Durable, reliable, sustainable, it gives the impression of a powerfully built all-in-one monolith. But it is worth a little bit more pressure towards each other the upper cross member of the seat side — as the chair will pliable to take shape, turning into a flat package. And if reverse pressure is routed again to a certain point, forming a rigid structure, like all its parts are firmly knitted together by nails.

Durable, reliable, sustainable, it gives the impression of a powerfully built all-in-one monolith. But it is worth a little bit more pressure towards each other the upper cross member of the seat side — as the chair will pliable to take shape, turning into a flat package. And if reverse pressure is routed again to a certain point, forming a rigid structure, like all its parts are firmly knitted together by nails.

What is the secret of such a metamorphosis? Let us consider the unit chair, to understand, to achieve such mobility and the reliability of its parts.

The main elements

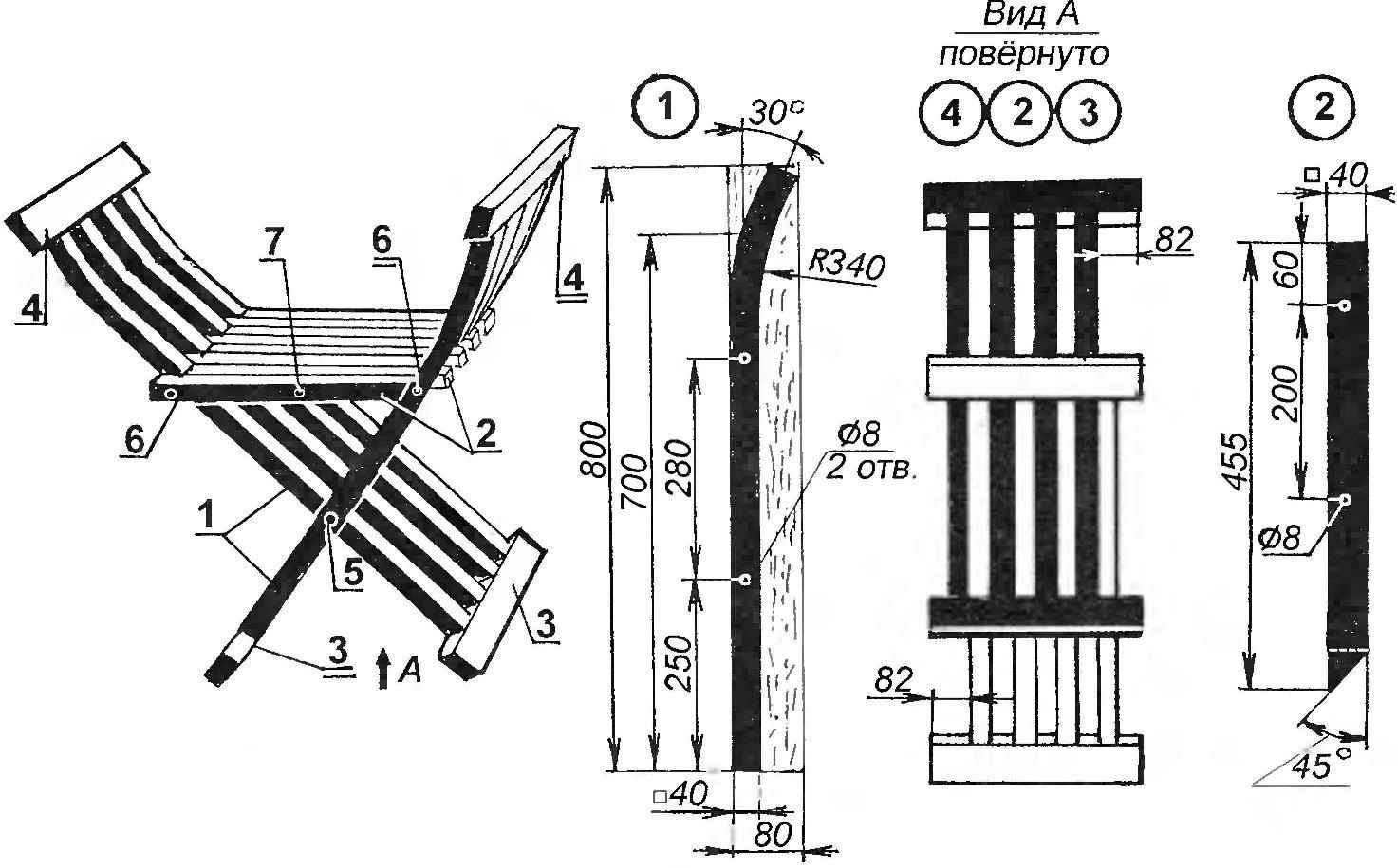

The main components of the design, of course, sides that represent blocks of bars each of which top and bottom linked in a kind of frame cross bars. Between the last signed four long bar, threaded between the same from another block.

In the lower part through the cage bars both blocks passed a metal rod, which is their axis, allowing the sidewalls to come together when folded and to divorce the parties in the formation of the seat. And make it horizontal short bars connected to the bars of the side walls in an original way. It actually hides the secret of the chair.

