No matter how virtual games no relish computer modern children whatever transformers and electronic automatic devices may fill the shelves of children’s sections of shops — still in children remains inescapable desire for simple projects, especially dynamic, movable, Yes, to deal with them at the table and in the yard, on the air. And rightly so, those parents who want to encourage kids these aspirations, especially in our days of General inactivity and lack of technical creativity.

This art project for kids that older kids can make themselves, and the youngest will help parents, and is a proposed flying model glider. It resembles a popular among children of all times paper dove, making the waving hand of a beautiful, though short, planning. And the model will appreciate the real and long flight: she has a propeller and rubber motor.

What is? Model motodeltoplan differs utmost simplicity and therefore accessibility to children even of preschool age. There are no difficult to manufacture parts or any special trudnosgoraemyh materials — all that is required for its production, will be able to find and pick up at home.

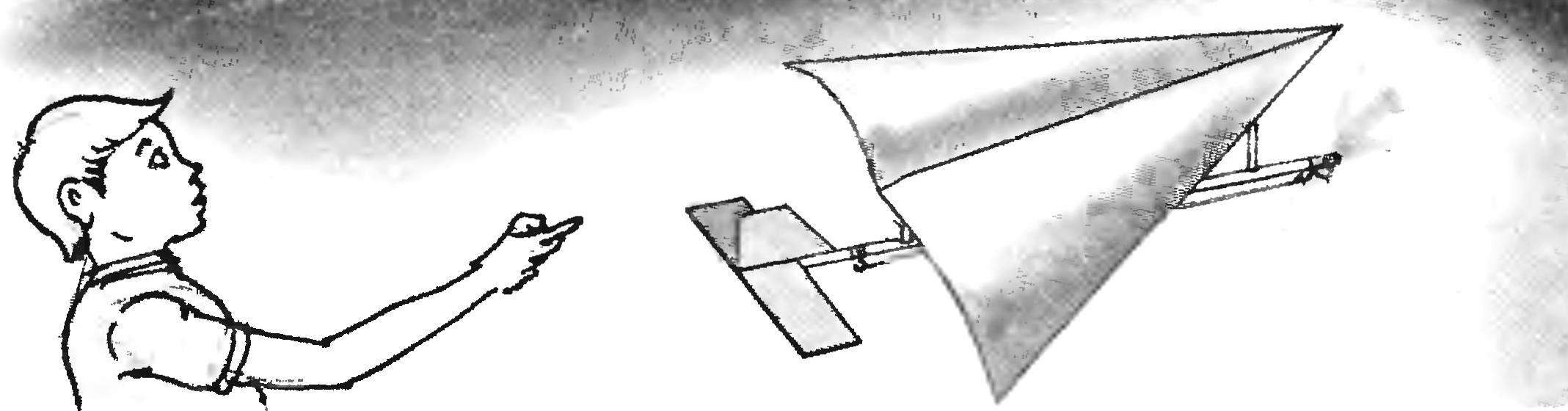

Offer miniature aircraft consists of three main components: the “fuselage” as a rail and attached to it a triangular wing and the rubber motor.

Fig. 1. Trike:

1 —propeller; 2—bracket screw; 3—hooks of the rubber motor; 4—rack; 5—front wing; 6—wing; 7—rubber motor; 8—stabilizer; 9—keel; 10—back front wing

“Fuselage”. It represents wooden rejku section 10×10 mm and a length of about 450 mm. If the ready is not, and to make this difficult, you can use sold on the construction markets or hardware stores window glazing beads, used for fastening the glass on the frame. In any case, the rail is very carefully polished to remove burrs and traumatic sashay, and then shall be cut to the specified size.

Rail mounted almost all other components and parts. So, the tail portions are attached to the stabilizer and fin, cut from a thin, but hard cardboard. These parts are installed on glue PVA in a cross cut, carefully made using a jigsaw or small handsaw. With a slight indent from them to the rail strong thread wound hook for the rubber motor.

In the front part is attached to the bracket of the propeller. It is a tin stripe, curved as shown in figure 3, the Ends of the bracket also primatyvajutsja thread to the rail, and through holes in vertical planes skipped the hook for the rubber motor, which serves both the axis of the propeller, detachable from the bracket with two planted on her beads or plastic washers.

For wing mounting on the rail are mounted two racks from the same wooden slats or stiff wire Place of their final attachment is determined by the result of balancing the assembled construction.

Wing. The frame is composed of three rods (or wire rods), connected as shown in figure 2. These rails are rigidly connected (glued) on top deltakilo with scarves (made of cardboard). Rails attached to the “plane” of the wing made of paper or plastic film, cut (empirically) in the form of an isosceles triangle. His average rod wing is attached to two racks, one of which (front) is higher than the other — to give the wing the desired angle.

Fig. 3. Rotor part:

1, 1A—blades; 2—screw terminal; 3—front hook axis to lock the screw; 4—beads of the role of bearing; 5—bracket screw; 6—rear hook pivot attachment of the rubber motor

Fig. 4. Manufacturer of rubber motor:

1 —Board-base; 2 nails; 3 — winding of rubber thread; 4—end tie from the thread; 5—ready end loop (2 PCs) rubber motor

Propeller. It is a compound: its middle part is a wooden rod with a diameter of 10 mm and a length of 45 mm, with cross-shaped cuts on the ends: they are on glue (“Moment”, PVA) are inserted the blade, cut from rubber or plastic (screw tin dangerous for children). The end of the wire to the axis of the screw is bent in the form of cramp and deep into the wooden rod of the screw.

The rubber motor. For its production it is best to use model aircraft tires (though at the worst can come and cut thin strips from the pharmacy flat wiring harness). Measurements on the fuselage and the distance between harvested for the rubber motor hooks, to any Board are driven two nails between and is wound a few turns of rubber. With the help of threads near each nail rubber shrinks, and the resulting loops clings to the rubber motor hooks To the rubber motor work better, his threads are greased (e.g., vaseline). Install the rubber motor can be directly by the propeller, and separately (e.g. using a hand drill).

B. RAWSKI

Recommend to read AUTOMATIC TRAFFIC SIGNAL Children's railway — one of the most loved games boys. But if it has control elements, for example a traffic light with automatic switching of lights, the game becomes even more fun. ... NO INJURIES When sharpening saws with a file, if it is not docked, holding her hand runs the risk of injury from sharp teeth. To avoid this, make of a segment of hose to the loser at hand — work... Scroll back to top

No matter how virtual games no relish computer modern children whatever transformers and electronic automatic devices may fill the shelves of children’s sections of shops — still in children remains inescapable desire for simple projects, especially dynamic, movable, Yes, to deal with them at the table and in the yard, on the air. And rightly so, those parents who want to encourage kids these aspirations, especially in our days of General inactivity and lack of technical creativity.

No matter how virtual games no relish computer modern children whatever transformers and electronic automatic devices may fill the shelves of children’s sections of shops — still in children remains inescapable desire for simple projects, especially dynamic, movable, Yes, to deal with them at the table and in the yard, on the air. And rightly so, those parents who want to encourage kids these aspirations, especially in our days of General inactivity and lack of technical creativity.