This is due to the specific design of the chair. Externally perceived as a single structure, similar to conventional similar items of furniture, the transformable chair is on the sides additional “legs”-the struts and consists essentially of two independent nodes connected by a strip of piano hinge in the middle “cut” of the seat.

Thanks to this hinge the back of the seat with backrest and legs can fall on the front part, forming a ladder.

The resulting ladder is quite stable, since its feet are the two remaining strut from the front of the seat and front legs and the overturned chair. And the stairs serve as a wooden platform, fitted between the legs and braces, as well as the seat itself.

Suitable for the manufacture of a chair-transformer material is any solid wood (oak, walnut). The figures represent the types of stool on the front and sides and how it looks after the transfer to the position of the stepladder.

The main elements of this design — like a conventional chair. The unusual starts with the seat: it is cut and coupled with a piano loop; accordingly, sawn and its supporting rails. To carham on the sides of the seat on both sides of the slit are mounted on two pairs of struts. The lower ends of the rear pair are connected (via the wedge-shaped bars-spacers) from the rear legs.

In the pictures the front legs of the chair depicted turned, and the back is slightly deflected from the vertical, not every contractor is under force. Therefore, you can use just straight bars with dimensions 40×30 mm. Also do not have to repeat the shown connection of the struts with tsargami and rear legs — easier to do the struts patch (by the way, this option will allow you to get a convertible chair even out of the ordinary).

With these simplifications let us consider the manufacture of chair-ladders. For racks the rear of the chair, take two pieces of wood cross section 40×30 mm and length 840 mm: they form the back of the chair and rear legs. The upper crossbar — straight or curly (as the picture) Board size 40×20 mm and a length of 370 mm; the second plank of size 25×20 mm and a length of 370 mm. with brasaemle them in four vertical slats size 25×10 and a length of 300 mm they form the back of the chair. All connections of these parts — pin, with glue (carpenter’s PVA).

At the bottom of the chair legs attached to the wedge-shaped spacer of the bar of 40×30 mm — for connection of struts; and under the seat between the uprights on the plug-in round thorns — drawer side boards of section 30×20 mm and a length of 340 mm. At this level, and also by inserting the spikes on the racks are installed side rails up to a length of the section seat, at the end of each of the rings it is attached to the brace of Board cross-section 30×20 mm, the lower end of which is connected with a wedge-shaped spacer rear legs (all joints — tongue and groove, glue). Between the rear legs and braces into their slots is inserted a step out of the Board section 120×20 mm.

Fig. 1. From the chair—a ladder:

1 — the front legs of the chair; 2 — bar-spacer (ligament brace with back stem, 2); 3 —step (front, “lower”); 4 — seat; 5 — front drawer side; 6 — stand (at the bottom of they rear legs); 7—lower cross member of the backrest; 8—vertical crate backless; 9—upper cross member of the backrest; a 10—step (back, “top”); 11—rear brace (2 pieces); 12 — front brace (2 PCs.); 13—drawer side front spacer (2); 14—rear-side-bar-spacer (2 PCs.)

On top of the drawer sides with the struts overlaps half of the seat is made of furniture Board, chipboard or plywood size 410x266x20 mm. Thus the rear unit transformable chair is ready.

We need to raise the front end. Her legs form of bars sizes 40×30 mm and a length of 400 mm, which Shipov connection fixed front drawer side boards of size 30×20 mm and a length of 340 mm. respectively On the sides of the legs using spacer-drawer sides are connected with two struts of appropriate length out of the Board with dimensions 30×20 mm at the same angle as that of the rear struts.

As the rear of the chair unit, between the front legs and struts set step out of the Board section 120×20 mm and the required length, and the top front of the unit — the second half of seat of the same material that was chosen for the rear of the unit.

Now both units are connected superimposed on the stacked halves of the seat with a piano hinge. For ease of carrying in the wide part of the seat can be made a cutout for the arms, and the struts mounted the locking hooks.

Finished chair-traditional ladder for furniture varnishing or painting with oil or enamel paints. Before spraying to emphasize the texture of wood and color used alcohol stain or a stain from salts of certain metals. So, the treatment with iron sulfate gives the tree a gray or black color; for example, copper sulfate stains the wood in jeltokoren tone. These effects will be maintained and even slightly enhanced by a subsequent coating of varnish.

