Like to gain the space velocity of the rocket help a three stage engine, three cutter proposed Odessa innovator P. I. Podolyan instead of one, possible to achieve “cosmic” speed cutting worm thread is one of the most common in modern engineering.

Like to gain the space velocity of the rocket help a three stage engine, three cutter proposed Odessa innovator P. I. Podolyan instead of one, possible to achieve “cosmic” speed cutting worm thread is one of the most common in modern engineering.

Usually to improve the efficiency of the tool he is trying to give the versatility to get to perform several operations.

But… traditionalism of thinking — not a good assistant in technical search. “What if we go the other way: “split” operation to split the load experienced by the cutter, a few tools?” — has set itself the task of P. I. Podolyan. So there are three cutter: a cropped, tapered and integral (lapping).

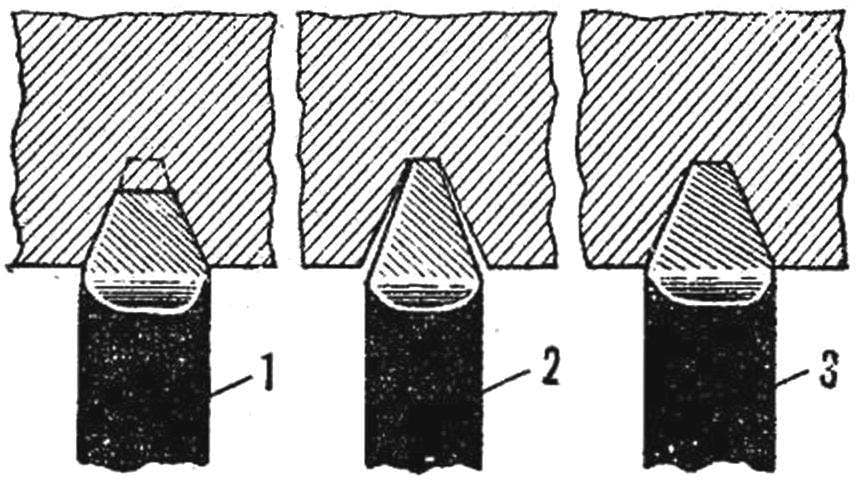

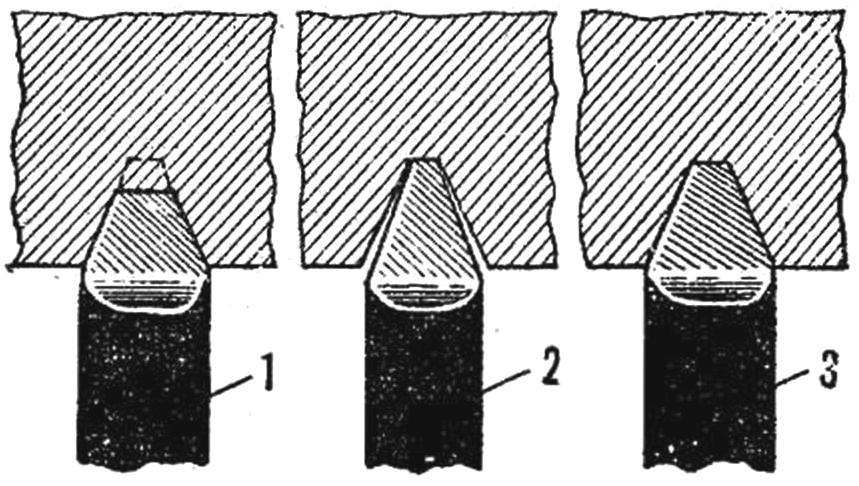

“Trio” worm cutters:

1 — rough, half groove profile, 2 — full depth, 3 — fine, full profile.

Cutting the groove is performed alternately by each of them. First, though, and fits the profile of the groove, but half shorter and only her outlines; the second at full depth, but narrower by 0.5 mm from each side edge; the third — finishing. All cutters work with a lower voltage at higher speeds, giving a considerable gain in time, considerable savings, including by reducing wear of the cutters. In the end, the high quality processing performance has increased five times.