The article with the same name, telling about interesting decorative works from wrought iron, made famous Yugoslav craftsman Dmitry Petrovich (“M-K”, 1977, M 8), attracted the attention of readers. In the letters received, there were suggestions to continue this topic. For those who want to decorate your home interior crafts crochet with metal wire and steel strip, put some more designs from the book of D. p. “with Their hands”.

The article with the same name, telling about interesting decorative works from wrought iron, made famous Yugoslav craftsman Dmitry Petrovich (“M-K”, 1977, M 8), attracted the attention of readers. In the letters received, there were suggestions to continue this topic. For those who want to decorate your home interior crafts crochet with metal wire and steel strip, put some more designs from the book of D. p. “with Their hands”.

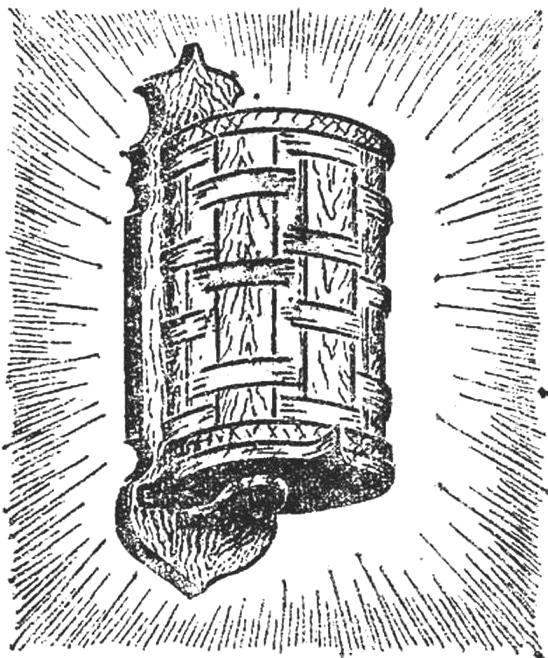

BOOKSHELF

MATERIALS. Forged (or reinforcing) rod Ø 6 mm, metal strip 10X2 mm, primer for metal, paint.

MATERIALS. Forged (or reinforcing) rod Ø 6 mm, metal strip 10X2 mm, primer for metal, paint. TOOL. Hacksaw, file, welding transformer, electric drill, drill Ø 8 mm, hammer, ruler, paintbrush.

HARVESTING PARTS. Parts of the sidewalls 1 and 2 is cut away from metal strip with a hacksaw. Edges processed with a file. If the metal thickness up to 4 mm, bending can be performed in cold condition. The workpiece of thicker material have to pre-heat and hit with a hammer on the anvil.

Details of the shelves 3 and 4 is made and the bend of the rod. All dimensions indicated in the drawing.

Item 5 for the suspension of shelves cut from a strip of metal with a hacksaw, then process a file, then drill a hole Ø 8 mm.

ASSEMBLY. All the blanks are laid out in two sets and sealed in accordance with the pattern to make two sides and two slatted shelves. The connection of the handle with a file. Then the parts are welded together shelves and shelf ready. All surfaces are meticulously primed and coated with paint of any color.

