My home library is quarter of the self-made volumes that the quality of the binding and design are not inferior printing samples. In the literature in some detail with illustrations of the technique of restoration of books, but none of the authors does not lead the machine design.

My home library is quarter of the self-made volumes that the quality of the binding and design are not inferior printing samples. In the literature in some detail with illustrations of the technique of restoration of books, but none of the authors does not lead the machine design.

This circumstance gave me the idea to develop a simple device, which is much easier to work on the restoration of old or worn books in the home. Here is his description and use cases for different methods of binding, the technology which it is easy to find in the literature (the list of which is given at the end of the material).

The machine is portable, easy to use, takes up little space. At homebrew General arrangement drawings of the product and its description, I believe that to master its production and to companies mestproma. To release it could be disassembled, for Assembly it would take only a screwdriver.

Capabilities of the machine

Universal binding machine is designed for all types of bookbinding at home. It allows to prepare the book block for binding the inserts in the cover. When optional equipment disk knife, gobelen and a hacksaw with fine teeth, and other necessary tools and materials, the machine will be indispensable to any bibliophile.

The machine allows to produce:

- Cover of sheet material the sewing “mess up”.

- The binding of the set of all journals by the method of “cuts”.

- Hand sewing book books per unit method “the splits”.

The machine can handle sheet blocks the most common sizes — from pocket to magazine formats. Depend on the specific sizes of parts and accessories. For orientation I will give only General data of the proposed device: a useful area of work — 300x270x80 mm; the maximum height of the processed block is 80 mm.

Feature of the machine is the ability of cover sheet material by the method of “cuts”. In this case, the possible simultaneous operation of three blocks with thickness up to 20 mm each.

