Cut the correct glass circle is not so simple. Usually on the sheet steklografom put the outline of future disk, and then not spend a dozen tangents. The resulting polyhedron is brought to the circle by a fine-grained whetstone. It is much easier to make this work with a homemade tool. Its basis is the caliper. The inner leg is clipped and hard solder attach pad. After Stripping through her and the leg is drilled through hole. In the resulting plug is inserted carbide roller from a standard glass cutter. As the axis is used, the bolt of suitable diameter. On the anchor leg of the caliper push the plastic mold. And the last thing you need to do is the metal disc Ø 30 mm with naturalnym in its center a recess with a glued to it with rubber gasket.

Cut the correct glass circle is not so simple. Usually on the sheet steklografom put the outline of future disk, and then not spend a dozen tangents. The resulting polyhedron is brought to the circle by a fine-grained whetstone. It is much easier to make this work with a homemade tool. Its basis is the caliper. The inner leg is clipped and hard solder attach pad. After Stripping through her and the leg is drilled through hole. In the resulting plug is inserted carbide roller from a standard glass cutter. As the axis is used, the bolt of suitable diameter. On the anchor leg of the caliper push the plastic mold. And the last thing you need to do is the metal disc Ø 30 mm with naturalnym in its center a recess with a glued to it with rubber gasket.

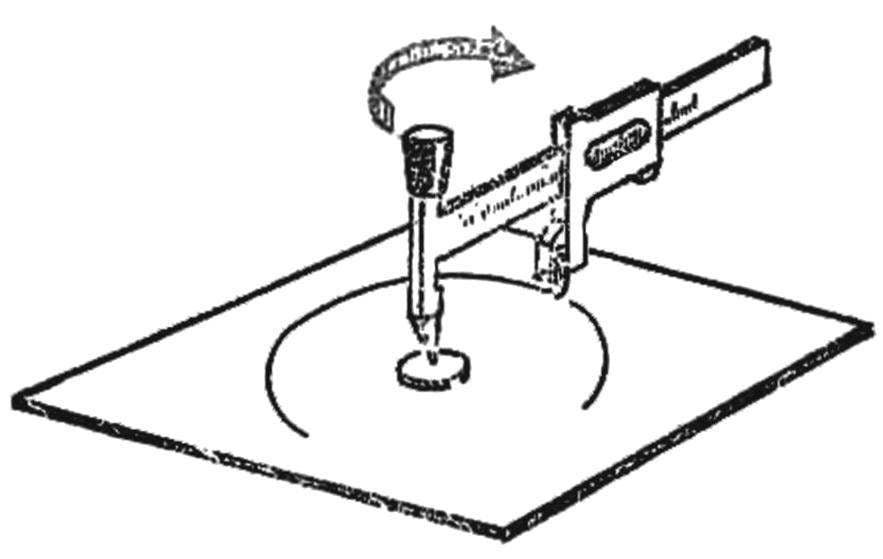

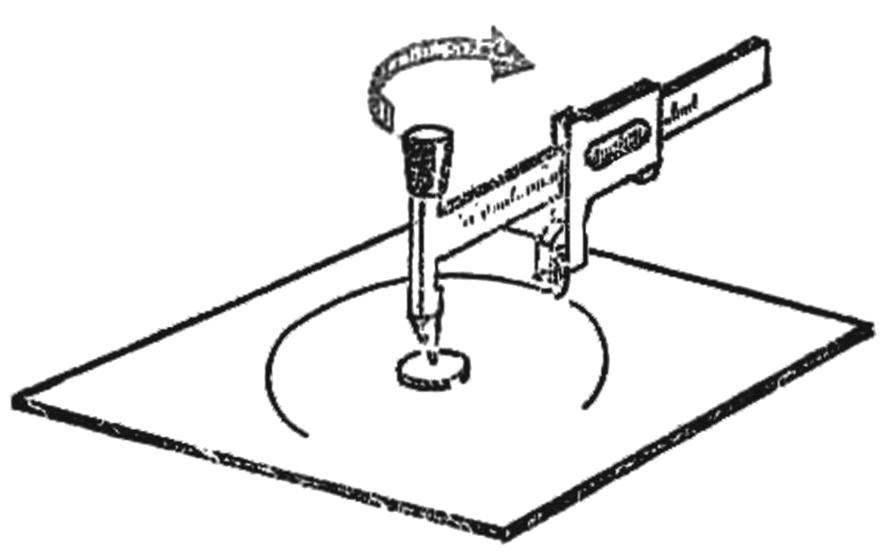

Cutting is performed as follows: the center of a glass workpiece, place the metal disc, the support foot of stangensellerie install in the hole and, holding the tool by the plastic fungus, with light pressure rotate the tool 360° In this case should be heard the characteristic crunch. Further cautious tapping along the cut line will separate the disk from unnecessary material.

Acquiring some skills, you can not only cut the glass discs (slightly easier), but the holes in the monolithic glass.