Driven wheels turn with the steering of the machine equipped with double-hinged rocker (steering triangle). In the steering mechanism uses the pull out steel wire type of OVS with a diameter of 2 mm and idler arms, cut from 2-mm aluminum. Joints of the steering mechanism is made using rubber liners, that enables the steering tie rods to deviate from the plane of their rotation. Of course, it would be much better to use brand ball joints, however, our simplified design works better than.

As mentioned, the motors are mounted on the rocking rear axle. For this purpose, the rocking bent shoulders, forming a kind of engine mount, the engine mounted on it a pair of poluchaut bent sheet aluminum 1.5 mm thick. the horns are also mounted axle, and on them — nylon gear wheels and rear wheels of the car Master (brass or steel) gear fixed on the motor shaft. Gear ratio gear set — from 1:7 to 1:8.

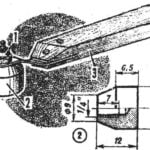

A typical hinge design of traction control:

1 — tie rod (wire OVS d2); 2,6 — washer (steel); 3 — rocking or rotary fist; 4—liner (the part of refill gel ball pen); 5 — elastic sleeve (rubber); 7 — nut M2. Mount washer 2 to the steering track rod 1 — soldering; fixing nuts 7 at steering track rod 1 — nitro

Type design of swivel rocking suspension:

1 —M4 nut; 2 — washer; 3 —rocking suspension (D16T sheet s2,5); 4 — spacer (polyethylene or nylon); 5 — spacer (D16T, pipe 8x 1,5); 6 — axle (steel 50KHFA Serebryanka, rod d5); 7—bracket rocking (D16T sheet s2,5); 8 — liner (polyethylene or nylon); 9 — friction bushing (polyethylene or nylon)

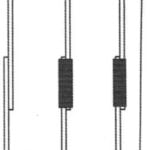

Stroke switch:

1 — M3 bolts and nuts fastening the contact plates; 2 — contact plate (relay); 3 — clips; 4 — upper part of the switch housing (organic glass); 5 — the lower part of the body (an organic glass); 6 — jumper wires (wire d0,5 in vinyl insulation); 7 — movable lamella (glass fiber s3); 8,9 — battery batteries or battery cells

Front (A) rear (B) wheel model:

1 — bus (porous rubber, fixed to the hub with glue “Super”); 2 -hub (D16T, rod d50); 3 — bushing (bronze or brass, rod d12)

The wheels of the car are chiseled out of aluminum and hub homemade tire of sponge rubber. Of course, it is better to use a brand of pneumatic tyre with studs-lug-mi, but for the simplified car is fine and the homemade. These tires are best made on a lathe by using a sharp knife-cutter, using lubrication during the processing of the rubber a solution of soap or kitchen detergent “Bingo”, “Shine”, etc.

To control the car used with only two teams and two servos, one for steering and the other to control the progress of the model using the switching power source and the motor. The second servo is connected with a homemade traction bar switch that allows you to connect two battery packs in parallel with reverse polarity (reversing), in parallel with direct polarity (the first speed) and consistently with a straight polarity (second speed). The switch is a glass fibre laminate plate with pistons connected to the back of the jumper. Plate, thrust connected with the steering machine, can move freely in the housing, glued Plexiglas. On the housing there are two contact groups; one group of four contacts are connected with batteries, the other with a motor.

It is considered that in the manufacture RC car with electric drive can not do without supernatural and superaccumulation. So, brand RC buggy most commonly used frame Nickel-cadmiu-tions batteries with sintered electrodes with a capacity of 1200 mAh voltage 7.2—8.4 V and the motor “Mabuchi” RS-540 CX. Meanwhile, for the proposed here model is quite suitable two or four blocks of the standard AA-batteries-class “Alka-line” or rechargeable batteries (diameter of each such current source 15 mm and length 50 mm) at four sources in the block and, as has been said, quite widespread, modelista motors speed 400.

It should be noted that the design of the drive allows the car to use and any other suitable engines, even a low power one type DK-5-19. They, by the way, you can install two on each rear wheel, but if you want to do the leading and the front axle, equipping it with the same motors.

Body buggy wikiepedia of tripati layers of fiberglass and epoxy binders on the disc. For a single instance of the body blank is the easiest way to make from foam, proshpaklevat her clay. If it is supposed to series of housings (even a single model will require several buildings for the rapid replacement of broken races), sometimes it makes sense to make a wooden collapsible, otherwise, flanging and undercuts will not allow to remove her shaped shell.

The finished shell is aligned with autosplice, barked and covered with primer and two coats of enamel. Window on the model do not have to make transparent, enough to simulate, having painted the body in locations grey or black paint.

I. TEREKHOV

Recommend to read

THE HEATER IS A SOLDERING IRON

THE HEATER IS A SOLDERING IRON

Usually wings models air combat and cord upholstered Mylar film. Stick it to the frame using BF-2, and the joints are heated with a soldering iron with a special nishikoi. In the Studio... BOW FROM OLD SKIS

BOW FROM OLD SKIS

As you know, many fans of the game knight battles themselves make for yourself armor, swords, shields and bows. Use a hint how to make a good elastic bow made of two halves of old skis....