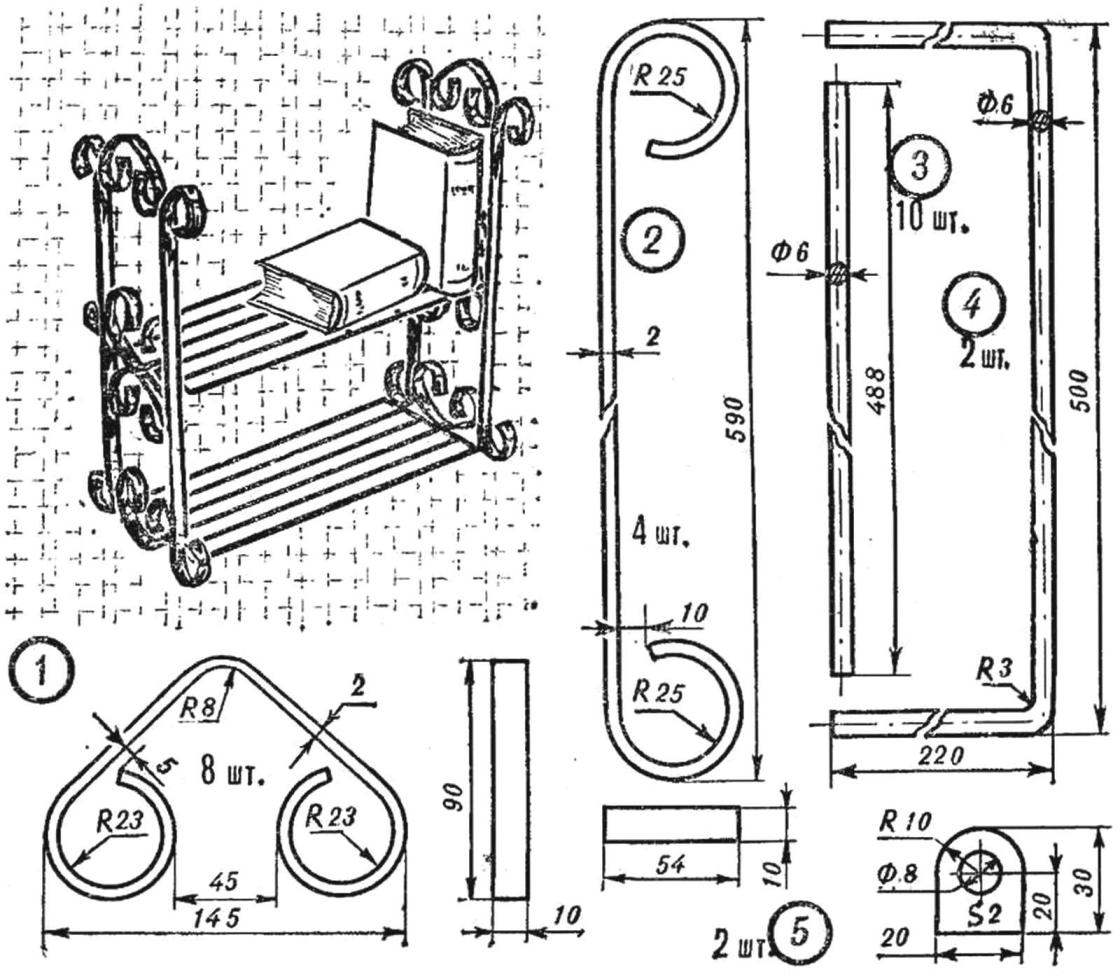

STAND FOR NEWSPAPERS AND MAGAZINES

MATERIALS. Forged rod Ø 5 mm, a metal strip with a thickness of 1 mm and a width of about 40 mm plywood 1 mm thick, colorless wood varnish, primer and paint.

MATERIALS. Forged rod Ø 5 mm, a metal strip with a thickness of 1 mm and a width of about 40 mm plywood 1 mm thick, colorless wood varnish, primer and paint. TOOL. Hacksaw, file, hammer, pliers, saw, compass, welding transformer, mater the tassel.

HARVESTING PARTS. For details of the pens 1 take two rods with a length of 1000 mm and bend in accordance with the drawing. The base part 2 is shaped, as shown in the figure, then both edges are welded and a file handle spot welding. Part 3 (leg) is clamped in a Vice and bent with a hammer. Transverse base part 4 is cut away from the rod with a hacksaw, smooth the ends with a file. In accordance with a pattern of the required form is attached and parts of the sidewalls 5, 6. A circular plate 7 is cut from metal strip and process a file.

From plywood using a saw or sharp-pointed knife, cut into 8 strips, sanded them with sandpaper. Two sides plywood covered with a colourless varnish or linseed oil.

ASSEMBLY. To the frame base 2 welded to the cross parts 4 and leg 3, then the handle 1. To detail of side b with one end welded to a circular plate 7 and the other ends they are connected to each other and are welded to the frame base at a slight angle. After that it welded to the helical part 5 and the remaining plate 7.

Stand is painted, and in it are inserted the plywood strips.

