Commercially available household juicer electric have low productivity, and fruit in the chopper have to lay manually one by one. The housing of the centrifuge has a very small capacity and quickly filled the damp ground, and for cleaning it is necessary to stop the actuator, remove the cover and the housing. This is inconvenient and is associated with non-productive downtime.

Commercially available household juicer electric have low productivity, and fruit in the chopper have to lay manually one by one. The housing of the centrifuge has a very small capacity and quickly filled the damp ground, and for cleaning it is necessary to stop the actuator, remove the cover and the housing. This is inconvenient and is associated with non-productive downtime.

In the design circle of the Chernihiv regional station of young engineers designed and tested a prototype ramjet extractor, which eliminates manual single supply of fruits, provides continuity, as pressed the weight of fruit comes in a separate container, from where unloaded.

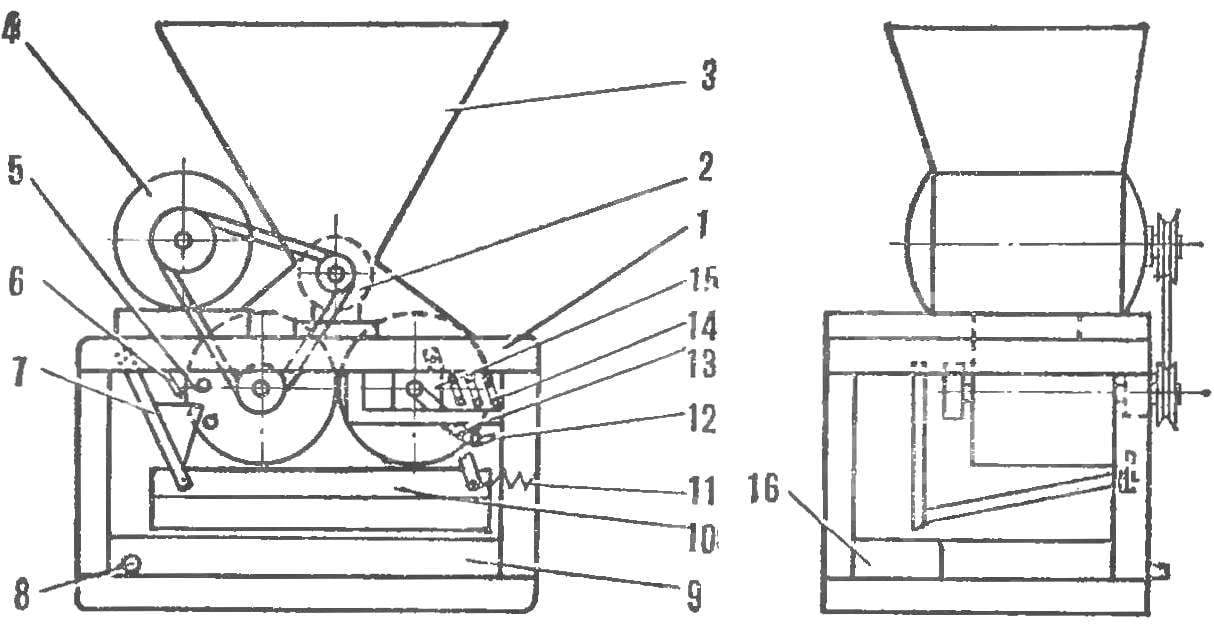

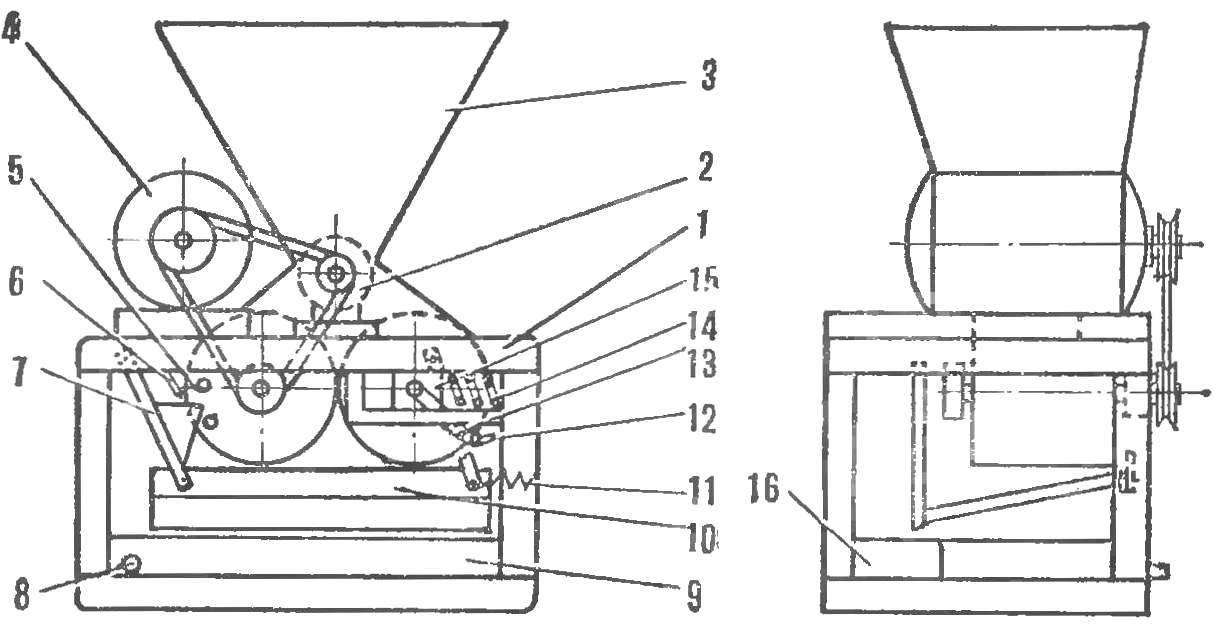

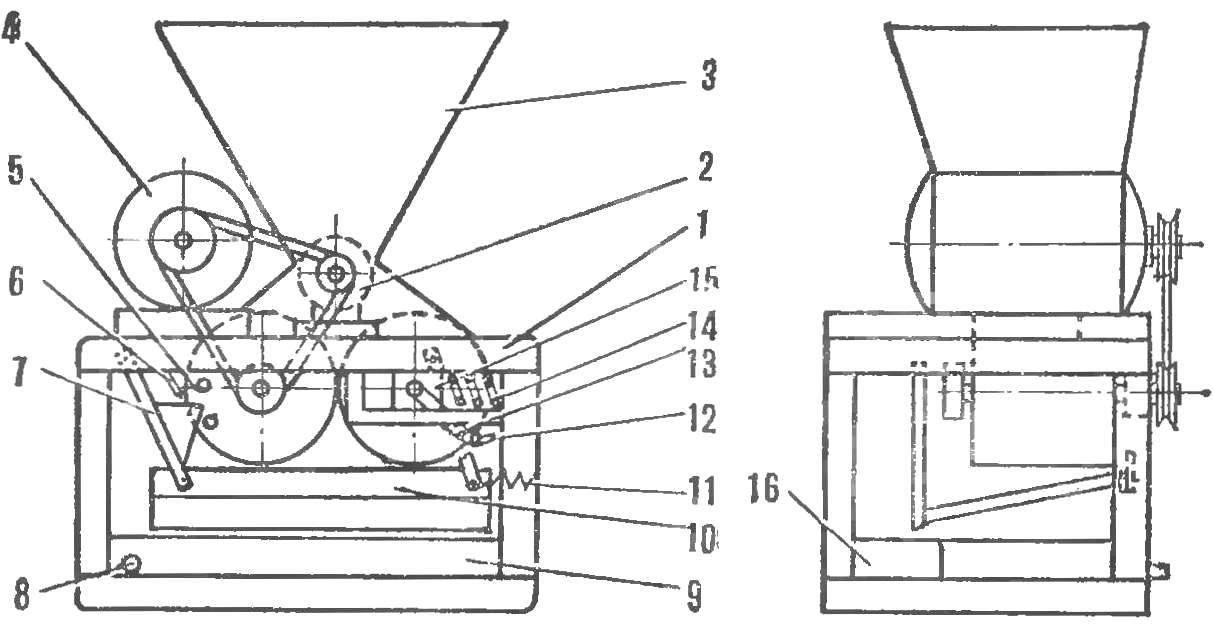

The figure shows a scheme of the described disposable operating from single-phase motor. The frame is welded from steel angle 30X30X3 mm. the ball bearing of the shaft of the working body, which is a steel axle on the last fixed hob in stainless steel. At the front end of the shaft seated on the keyway on the pulley belt transmission.

