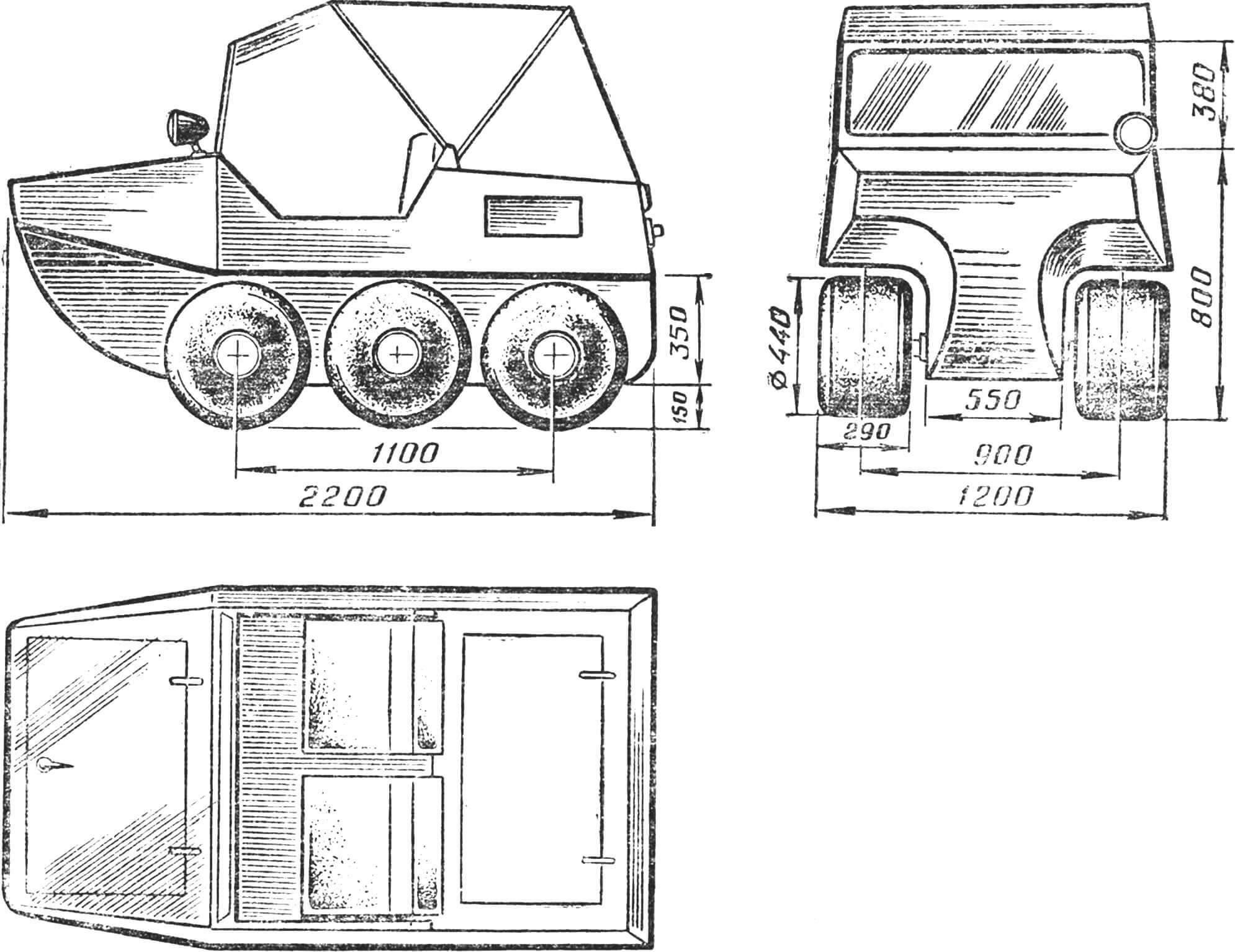

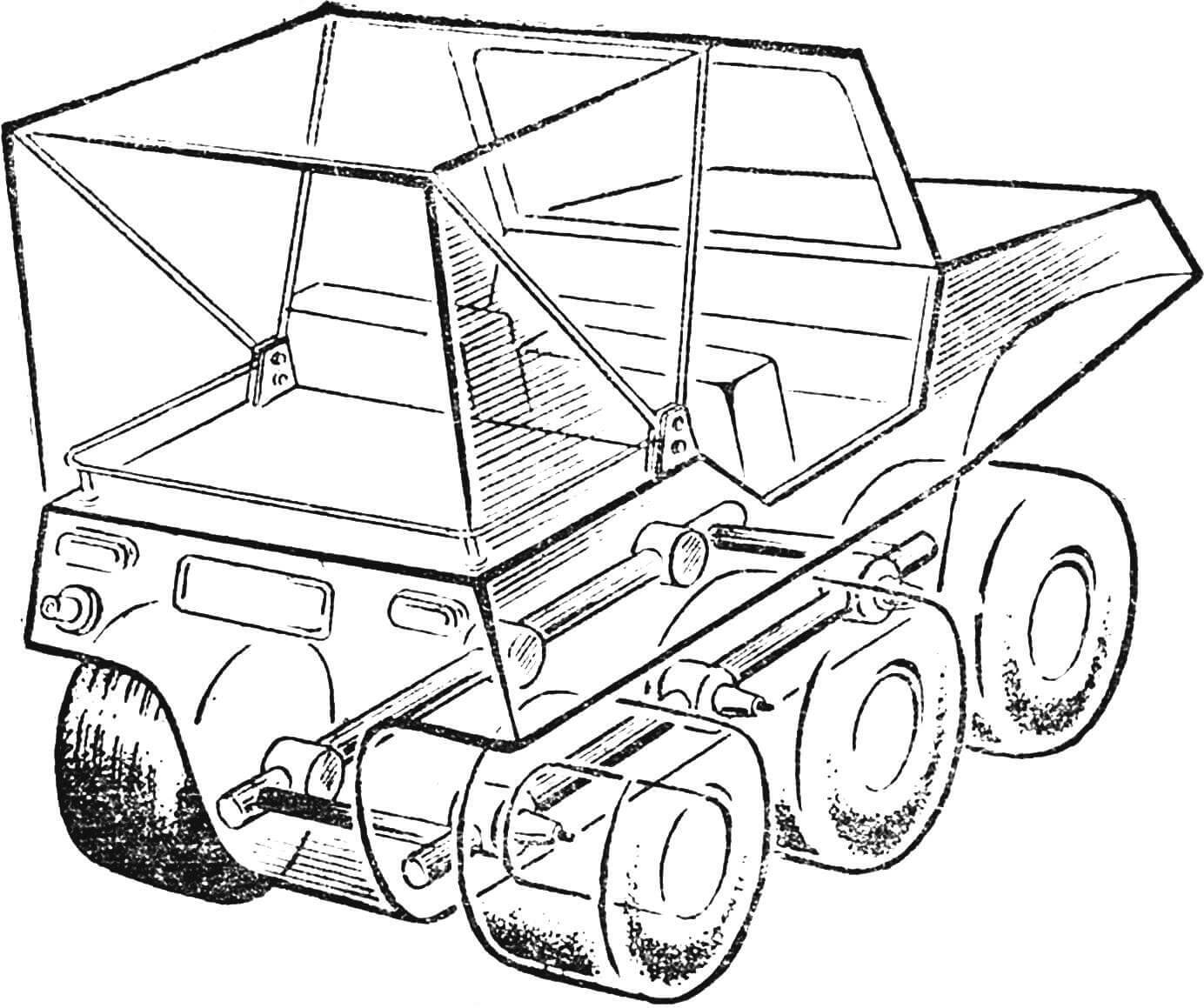

The amphibious all-terrain vehicle was built over five years and first left the garage in 1969. Traveled more than 1000 km. Tested on rough terrain, on snow, on water, on marshy, sandy, clay soils. Tests have shown that the vehicle’s cross-country ability is almost universal.

Dimensions – 2200×1200 mm. Weight – 200 kg. Maximum speed (on asphalt) is 45 km/h. Frame – tubular (50X2), welded (electric welding). The body is duralumin, sealed, riveted. Engine – IZH-56, single-cylinder, 350 cm 3 , with forced cooling, 12 l. With.

Ignition is combined: from the alternator and from the battery. There are two cams on the motor shaft, and two breakers on the housing. Both work independently of each other. If one fails, a backup will replace it. DC breaker (battery powered) – with manual advance adjustment. Winding is manual, using a sector lever with a cable. A selenium rectifier is used to charge the battery.

