Having a solid, high-performance grain crusher on a farm or personal homestead is not a whim, but rather a necessity. This is especially true when considering the high cost of ready-made “store-bought” feed mixes and the frequent mismatch between their quality and what is advertised. However, which specific design from the existing variety of crushers (including homemade developments published at various times in the pages of the “Modelist-Konstruktor” magazine) should one choose?

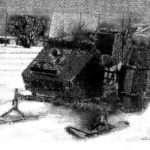

Centrifugal grain crushers, for example, enjoy well-deserved popularity (see fig. 1). Their operating principle, and the designs themselves, largely resemble the well-known electric coffee grinder. Grain is destroyed by knives rotating at high speed, with intensive cutting occurring at the walls, where the raw material is thrown by centrifugal force. Operational adjustment of grinding is not provided here (see table); the size of the cut fraction is determined by the sieve mesh, and productivity—by the sharpness of the knives, their size, and rotation speed.

| Type (class) of grain crusher | Grain destruction | Machine working parts | Method of construction adjustment | Publications in “M.-konstr.” magazine | |

|---|---|---|---|---|---|

| cutting | compression | ||||

| Centrifugal | + | – | knives | none | 7’84 |

| Auger | – + | – + | auger | difficult | 12’93 |

| Mill | + | – | millstones | complex | 6’97 |

| Roller | – + | – + | rollers | simple | 6’97 |

| Combined | + | + | combination | difficult | 5’01 |

In auger grain crushers, both cutting and crushing of grain occur thanks to a rotating steel polyhedron (usually a hexagon or—in a number of homemade designs—the splined part from a driveshaft) and blocks with hardened splines. The resulting product usually moves along the axis, facilitated by the offset of the output opening forward relative to the input hopper. Main disadvantages: blunting of edges, leading to reduced productivity, and the absence of clear gradation of the sizes of the resulting fractions due to poorly ground grains slipping through at moments of “zero rotation angles” of the working edges. More advanced designs with a helical (like a household meat grinder) auger, but these can be classified as combined crushers, since after the auger, a knife is also connected to the work here.

Mill grain crushers have, perhaps, the most ancient “pedigree,” which is largely due to the prevalence of abrasive stone in nature, and most importantly—its hardness. The emery wheel used for millstones remains practically “sharp” all the time, unlike the metal working surfaces of all other crushers, which have to be sharpened from time to time. The main disadvantage of mill grain crushers is the great complexity of adjusting the working gap L.

Roller crushers of grain, acorns, and similar raw materials are distinguished by simplicity and precision of gap L adjustment. As with auger grain crushers, the tooth profile can have a variety of shapes. However, the working surfaces of the rollers become dull over time, and if the sharpness of their edges is not restored, the grain crusher operates in a less economical mode—on crushing.

When manufacturing grain crushers of this type in a home workshop, one of the rollers (or even both) is replaced with a cylindrical grater (see, for example, the second variant of the development published in No. 6 of the “Modelist-Konstruktor” magazine for 1997), and if it has a calibrated mesh, then fractions of strictly specified size can be obtained as a result.

