Now many people believe that amateur construction enthusiasts have disappeared from our lives. Forever, they say, they remained in Soviet times. This is a completely wrong opinion. Yes, today there are no structures supporting DIYers and modelers, as there were before. Numerous previously state-funded clubs and clubs have closed, the regular exhibitions of Scientific and Technical Creativity of Youth (NTTM) in the past are not held, and there is no television program similar to “You Can Do It”. Nevertheless, there are plenty of people who want to engage in technical creativity! But where to start? After all, today’s youth – the Unified State Examination generation – didn’t even have labor lessons at school…

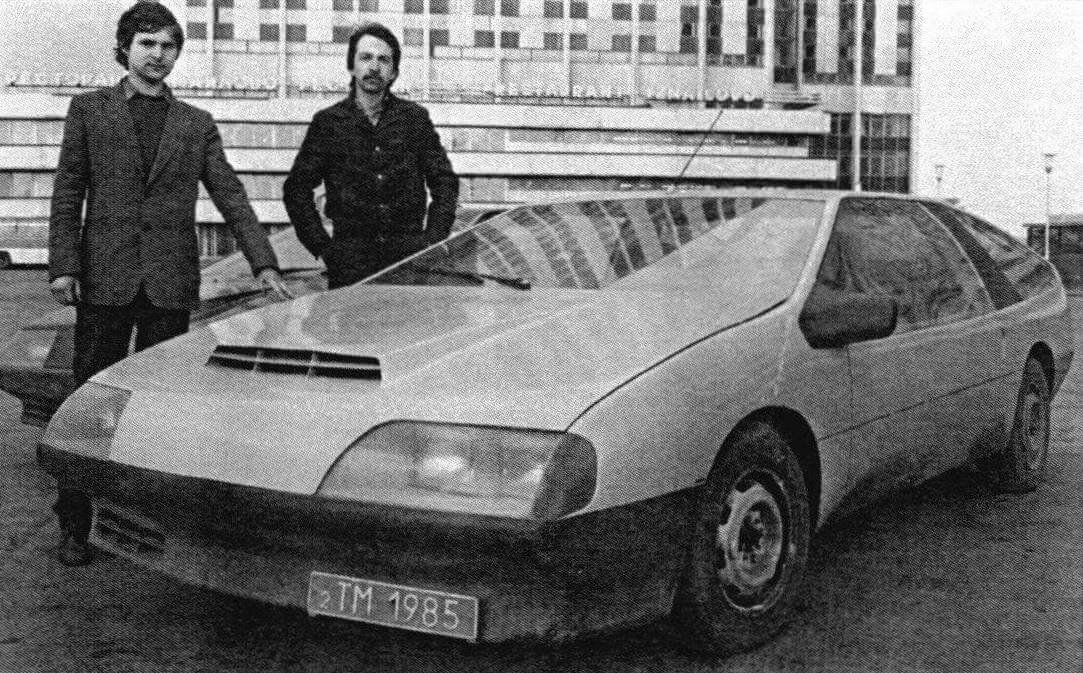

The “Commandments” brought to your attention were written quite a long time ago. Their author is a famous Moscow automaker, the creator of the once sensational Minimax car, Candidate of Technical Sciences P. S. Zak. However, his recommendations, which have not lost their relevance to this day, will be useful to all beginning amateur designers who are just planning to build a homemade car, all-terrain vehicle, airplane, walk-behind tractor or something else.

So, do you want to know where to start?

The ultimate goal comes first!

Usually they start with the immediate goal: I want to make “like this” car! They don’t think about their ultimate task. But sooner or later it will reveal itself and most often – halfway, when a lot has already been done… The classification of homemade people will help you understand yourself.

Simplified . He proceeds from the common misconception that making is “cheaper than buying.” The sooner you realize that this opinion is wrong, the less money and effort will be spent in vain. A special category of simplifiers – often unskilled – is trying to make a “real” car, that is, indistinguishable from the factory one. The sooner they understand that the car plant cannot be surpassed, the cheaper this vain desire will cost them.

Maximalist . This can be called those who certainly dream of impressing others. Make it so that no one has… A prestigious car! So that in form it must be super sports, or in content it must be computer-integrated and automated. As a last resort, at least with retractable headlights, a TV and a stereo color and music center!

Individual . This is someone for whom commercially produced designs are not suitable. These people need a special-purpose vehicle: an all-terrain vehicle or an amphibian, a self-propelled dacha, an original city tricycle or a jeep tractor.

Creator . A person who “can’t help but do.” He gets satisfaction from the creative process itself. In the extreme, it’s even like this: it’s enough to do, but there’s no need to drive.

So who are you? Do not feel sorry for yourself in self-determination. This will help save labor and time.

Be puzzled!

