The main components

A chair is a bundle of two main components – the wooden frame and soft pillows. Both components can be produced and used independently, separately, which also provides additional facilities. From the figures it is evident that a wooden frame is placed a soft mattress, consisting of two interconnected cushions: seat and backrest.

Frame

On closer examination it is seen that the frame of the chair consists essentially of four independent frames, two side walls, the seat and backrest collected from boards in the thickness 20 mm. the first three are connected rigidly, by inserting wooden pins and screws, forming a strong design base, and the frame of the backrest attaches to the seat frame on hinges that allows you to install it quite freely, being able to change the angle (by what means – will be considered separately).

Sidewall

Essentially, their frames are simple rectangles, the horizontal part longer than vertical. They are connected to each other using nails glue (casein, wood, PVA, “Time”).

In the rear part of the frames, just below the middle, there are notches for attaching the seat frame.

Above them on the horizontal part side (the outer side) are attached to a metal comb, which

can move the supporting metal rod of the back while changing its inclination.

In the front part of the sidewalls at the rear cutouts are counter cutouts for the support bar to the seat frame, since the latter extends slightly forward beyond the frame sidewalls.

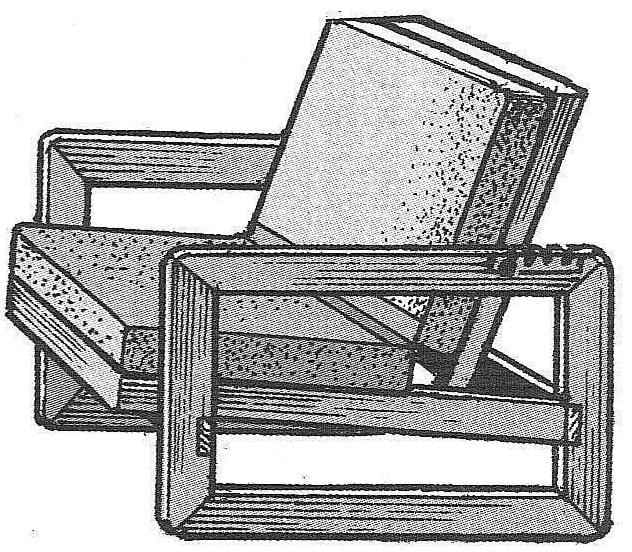

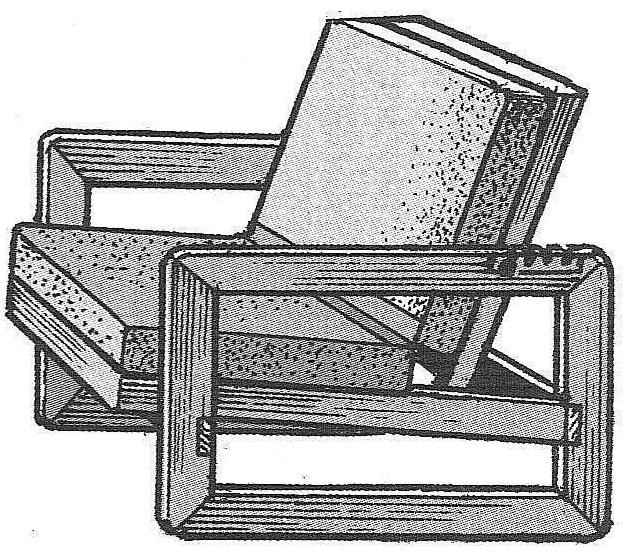

Fig. 1. Easy chair with variable inclination of the back:

1 – side; 2 – the frame of the seat; 3 – collector; 4 – slit panel; 5 – a clip (rod or tube); 6 – frame of the backrest; 7 – lathing; 8 – the bearing Seating; 9 – rear screed sidewalls; 10 loop (2 PCs.)

Seat

For the manufacture of its frame, you can use boards narrower section 60×20 mm, combining them together in position “on the edge”. They are joined by means of screws or plug-in round thorns. The rear strap of the frame is longer than the front speakers its ends can be embedded in the rear side panels. And the front part for convenience extends slightly beyond the edge of the sidewalls without connecting with them: it supports embedded in them strong bar.

In the rear of the frame (with a small indentation ahead) there are two fortochnyh loop for connection with a back.

Back

Its frame is also made of boards section mm 60×20, unlike the others it is not closed: its lower ends are not interconnected and are mounted on the hinge side of the seat frame.