For processing the fruit are loaded into a hopper of duralumin sheet, attached to the frame by bolts. Below the shaft of the working body are two cylindrical roll made of stainless steel. They squeeze the juice from the crushed mass of fruit. Axis of rolls mounted on ball bearings. Left swath —host: on its axis seated on the keyway on the pulley belt transmission, right is pressed to the left by the springs that provides the counter-rotation.

Scheme of juicers:

1 — frame, 2 — mill, 3 — hopper, 4 — engine, 5 — lead roll, 6 — scraper, 7 — suspension 8 — drain valve 9 — tank, 10 — mesh, 11 — spring SITA, a 12 scraper, 13 — leash scraper, 14 — spring driven roll 15 is moving in a Bush roll, 16 — tank storage of pressed mass.

Rolls placed below the inclined sieve, perforated aluminum sheet, the frame of which is suspended pivotally. Four pendants make oscillatory motion, which is achieved by action of the roller on the master roll, periodically discharge the desired suspension. In initial position the sieve is returned by the springs.

On the surface of the squeeze rolls sticks crushed. It is separated from the rolls scrapers. From the leading—scraper, attached to the frame, and the slave is mounted on two leashes connected with the axis of the roll.

Vitamin harvester works in the following way. Clean the berries are poured into the hopper. Then turn the motor, the rotating cutter-shredder. Under the action of centrifugal force, the crushed mass is dropped on the squeegee rolls. Juice, passing a sieve, flows into the reservoir, and the waste of fruit due to the oscillatory movements of the inclined plane of the sieve is discharged into the drive. As you fill the tank the juice is drained through the faucet in a bowl. A pressed mass may be removed with a ladle, without stopping the motor.

I. EVDOKIMENKO, Chernigov