At furniture factory No. 4 in Tiraspol participants NTTM has developed a vortex oil separator — special filter for cleaning compressed air used for the atomization of paints and varnishes when applied to a finished surface. Such a filter is necessary to obtain high quality coatings; trapped together with pressured air drop of moisture will lead to a local defect or colorful lacquer standing on the furniture during its final finish.

At furniture factory No. 4 in Tiraspol participants NTTM has developed a vortex oil separator — special filter for cleaning compressed air used for the atomization of paints and varnishes when applied to a finished surface. Such a filter is necessary to obtain high quality coatings; trapped together with pressured air drop of moisture will lead to a local defect or colorful lacquer standing on the furniture during its final finish.

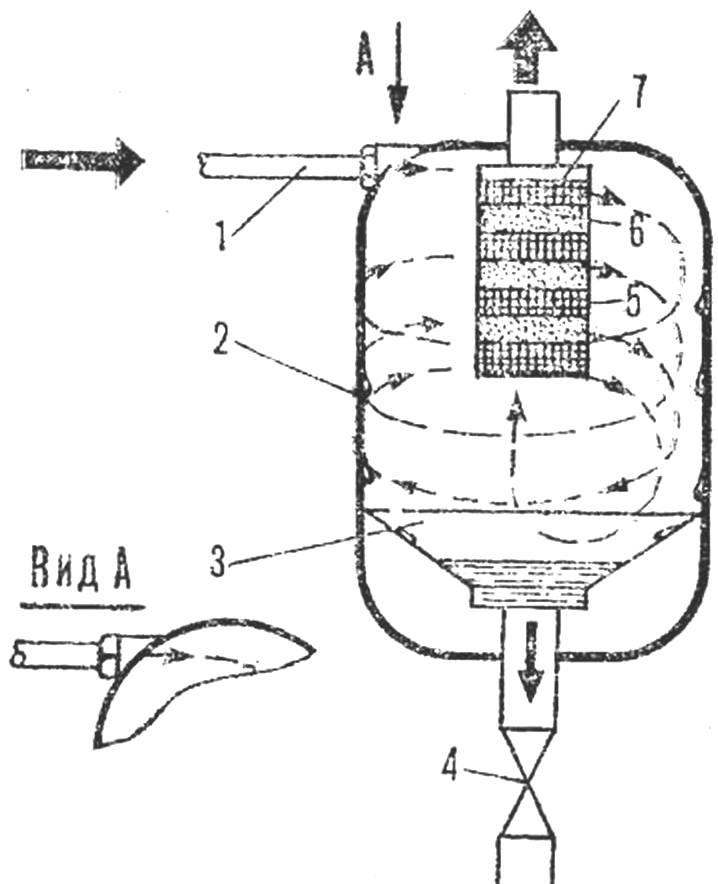

For cleaning the supply air, young innovators have proposed to use a cylindrical container, where the air should come in at such an angle to the walls to flowing around them, he swirled. It is a kind of air centrifuge: vortex air jets droplets of moisture under the action of centrifugal force to fly off the walls and settle on them. The accumulation of they fall to the bottom of the vessel, where there is a conical funnel. Through it, moisture gets into “quiet” the lower part of the sedimentation zone with a drain tap.

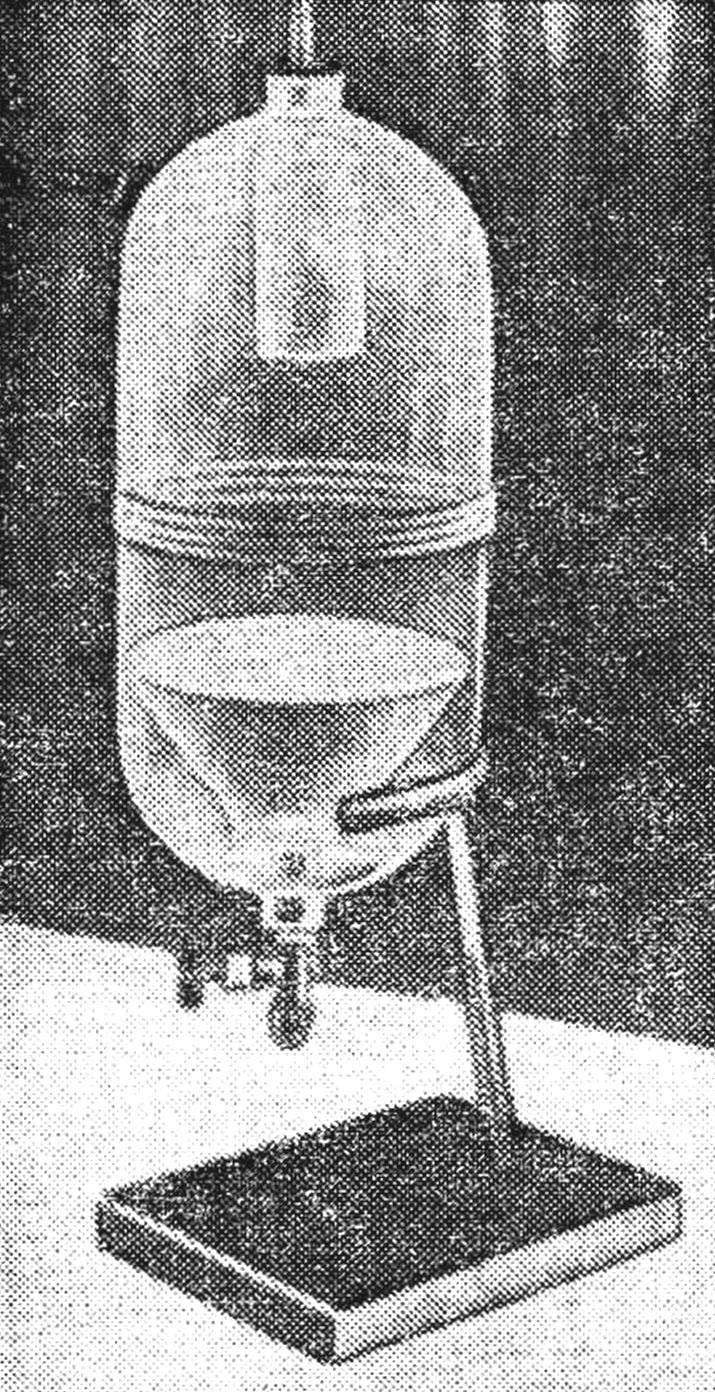

Vortex filter and its scheme:

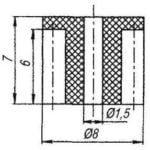

1 — inlet port (tangential input — see view A), 2 — cylindrical body, a 3 — funnel settling zone, 4 — drain cock 5 — filter 6 — layer glass, 7 — fabric layer.

And in the upper part of the tank where there is the outlet for air, installed the tubular filter with the layered filler of glass and fabric.

Despite the simplicity of the device, this oil separator provides high quality air purification.