Many city dwellers like to relax in his bathhouse, but in most cases this opportunity they have. Even the owners of garden-plots do not always have the conditions to build a full bath: one does not have enough space, the other funds, and to the third of both. Here to such “unfortunates” whose desires do not coincide with the possibilities, took it myself and I until my hands came across a book “How to be a farmer”, which tells of a small bathhouse.

Many city dwellers like to relax in his bathhouse, but in most cases this opportunity they have. Even the owners of garden-plots do not always have the conditions to build a full bath: one does not have enough space, the other funds, and to the third of both. Here to such “unfortunates” whose desires do not coincide with the possibilities, took it myself and I until my hands came across a book “How to be a farmer”, which tells of a small bathhouse.

This idea I took that as a guide for action and designed and built a mini-steam room. It is designed for one person, it is not even a changing room, locker room. And although there compared with conventional bath a little tight but its direct functions steam room performs perfectly. Another advantage is that the structure is foldable (collapsible) and to carry it even in the trailer car.

In appearance the bathhouse-steam room more like a shower cubicle. Her dimensions were: length x width x height — 1600x1200x2400 mm.

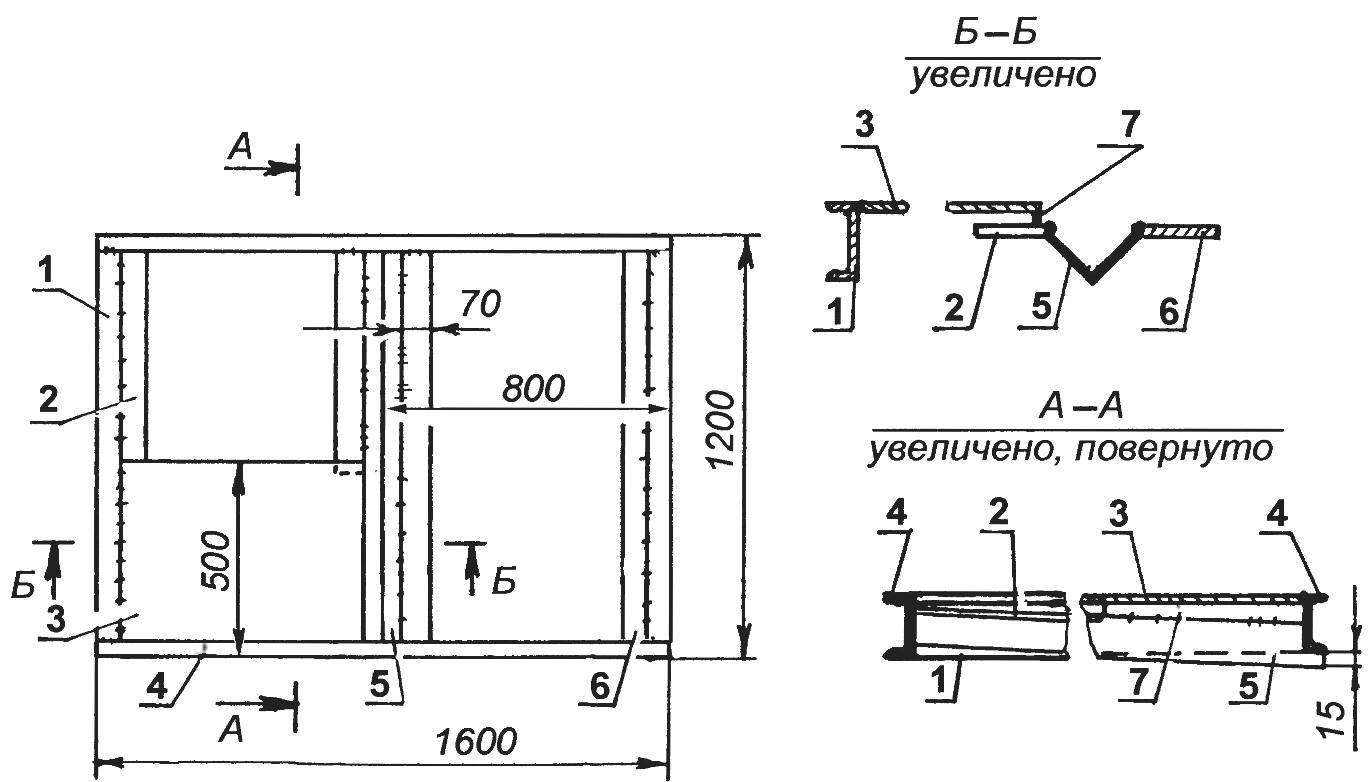

The construction of baseless (mounted on the 6 bricks: 4 pieces set at the corners and two on the middle length — near the drain of the groove), and therefore must be rigid and durable base-package. Package (beams and cross-beams) is made of steel channel number 8 (with shelves 40 mm and a wall height of 80 mm) in the shape of a rectangle with sides of 1200 and 1600 mm.

