The journal “Modelist-Konstruktor” has more than once published materials about homemade “refrigerators,” where natural cold is used for storing food, of which there is more than enough in the middle latitudes of our country, not to mention its north. In all these devices, when the frost is too severe, the optimal temperature is maintained by heating the container with food. The sensors used for this are very diverse, yet somehow it never occurs to anyone to take advantage of the phase transition effect. In short—the physical phenomenon that accompanies the freezing and melting of water.

As is known, when water freezes, it increases in volume, and this can quite well be used to drive various mechanisms. I would like to present to readers’ attention several devices where this effect works successfully.

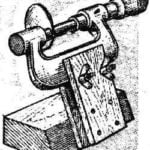

Electric heater switch. It can be used in polystyrene-insulated boxes, which are sometimes installed on a balcony or outside a window. A heater—for example, a medical electric heating pad—is placed on the bottom of such a “refrigerator.” Above it is positioned a second bottom—an aluminum tray, on which perishable food is placed. The temperature sensor is also placed here. It is a sealed container made of elastic material (for example, polyethylene), filled with water. It is desirable that this vessel have the shape of a parallelepiped—such containers are sometimes used for packaging shampoos or lotions.

1 — sealed polyethylene vessel filled with water, 2 — electrical contact (microswitch), 3 — electric heater (medical heating pad), 4 — bottom (perforated plate), 5 — stored food, 6 — polystyrene or wooden box.

The flask is positioned in a rigid frame, on the wall of which normally open contacts or, better, a limit microswitch are mounted. When the water in the flask freezes, its thickness increases and the vessel wall compresses the contacts, switching on the tray heating. The side wall travel can reach 10 mm with a flask cross-section of about 30X70 mm. After the heater is switched on, the ice melts, the vessel returns to its original shape, and the heating pad switches off.

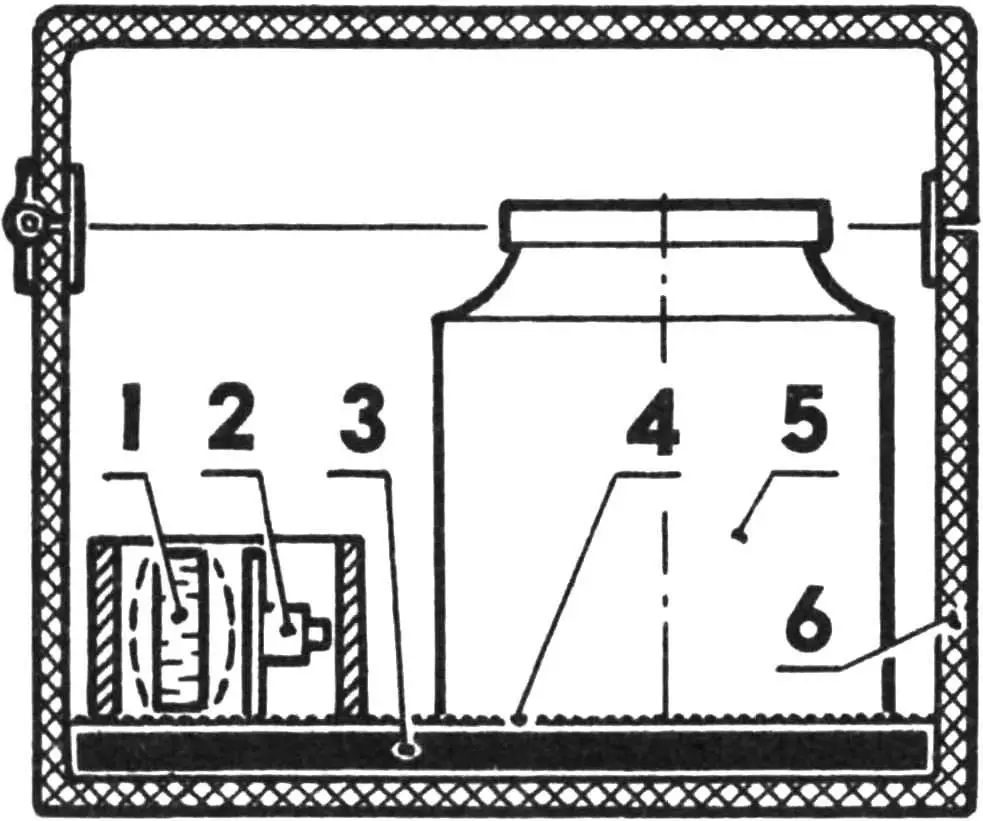

Without electricity consumption. If food is stored in a cold zone on a windowsill, which forms when a heat-insulating barrier is installed at its edge (in the simplest case, an ordinary board or, better, a polystyrene plate), then such a simple storage can also be equipped with a device that maintains the temperature in the cold zone at 0°C. The main role here is also played by a polyethylene flask filled with water: when the water in it freezes, it increases in volume, the force is then transmitted through a rod and lever to the heat-insulating barrier, and the latter rises. A gap forms under the barrier, through which cold air flows down, making room for warm air flowing from above, from the room. With a lever arm ratio of 1:5 and a working travel of the flask-sensor wall of 10 mm, the width of the resulting gap can reach 50 mm. For greater effect, the raising and lowering of the barrier can be linked to closing and opening the window.