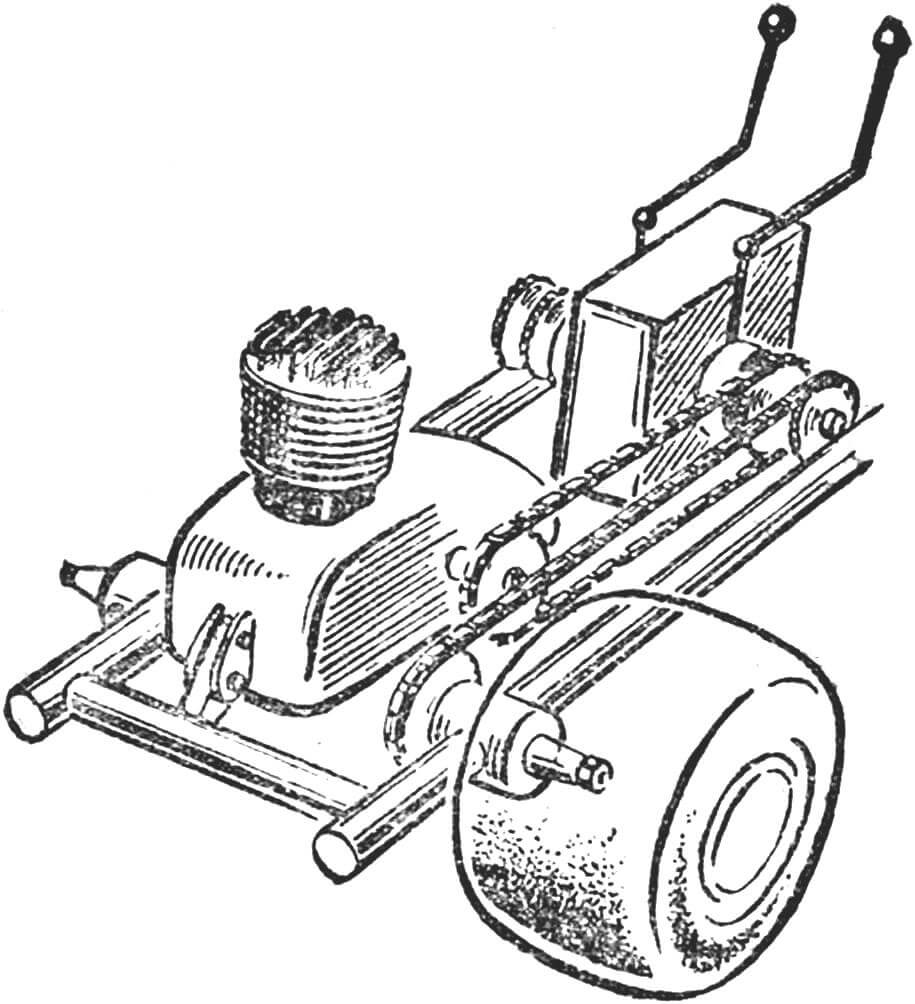

The transmission from the motor to the wheels is a chain transmission through a differential or clutches from a motorized stroller (or a cargo scooter). In the first version of the all-terrain vehicle, all wheels are driven, turning is done by braking the wheels on the left or right side. In the second – four wheels are driven, the front wheels are steered, and the turn is rack and pinion control from the C3A. Now work is underway on the third option: all wheels are driven, control is lever, turning is turning off (via clutches) the wheels of the left or right side.

