It is generally accepted that a drill is the main tool DIY, hobbyists tinkering something with their hands for home, for family, as well as the main means of mechanization of labor-intensive processes in the creation of makeshift equipment. It is not surprising, because thanks to various auxiliary or additional devices drill can replace even some machinery. For example, a drilling machine, which can produce very simple equipment, published in the Hungarian magazine “Earmaster”.

It is generally accepted that a drill is the main tool DIY, hobbyists tinkering something with their hands for home, for family, as well as the main means of mechanization of labor-intensive processes in the creation of makeshift equipment. It is not surprising, because thanks to various auxiliary or additional devices drill can replace even some machinery. For example, a drilling machine, which can produce very simple equipment, published in the Hungarian magazine “Earmaster”.

Appointment and device

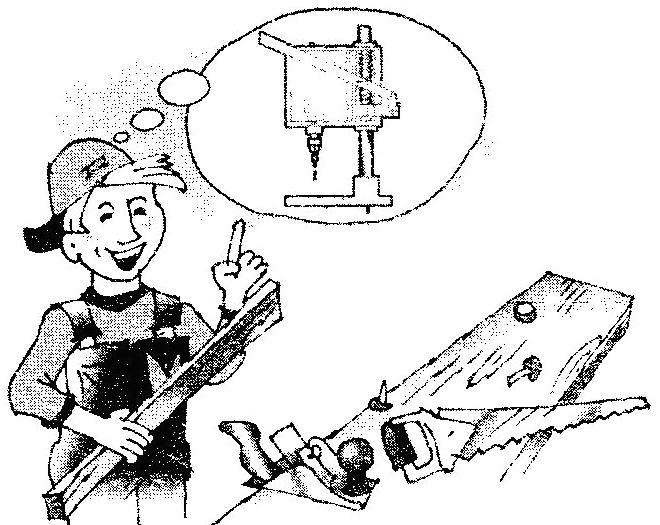

The proposed equipment drill will be able to perform the functions of a small desktop machine for drilling operations in the manufacture or repair of various small household appliances, as well as in Amateur radio construction. It provides sufficient precision even when curved milling or grinding, polished smooth or relief surfaces of various materials.

It does not need any scarce parts, components or materials and special tools: everything will be made out of available funds available to any DIY enthusiast. More than that: will not even need special design skills or experience with the materials and tools. This is easily seen, reading the device the proposed device.

So, besides the already mentioned drills (any model and brand) enough to have a small amount of scraps of boards with a thickness of 20 mm, a small tubular rod 25 mm in diameter and not very rigid compression spring. From tools, use only those that are always there in the household: wood saw for cutting out blanks Yes screwdriver with screws for Assembly.