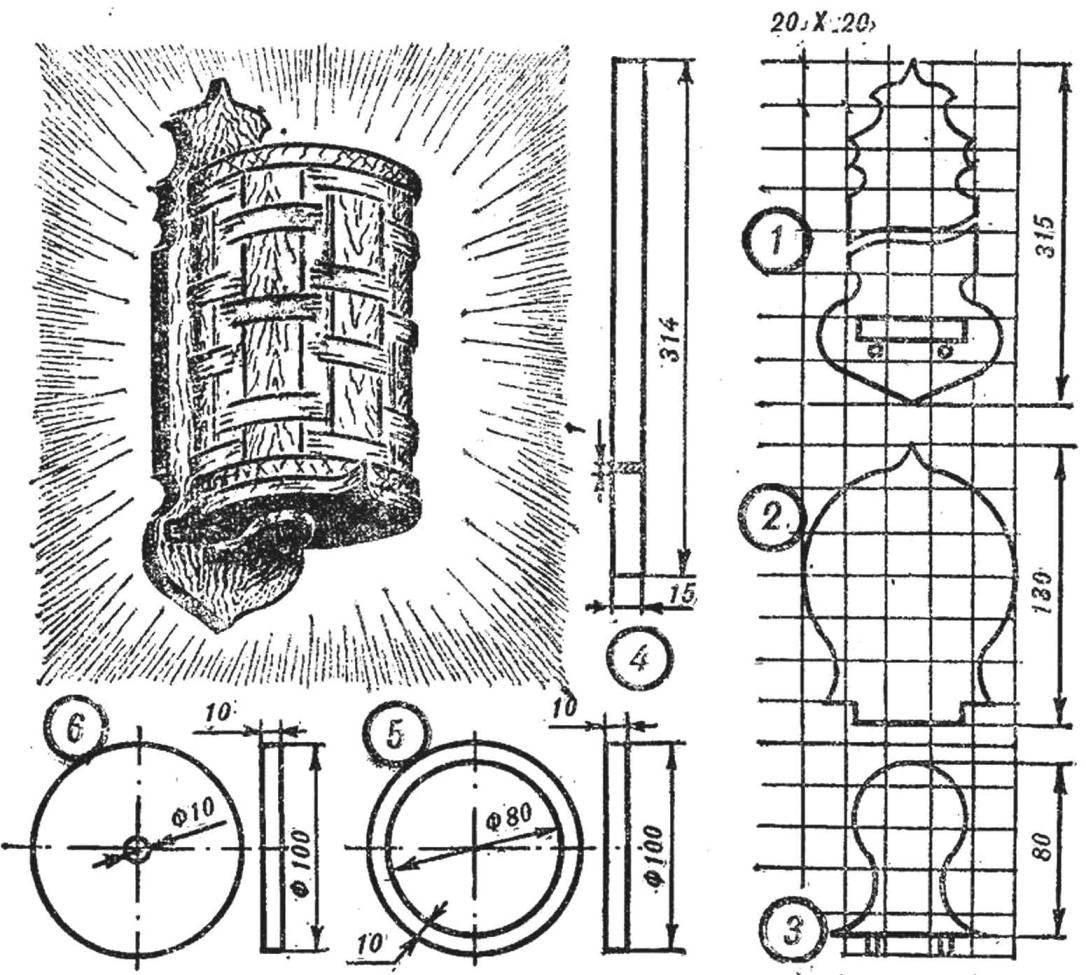

WALL LAMP (SCONCE)

MATERIAL. Thin veneer wide Board or plywood 10 mm thick, colorless wood varnish, wood glue.

MATERIAL. Thin veneer wide Board or plywood 10 mm thick, colorless wood varnish, wood glue. TOOL. Bow saw, a drill, drill bit, Ø 8 mm, hammer, sandpaper, a jigsaw, a ruler and tassel.

HARVESTING PARTS. All the parts of the bracket (1, 2, 3) are transferred to the correct scale on thin cardboard and cut out. Are templates. With their help it will be easier to reproduce the form and dimensions of parts on plywood.

If the material selected wide Board, it must first be processed a plane and sanded with sandpaper.