In the middle of obvjaza is arranged in the overflow groove of a steel angle 75×75 mm Groove has a bias, but because one end is welded to the beam obvjaza flush with its top, and the other is lowered 15 mm for the bottom shelf of the channel, forming a triangular hole with an area of 2.5 — 3 SMZ for water drainage.

Groove conventionally divides the bath into two halves. On the part of one of the halves (the right of the door) is arranged a horizontal platform made of steel 4 mm sheet, which is a cylindrical steel oven doors oriented to the center of the bathhouse.

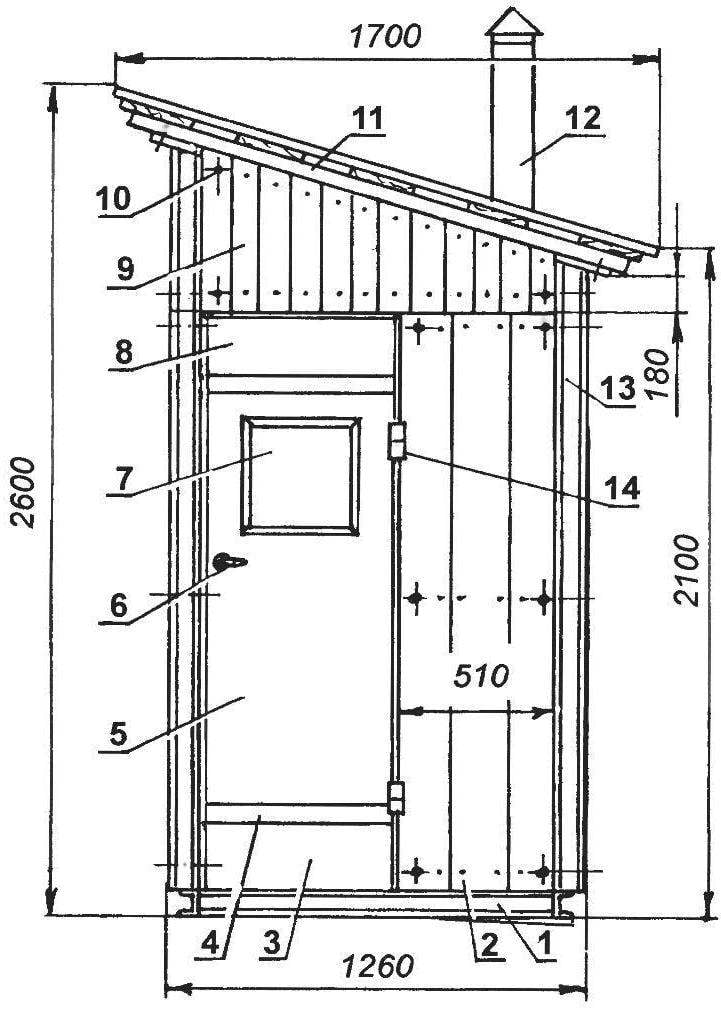

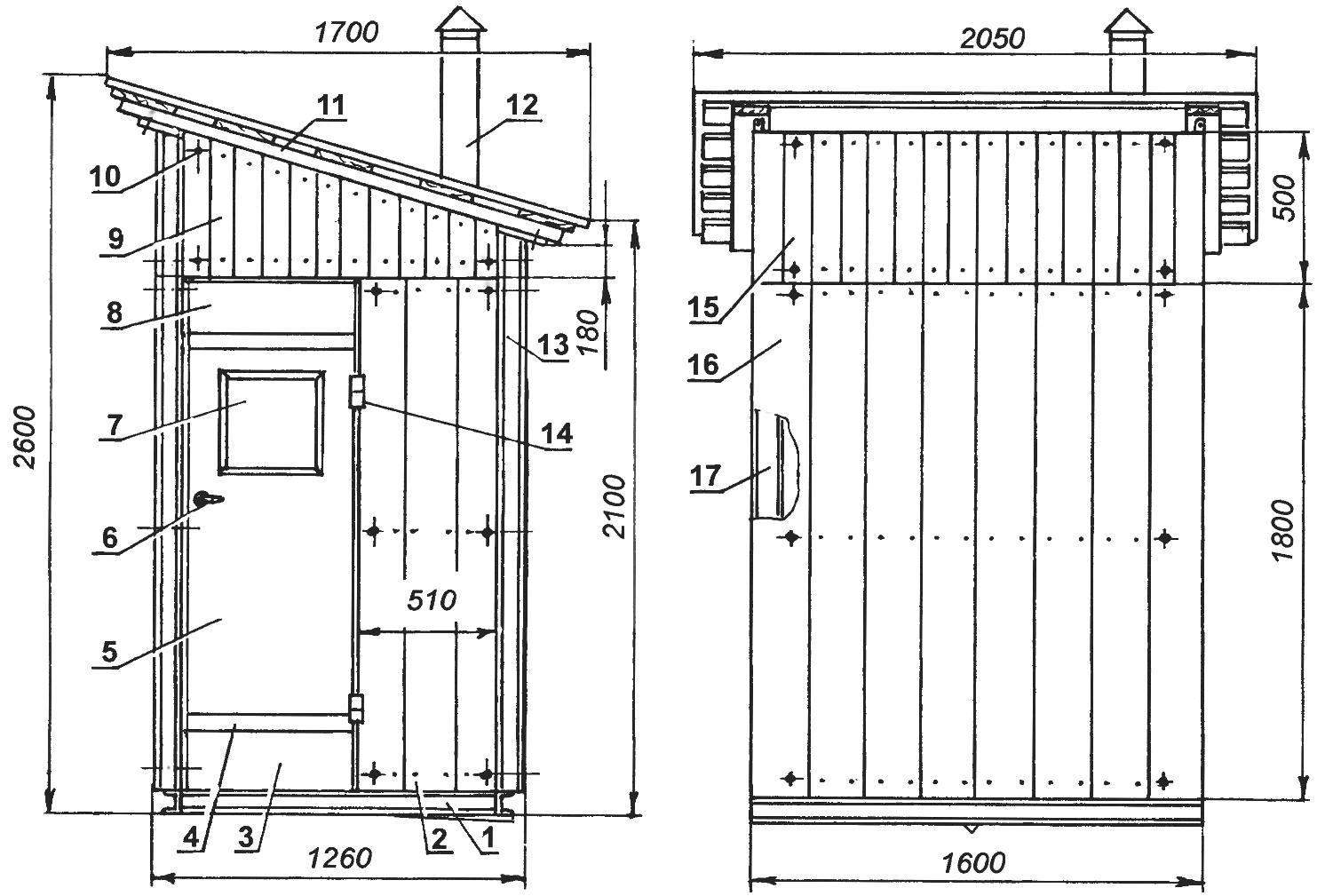

Single bath:

1 — package (steel channel No. 8); 2 — partial side shield; 3 — threshold; 4 — strap (2 PCs); 5 — door; 6 — the handle of the door; 7 — a; 8 — lintel; 9 — upper side plate (2 PCs); 10 — stud M10 (38); 11 — krasivoy shield; 12 — rough furnace; 13 — upper rear shield; 14 — door hinge (2 PCs): 15 — upper front shield; 16, the main shield (2 PCs); 17 — lateral full shield

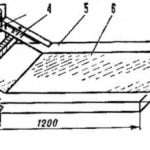

Package (base) baths:

1 — cross beam (channel No. 8, L120, 2); 2 — short floor support (steel strip 70×50, L660, 2); 3 — a platform for the furnace (steel sheet s4); 4 — longitudinal beam (channel No. 8, L1600, 2); 5 — groove (the area 75×75, L1160); 6 — long floor support (steel strip 70×5, L1120, 2); 7 — a wedge-shaped insert to cover the gap (2 PCs.)