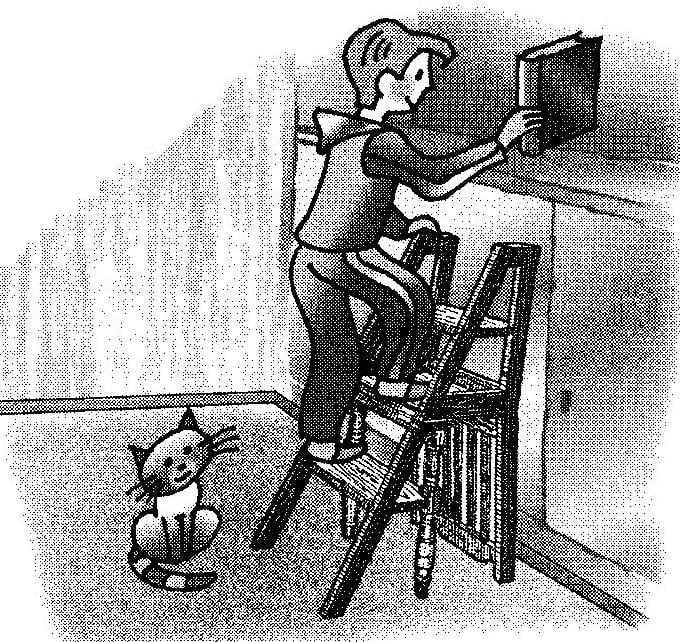

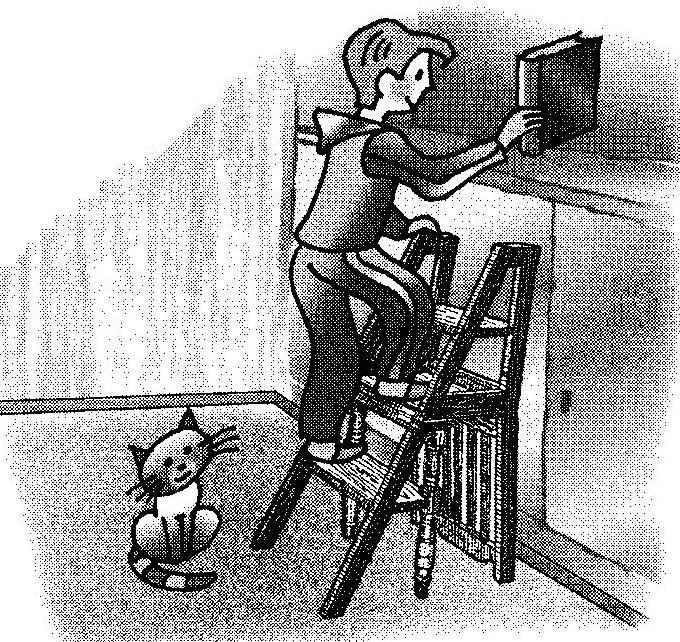

Fig. 2. Scheme of transformation of a chair into the ladder:

And—piano turn on the loop back unit of the chair (the back of the seat if it rests on the front and the back of the chair is on the floor); B—the front part of the chair, a support block of a ladder. The seat also plays the role of a step

If the wood does not have a winning texture or contains any flaws (for example, the abundance of knots), it is better to use for finishing the paint. You should only keep in mind that heavy-bodied oil paint must be diluted with linseed oil in the ratio of 1 part linseed oil to 3 parts paint. Many people prefer painting with enamels or nitrocellulose. They dry faster and, unlike oil paints, which gives a slightly matte surface, give a nice light gloss. Thickened enamel is also better diluted with a suitable solvent, for example, the # 646 and # 647. Staining to perform better in several layers with intermediate drying (for 24 hours) and grinding a fine-grained skin.

Recommend to read MOPED TRAILER A moped is often considered an expensive toy for children. And in fact, a significant portion of these two-wheeled machines are purchased by young people for purely recreational purposes.... FIVE-BAND EQUALIZER Equalizers are designed for frequency correction of the playback devices. The scheme of such a device published by the Romanian magazine "Technium". We are talking about passive bandpass...

The step stool shown in the drawings, can find many uses: as in a city apartment and in the country or in the garage. It is convenient because apart from its main functions due to the small transformation turns into a ladder.

The step stool shown in the drawings, can find many uses: as in a city apartment and in the country or in the garage. It is convenient because apart from its main functions due to the small transformation turns into a ladder.