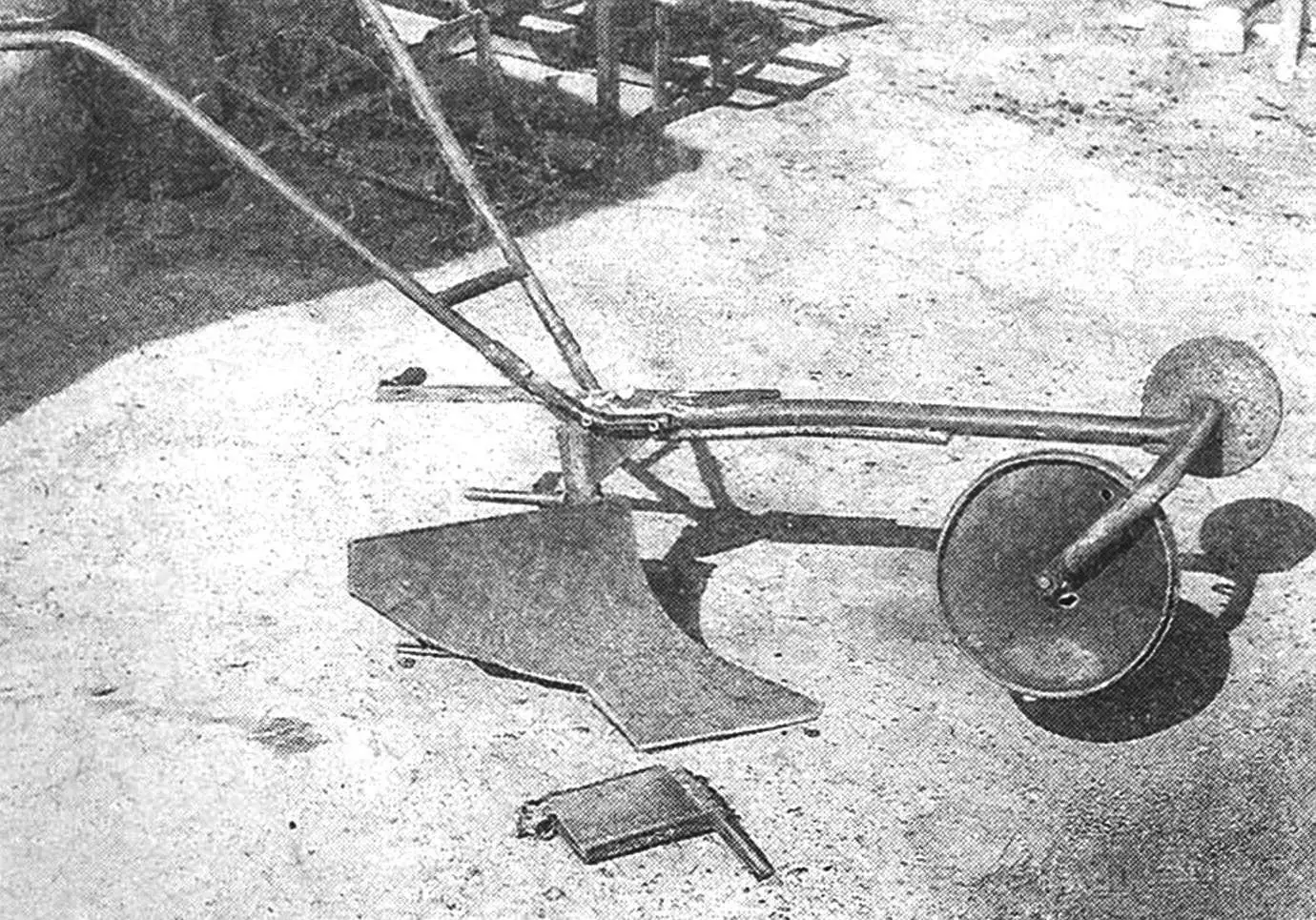

«Hitch… a winch» — under this headline, material about my developed electric plowing system was published in “Modelist-Konstruktor” No. 8, 1995. A far from minor role in it is assigned to the towed plow, the design of which is proposed to be made as lightweight as possible (to reduce fatigue when carrying it to the beginning of each furrow).

