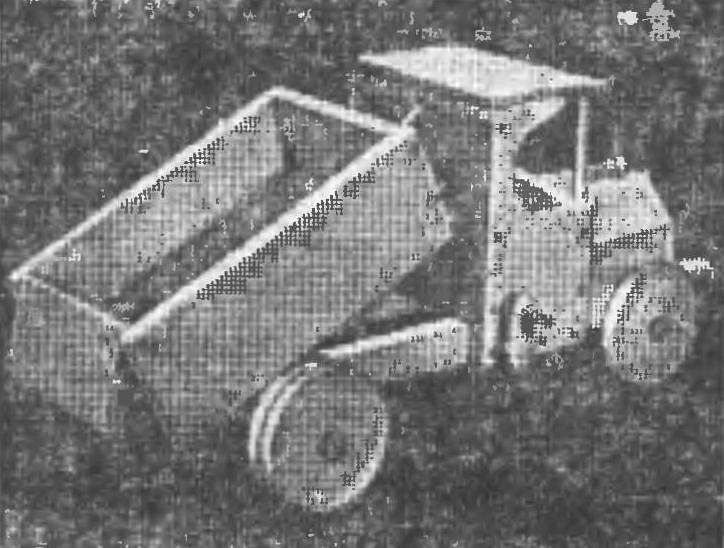

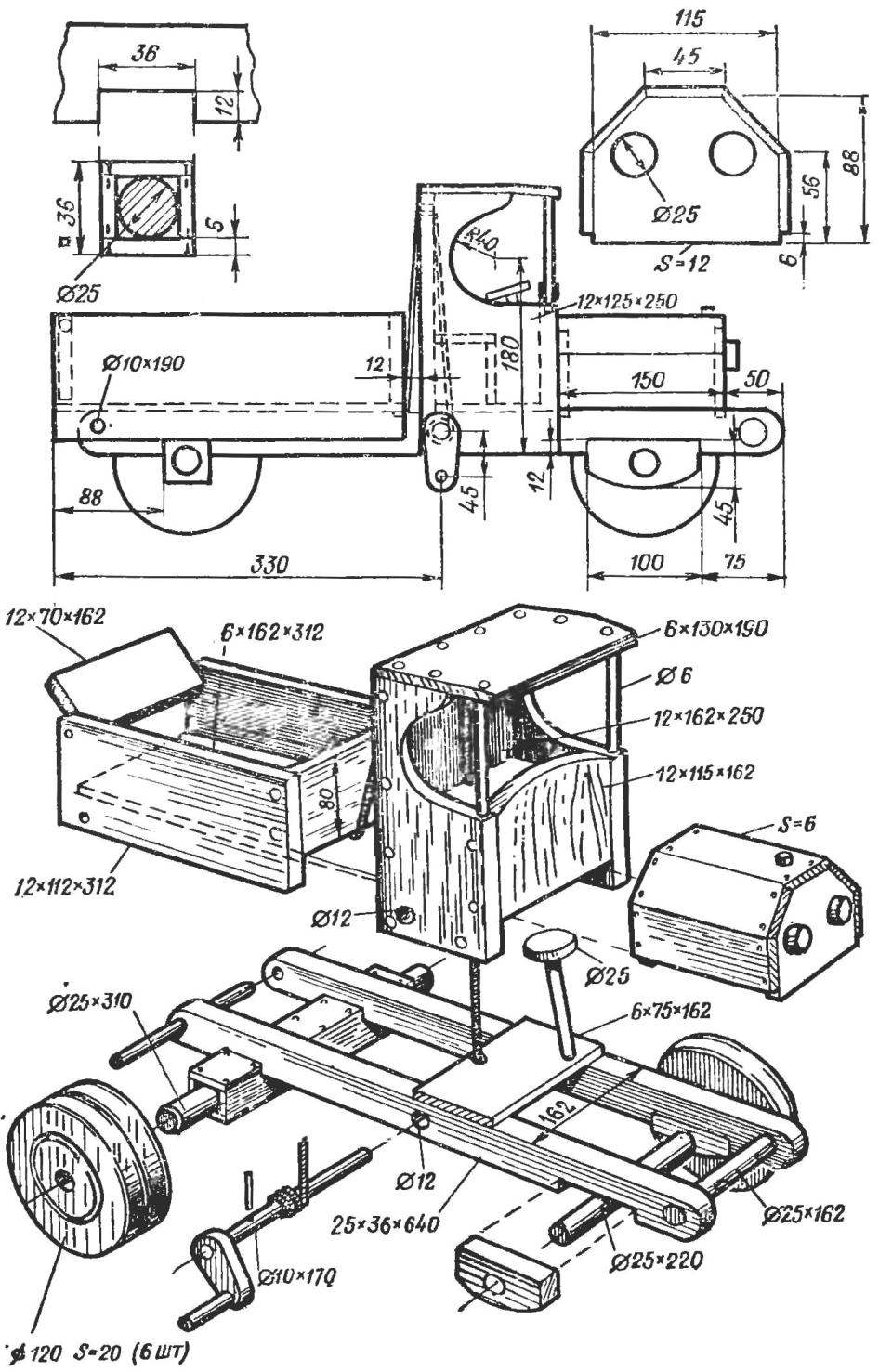

All the details of this wooden truck, so the tools for the job need simple: kicks jigsaw, drill, sandpaper, files. The frame consists of two strips of a cross section of 25X36 mm and a length of 640 mm. Transverse elements: a round wooden rod with a diameter of 25 mm (front), plywood plate 75X160 mm thick of 6 mm (bottom cab) and box rear axle, assembled with glue n small studs made of plywood with a thickness of 5-6 mm. At the rear of the frame in the middle of the drilled hole 12 mm in diameter — one for the axis of the body, and the other for the main winch of the lift.

All the details of this wooden truck, so the tools for the job need simple: kicks jigsaw, drill, sandpaper, files. The frame consists of two strips of a cross section of 25X36 mm and a length of 640 mm. Transverse elements: a round wooden rod with a diameter of 25 mm (front), plywood plate 75X160 mm thick of 6 mm (bottom cab) and box rear axle, assembled with glue n small studs made of plywood with a thickness of 5-6 mm. At the rear of the frame in the middle of the drilled hole 12 mm in diameter — one for the axis of the body, and the other for the main winch of the lift.

Front axle are made of rails of circular cross section with a diameter of 25 mm. It rotates in two bearings — a wooden (beech) wedges 25Х45Х100 mm with hole Ø 25 mm Wedges-bearings are glued in grooves of the frame.