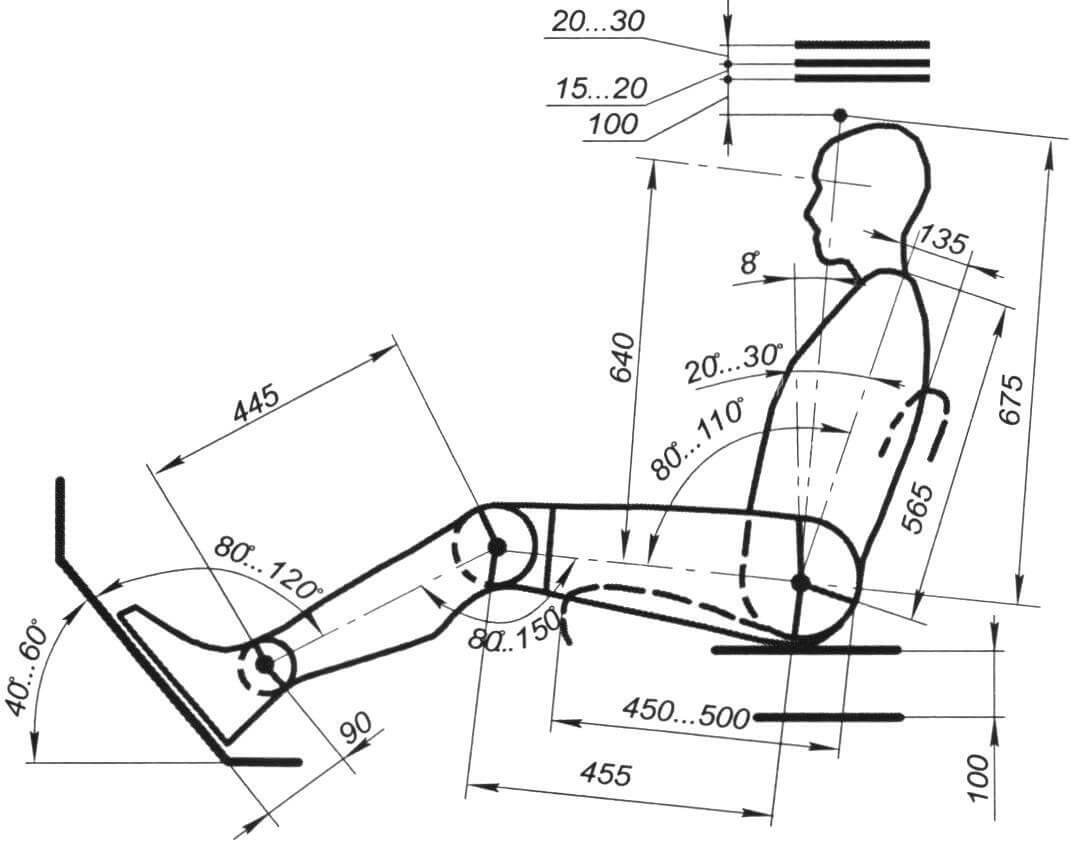

Take courage and throw down on paper the main characteristics of your dream: purpose, capacity and load capacity, speed, engine type, layout, chassis, dimensions and weight. Date it and put it away for a while. After a week, try to compose the second option. Then the third… The seventh…

At the same time, it is recommended to “splash it out”, even if at first you don’t feel like you’re ready for it. Also D.I. Mendeleev argued that any hypothesis is better than none. In the end, instead of the wrong one, another, more correct one will appear. Over time, its fallacy will become apparent. This process is endless. But each new hypothesis is usually better than the previous one. And here the developer needs common sense to stop in time, because the point is not in the constant search, but in the result.

Don’t take what you can do without

To be honest, miracles captivate everyone. But such fundamental qualities as cross-country ability, capacity or maneuverability can also become extraordinary. Or secondary ones – for example, automatic control of the engine and gearbox, body heating or, say, ground clearance.

Do not overload the project with an abundance of “tchotchkes”; behind them the main concept of your design may disappear. As soon as you sense signs of such danger, make a list of what you want to see in your creation. And then write down from there what you can’t do without. The result should be a list containing the necessary set of “miracles”.

Divide the rest into two parts, and find the strength to forget the larger part forever, leaving only what can be done later, after the created unit has moved. The moving structure will ask new, as yet unknown questions. Taking them into account, make a list of improvements in order of importance. And, generally speaking, everything is much more visible from the seat of a completed car!

If you can’t do it, don’t do it!

Before you take on direct work on the car, it’s time to once again evaluate whether your desire is worth the gigantic work to which you are dooming yourself. And how many unforeseen disappointments will still be encountered on this difficult path!

Maybe it’s still easier to purchase a ready-made design? And if you just want to tinker with hardware, buy some old Moskvich. If this is not the case, then we sincerely wish you success and courage – you are joining the free brotherhood of home-made workers.