And now I offer the readership a new version of a “feather” plow. Its mass is indeed small—13.7 kg (excluding handles) plus an additionally installable 4.5-kilogram weight (for better penetration into the soil, cutting and turning of the layer). Compared to my earlier developments and the prototype by G. Odegov from Nizhny Tagil (“Modelist-Konstruktor” No. 6, 1990), the proposed design also differs in having a deep cutout in the working body, which significantly reduces soil resistance, and a number of other technical solutions.

I manage the electric winch and plow alone, which is a wonder to those around me. The whole village gathers to watch how the plow is “operated by an evil force,” while the plowman seems to merely be present: in a white shirt and polished shoes. From the point of view of outside observers, it’s quite difficult to call my actions on the plot of land work at all.

First, I place the plow itself at the beginning of the future furrow and make two “digs” with a shovel so that the share immediately enters the ground. Then I head to the electric winch and, standing on the tubular base of the anchor, turn on the electric unit.

Rotating, the winch drum winds onto itself (feed from below) a nylon cable with the plow tied to it. And a sufficiently deep, even furrow appears on the plot of land. After it (following another transfer of the plow) comes the second, third… And soon the entire plot turns out to be plowed.

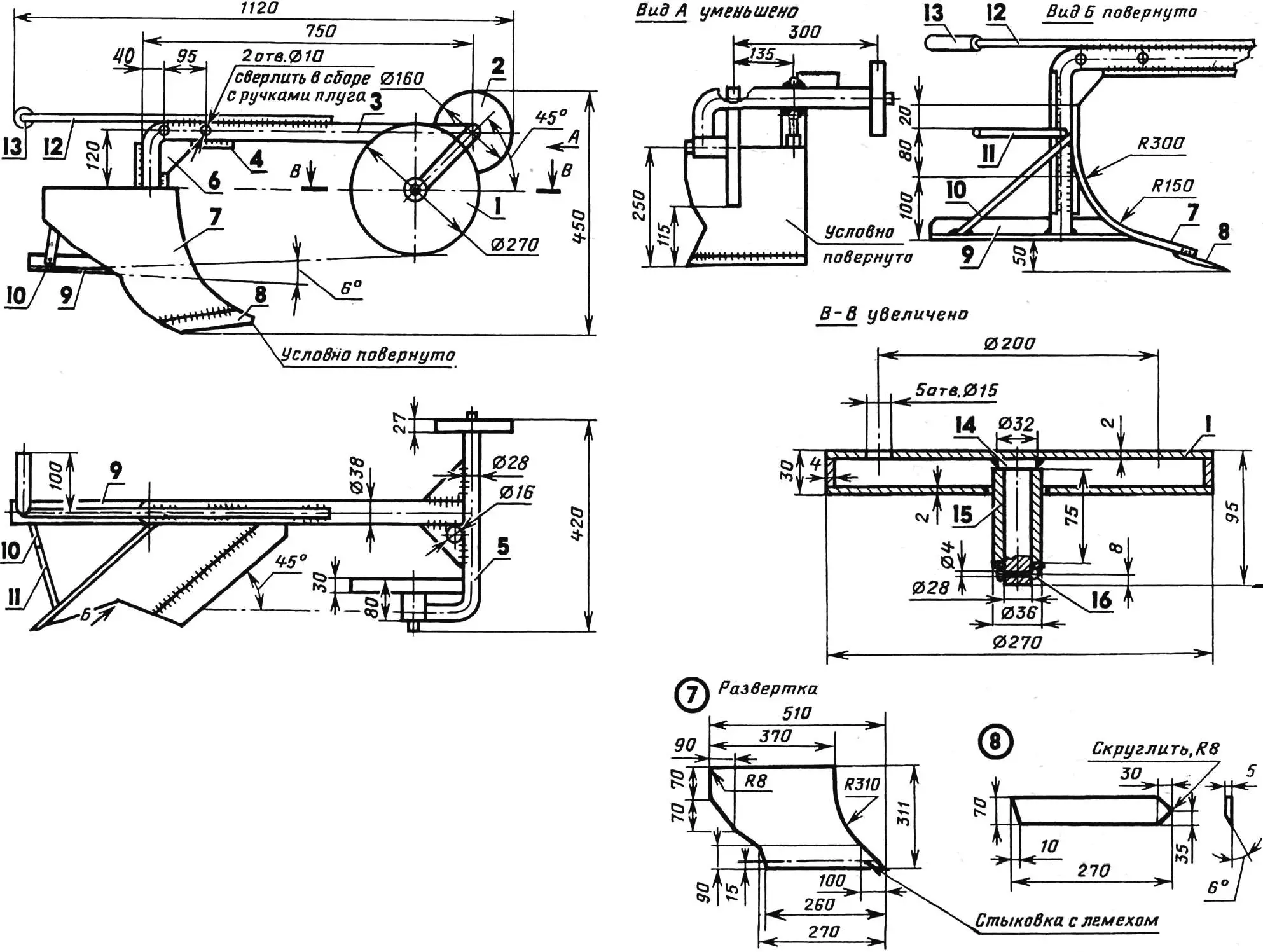

1 — furrow wheel disc, 2 — landside wheel, 3 — beam (steel tube 38×4), 4 — reinforcement element (steel rod Ø 14, 3 pcs.), 5 — cross member (steel tube 28×3), 6 — gusset (St3, sheet s5, 3 pcs.), 7 — moldboard (from high-pressure gas cylinder body), 8 — share (wear-resistant steel, sheet s5), 9 — slide (steel angle 30×30), 10 — spacer (steel rod Ø 16), 11 — pin (steel rod Ø 16), 12 — L-shaped bracket (steel rod Ø 16), 13 — handle (rubber hose segment), 14 — axle, 15 — bushing (steel tube 36×4), 16 — cotter pin, washer.

I don’t touch the handles during the working pass on light and medium soils—thanks to its special “geometry,” the plow excellently “holds” the furrow without any help from the plowman. It plows on its own even on uneven (unlike the already mentioned Odegov prototype), hilly plots. By the way, this feature makes my plow truly indispensable for returning to agriculture lands destroyed by war. For example, when plowing old minefields in Belarus and new ones—in the “hot spots of the planet.” One only needs to take care of appropriate protection for the plowman himself, equipping him with at least an armored shield.

