Mini tractor trolley. The design of the mini-truck went, as usual, the units of various automobiles and agricultural machines, end time. I was able to fairly compactly place them in a small volume, making the frame left plenty of room for cargo and even passengers.

Mini tractor trolley. The design of the mini-truck went, as usual, the units of various automobiles and agricultural machines, end time. I was able to fairly compactly place them in a small volume, making the frame left plenty of room for cargo and even passengers.

The positioning units of the tractor, I did not philosophize and acted on the principle: the simpler the better. The homebrew there is a rule: want to do innovative machine — to use an unconventional layout, but if you want to the car was reliable and workable, stick to the classic layout — it rarely fails. In this I have been convinced on their own experience.

The name of the tractor — “Ocarinas-2” — in honor of the village of Ocarina where we have a house with land. The first “Ocarinas” (mini-tractor) and it works fine there and to this day, performing in the garden almost all the heavy work of plowing, harrowing, ridging, harvesting and transportation of crops. So problems with it I have.

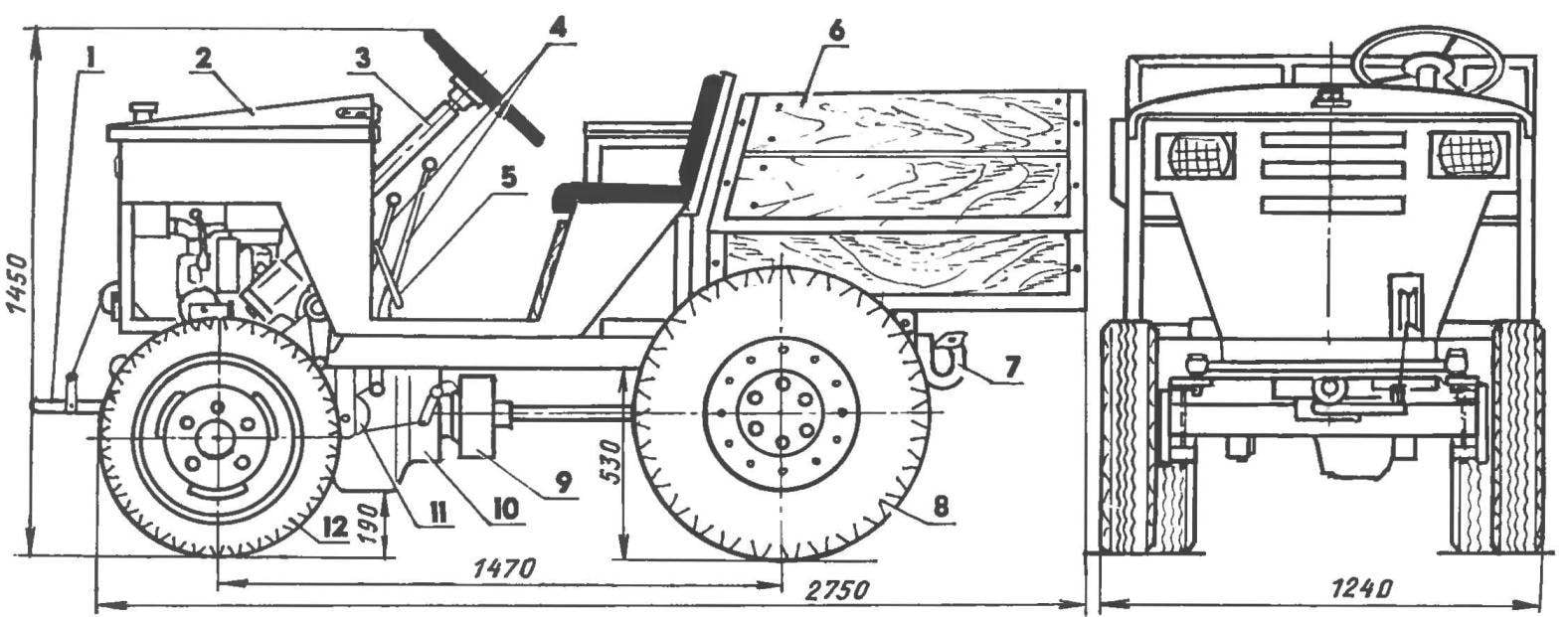

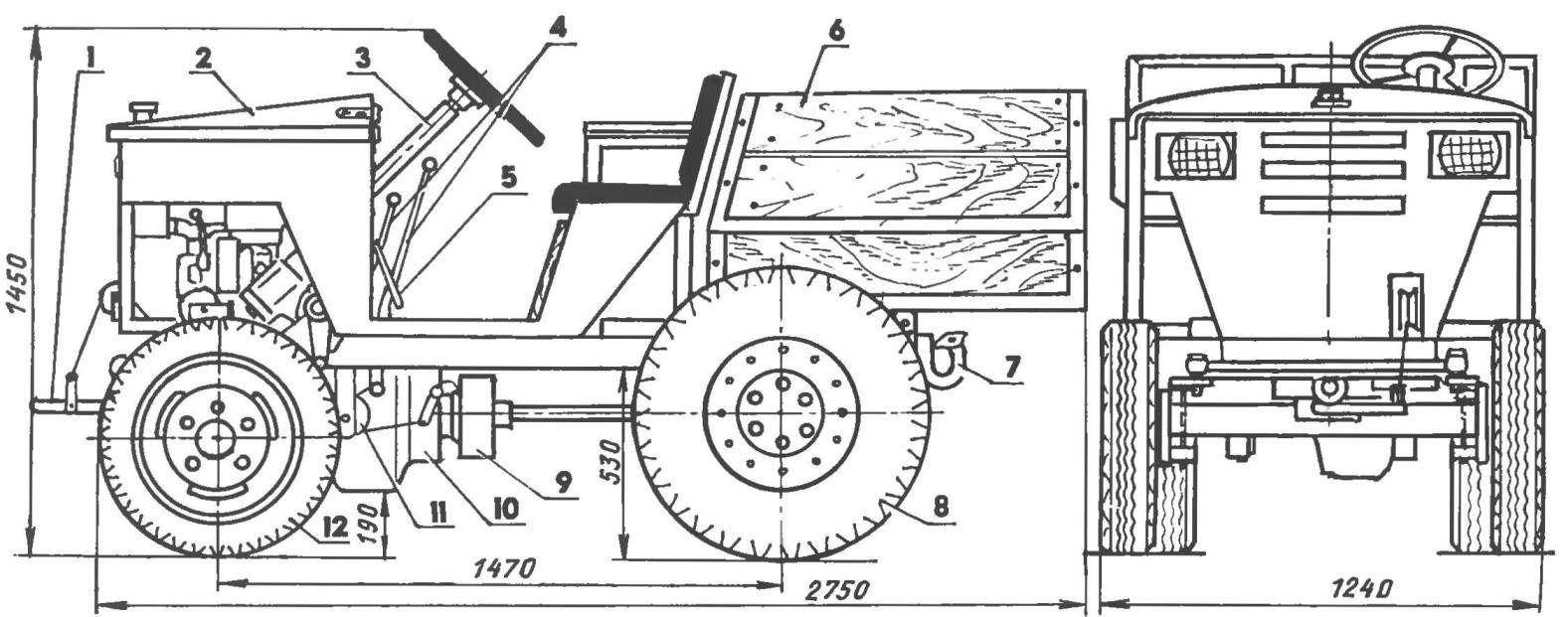

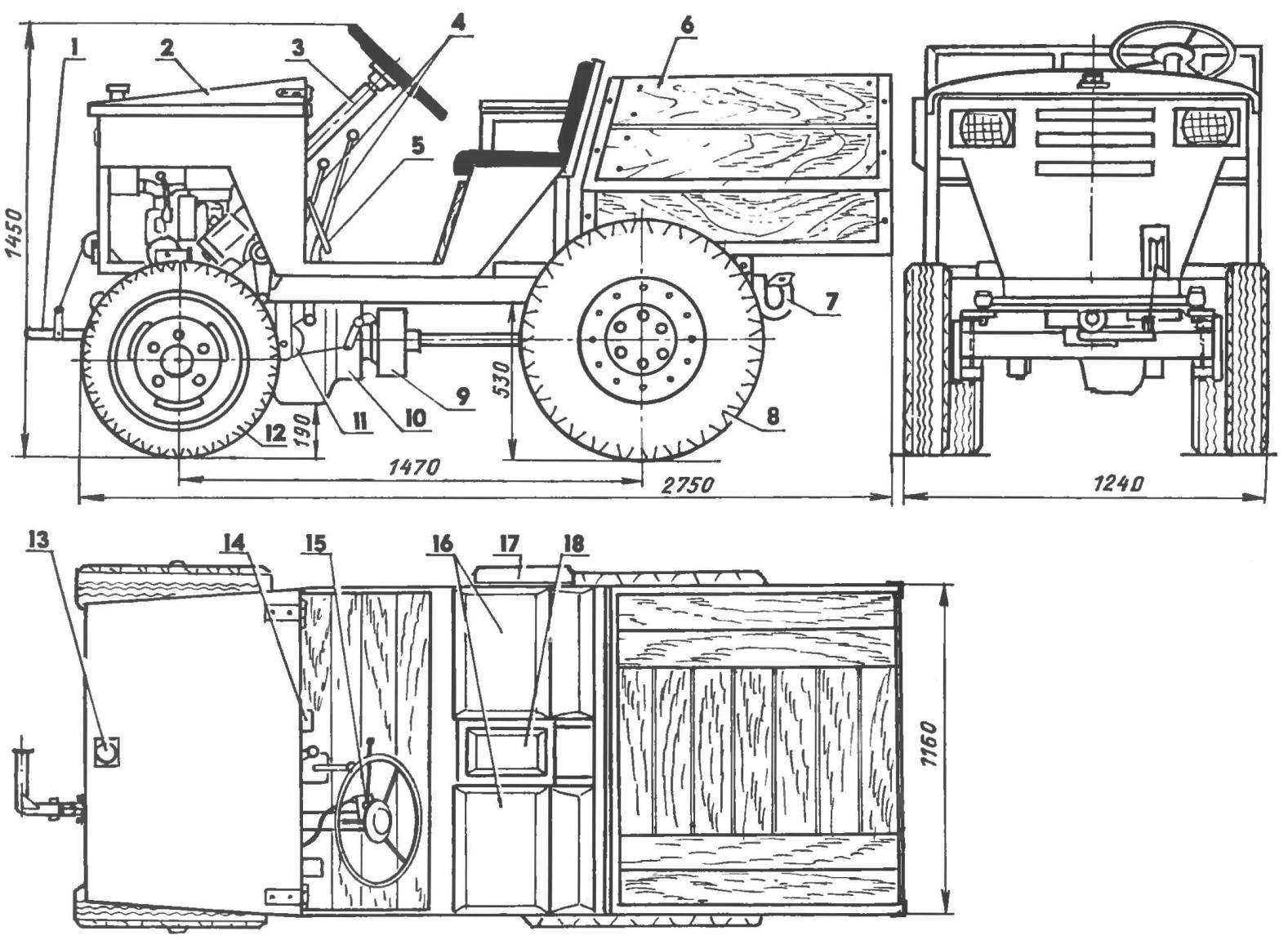

Mini-tractor “Sorinet-2”:

1 — pedal start engine; 2 — hood engine compartment; 3 — steering column, 4 — levers, gear shift, 5 brake pedal; 6 — body; 7 — tow hook; 8 — rear wheel; 9 — a brake mechanism; 10 — transmission; 11 — a pulley of a drive of brakes; 12 — front wheel; 13 the neck of the radiator; 14 — a coupling pedal; 15 — sector “gas”; 16 — seat driver and passenger seats; 17 — armrest passenger; 18 — the trunk

Frame mini-tractor with frame, engine compartment, floor and seats:

1 — limber (area 35×35); 2 — support of Chuck (area 35×35); 3 — solitaire (in the sheet s4, 14 items); 4 — mounting brackets of front axle (area 40×40); 5 — contours of the lateral cladding; 6 — lodgements engine mounts (area 40×40); 7 — l-shaped bracket steering gear mounting (sheet B4); 8 — floor frame (area 35×35); 9 — front support of the seat (tube 100×50, 2); 10,21 — cross-beams (channel № 10); 11 — side panel (corner 35×35, 4 pieces); 12 — the contours of the fuel tank; 13 — rear piping of the engine compartment (the area 35×35); 14 —beam mounting more checkpoints (area 40×40); 15,22 — spars (channel number 10); 16 — seat frame (area 35×35); 17 — back support adjustment (area 35×35, 2); 18 — the back of the seats (the area 35×35); 19 — mounting brackets rear axle (40×40 area); 20 — rear bracket of the body (area 50×50,2); 23 — armrest-passenger (area 35×35); 24 — mounting more checkpoints (area 40×40); 25 — front bracket body mounting (sheet s4, 2); 26 — member body mounting (area 35×35)

