It’s hard to say which is harder: to put on or take off hard a spring ring serving as a seal between the walls of piston and cylinder internal combustion engines, compressors, pumps, certain pumps. The more valuable a simple tool created by young innovators at the Pavlodar tractor plant. It makes it easier to perform both operations.

It’s hard to say which is harder: to put on or take off hard a spring ring serving as a seal between the walls of piston and cylinder internal combustion engines, compressors, pumps, certain pumps. The more valuable a simple tool created by young innovators at the Pavlodar tractor plant. It makes it easier to perform both operations.

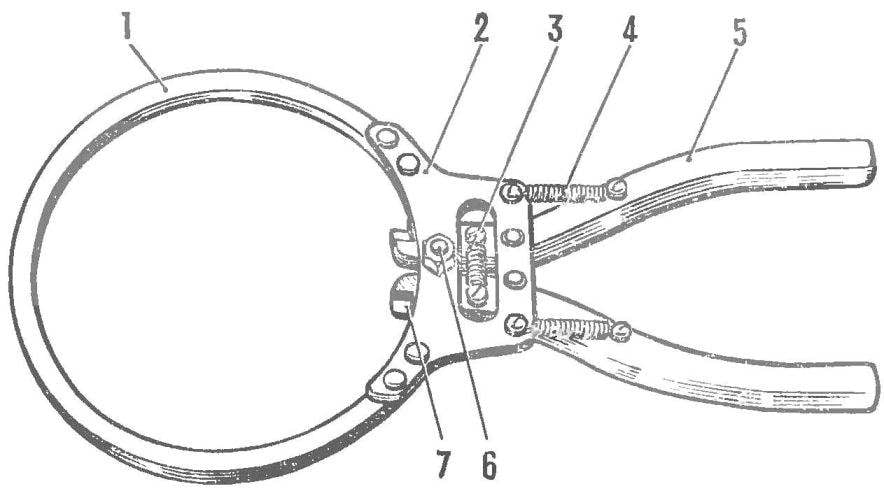

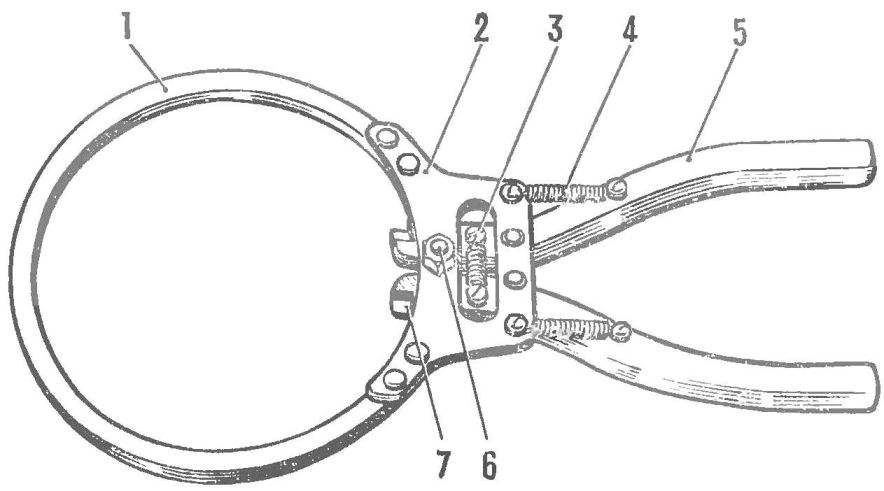

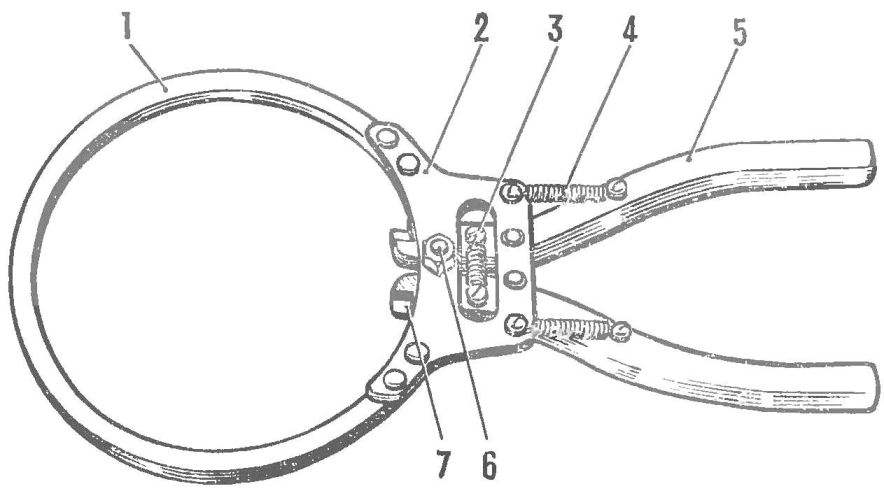

Externally, the device resembles pliers, instead of the sponge it — ring holder. It connects with lever handles plate in the slots which includes a compression spring. The latter supports the handle in the rest position: closed working reeds. Serve the same purpose, two additional spring connecting the handles to the plate. In addition, the plate has a adjustment screw that sets the size of the reeds divorce tool; it provides the necessary release ring and at the same time protects it from breakage.

The principle of operation of simple devices. The piston ring is inserted into the annular holder so that it locks (connectors) rested in the reeds. When compression of the handles, the ring will expand and will be easy on the piston. To remove the ring fixture is inverted by 180°, is mounted on the piston and, entering the tabs on the locking connector, the piston ring compress handles: ring pulls apart and easily removed from the piston.

Activity of “forceps”:

1 ring holder, 2 — plate, 3 — simna spring 4 — additional coil spring, 5 — handle, 6 — adjusting bolt 7 — reeds-unlatches.

The introduction of devices for installing and removing piston rings not only considerably facilitates the work on these operations, but also allows us to exclude marriage and to reduce the time of repair of piston group of engines.