Original folding chair:

1—sidewall;

2—the”comb” of the seat;

3—support side (lower cross);

4—arms (upper tie bar side);

5—lower axis of the side walls (metal stud);

6—axis “combs” of the seat;

7—the Central axis of the “combs” of the seat;

8— insertable cylindrical stud (16 PCs.)

If you look closely at the seat, we see that its constituent bars have different ends: one direct and the second chamfered. Straight ends pivotally connected with the nearest bars one the sides, and beveled just lie on the bars of opposing sidewalls. The bars seat alternate: if one beveled end goes to one side, the adjacent — to the opposite. It’s as if two combs included their teeth at each other. The result is a solid, without gaps, smooth seat.

However, it would seem that in this connection, when the seat bars are attached only at one end, the sidewall would have to disperse and be on the floor. However, this is not happening. The fact that through the middle of all bars in the seat missed the metal shaft of the second axle seat. It provides rigidity in the unfolded form, and this same axis was retained the ability to fold the chair in a flat pack.

Manufacturer

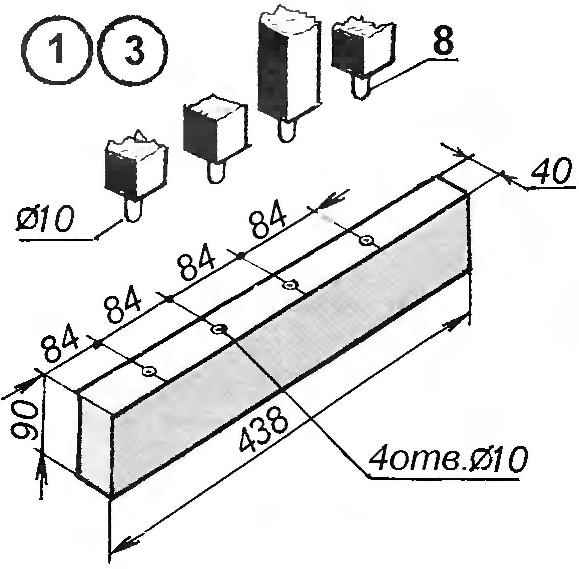

Side chairs can be made from straight bars, but to make them aesthetically pleasing and comfortable view better to cut them with a somewhat curved on one side by the end, like a ski. This will suit the Board thickness of 40 mm. Of them will need to procure the tie bar and side bars for the seat.