The devil is not too much and not too little

One extreme among do-it-yourselfers (primarily engineers of various specialties) are “draftsmen.” They draw general views, then – options, develop designs for almost all components and parts. As a rule, this is due to the fear of taking a hacksaw, drill, hammer or chisel.

The other extreme (usually humanitarian workers and drivers) are “tweavers”. They will build the bridges, put the longitudinal profiles on them and begin to weld the cross members. Then it turns out that the engine does not fit there. The “tweavers” are not shy about redoing them several times. And having completed half the work, they sometimes find themselves faced with an insoluble problem – the intended design does not work out. It’s even worse when you have to “dress” a ready-made chassis into a body that is not designed to fit the “figure”… It’s unlikely that anyone will like such a car.

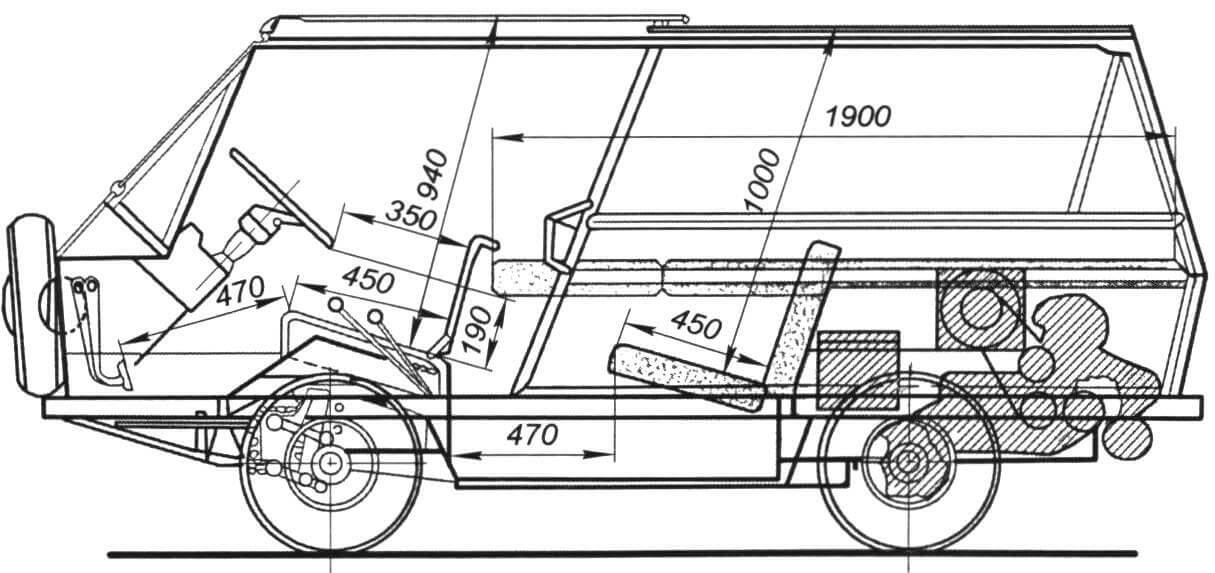

As usual, a reasonable middle ground is acceptable. A layout on a scale of 1:5, a general view in three projections, a plaza drawing (preferably in full size) and a three-dimensional model on the same scale – this is the first initial minimum. Moreover, the model is necessary here to the same extent as the drawing. It is imprudent to limit oneself only to the general appearance and layout.

When creating nodes wherever you can do without drawings, it is better to do it locally, if necessary, cutting out templates from cardboard. If you can’t do without drawings of the units, do them 1:1. The 1:2 scale is the most deceptive, get used to using only two – 1:5 and 1:1. True, the general view can be drawn at 1:10, or even 1:20. It makes sense to prepare detailed drawings for parts only if you have to order them somewhere.

And the home “car factory” needs a director!

First of all, “production” needs to find a room for work. It should be separate and… warm – no work in the cold.

The main machines should be a workbench with a large vice and an electric drill. An electric abrasive cutter will also be a good help. Don’t skimp on tools. But don’t follow the example of those who switch from building a car to collecting all kinds of devices, creating a kind of museum of tools. As soon as it turns out that it is easier to buy the necessary key in a store than to find it in your “bins”, this will mean that the farm has exceeded the “critical mass”, and it is time to mercilessly reduce it. Keep your existing tool ready: it’s no longer the case when you need a chisel, but it’s dull, and you take a drill, but it’s chipped.

Basic materials – both profiles and sheets – must be prepared in advance. You can, of course, allow yourself to interrupt the process in order to get some special material or fasteners, but it’s still better not to waste working time on this. We must value the rhythm of work and not be distracted by “plugging holes” due to organizational troubles. If you work not alone, but with two or three of you, this is even more important, because collective downtime is much more expensive.

Model and layout!