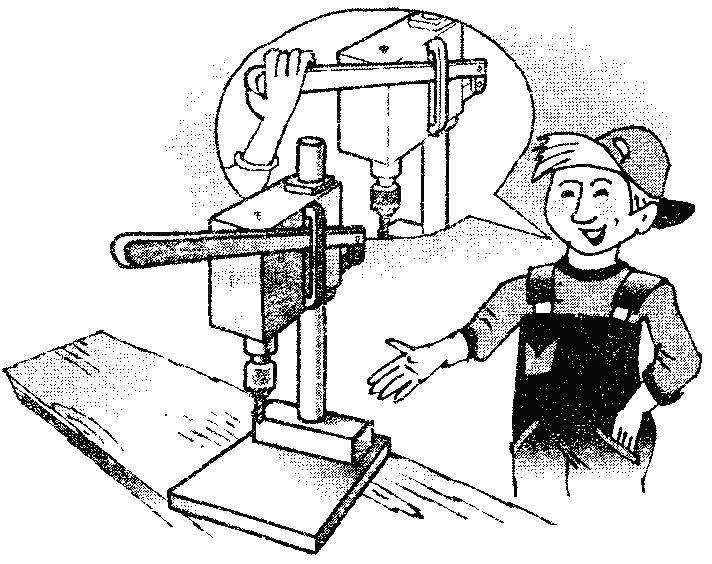

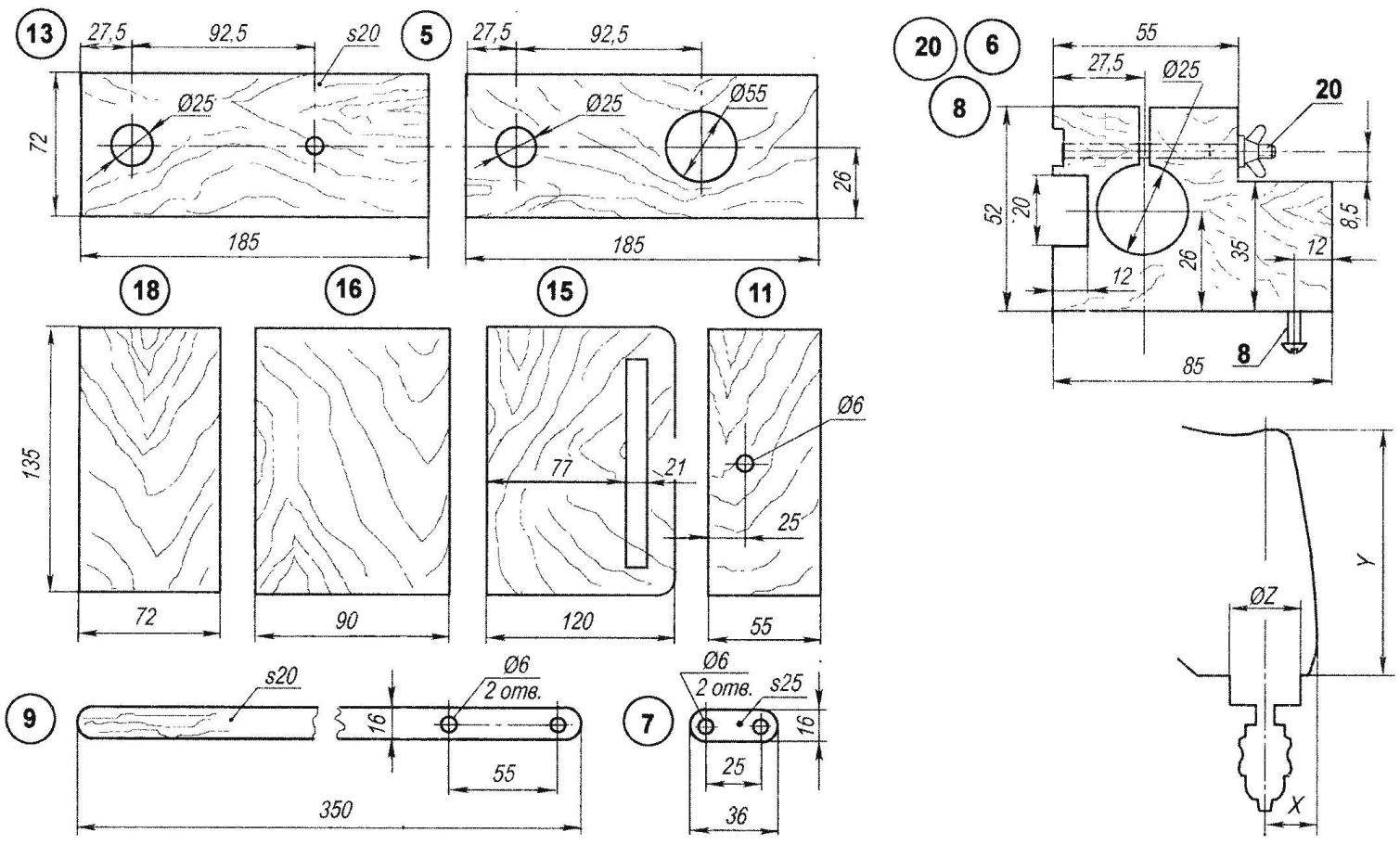

Desktop machine from drills:

1 — support (working area); 2 — slip rail with socket for rod; 3 — rod; 4 — door (wooden dice); 5 — the bottom of the case; 6 is the supporting base of the spring (the locking mechanism in elevation, the shoulder of the working arm; 8 — the axis of the hinge shoulder; 9 — the operating lever; 10 — the axis of the working lever; 11 — the rear wall of the compartment spring; 12 — spring; 13 — housing cover; 14 — guide reference of site; 15 — bulkhead housing with a thickness of 20 mm; 16 — the rear wall of the compartment drill; 17 — clamp drill (screw); 18 — side panel of the housing with a thickness of 20 mm: 19 — drill; 20 — locking screw pad spring

The very equipment a drill is a small wooden case in the form of an open box mounted at the desired height on the vertical rod, which is fixed on a flat support, serving simultaneously and the work place. Inside the box is placed and secured with the drill, which together with the housing can make the needed vertical movement, driven lever and return spring. The lever is pivotally connected with the housing and moving the locking pad on the bar; on the same ground rests the return spring inside the housing mounted on the bar. The lower end of the rod is inserted into the socket surface of the beam on the support fixture.

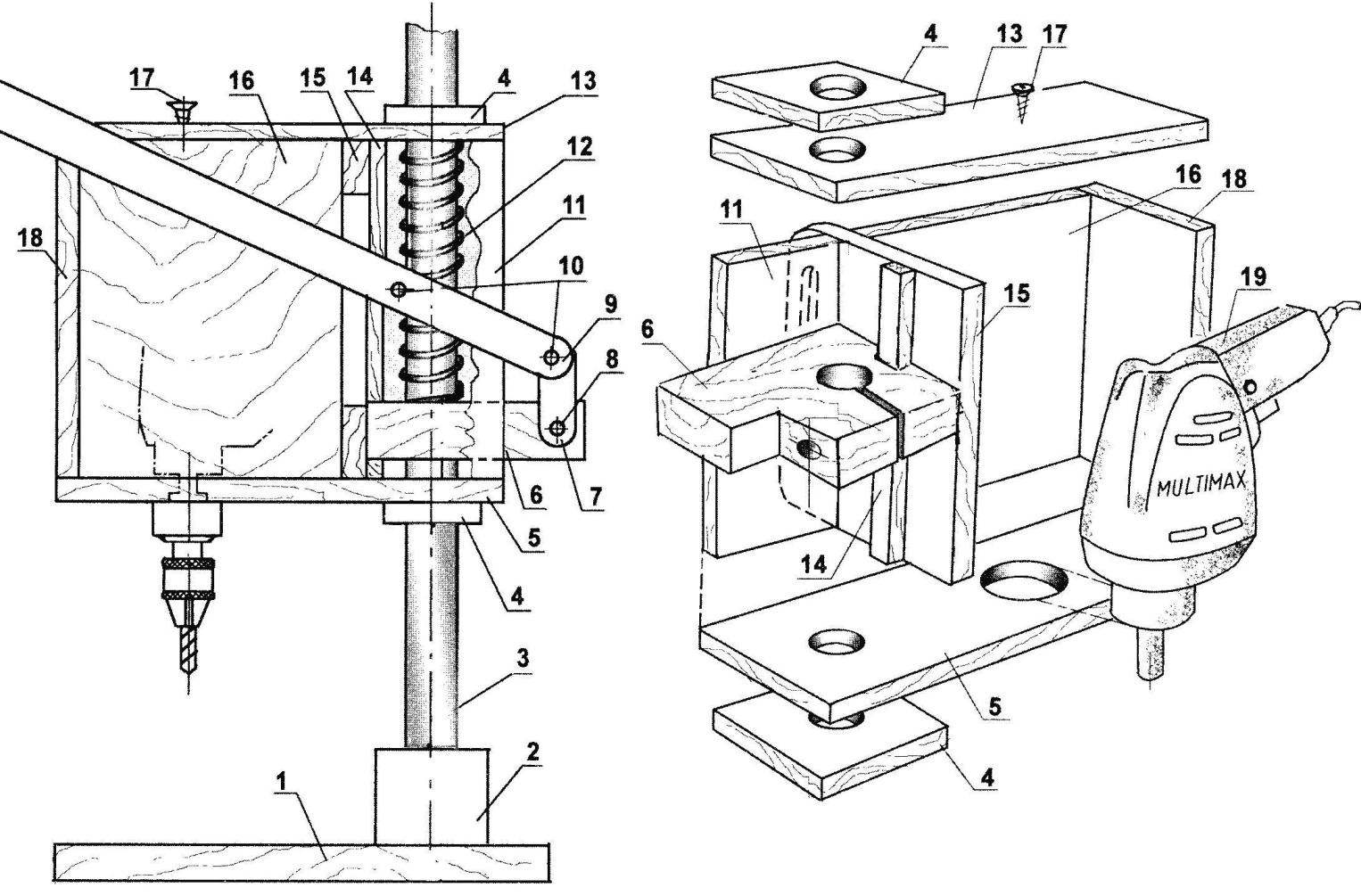

Case

As already mentioned, the housing is assembled from wooden pieces in the form of an open on one side of the vertical box has a composite rear wall, a lid and a bottom, one sidewall and the internal partition separating the compartment from the drill compartment return spring from its bearing pad.

The baffle in the Assembly extends beyond the rear wall; on this projecting edge, it has a slit neckline, which moves the operating lever. From the spring to the baffle is attached to the vertical bar, which is in the groove of the support platforms of the springs when the platform is fixed on the rod, the bar plays the role of a guide, to prevent accidental rotation of the body during the stroke.

The housing cover has two openings: one — under through the rod; the second, a little under the screw or screw fixing is inserted in your slot drill. At the bottom of the body also two openings: the small rod and big — the size of the neck of the inserted drill. On both panels along their outer surfaces are attached an auxiliary lining—wooden plates with holes for the bar (original bearings).

The sidewall compartment of a drill together with the partition wall play the role of stiffening the whole structure.

The operating lever

By itself, the operating lever is simple: is a wooden bar behind the body, which is passed into the slot of the partition and connected with bolt axle housing. At the end of the lever has a second such axis for docking with the articulated arm that connects it to the anchor point of the spring.

