The compressor is one of the machines, which are frequently encountered in various production areas. Among the vulnerable sites that require durability and long remained a piston ring. It wear led to the deterioration of integrity, performance and efficiency of the unit.

The compressor is one of the machines, which are frequently encountered in various production areas. Among the vulnerable sites that require durability and long remained a piston ring. It wear led to the deterioration of integrity, performance and efficiency of the unit.

Innovators of industrial Association of Southernrebeler proposed non-metallic piston ring. It is made in the form of split cuffs of a G-shaped cross-section of a graphite-fluoropolymer with the necessary elasticity and high wear resistance. The profile cuff is selected so that one of her springy flange seals the surface of the cylinder and the second piston groove.

Edge of the new ring due to its own elastic forces of the gas pressure, as well as additional rasinovo devices — expander, fit snugly to the cylinder walls that provides a high integrity, regardless of the degree of wear, thermal deformation, and even the precision of manufacture. Installing new rings on the piston does not require any complicated modifications or alterations and is available to any workshop.

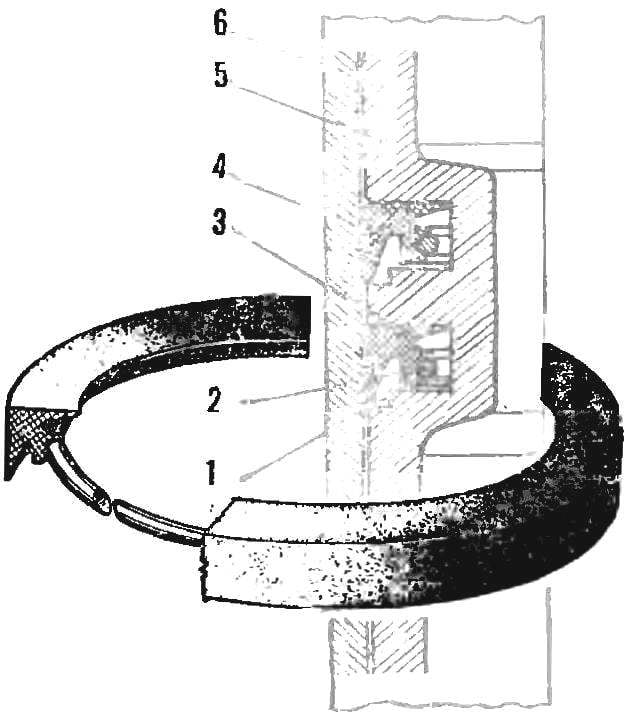

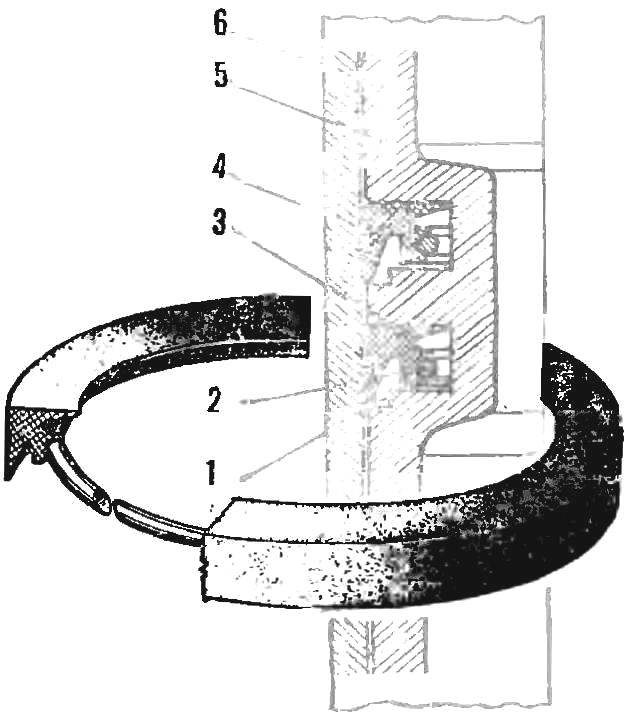

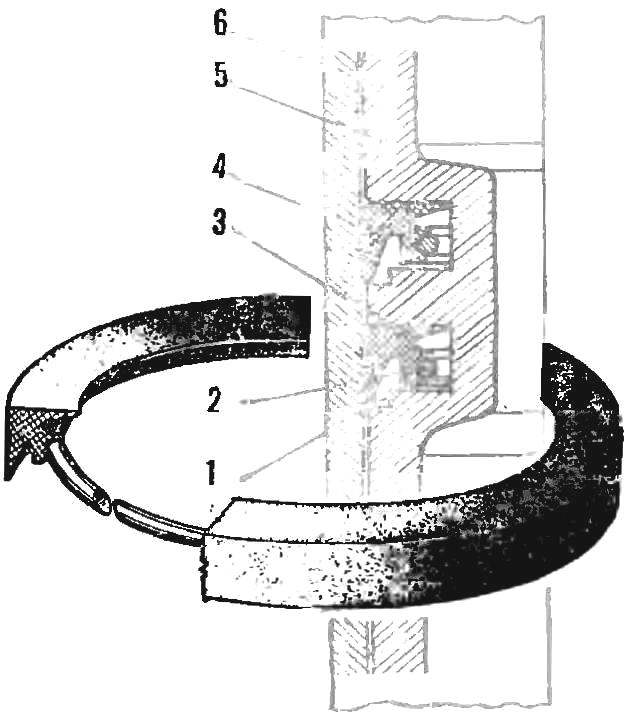

Collar for piston:

1 — base cuff, 2 — expansion ring (flat or round), 3 — edge, the sealing piston groove, 4 — edge, the sealing cylinder 5 — piston 6 — cylinder.

Use as material rings made of a graphite-fluoropolymer different brands allows you to transfer compressors to operation without lubrication of the cylinders. When this cuff is twice as long as conventional cast-iron rings.