In various treatment machines, cleaning the role of the washcloths make circular nylon brush. But making nylon circles and repairs them after wear synthetic bristles — a difficult and time-consuming. It is therefore understandable the interest that was involved in one of the sections ENEA brush original design, combining such important qualities as lignoboost and durability.

In various treatment machines, cleaning the role of the washcloths make circular nylon brush. But making nylon circles and repairs them after wear synthetic bristles — a difficult and time-consuming. It is therefore understandable the interest that was involved in one of the sections ENEA brush original design, combining such important qualities as lignoboost and durability.

The base of the brush consists of two connectable sleeve half circle of Seating and clamping. Their edges form a circumferential groove. In it, the circumferential belt, seamed nylon strands and pressed when the coupling of the two halves of the circle, yarns of the same cut at the desired diameter.

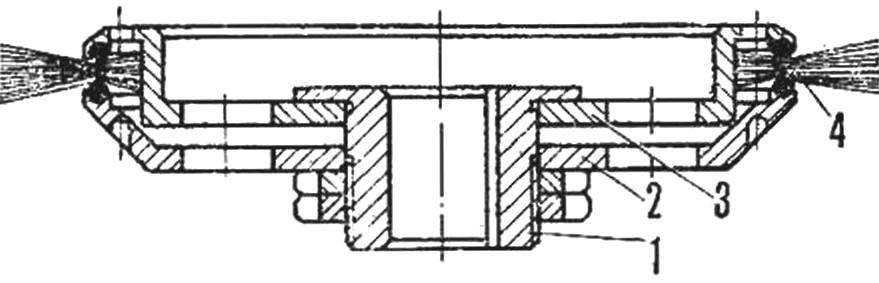

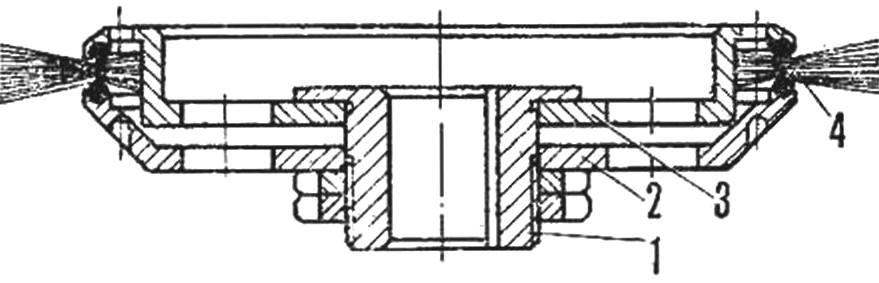

Team nylon brush:

1 — make sure that the coupling nuts, 2, 3 — Seating and clamping of the half circle, 4 — nylon thread.

The consumption of nylon in a brush is reduced by half. And she wears less. The fact that the pressure range has 12 inclined holes drilled at an angle of 15°. They sucked during the rotation of the air and drive it into the working area, which is six to seven times increases the durability of the brush.