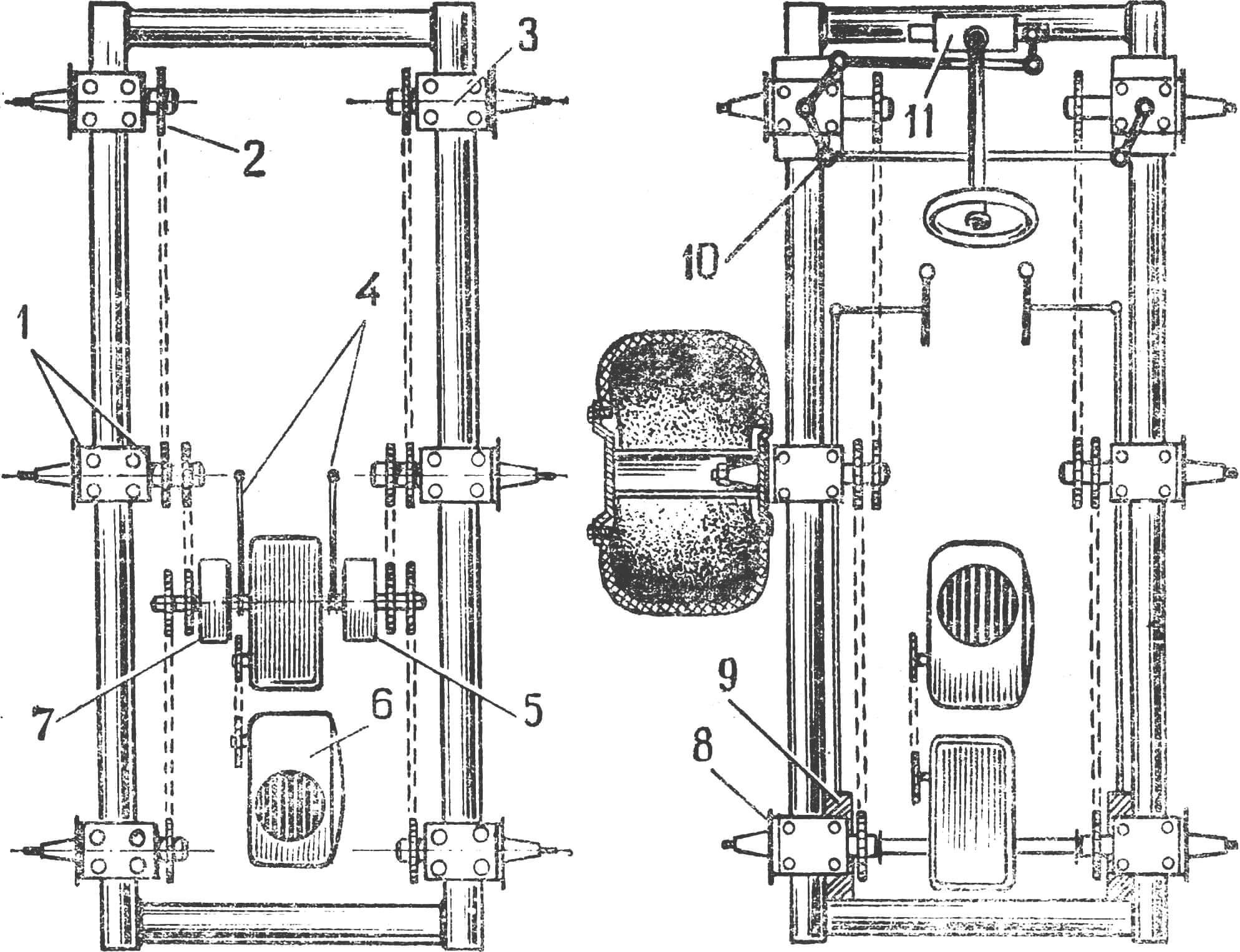

1 – hub, 2 – driven sprocket, 3 – hub, 4 – control levers, 5 – clutch, 6 – engine, 7 – clutch, 8 – hub, 9 – brake device, 10 – tie rods, 11 – steering mechanism.

Wheels – hubs with N205 bearings, can be used from a motorized stroller or a cargo scooter. Tires – wide-profile, low pressure, homemade. Tire diameter – 440, width – 290, internal diameter – 130 mm. The pressure with one driver in the front tires is 0.15 atm., in the rear tires – 0.1 atm.; with driver and passenger and front and rear – 0.15 atm. Tires of this type eliminate suspension from the structure, provide high maneuverability and (together with a sealed hull) reliable buoyancy.

Materials for making tires – raw rubber (substandard), sheet, 2 or 0.9 mm; rubberized cord, aviation gasoline. The technology is conventional (factory), transferred after a series of experiments to homemade equipment. The mold is machined from duralumin to the shape of a wheel. The vulcanizer is electric, made of an iron barrel, with 3.5 kW heating elements. The vulcanization pressure is 6 atm, the temperature is 147°.

N. KORCHAGIN, mechanic