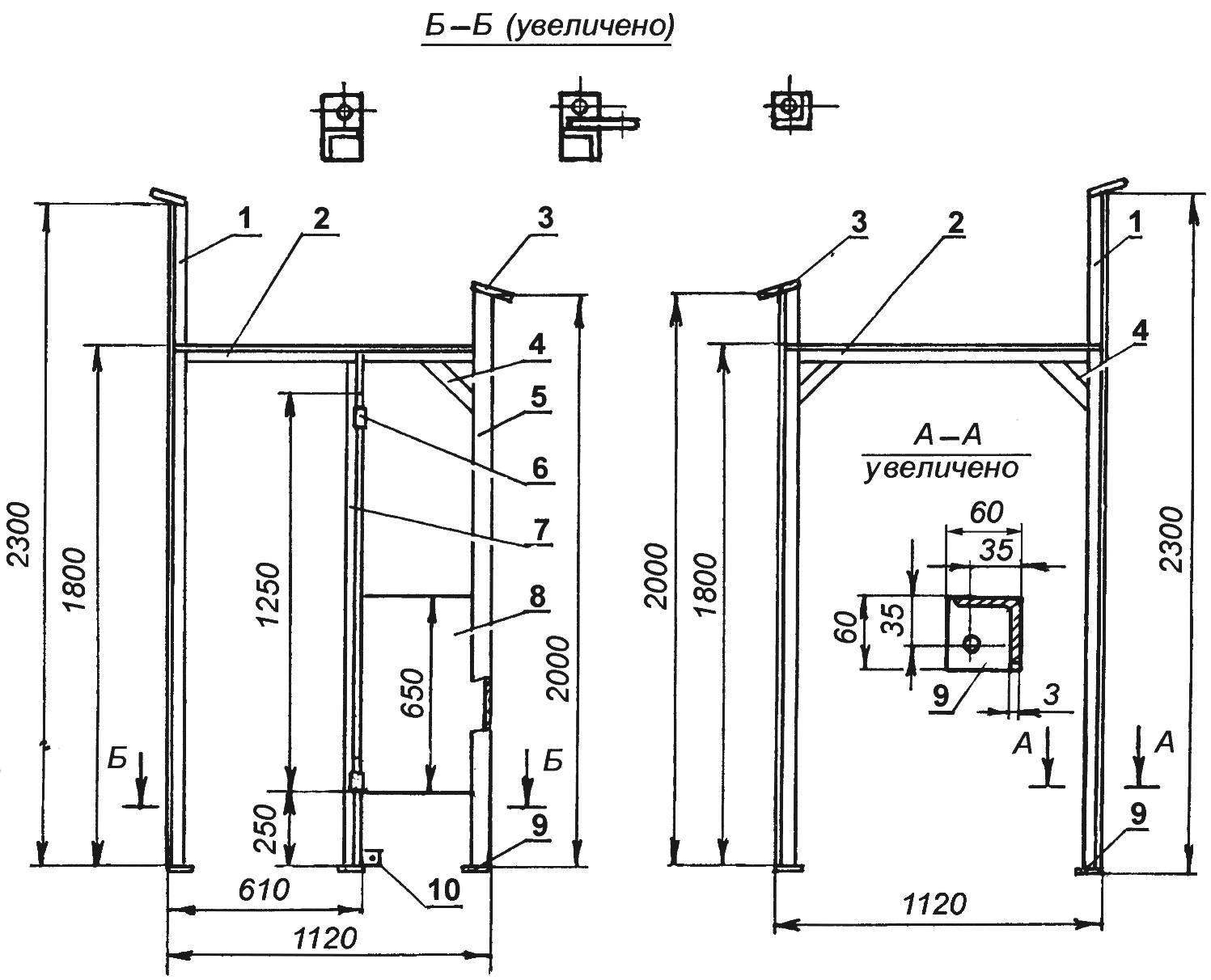

Articulated frame (all parts except specifically stated, is made of steel bent corner 70x70x3):

1 — high rack; 2 — bolt; 3 — brackets (steel sheet s5, 4 PCs); 4 — gusset plate (steel strip 60×4, 3). 5 — low rack (2 pieces); 6 — door hinge (2 PCs); 7 — front of the door jamb; 8 — reinforcement plate (sheet s3); 9 — thrust (steel sheet s5, 5 PCs); 10 — additional bracket incomplete side wall of the shield

To the edges of the groove and the cross strapping with their inner sides flush with the upper edges welded by steel strips with a width of 70 mm from a 5 mm sheet — they serve as supports for the floor boards. Since the stripes on obviate welded horizontally, and a drain area is with a slope, the floor has a double slope: on the sides to the center and from the front wall to the back.