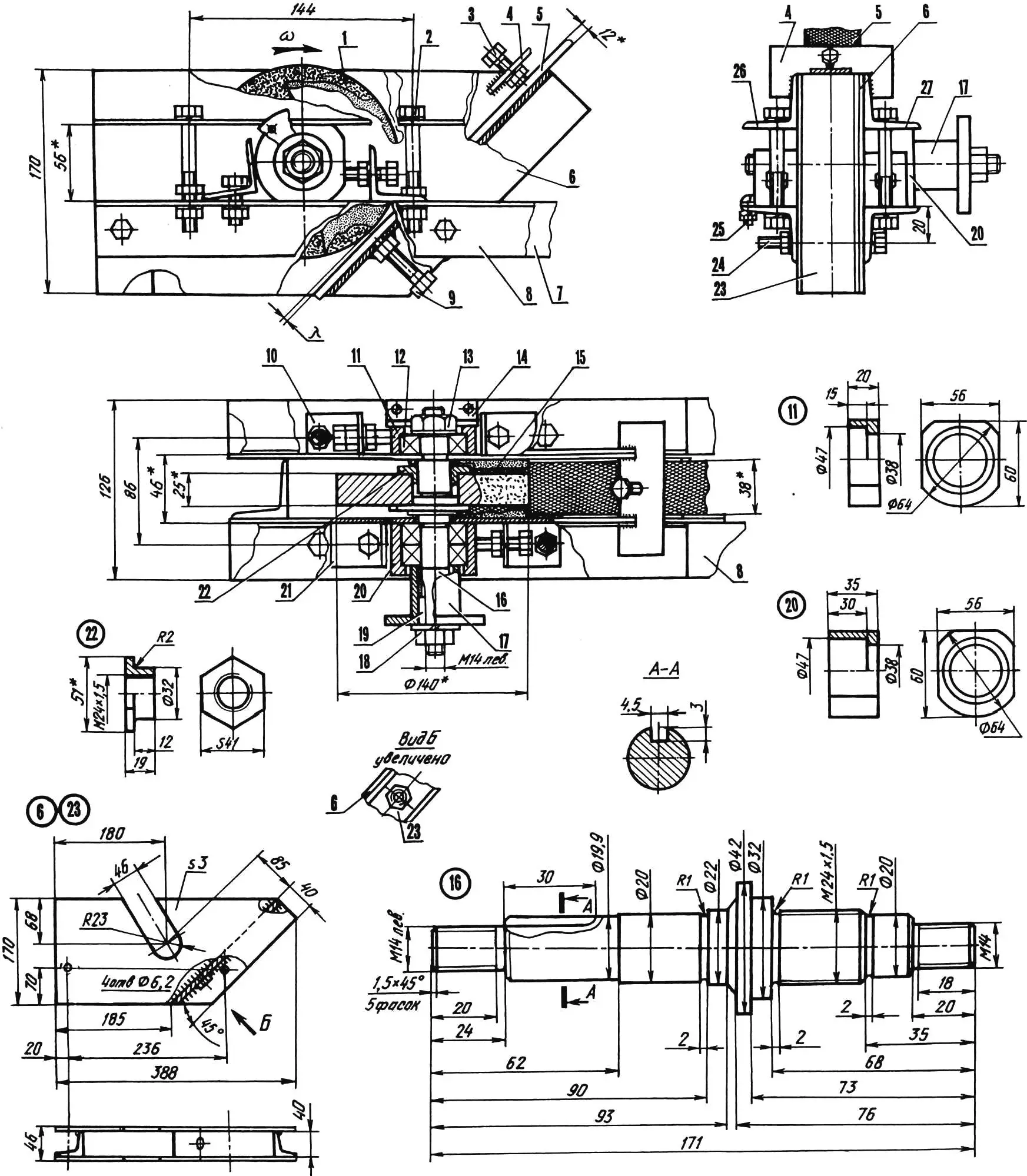

Among combined grain crushers with minimal manifestation of the above-mentioned disadvantages, one can include the homemade “Khadizhenskaya” design, which is proposed to be built by readers of the “Modelist-Konstruktor” magazine. Its basis is an emery wheel (mounted on a horizontal shaft rotating in single-row radial ball bearings 80204 with two protective washers) and a bastard file installed at an angle, at a distance L from it (working gap).

The raw material is drawn by the rotating emery wheel into the space between the cylindrical surface of the emery and the file L, where it is crushed to the required fraction. The required value of L is set by an adjustment unit made on the basis of a bolted connection.

1 — emery wheel; 2 — tie post-bolt M8 with two nuts and Grover washer (4 sets); 3 — mounting-adjustment bolt M8 with nut and Grover washer (5 sets); 4 — welded crossbar of upper half-frame — stop of mounting-adjustment unit (3-mm sheet, St3), 5 — bastard file 12×38; 6 — housing wall (3-mm sheet, St3, 2 pcs.); 7 and 8 — lower front and rear side members; 9 — adjustment bolt M12; 10 — post (2 pcs.); 11 — rear bearing unit housing (steel 35); 12 — bearing 80204 (3 pcs.); 13 — nut M14 with washer; 14 — stop-fixer; 15 — semicircular cheek-seal (aluminum or textolite, 2 pcs.); 16 — shaft (steel 40); 17 — flange (steel 35); 18 — nut M14 (left-hand thread) with washer; 19 — prismatic key 4.5x5x25; 20 — front bearing unit housing (St3); 21 — radial bearing unit fixer (2 pcs.); 22 — clamping nut (steel 35); 23 — side wall of housing (2 pcs.); 24 — tie-bolt M6 with nut and Grover washer; 25 — bolt M4 with nut and Grover washer; 26 and 27 — rear and front side members of upper half-frame, respectively;

material of parts pos. 7, 8, 10, 21, 23, 26, 27 — steel angle 40×40; fastening elements of part pos. 15 are conventionally not shown