1 — sealed polyethylene vessel filled with water, 2 — rod with thickening at lower end, 3 — lever, 4 — heat-insulating polystyrene plate, 5 — stored food, 6 — air flow through gap under plate.

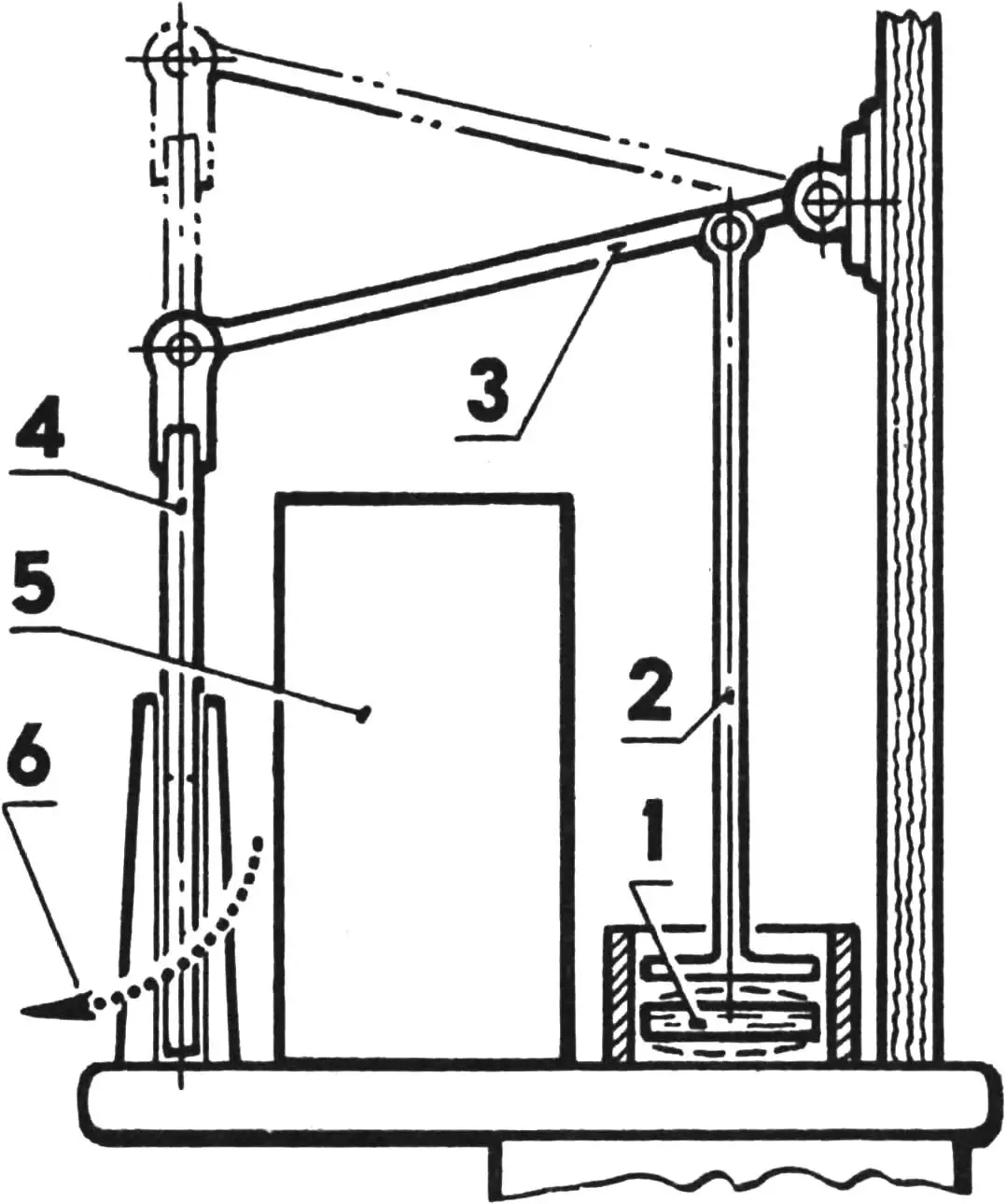

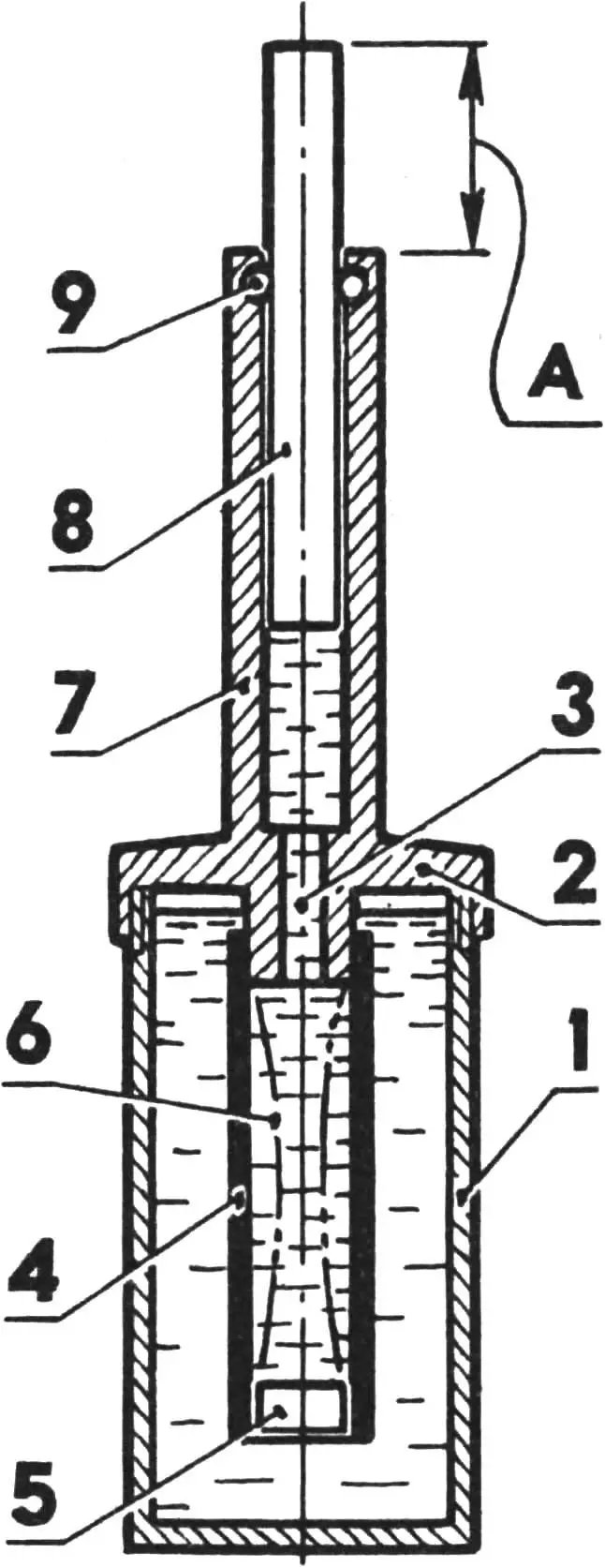

Sensor with hydraulic converter. The working travel of the actuator can be made quite large even without a lever system, if a kind of hydraulic converter is used as the sensor. It consists of a rigid metal vessel, inside which an elastic rubber tube is positioned; one end is plugged, and the other is connected to a hydraulic cylinder, in which a plunger can move. The cavity of the metal vessel is filled with water, while the rubber tube together with the hydraulic cylinder is filled with motor oil.

When water in the vessel freezes, the ice compresses the rubber tube, thereby forcing oil into the hydraulic cylinder, which raises the plunger. The latter moves dampers or flaps that regulate the inflow of cold air. The working travel of the plunger depends on the volume of the metal vessel and the diameter of the plunger: the larger the first and the smaller the second—the more the plunger extends when water freezes.

1 — sturdy metal vessel, 2 — threaded lid, 3 — through channel along lid axis, 4 — rubber tube segment filled with oil, 5 — plug closing lower end of tube, 6 — oil with low freezing point, 7 — boss on outer part of lid (hydraulic cylinder), 8 — plunger, 9 — rubber ring for sealing; A — plunger displacement when water freezes in vessel.

Practice shows that to actuate the flaps of the simplest “refrigerator” on a windowsill, mentioned above, a cylinder with a volume of only 100 ml is sufficient.

The sensor with hydraulic converter is also interesting in that it allows remote control of various devices (for example, closing greenhouse or hothouse flaps when the temperature drops below zero degrees). For this, the cylinder with the elastic tube placed in it is connected to the actuator hydraulic cylinder by a long copper or aluminum tube.

N. BEZBORODOV