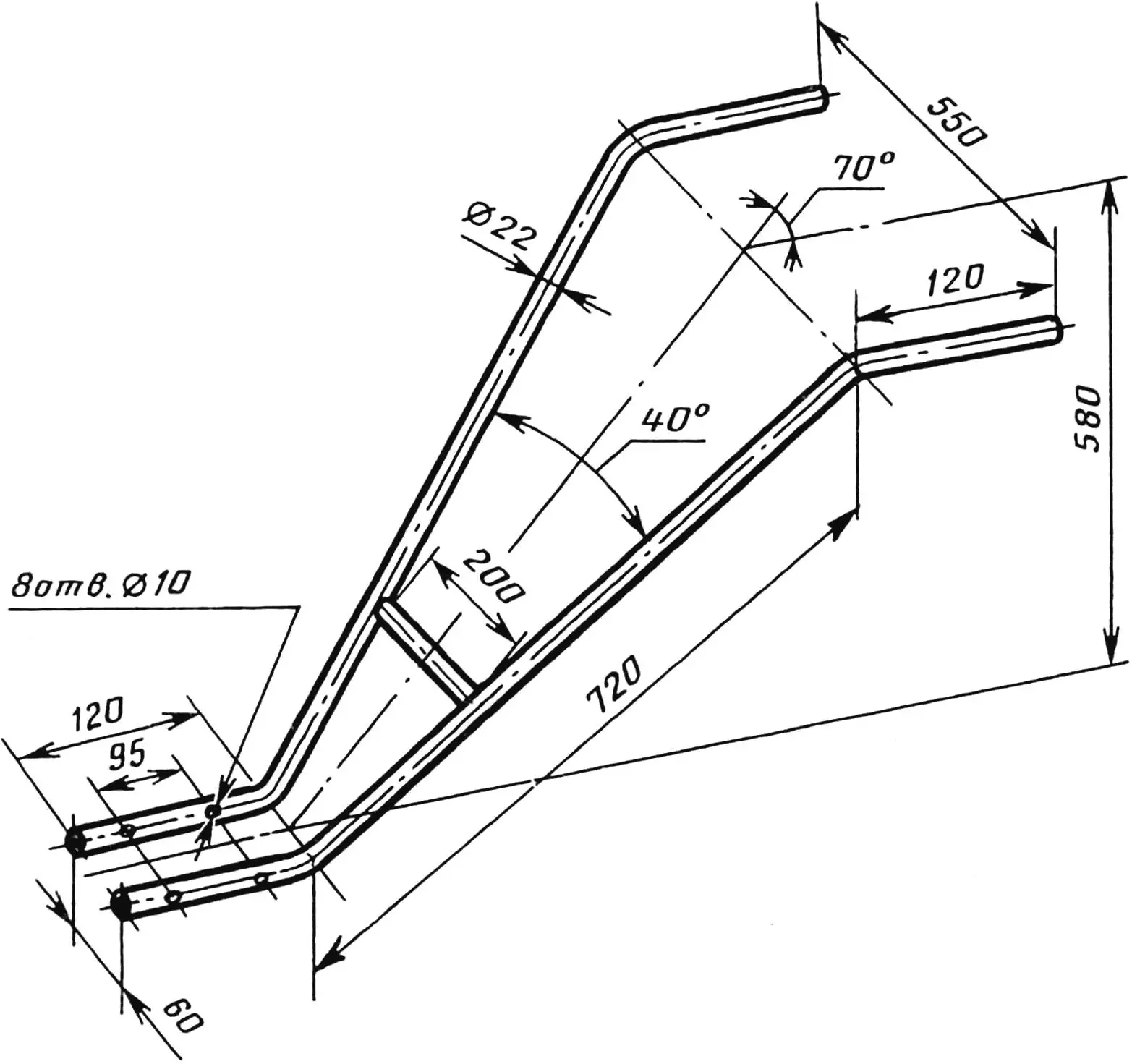

As for stump removal or, say, plowing heavy clay soils, there’s nothing left but to “lean on” the plow handles. Fortunately, their configuration is convenient, taking into account ergonomic requirements. The handles are removable (so the plow doesn’t take up much space during storage and transport), made from segments of steel tube 22×3 and together with the welded spacer have a total mass of 2.7 kg.

The plow beam is also made from tube 38×4 with reinforcement by welded gussets and 14-mm steel rods. As the share, a plate of wear-resistant alloy steel sharpened accordingly is used. It is connected by electric welding to the moldboard, cut according to a development from a gas cylinder. I am convinced that together with the already mentioned triangular cutout and the experimentally found angle of attack of 6°, such a technical solution contributes as well as possible to improving the plow’s operational qualities.

The furrow and landside wheels are homemade. Made from sheet steel 2 mm thick using tube segments as welded axle and hub. But ready-made parts can also be adapted here—from decommissioned agricultural machinery.