In this regard, between the horizontal area under the stove and the floor at the entrance, and between it and the drain area will remain wedge-shaped gap… In the form of slits should be cut steel strips and cover up the cracks, privaris strips to the edges of the site. Board plates are fastened with nails — to this end, drilled holes with a diameter of 0.1 — 0.2 mm smaller than the nail. Bent nails from the bottom. Floor boards should air humidity (over 25%).

The design of the walls of the bath carcassona. The frame consists of two half-frames. Stand each of them — high and low — are linked only by the crossbars with the braces (without the lower and upper connections).

In one of the half-frames welded in another short extra front — door jamb. The height of the jamb until the bolt, and therefore the latter is more and lintel. The role of the second jamb corner performs high stand. Short rack frame with M6 bolts attached half loop nazemnyh door hinges.

To the lower and upper ends of the corner uprights welded to the steel plate 5 mm thickness: bottom of square (50×50) glides; top — tilted (by the angle of the roof) brackets. Through thrust through matching holes with bolts M8 racks are mounted to the base. Brackets attached shed roof.

The shields on the walls — layered. The basis of the shield is a frame made of boards and planks of 40 mm thickness of the boards 140 mm wide made rack, and the bars 45 mm width — piping (upper and lower), and jumper. Jumper shallowly embedded in the rack, and bruski obvjazok and stands just docked at an angle of 90°. All parts of the frame between a downed nails “stoddartii”, and the bars are pre-drilled holes with a diameter 1 mm less than the nails. In the jumper nails hammered at an angle of about 45°.

The inner side of the frame of the shield first closes the packaging carton, then with plastic wrap and sheathed vertically spaced krommenie quarter sliced 15-mm boards (lining) of deciduous wood.

Further, the shield is flipped, and spacing frames are filled with polystyrene and foam chip with a small (2 — 3mm) in excess of level of insulation over the elements of the frame. Then the frame is sheathed on the outside with the same siding (but you can choose from wood of coniferous breeds), is arranged vertically. Using the same technology and the same design are made and pediment (top) boards, both rectangular and triangular.

Wall boards are fastened to the racks semiframes (corners) of the coupling studs M8 and a length of 150 mm with washers with a diameter of 30 mm. To this end, the shields and the racks semiframes are drilled at the place corresponding holes. And again. To the walls without gaps, to the contact connecting surfaces are nailed strips of felt.

The roof and ceiling of the bathhouse made of combined. The design of the ceiling same as wall panels, but without the external covering of the wagon. Instead, on top of the nailed sheathing boards-“twenty” with a slight overhang on all sides, and she laid a soft asphalt roof.