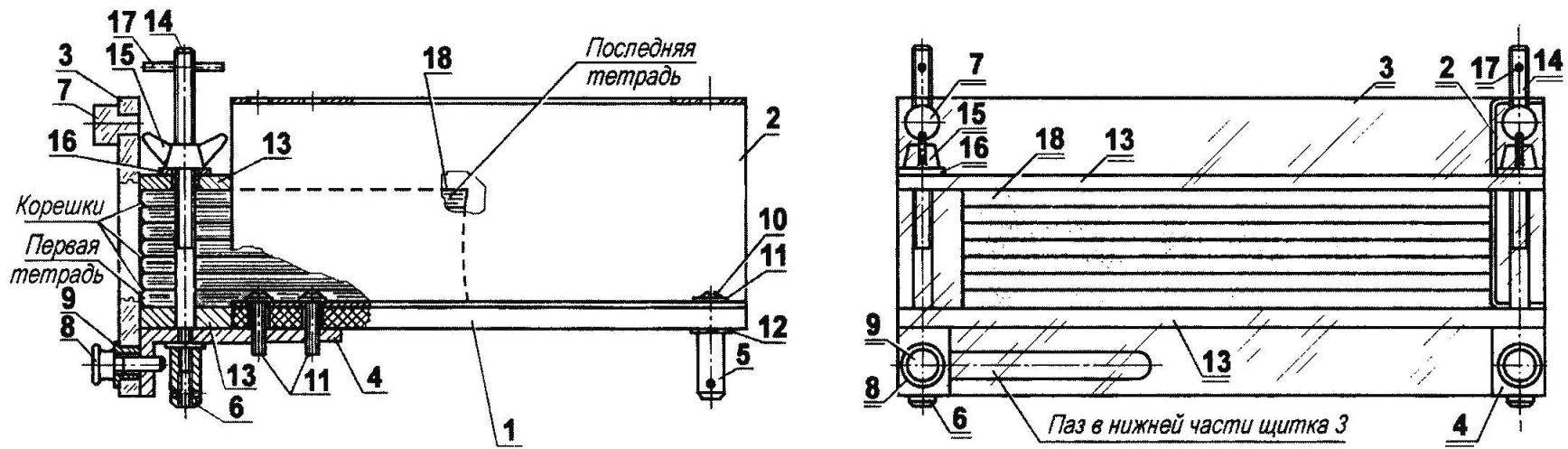

Structure and purpose of components and parts

The machine consists of the frame and the grip (see figure). Base is for installation and training of binded block to work. Includes the following parts: base (text – or fiberglass with a thickness of 10 mm); flange (steel sheet); the thrust plate (made of Plexiglas with a thickness of 10 mm; its transparency allows you to visually identify possible defects in the packing of sheets in the block); mounting bracket (for connection of host clutches with the frame); a leg made of aluminum D-16T, 2 PCs. (right, in addition to the supporting function, serves to connect the side with the base); leg-lock nut, 2 PCs (except the reference function that serves as a locknut, locking vise node on the frame); the upper leg, 2 pieces (made of Plexiglas, serves as a support machine when turning to vertical position for pushing the block on the spine); the clamping screw, 2 pieces (serves to connect the thrust plate with mounting parts and support the machine in upright position); the bushing clamping screw (brass); М8х25 screws and washers (10 PCs).

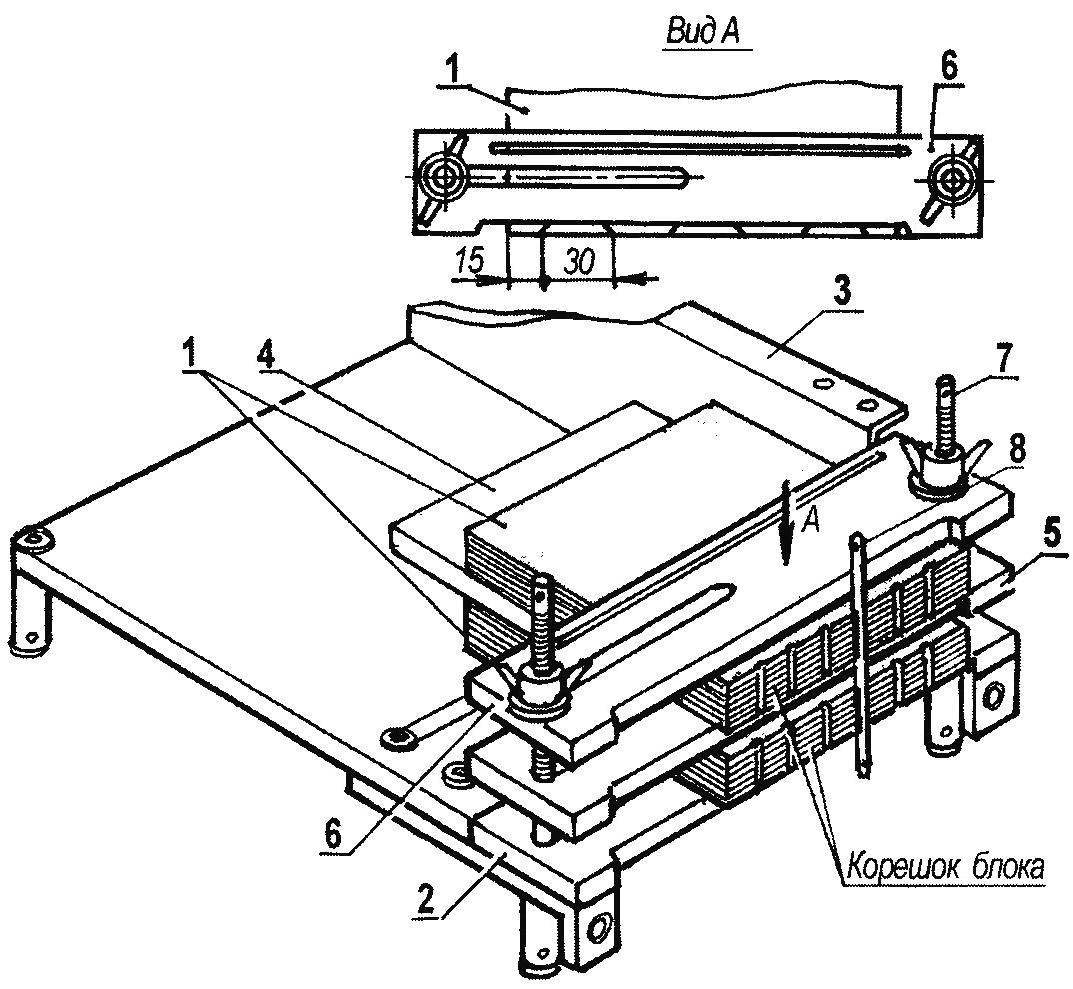

Binding machine:

1 — base; 2 — Board – side plate; 3 — resistant clear shield (plexiglass); 4 — mounting area; 5 — leg (2 PCs); 6 — leg-vise lock nut (2 PCs); 7 — upper leg (the support in the translation of the machine in a vertical position); 8 — clamping screw thrust plate; 9 — bushing clamping screw; 10,11 — mounting screws with washers (4 pieces); 12 — washer lock (4 PCs); 13 — upper and lower pressure plates; 14 — pin vise (2 piece); 15,16 nut-lamb with washer (2 PCs); 17 —the handle for pins of the grip; 18 — pack notebooks binded books (top edge — to the side of the base)

Host vise is used for clamping of binded block before processing the root. It includes the following details. The main one is the pressure plate made of sheet steel with a thickness of 10 mm. They provide compression unit. Also jig when drilling holes in the block (sewing method “puncture wounds”) and gaskets in the grooves propilivanie (sewing method “cuts”) at the same time two or three blocks. When sewing block books “the splits” are the lower and upper rails for stringing twine or braid. Plate is pressed against the block with studs (2 PCs.) of steel and nuts-lamb (2 pieces) with washers.

In the sewing version of “the splits” upper plate is secured on the studs (stretching the string) through the auxiliary nuts (2 PCs) underneath. Sewing “cuts” under the second and third notebooks fit the alignment plate is a strip of PCB. To tighten the studs and clutches the legs of the frame, use the knob of the steel rod.

Left mounting area that attaches to the base via parallel grooves, can move towards the side, which is necessary to loosen the mounting screws. The same ability has, and the left-hand pin Vice. This design allows you to work with a block of any size.

Trouble “puncture wounds” (“vtocco”)

This method is used when twisting the sheet material (such as logs) is left in firmware, to indent text with a minimum width of 15 mm.