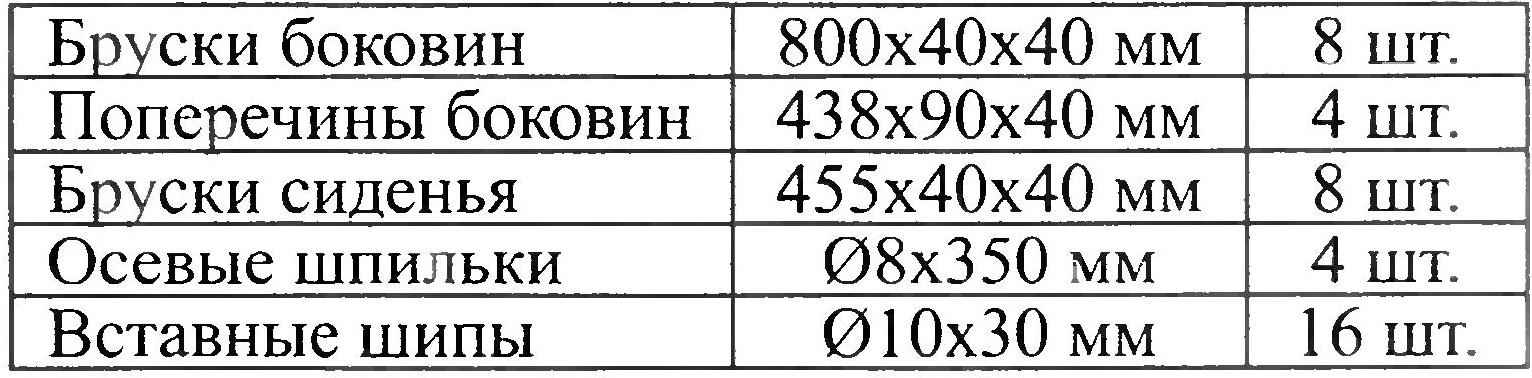

The source material for couch

At the ends of the bars of the sidewalls and along the mid-line of each cross member are prepared holes for round tenons. In accordance with the submitted drawings in the bars of the sidewalls and seat of drilled holes through which will be passed in the Assembly of metal rods (axles). The latter are studs 8 mm diameter, threaded on both ends (available with rasklapanje cap on one end and a nut on the other). Studs you will need 4 pieces, cross bars — 4, bars for sides — 8 bars of the seat — too 8.

Assembly

It is better to start with the sidewalls. First bars with curved ends by inserting the studs with glue (carpentry, casein, PVA) are connected to the crossbars. The resulting two “combs” of the sidewalls are inserted into each other, and lower their upper ends similarly connected with their crossbars.

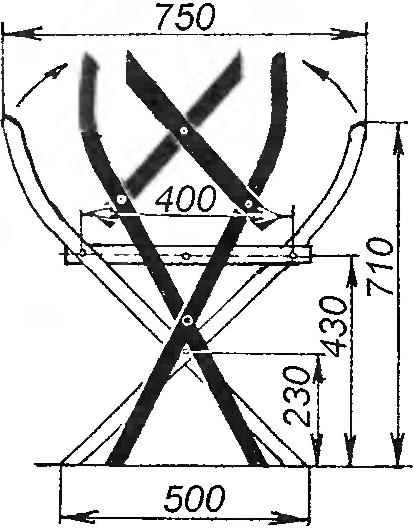

Dimensions of the chair and its folding

At the bottom of the hole sidewalls is ignored, the axial stud and secured with nuts and washers. Further between the bars are set side bars of the seat, also four pieces for each side, and connect them with two metal rods. Bars seat installed in their side given the diversity mentioned above, forming an inverted “comb”. Unfolded seat the ends of the combs of the seat (2) must rest against the bars of the side walls (1). After verification of correct installation through the middle bars of the seat pin is passed and secured with nuts and washers.

Finish

It is better to perform on the stage of blanks. Each wooden detail is carefully processed cloth, sanded and varnished in several layers with intermediate drying and additional grinding

Instead of coating parts can be painted with enamel or oil paints. If the chair were performed to give, to paint the details better in bright colors on the green background of the site it will look festive, elegant.