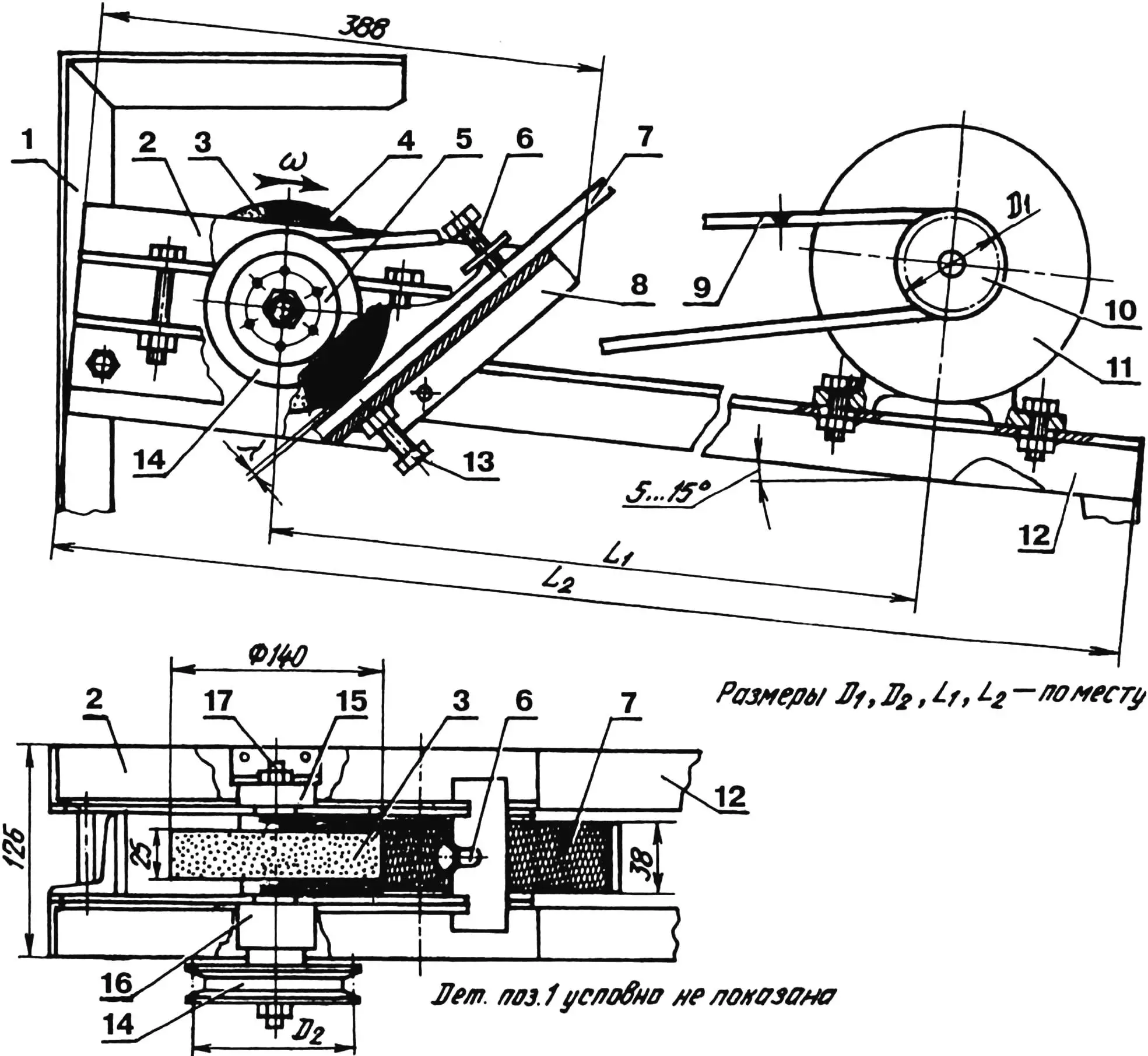

The power unit is a single-phase electric motor with a power of 1—1.5 kW, the torque from whose shaft is transmitted to the crushing unit via a V-belt drive. The sizes of pulleys adapted from decommissioned automotive and tractor equipment are based on the ratio of rotation speeds of the driving and driven shafts. The belt is cord-twine, reliable, with cross-section B. To simplify and reduce the cost of the design, adjustment of its tension is carried out… by “slipping” of the power unit downward, under the influence of its own mass, for which the frame with slots made in it for the electric motor mounting bolts is installed at an angle of 5—15° to the horizon.

The main materials required for manufacturing the “Khadizhenskaya” grain crusher are steel angle 40×40 mm, bolts M4, M6, M8, and M10 with nuts and spring washers, as well as 3-mm St3 sheet. The housing is welded. Its front and rear walls are cut from 3-mm St3, and segments of the above-mentioned angle are used as side walls. The shaft is turned from steel 40, and the bearing housings, as well as the clamping nut, are made from steel 35.

Side members forming the frame are mounted to the front and rear walls of the housing with tie bolts (with subsequent fixation by welding). The pre-assembled shaft unit with emery wheel is inserted into the inclined slots of the walls with cheeks-seals fixed inside. The bearing housings are clamped from the sides by corresponding fastening elements, and from above—by side members mounted on post-bolts M8. Axial displacement of the crusher shaft is prevented by fixing an additional post on the rear side member of the frame.

The bastard file is placed on an inclined side wall (inside the grain crusher housing) in such a way that the required working gap is maintained between its working surface with notches and the radial surface of the emery wheel—for this, mounting-adjustment and adjustment units are provided in the crusher design. The flange, mounted using a prismatic key on the driven shaft, serves for quick installation of any pulleys, including those from automotive engines.

1 — hopper bracket; 2 — upper side members; 3 — emery wheel; 4 — semicircular cheek-seal (2 pcs.); 5 — flange; 6,13 — mounting-adjustment bolts; 7 — file; 8 — housing; 9 — V-belt drive; 10 — driving pulley; 11 — single-phase electric motor (220 V, 1—1.5 kW); 12 — lower side members; 14 — driven pulley; 15 and 16 — rear and front bearing units; 17 — shaft;

