The first thought that comes to mind is settlers after obtaining a warrant for the apartment, how to drill holes in concrete walls, what to drive screws and crutches: wooden cork or vinyl chloride tube how to attach the hooks to cement the veneer sheets? Meanwhile, there are many designs of a variety of tubes, and you will always be able to make any of them, taking into account the thickness and strength of the walls, their technical capabilities and the projected number of hooks and screws that you will need to drive into the wall.

The first thought that comes to mind is settlers after obtaining a warrant for the apartment, how to drill holes in concrete walls, what to drive screws and crutches: wooden cork or vinyl chloride tube how to attach the hooks to cement the veneer sheets? Meanwhile, there are many designs of a variety of tubes, and you will always be able to make any of them, taking into account the thickness and strength of the walls, their technical capabilities and the projected number of hooks and screws that you will need to drive into the wall.

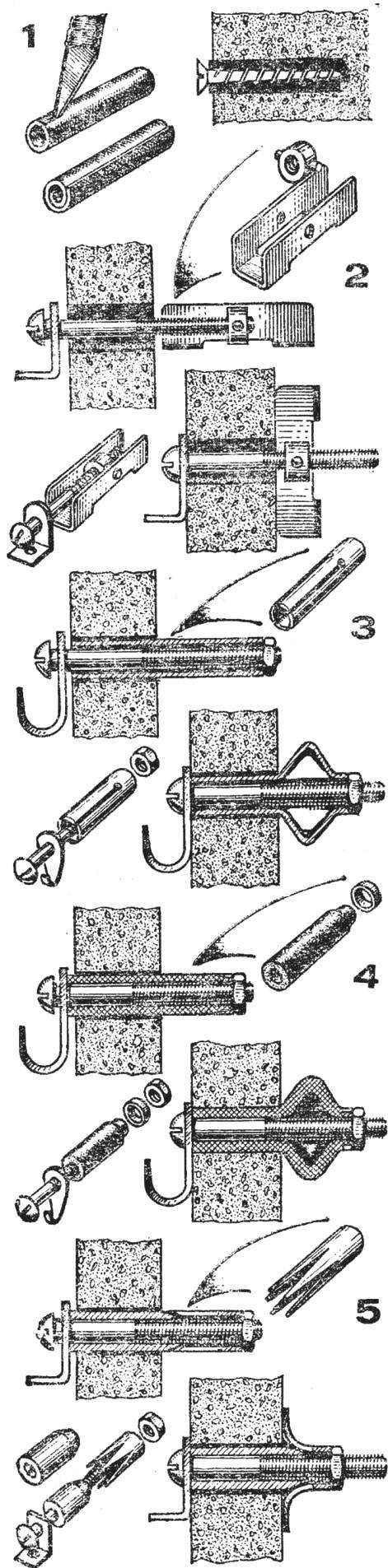

The simplest variant is known to all the wooden cork out of a dense wood. Its section should significantly exceed the diameter of the prepared hole. The tube is hammered with a hammer, then a drill thinner than the intended nail or screw, nastelivaetsya hole. Unfortunately, these plugs do not always provide a sufficiently strong fixing: the tree from time to time crack and I. it would seem that securely fastened the curtains or plates fall on your head.

Much better “behave” tube of vinyl chloride tubes (Fig. 1). The only condition is somewhat greater diameter than the diameter of the drilled holes. Note also that the screw and without the tube needs to go into it without

play — otherwise, your work will be in vain. The tube make a longitudinal slit, roll it into a tight “sausage” and insert in hole. Before screwing in the screw don’t forget to lubricate it with soap, it goes in easier.

But these tubes are only suitable for thick concrete or brick walls. For hollow same asbestos can select one of the following.

For example, such (Fig.2). It’s a long screw with a continuous thread, but the trick is not in the screw, and the bracket has a special form, a segment of the U-shaped profile with a hole drilled in the middle for the screw diameter. The nut is also quite common — it is cut out of sheet steel so that it had two “ear”. They are introduced into the holes in the bracket — the fixture is ready. Nagisetty screw on the nut, the bracket is installed along the screw and skipped into the hole. Then you can start to turn the screw as the bracket will unfold at 90°, and no forces will not be able to remove it from the wall. To Assembly under the screw head goes on the back of the hook, ring, etc.

And here is another tube design — aluminum tube with an inner diameter slightly larger than the screw diameter. With a hacksaw on the tube is a longitudinal cross-incision — tube ready to use. In the wall making the hole, the fixture is laid in it, and the nut reaches the stop (Fig. 3).

This fixture is suitable not only for through holes, but also for the deaf.

Small note: to make the petals of a tube bent in a desired location, on its outer side with a thread file propisyvaetsya shallow groove (0.25 mm).

In cases where the wall covering does not allow to use a tube of a rigid structure to help a thick-walled rubber tube (Fig. 4). Mount same as above, with the only difference that there are no slots to do. At the end of the tube, it is desirable to pull the bandage ring.

Of metal tubes it is possible to make quite a few simple and reliable tubes. Here is one of them. In the end, a few cuts, and the resulting “tails” are slightly bent. The screw must be mounted consistently hook, cut the tube and nut. The resulting package inserted into pre-drilled a hole in the wall. It remains to tighten the screw, the “tails” will disperse to the sides, providing a completely secure attachment (Fig. 5).

All is well, you say, but how to make the hole? Concrete is highly unsuitable material for drill, but if you wish, and it can be fast enough to drill any hole.

Here is one method. First of all, you will need a reamer of the appropriate diameter; the end is sharpened like a chisel. Use it the same way as a jumper: set to the desired location and tapping of the hammer on the scan that after each stroke rotates a small angle, the knock out hole. A hole with a diameter of about 6 mm will take only 10 — 15 min.

The same subelite you can do not only scan for this purpose is quite suitable and conventional drill, it is necessary only to sharpen the “spatula”.

But the best hole is obtained using the electric drill and pobeditovye drills. In this case, however, there are difficulties with its regrinding, which is only possible on high-speed grinded with corundum circle.

And a few more little tips: do not hammer nails into concrete walls — even if they are there and will then hold all different will not; do not try to hastily turn the screws in carelessly planed and scored in the tube wall, take a couple of evenings and make the desired number of tubes.