Parts of the ceiling 5, 6 are cut out with a jigsaw or bow saw. It should be remembered that when operating a saw should always be in relation to the Board under a 90° angle. The edges of the blanks trimmed by a sandpaper. In the geometry shown places holes. Detail of the ceiling 4 — metal band, twisted with plywood (200X30X2 mm).

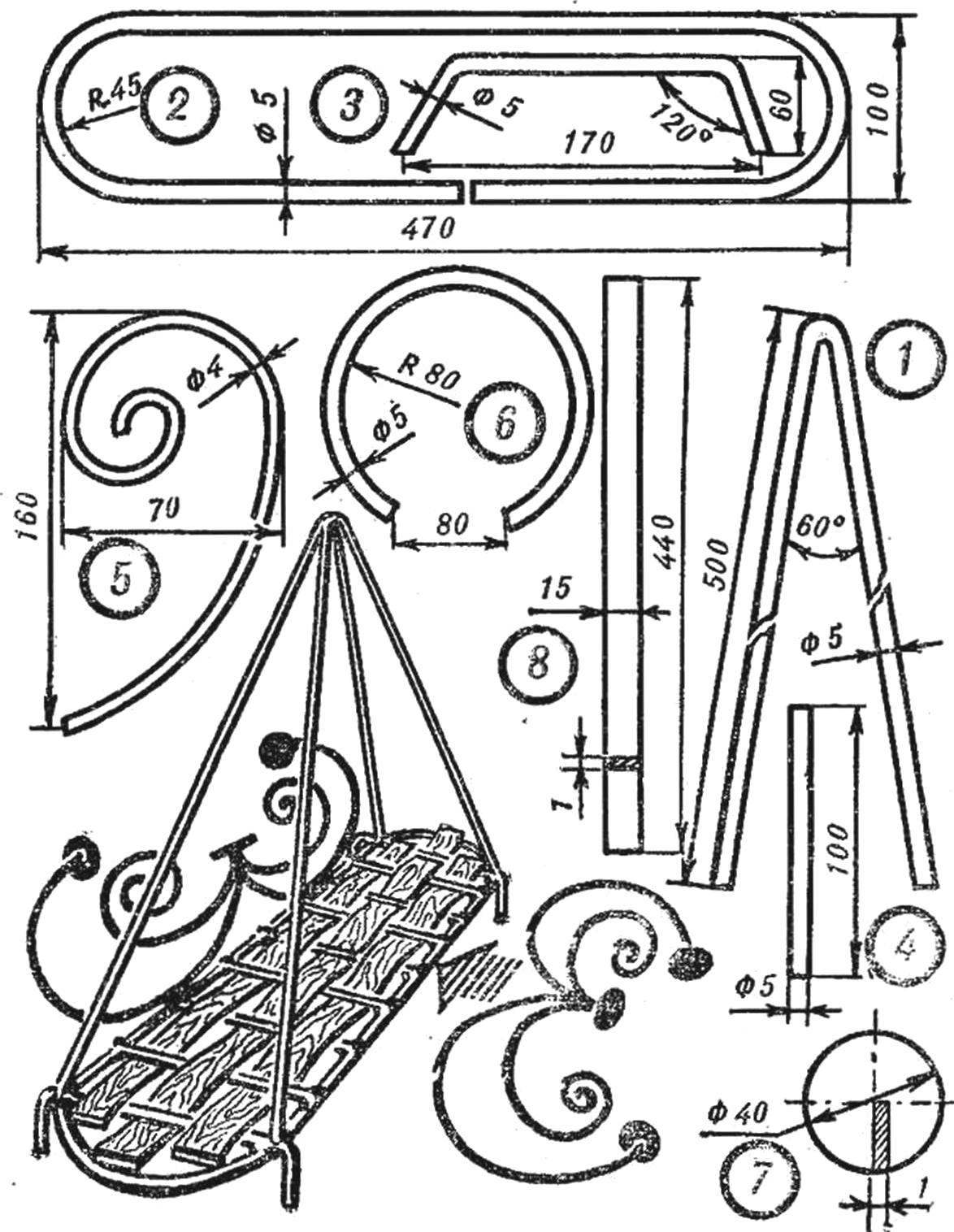

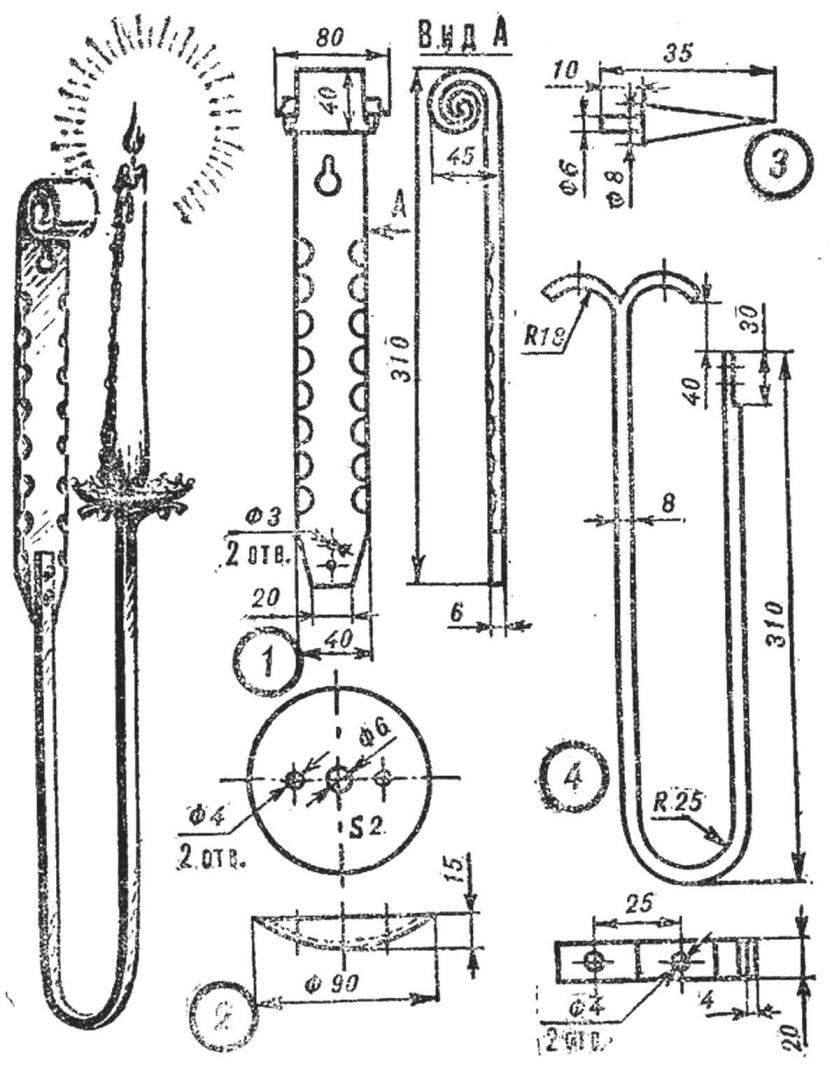

CANDLE holder

MATERIAL. Metal strip 6×40 mm, sheet metal thickness of 2 mm, flat rod, 8×20 mm, paint.

MATERIAL. Metal strip 6×40 mm, sheet metal thickness of 2 mm, flat rod, 8×20 mm, paint. TOOL. Hacksaw, half round file, flat file, hammer, drill, drill Ø 4 and 6 mm needle for markup, the core, the line.

HARVESTING PARTS. Detail of bracket 1 is cut with a hacksaw and a file is being processed. At the edge of the workpiece round file applied ornament. Then drilled holes.

Round detail 2 of sheet metal is cut with scissors. After processing the workpiece edges give the bowl with a hammer. Hole Ø 4 and 6 mm are drilled in accordance with the drawing.

Needle under a candle 3 is made with a file.

Detail of the bracket 4 — from bar 8×20 mm. One end is processed under the dock with item 1, the second into the cold or hot state is given shown in the drawing form, then drilled holes for connection with the workpiece 2.

ASSEMBLY. The Assembly of parts is done by welding or using rivets. First joining parts of the candle 2 and 3 along with part of the bracket 4. After that, everything is attached to the primary bracket 1.

Candle holder is covered with rails or dark green or red patinets.