parts pos. 9, 10 and 14 — from decommissioned automotive and tractor equipment

As noted earlier, a single-phase electric motor is required for the “Khadizhenskaya” to operate in a household electrical network. Connection is through an isolation transformer, ensuring safety in case of insulation breakdown and other abnormal situations. However, if necessary, the scarce “single-phase” motor in rural areas can be fully replaced with a three-phase electric motor, including from agricultural equipment that has exhausted its service life. Having verified the serviceability of the “three-phase” motor, it is connected to the household electrical network according to a circuit with phase-shifting capacitors, the features of which have been repeatedly described in the pages of the “Modelist-Konstruktor” magazine (see, for example, publications in No. 11’90, 12’92, 8’95, and 8’99).

The electrical equipment of the grain crusher also includes a magnetic starter, current relays, a maintenance switch with visible circuit break… In short, it is desirable to have everything so that work on such a crusher is absolutely safe.

Simple to manufacture, the “Khadizhenskaya” grain crusher does not present particular difficulties in its maintenance either. Replacement of the emery stone, for example, is performed in the following straightforward sequence.

First of all, the adjustment and mounting-adjustment bolts are maximally loosened and the file is removed from the construction. Unscrewing the lower nut on the tie post-bolts M8, the upper half-frame is removed. Then the practically still unassembled crusher shaft unit is pulled out from the housing walls in the direction of the lug travel (of course, having removed the M12 nut located at the rear for this purpose). The rear bearing unit is removed, the clamping nut is unscrewed, and the emery wheel is replaced. Assembly of the updated grain crusher is performed in reverse order.

Actually, one cannot deny the “Khadizhenskaya” in terms of service life duration, as they say. Everyone can be convinced of the validity of this statement by building such a reliable, solid grain crusher for themselves—fortunately, very little effort and money will be required for it.

V. ZORIN