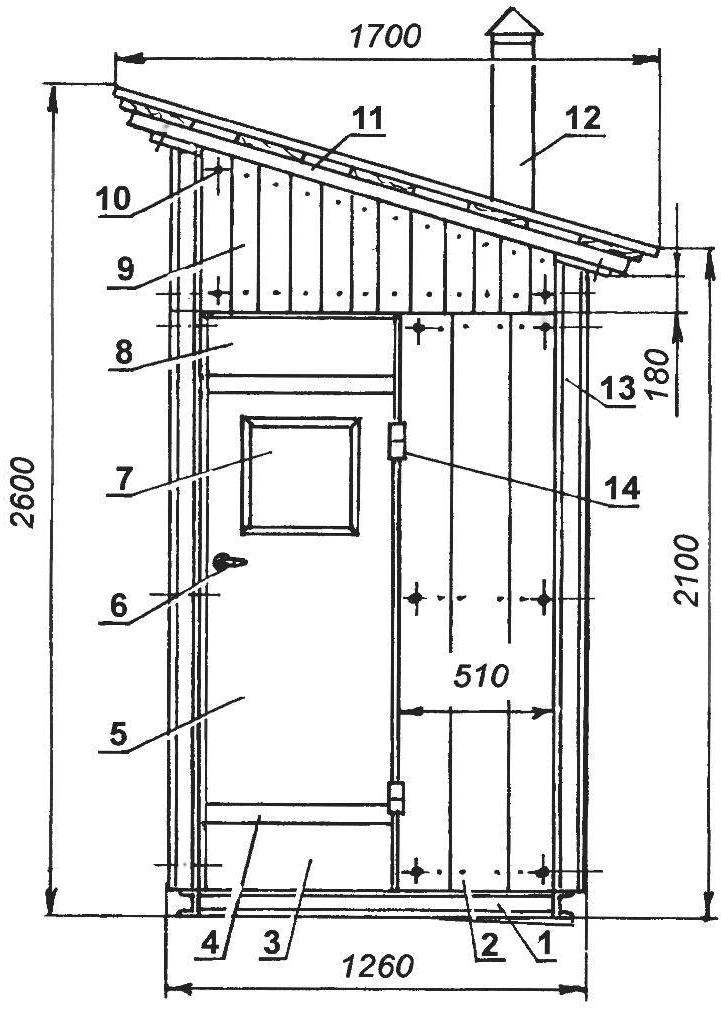

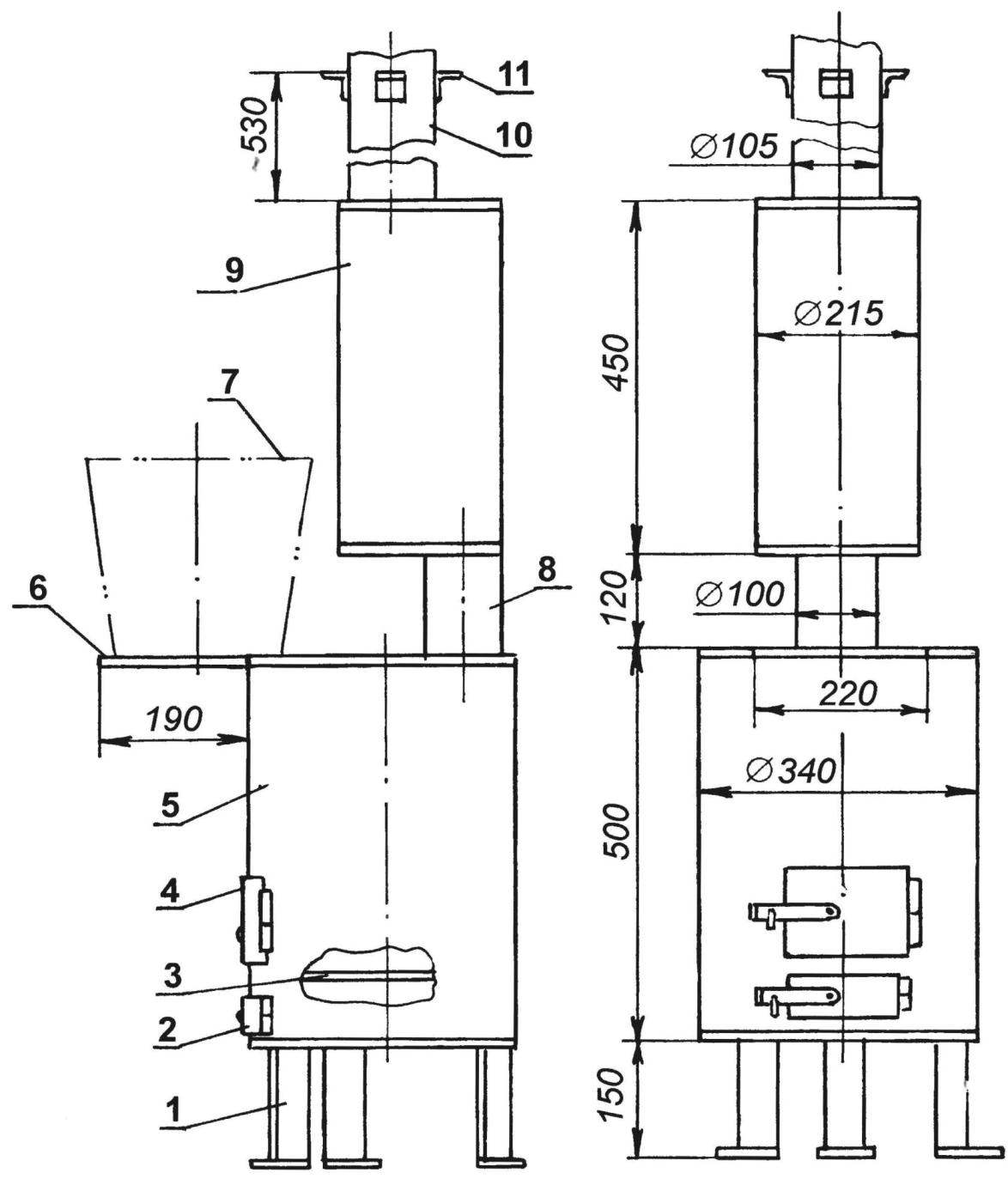

Oven:

1 — leg (area 63×63, 3). 2 — door blower; 3 — grate (steel sheet s10); 4 — furnace door; 5 — the furnace body (steel pipe 340×10); 6 — Playground for water containers (steel sheet s8); 7 — capacity for hot water (bucket): 8 sleeve (tube 100×6,5); 9 — expander (tube 215×6); 10 — flue (pipe 105×4); 11 — brackets for the sandbox (the area 35×35, 4 PCs.)

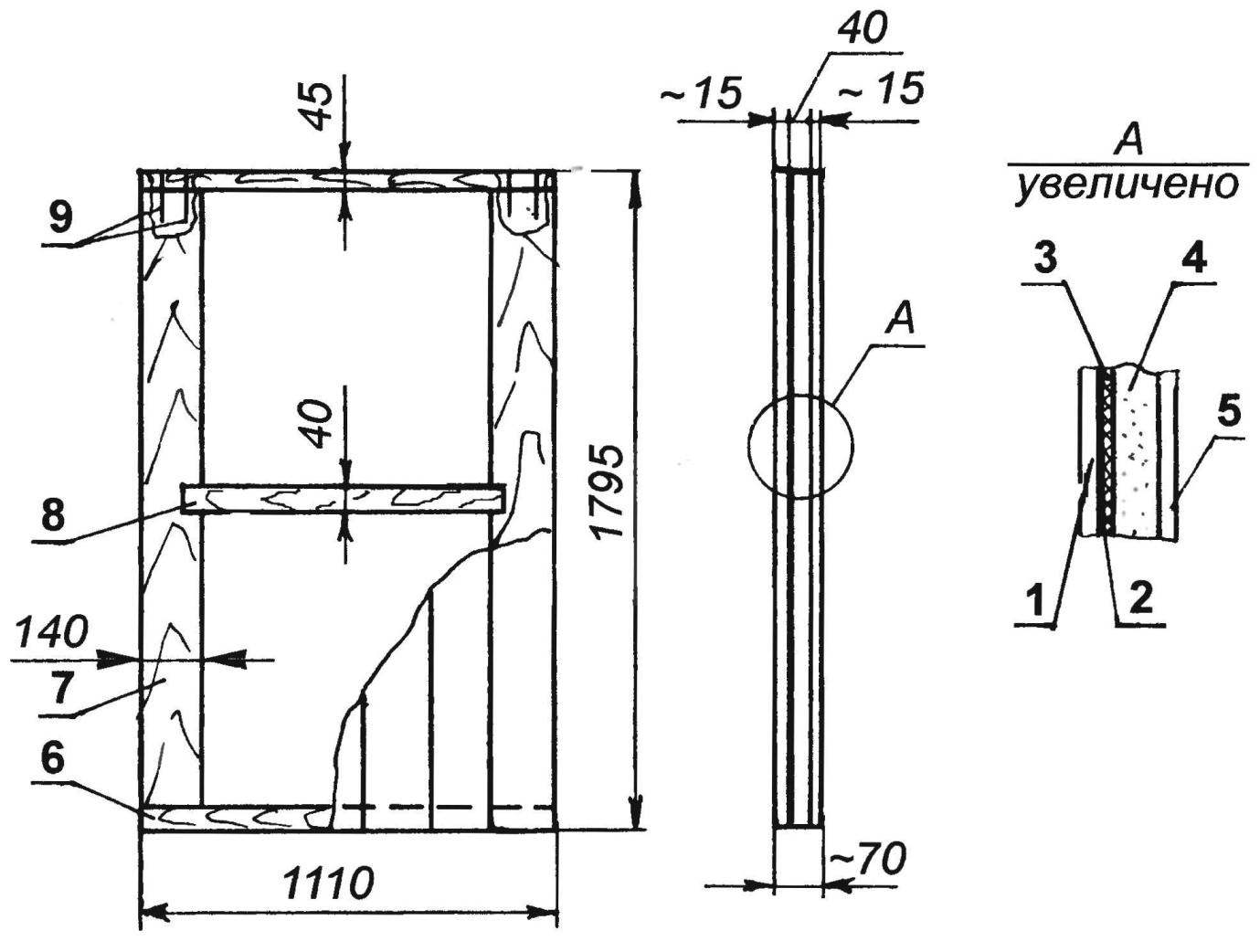

Design wall (full side) of the shield:

1 — the inner lining (the lining s15); 2 — polyethylene film; 3 — packing cardboard; 4 — insulation (construction foam, s40); 5 — the outer covering (lining s15); 6 — rail frame (timber 45×40, 2); 7 — front frame (140×40 Board, 2); 8 — jumper (timber 45×40); 9 — L200 nails (as required)

The door used standard residential, lined with hardboard (MDF) — these are a just throw. The door is fitted in place, it cut the window size 350×200 mm and zastakljena in two layers, not to fog up. Door-cut off the top and bottom (up to loops). Of them arranged accordingly, the threshold and the lintel. The edges of the inner side of the door are upholstered with strips of felt.

“Blind” (without door) side walls arranged shelves on the bars, nailed at a height of 800 mm to the front and rear walls fit Board-“sorokovka” 400 mm wide. shelf is installed Near the step height of 430 mm, which can be used as a seat.

To prevent accidental contact with the stove is a wooden lattice climbing a fence with a height of 1.5 m and width 1 m.

As the oven from the wall is only 250 mm, as fire prevention portion of the shield rear wall behind the oven studded with roofing iron. In the side wall performs this function reinforcement plate.

Sauna stove made by the type column. The main part of the furnace — the furnace used for the finish. It is made of thick-walled (10 mm) steel pipe outside diameter 340 mm. Bottom and lid of the furnace — steel 15-mm plate. To increase the heat transfer leaving the hot gases above the combustion chamber is mounted another cylindrical dilator with a diameter of 215 mm and a height of 450 mm. It is made of pipes with a wall thickness of 6 mm and welded on both sides with flanges of the same thickness.

Extender with the combustion chamber are connected by a vertical sleeve — cut round pipe diameter 100×87 mm and a length of 120 mm. the Sleeve is offset from the center to the wall of the spreader and the shell of the furnace (in the opposite direction of the doors). In the upper flange of the extender welded in the lower end of the chimney, and it is also off-center to the wall of the expander, but only in a diametrically opposite direction from the sleeve. The pipe itself has an internal diameter of 97 mm, and the thickness of its walls is 4 mm. Length of the chimney so that it towered above the roof not less than 0.5 m. the Upper end of the pipe is covered by a cap, to random sparks flew far away, and rain water does not leak through the pipe into the furnace.

On the chimney at the height of the bolt is set to fire a box of sand, made of steel sheet with a thickness of 3 mm. the Size of his bottom 700×600 mm with flanging height of 40 mm. Hole in the bottom of the pipe is cut on site. One edge of the drawer rests on the Rigel articulated frame and fastened to it with two M6 bolts through the corresponding drilled simultaneously in both parts of the hole. To hold the box on the pipe is welded thereto four brackets from the corner of 35×35 mm. Thus the box is the console that holds the chimney (along with the extender) in a vertical position.

Grate furnace is made of 10 mm steel plate with longitudinal parallel slits with a width of 10 mm by 20 mm. Grating, and the box rests on three brackets from the corner of 35×35 m, is welded inside the firebox.

In the sequel to cover the firebox welded to a small console area of 8-mm steel sheet. It is put a bucket of pre-heated water to warm.

If other source of heat, in addition to stoves, not expected, then for water heating will have to do on the lid of the furnace, the additional capacity with the crane. Furnace installed at the venue on three legs from the corner № 6,3. To the corners of the bottom welded base plate with holes through which bolts M6 legs are attached to the plate site.

In practice it turned out that the blower door is not so necessary.

The design of furnaces for a bath, of course, not perfect, but I assumed that he had in stock.

In order to heat the bath, in the summer it takes about 4 kg of firewood. Firewood is prepared in the form of thin kurochek length not more 300 mm. Steam can already fifteen minutes after the start of the furnace.

The choice of the location for the bath should be approached responsibly. First, consider prevailing wind direction — downwind to reach for emitted sparks area were not legkovozvodimyh objects. Secondly — flow or filtering of water used in the soil.

P. SPEAR, the city of Beloretsk, Bashkortostan