The appearance of the car is a great thing. And it’s not so easy to work it out. But your design will move next to modern machines, on which not only engineers, but also designers worked. They made dozens of models, including life-size ones. And it would be a good idea to follow their example. Having finished your model, look at it with a strict “outsider” eye. Show it to knowledgeable people. Make the second option, and maybe the third. The appearance, essentially, can only be worked out at this stage. Then it will be too late.

Then it is advisable to take on the life-size model. You can insert ready-made components into it that you plan to use: the chassis (suspension – front and rear), engine with gearbox, steering, seat, front window, etc. The body is reproduced in wood and cardboard. The slats imitate profiles, plywood and cardboard imitate cladding.

The model is necessary to clarify the relative position of the components, the placement of the driver and passengers, checking the ease of boarding and disembarking, approaches to servicing the engine and chassis, and in general it allows you to visually experience your future creation.

Layout also serves as a powerful tool in creating individual nodes. They are preliminarily reproduced in the form of profile templates, longitudinal and transverse. One, quite characteristic, may be enough to try on.

Four pillars: design, technology, finished components, materials

When creating any unit, you can, of course, proceed from purely design considerations: make it functional and durable, with minimal weight and dimensions. And for this design, select the appropriate technology and materials. However, the do-it-yourselfer, even more than the factory engineer, needs to provide for the possibility of realizing his idea. After all, he is his own supply department, technologist, and worker. Therefore, the homemaker has a special criterion for optimal design.

It is not a sin to borrow parts that are difficult to manufacture. For example, springs or suspension springs. And they will immediately determine the design of the entire assembly. You can put the material that, for some reason, is more accessible, at the forefront of optimization.

The “four-pillar” stability of the DIYer lies in the flexibility of using the “pillar” that facilitates the creation of a given unit, shifting the center of gravity of the work to the strongest (in solving a given problem) support.

The main thing is to have the talent of a “finisher”!

Even the most powerful desire is no stronger than ineptitude. But what if you don’t have plumbing skills? There are two ways here. It’s simpler to put together a company in which specialists would complement each other. And it’s harder, but gives independence – to gain the necessary qualifications, which is better to do also under someone else’s leadership or together.

There is another factor, no less important. This is consistency, character and will, forcing you to make an effort when physical and moral fatigue overcomes you. Oh, how many weak-hearted people gave up their work halfway… But what satisfaction you feel after overcoming temporary weaknesses! Having achieved a goal, you get not only a direct result, but also a feeling of joy of victory over yourself. And this, perhaps, will be the most important reward.

Remember safety precautions

When working on your creation you will have to perform various technological operations. Some are unsafe. At production there is a special safety service, but here it’s just you. A circular saw or abrasive cutter can even cut off a finger. The sharpening machine should be left without an eye, heavy units should be pressed down. What about fire hazards? This is all very serious.

No less important are safety elements in the design of a homemade product in case of an accident. The placement of the gas tank, the protection of the driver and passengers by the body structure from impact or rollover are issues of so-called passive safety. But factors such as visibility, brakes, and steering also have a direct bearing on safety.

Given the vital importance of these issues, it is not enough to keep them in mind. State your weak points on paper. Find the strength in yourself to beware in time if some requirements are not met, or even to abandon a scheme, layout or design solution that does not provide adequate safety. In such a case, “perhaps” can end badly.

Respect “epoxy” to the point of fear!

Not everyone knows that production, where products are glued from fiberglass with epoxy resins, is classified as particularly harmful, and there is usually special supervision over compliance with safety regulations: areas are equipped with forced exhaust ventilation, and automatic devices with recorders monitor the content in the air harmful and poisonous gases. You cannot create such conditions at home, and many are not even aware of the danger of serious illnesses, including lung cancer.

At the same time, in terms of mechanical properties, some similar materials – for example, polyester resins – are not much inferior to the insidious “epoxy”. By the way, parquet varnish is also quite suitable.

You also need to be careful with fiberglass, because the smallest particles of its fibers penetrate into the skin of your hands and into the respiratory tract. Acceptable substitutes are cotton fabrics, percale, canvas or fairly durable synthetics.

It’s not just fashionistas who need to lose weight

Already in principle, a homemade moving structure is heavier than a purchased product. This inevitably manifests itself due to the fact that the load-bearing body is too complex to calculate its strength. In industry, testing the optimal version of the “strength-lightness” dilemma is carried out experimentally. A do-it-yourselfer cannot do this. He has to either separate the functions of the body and frame (which leads to almost doubling the mass of this complex), or deliberately overweight the body. For this reason alone, such a device will be 20-30 percent heavier.

Practice shows that if you do not specifically monitor the weight of each part, then the homemade product turns out to be one and a half times (and sometimes more!) heavier than a factory-made machine of the same class. And this means increased fuel consumption, worse dynamics, and lower load capacity.

Petr ZAK, Ph.D.