In the middle part of the back on the sides vypressovyvaetsya elongated slots, patch reinforced metal plates with the same longitudinal holes (slots). In the grooves of the back is inserted a metal rod (or tube) with a diameter of 10 mm and a length more than its width: it is a latch angular position of the backrest – its ends are in the corresponding socket of the comb on the side of the chair. For convenience, the ends of the clip are closed by suitable plugs.

Fig. 2. Dimensions of chairs and dimensions of its parts

Crate

Since the chair is supposed in a soft way, i.e. using the invoice part of the pillows, need the seat and backrest can be further developed to cover them infrequent crate of bars cross-section 30×15 mm. They are located mainly at the place, with gaps between them on their widths. The back of the seat (at the back) remain open.

To the frames of seat and back slats are attached with screws VPO-Ty, for which the upper part of the holes under them respectively razzenkovyvajut.

Pillow

Their role can perform the appropriate (or altered) from the existing old folding furniture. But it is easy to make and a new, specially adapted to the dimensions of the frame of the chair. Appropriate technology is repeatedly published in the magazine.

As a rule, it uses a dense fabric – like drapery or furniture upholstery, and foam, as the most accessible soft material, usually offer furniture or hardware stores. Of course, the more suitable the latex: it’s not as pressed and lasts longer, but less accessible for independent use. In a pinch you can use cotton mattresses or old blankets, and fans of design will accommodate extreme and there are now all kinds of inflatable products (rubber or plastic).

Fig. 3. Soft cushion chair:

1 – seat; 2 – back; 3 – a fabric “loop” pillows

The dimensions of the cushions should meet the dimensions intended for these parts of the seat and backrest.

Be interconnected pillows come in zippered or a simple cloth loop.

Assembly chair

The sequence of manufacturing and Assembly of the elements of chair has its own peculiarities, dictated by the characteristics of the structure itself.

Better to start with the sides, because they tied the accession of other elements. Therefore, after assembling each of them runs training just places bundles with seat and backrest. To do this, first set (on the screws) combs. Then in their grooves, as the conductor, round by bastard a file prepared transverse grooves for rod latch backless. Remains to saw through grooves under the heel of the seat and the supporting bar – and sides ready for Assembly.

Seat frame is simple, only the back part out dimensions for insertion into the corresponding slots of the sidewalls. Stepping back from her for about a quarter of the length, fasten the loop to the back, and then – plank sheathing.

You can now perform the first stage of Assembly: connect the side support beams, and in the rear of their slots to enter the back seat. All connections – glue (or carpenter’s casein, PVA or “Moment”), with gain screws.

As already mentioned, the frame of the back is not closed, but thanks to the crate, she gets the necessary rigidity. Previously in her side, about a third of the length from the top, using a drill and round file dracevo are longitudinal cracks and are reinforcing their false plate with similar slots, then enter the rod-locking position of the backrest. It remains to connect the bottom of the back, with hinges on the seat and the seat base is ready to accept parallel produced soft pillows. For greater aesthetics, all wooden elements can be covered with light or dark furniture Polish – in several layers, with careful intermediate drying and polishing.

As already mentioned, the pillows are made separately: it’s easier to fulfill them “stuffing” and the case, and later knock them out or cleaned from a dust, to wash. But to use the chair more comfortable, of course, that they were connected. The easiest option is to sew a fabric at the junction of the “loop”. However, because of these operational conditions it is better to connect the cushion with the aid krupnouzlovoj plastic zippers that are used, for example, on sports jackets and Hiking gear -if necessary it may be easily disconnected from each other, and then, on the contrary, easily connect again before placing them on the chair.

B. RAWSKI

Recommend to read WITH A ROPE in the construction of garden houses, flooring, poloa often ispolzuyutsya shields composed of slats or strips. To ensure a snug fit to each other by using a simple device consisting of... THE FLASHLIGHT FROM THE DETECTIVE All flashlights have a reflector giving a wide enough beam of light. But if you want a point — for example, the light pointer of the lecturer? Narrow beam, as if from hidden lamps in...

It will look good not only in the countryside but in a city apartment, featuring special convenience and originality of design (in addition, it is available for self-production). The fact that this easy chair has compared to other similar one is undoubtedly the winning advantage: the position of the backrest can be changed, giving it the most comfortable for you angle. Let us consider by what means this is achieved.

It will look good not only in the countryside but in a city apartment, featuring special convenience and originality of design (in addition, it is available for self-production). The fact that this easy chair has compared to other similar one is undoubtedly the winning advantage: the position of the backrest can be changed, giving it the most comfortable for you angle. Let us consider by what means this is achieved.