Working the lever is not called accidentally by pressing on its upper end the power is transmitted through the axle to the body of the device, which is lowered and inserted into it the drill makes stroke.

The supporting base of the spring

The supporting base of the spring — one of the main parts of the fixture, as it ensures the necessary operating level of the machine. Hence the peculiarities of its construction.

Running Playground of wooden rectangular pillars, in which is drilled a corresponding hole in the bar. Thanks to notch and long bolt pad can firmly be fixed to the rod at any desired height. And sawed her groove, as already mentioned, does not allow the body to rotate horizontally.

Support machine

The support of the machine consists of two parts: the work area and reference beam, into the hole which the inserted end of the rod.

The platform can be made of boards, sheet of thick plywood or chipboard. For greater stability on the lower side in the corners of the pad can be affixed to the thrust-slip rubber (not shown).

The parameters of the drills depend on possible changes of appropriate dimensions on the diagram of the machine:

x — projection of the front of the drill; — height; z is the diameter of the neck drills

The support rod is a wooden bar of square section with dimensions of 60×60 mm, which is drilled a hole under the rod of the machine. The latter is simply inserted into it, but may have additional locking mount (for example, thrust screw) that allows the completion of folding the device for compact storage.

Assembly fixtures

The Assembly also is simple, because all the main parts are made of wood, and hence the connection—typical of this material: for screws or plug-in round thorns (the dowel) and glue (carpenter’s, PVA).

First formed body parts harvested given the size of drills used, as well as working platform with a support beam under the bar. The operating lever with the pivot shoulder and anchor point for the springs collected separately, and then made the connection of all elements of the fixture.

This rod is mounted in a support on the working site; the operating lever is passed through the slit of the septum to the housing, and connected with it by a spring support and the spring are inserted into the housing, after which the Assembly fits over the rod.

Remains tighten the bolt to the support platform at the desired height on the rod, inserted into the body of the drill so that its neck entered in the corresponding hole in the bottom of the case, and secure it with a screw or screw through the hole in the housing cover. That’s all, you can start working by installing in a cartridge of a drill needed a drill.