quite high capacity – about 5 L/min, we had to construct a mini-distributor that sends most of the oil to the return line. The pressure of the portion of oil entering the compressor is controlled by a pressure gauge. Cooling of the air pump-compressor is liquid (first we filled it with antifreeze, then with water) by means of a radiator, which was used as the “heater” from a GAZ-53 truck. Extended operation of the compressor showed the effectiveness of the cooling and lubrication system.

Homemade parts for the compressor: oil pan (from 2-mm thick steel sheet), compressor drive pulley, and oil distributor. The compressor frame is welded from 50×50 mm angle iron. The receiver – a pressure vessel – is attached to it with clamps, and welding here is not desirable. To regulate pressure in the receiver, a safety valve (“breather”) from the ZIL-130 truck pneumatic system is installed. Compressed air is cleaned of foreign particles by a filter-separator from an NB-18 machine (guillotine shears).

The maximum pressure created by the unit is 1.2 MPa (12 atm), and if maintaining a system pressure of 0.5 MPa, it can work for several hours without stopping.

The compressor was built in just three days, and the costs for it by today’s standards turned out to be quite modest – about $30.

V. SHKARIN