Innovators of the Sumy machine building production Association named after M. V. Frunze developed high-performance grinding-machine, different from the existing compact and low weight. It makes it easier to perform time-consuming operations such as trimming welds, deburring of workpieces, the grinding work.

Innovators of the Sumy machine building production Association named after M. V. Frunze developed high-performance grinding-machine, different from the existing compact and low weight. It makes it easier to perform time-consuming operations such as trimming welds, deburring of workpieces, the grinding work.

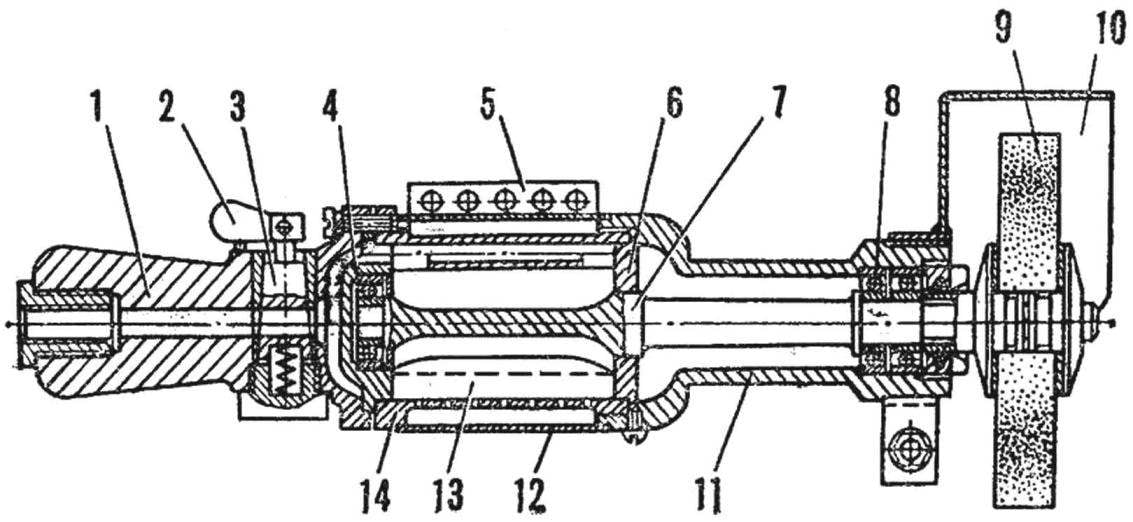

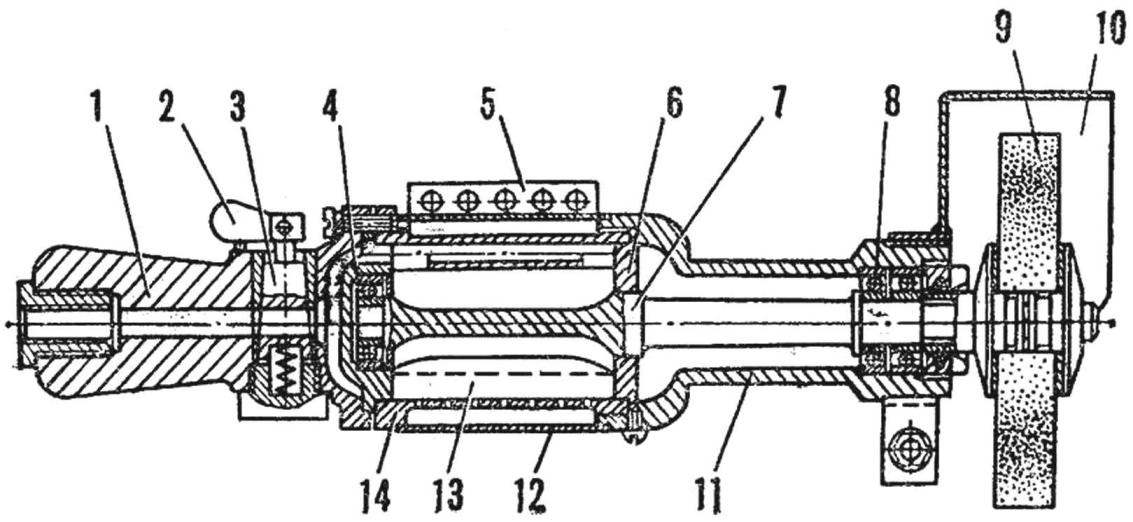

The machine consists of a casing-stator with the attached front and rear arms, which are located between the cover forming the working chamber. In the last concluded a rotor with blades, a shaft for a dual bearing fixed grinding wheel with the safety guard.

Turn on the instrument using the knob on the rear handle. When turning the rod presses the tube that leads to the compressed air: it runs along the channel of the handle in the working chamber. Closed between the stator and the rotor, the air pressure on the blades, causing the rotor to rotate, and exits the working chamber through the exhaust window and the casing, and then to the muffler. Interestingly, the window longitudinal, located at a generatrix of the cylinder of the stator with the displacement, so the air is pulled out simultaneously, which helped to significantly reduce the noise level when working.

Sander:

1 — the handle shank to the pneumatic system, 2 — driver, 3 — tube, 4, 6 — cover, 5 — damper, 7 — shaft, 8 — dual bearing, 9 — in grinding wheel, 10 — cover, 11 — crank, 12 — casing of the stator, 13 — exhaust window, 14 is the stator.

About the efficiency of the machine shows the amount of annual savings from its implementation — 9 thousand rubles Due to the ease and portability, the tool can be successfully applied even for hard to reach places in different structures and devices.