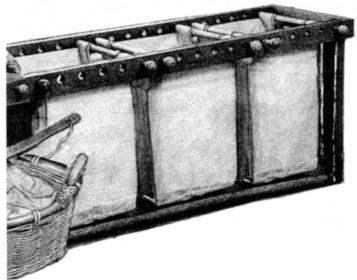

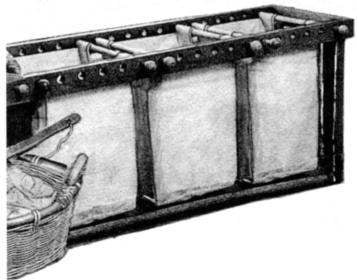

Rod cross member upper frame – pluggable: they can be easily removed, if necessary remove them with a filled bag from linen or change its width by moving the corresponding rod.

Fabric storage bins are made of thick fabric (upholstery, mattress) in bags rectangular shape. They are sewn from a separate or partially paired panels, for no particular pattern, in accordance with the size of the frame, in any order.

The upper part of the sidewalls of the bags has a cut-straps for hanging on rods top crossmember of the frame, but can be joined and a simple bend to get the appropriate pocket. On the front of the bag is convenient to make the inscription-a reminder, under what clothes he designed.

The manufacture and Assembly of

So, as already mentioned, the basic wooden structures are made of narrow boards (about 50 mm) and 20 mm thick, from which are cut blanks for frames and racks.

Since the fundamental conditions for the size of the structure will be allocated for it, and its manufacture should start with the frame or rather with its frames that have to be weighed.

And leading here will be the upper frame, the lower mostly partially repeat it, and racks are laid directly under it. In the blanks to the front and rear upper frame by means of rotation and the so-called pen drill bit of suitable diameter (about 20 -25 mm) is drilled a series of holes under the rods of the crossmember, and then they both connect to sidewalls using plug-in round thorns.

The main elements of the drive:

1 – stand; 2 – side panel lower frame; 3 – the back part of the lower frame; 4 – rod-tie front struts; 5 – the front part of the upper frame; 6 – cores-crossbar; 7 – rear part of upper frame

Likewise interconnected three blanks of the lower frame. Then to the both sidewall frames attached to the rack: the upper frame is inside it, and to the lower frame on the outside of the sidewalls. Additional rigidity will give the connection of the lower parts of the pillars a wooden rod with a diameter of about 25 mm.

The billet rods-crossbars: they can be saw from a wooden rod with a diameter matching the holes of the upper frame (or from cuttings of selkhozinvest respectively adjusted to make the holes).

It remains to produce the bags, bunkers. It is better to sew on the sewing machine and fit the height under the corresponding dimensions of the frame, and the total width of all three silos with gaps between them – the size of the upper frame.

The finished bags are mounted on the shaft of the strut – and three-piece underwear storage is ready to be installed in the designated place.

Finish

Although this design belongs to the disproportionately modest compared with the rest of the furniture in the apartment and it will be out of sight and in a secluded corner of the pantry or the bathroom – still its appearance should be pleasing to the eye, especially because to achieve it is not so difficult. And consider this better before the final build -for example, at the stage of preparation of design details.

The sidewall of the bag-hopper with straps for hanging on rods top crossmember of the frame