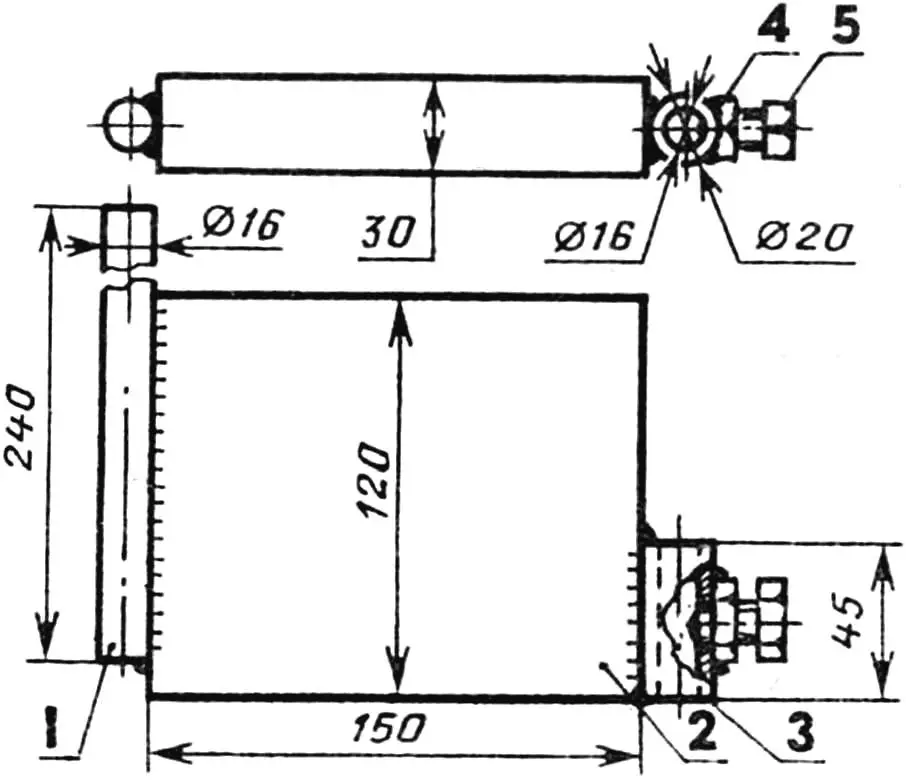

1 — rod (steel rod Ø 16), 2 — plate (St3), 3 — bushing (steel tube 20×2), 4 — nut M10, 5 — bolt M10.

As practice shows, a motorized tractor coupled with a cargo cart can become a good aid for the plow-electric winch. The design of such a unit has already been covered with sufficient completeness in the pages of the magazine, and the version I made doesn’t differ from it in anything essential. Except perhaps the brackets and similar “trifles” that fit well into the general concept of the tractor, which has a more powerful engine (from the “Turist” motor scooter), a resonant exhaust pipe (gases hit the ground with force and immediately spread out, not interfering with breathing), and a capacious cargo cart.

FROM THE EDITORS

The idea of using a plow towed by a “mechanized winch” is not new to farmers. Moreover, back in 1865, the enterprising Fowler attempted to introduce into practice plowing using cable traction and a steam engine (locomobile) located at the edge of the field. A cable passed through rollers was wound onto the flywheel of the latter. And it, in turn, drove the towed balance plow, which, moving along the field as plowing progressed, laid one after another transverse furrows.

Howard proposed a somewhat different approach to implementing this tempting idea. Thanks to a clever system of cables and blocks, the plow was towed across the field without moving the steam engine. But as with Fowler, such plowing had flaws. The plow didn’t “hold” the furrow evenly enough, cables got tangled and broke, complex machinery broke down. Plowing, as they say, cost a pretty penny, especially when using the variant with two locomobiles moving along the field. However, enthusiasts didn’t lose heart. Including in our country. The range of their creative search expanded. Especially after tests of an electric winch with balance plows were conducted in 1922 in Moscow, at the Butyrsky Khutor.

“Modelist-Konstruktor” also acts as a promoter of the “winch—plow” complex. Thanks to it, for example, the experience of V. Morozov from the village of Pavlovo-na-Neve (Leningrad Region), who processes his garden plot with an electric plow of his own making (see the material “Plowing… with an electric drill,” No. 9, 1981), became the property of many. Successful technical solutions contained in this design received their further development. The best of the developments that appeared later were presented to readers and subscribers of our publication with sufficient completeness and promptness (No. 3, 1989; No. 4, 1994; No. 2, 1995). A good aid, according to the recognition of the amateur constructors themselves, was also the comprehensive article “We calculate and build the plow ourselves” (No. 1, 1994).

The editorial board has no intention of closing this topic, which is interesting to many, judging by the editorial mail. And today’s publication is yet another confirmation of this.

V. RADKOV