Wheels can be cut from plywood thickness of 18 mm. wheel Diameter 120 mm Wheel will be identical and round, if you prepare them by planting on round the threaded rod (bolt, pin), clamped in the Chuck of an electric or hand drill. Drill it is recommended to commit in a desktop vise.

The body is assembled from planks or plywood plates, 12 mm thick, the bottom of the body is cut from six-millimeter plywood.

Cabin. Its side walls, front and back is made of plywood 12 mm thick, roof and details the driver’s seat — six-millimeter plywood. Items like the cockpit and the body are going to glue (casein, carpentry) and the round plug-in thorns — shkantah Ø 6 mm.

The hood of the engine. It will require a six-millimeter pieces of plywood, small nails and glue. The headlights and the radiator cap are made of pieces of round rods.

The cabin is joined to the frame with glue and dowels, the hood is attached directly to the frame n cab.

The final Assembly, note the ease of rotation of the wheels, winch lift and the axis of the body; if they turn in the corresponding bearings are not sufficiently fluent, then have the hole, providing a guaranteed gap.

If the details of the car are made carefully Assembly is made cleanly, without streaks of glue, then paint the truck should not be, better to cover it several times with varnish, pre-tuskuru the joints. Varnishing should be, removing the pre-the body, wheels and the winch lift.