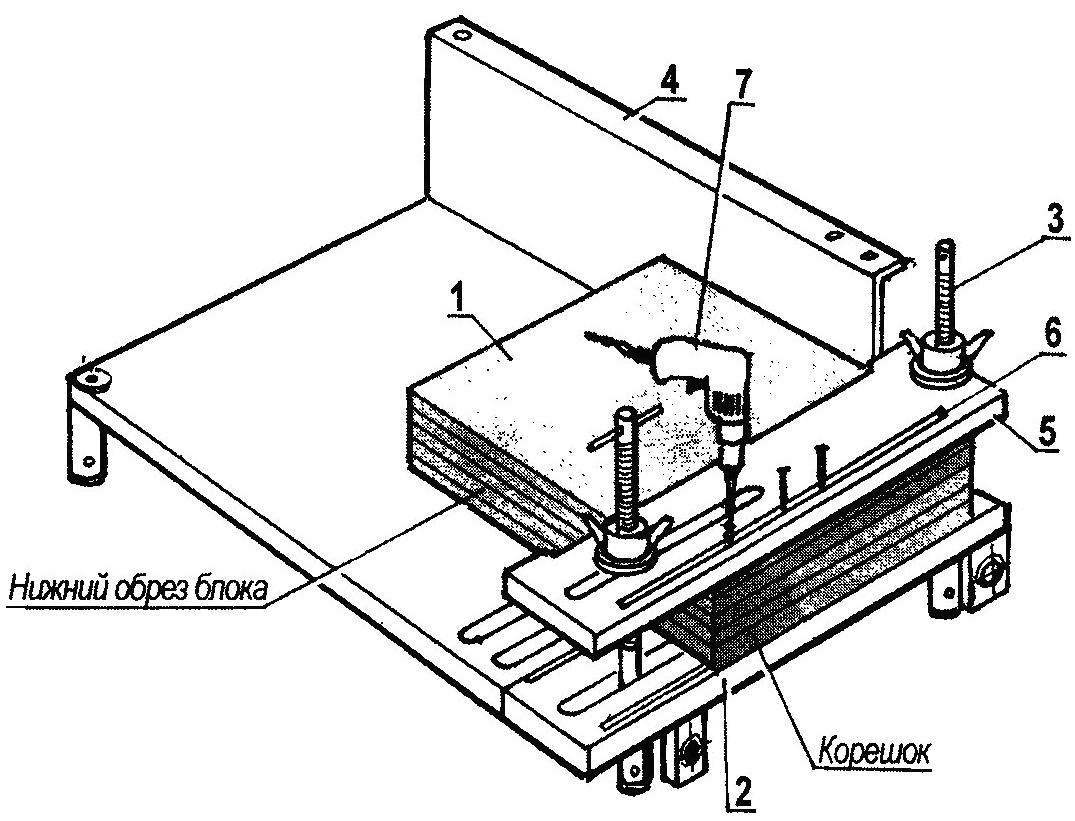

Binding method “puncture” (thrust plate is not shown):

1 — unit of sheet material; 2 — the lower pressure plate; 3 — pin (2 PCs); 4 — Board; 5 — the upper pressure plate; 6 — groove conductor; 7 — drill

For starters, the bottom plate must be worn on the studs of the longitudinal groove to the panel, then do all the preparatory operations on colliding binded unit on Board and on the spine. Remove the thrust plate. In block, clamped by the sheep, through the longitudinal groove of the conductor in the lower and upper plates to drill the entire length of the unit required (odd) number of holes with a pitch of 40 to 50 mm. it is important to have the indentation from the edge of the upper and lower edge approximately 15 mm. to Produce sewing unit.

Cover method “to the cuts”

This method is a type of sewing method “puncture wounds” (“vtocco”), but applies in cases where it is necessary to bind the sheet material from which the field at the fastening sheet on the left less than 15 mm: for example — books, made perfect binding (glue) method, brochures and books in soft covers, literary and technical journals large format, as well as old books, traditionally stitched “the twine”, but because of its dilapidation cannot be still sewing.

Unlike other types of cover this is most convenient and productive at home. It allows simultaneous processing of up to three units, with a minimum of labor intensity to deliver high quality, providing prolonged and repeated use of it.

The bottom plate should be worn on the studs of the external neck to the shield. To lay and push the block top edge of the Board. Put on top of any of the clamping plates similar to lower; to put beside her plate-strip and lay the second block, having the operation for pushing. To wear the upper plate and thumbscrews to pull the entire stacked package. To put the machine vertically on the shield and slightly loosening the vise, to finally push the whole package to the spine and to upper Board edge. Clamp the vise.

Cover “cuts” (the thrust plate is not shown):

1 — sets of books; 2 — bottom clamping plate; 3 — Board; 4 — lining plate-gasket; 5 — high pressure plate; 6 — upper clamping plate; 7 — stud grip; 8 — hacksaw

To return the machine in a horizontal position. Remove the shield and put the machine in a vertical position with support on the rear edge of the base and the side, so that the whole package turned up by the roots.

Hacksaw with fine teeth at the same time in both blocks to make 3 — 4 pairs of oblique cuts at an angle of 45° to each other. Continue to follow the sewing technique of “dovetail”.

Sewing books “the splits”

Bottom plate to put on the studs the outer cutout to the panel. Notebooks (journals) block, except the first and last fold so that the top was their last number. To move the block top edge to the side from the spine to the vertical plate. Then put on the upper clamping plate, orienting it to the shield similar to the bottom, and gently squeeze the block with wing nuts. To translate the machine in a vertical position with the support legs of the shield. Releasing the grip of the nut, finally push the block to the spine panel and top edge to the Board. Pull the grip unit nuts. To return the machine in a horizontal position, to check the quality of pushing through the transparent flap. If any notebook within the plane of the spine, the grip loosen and align the unit.

Remove the shield by unscrewing its screws. To set the machine in a vertical position with support on the rear edge of the base and the side, the spine unit will be at the top. The entire length of the spine to make a few cross cuts to a depth of 5 mm. to Return the machine in a horizontal position; remove the nuts and remove the upper clamping plate, and then, trying not to break the block, move it to the lower plate to the base, putting insurance on top of any cargo. After removing the bottom plate, flip it (internal longitudinal groove to the outside). The studs grip to wind the auxiliary nut, retreating from the top of the studs approximately 25 — 30 mm. top Wear plate, inner orienting groove similar to the bottom, and with her nut, screwed on top of the lamb, not pressing them to the plate.

