Where not only apply to refrigeration units today? And with all their diversity they all have the same weak point: if you acted up or broken-down engine, have to replace the entire cooling unit, since the casing is usually made all-in-one welded.

Where not only apply to refrigeration units today? And with all their diversity they all have the same weak point: if you acted up or broken-down engine, have to replace the entire cooling unit, since the casing is usually made all-in-one welded.

Young innovators sengileevskogo the district office of agriculture of the Ulyanovsk region showed NTTM-78 portable unit. They made it out of the ordinary, standard FGR-0,35. Before beginning repairs, they clamp Assembly directly in the casing in the cartridge lathe cutter and cut the seam welding, opening the case, like a tin can. To clamp in the Chuck jaws apply the inverse with extended jaws, and the other end biasing the housing revolving tailstock center of the lathe.

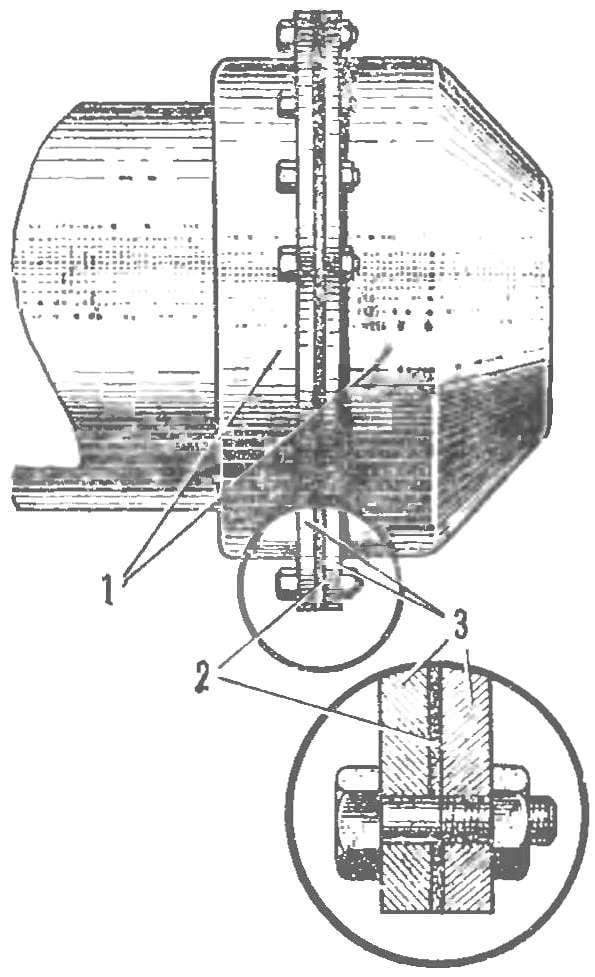

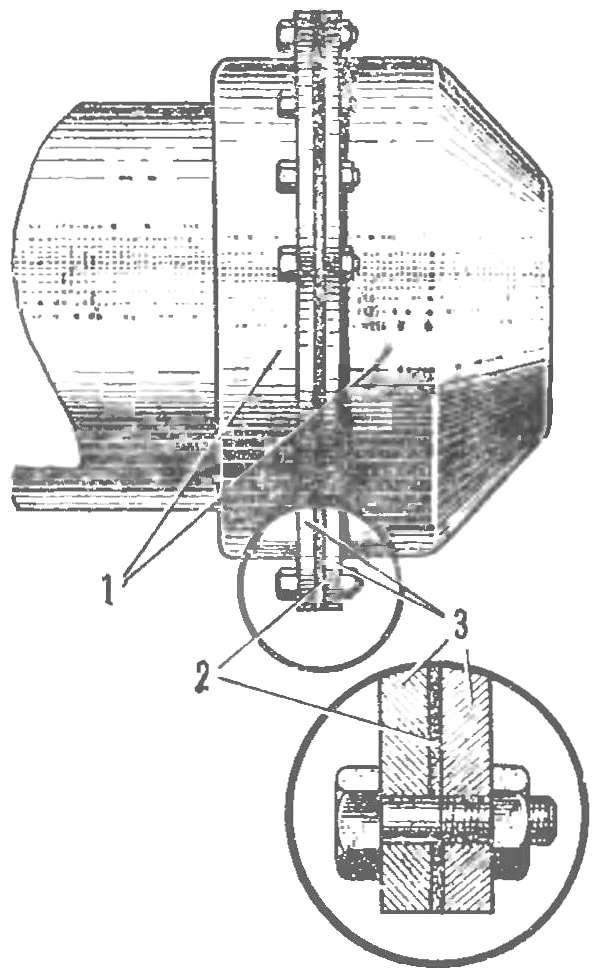

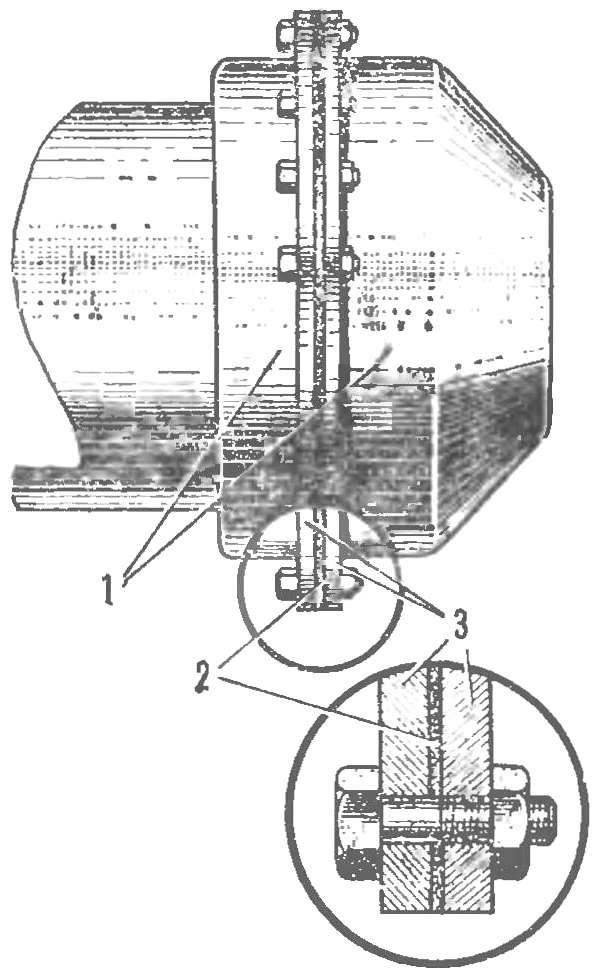

Flange hadagreed:

1 — detachable part of the casing 2 — paronitovye gasket, 3 — flanges.

Both parts of the opened casing welded flange external Ø 270 mm and internal 210 mm, made of steel with a thickness of 8 mm. In them in a circle Ø 250 mm drilled 24 holes Ø 3 mm for tightening bolts. Sealing is achieved by installing between flanges Parasitology strip.