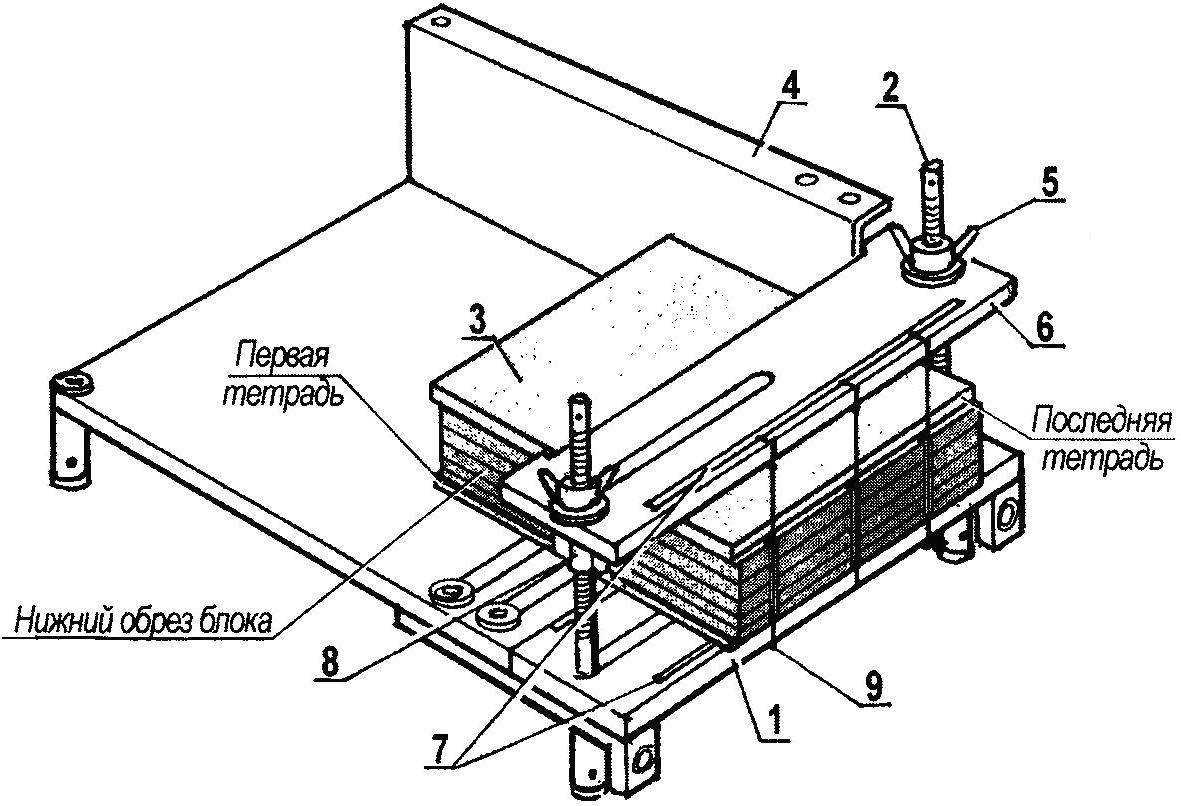

Sewing “the splits” (shield removed; the upper limit is raised and rests on the auxiliary nut):

1 — lower pressure plate; 2 — pins vise; 3 — block; 4 — Board; 5 — nut-lamb (2); 6 — upper clamping plate; 7, the longitudinal grooves of the plates; 8 — auxiliary nut stud (2); 9 — twine

Through the longitudinal grooves of the upper and lower plates to tie the twine on the number of cuts. Neatly tucked under the block bottom first and top last notebook of the block (indented to the depth of cuts), move it to the twines so that they were looking for cuts. Auxiliary turning up the screws, pull the twines. Now you can start sewing notebooks block on the technology, covering the strained strands of twine.

G. PATENT

Literature

- N. N. A swab. Twisting the book to everyone can. “The book”, 1970.

- Vladimir Yefimov. Bookbinding workshop at school and at home. — “Radyans’ka SHKOLA”, 1982.

- Newspaper. Book review, 1986 — No. 42,44,47,49,51; 1987 — No. 2.