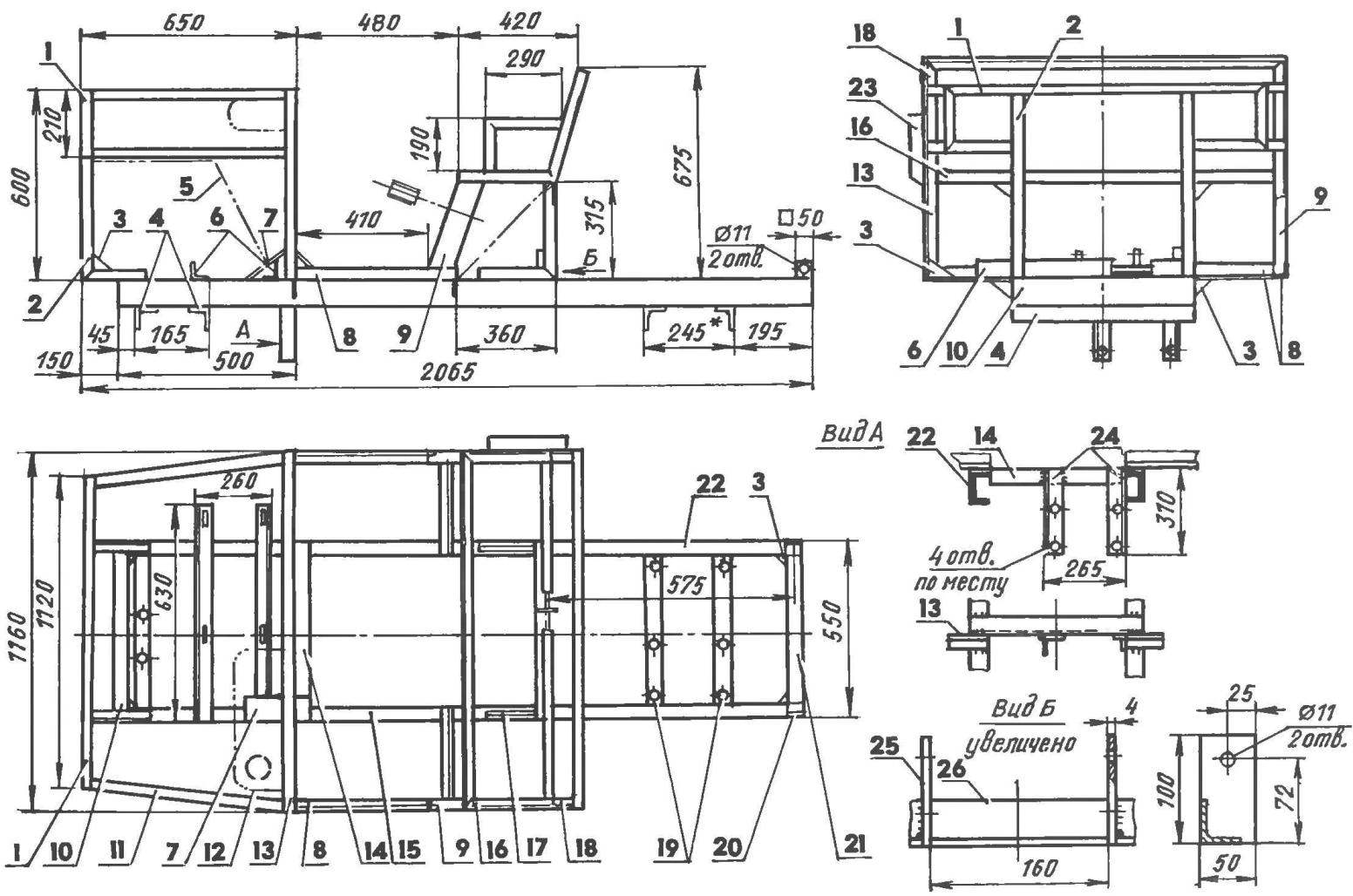

Kinematic scheme of transmission mini tractor:

1 — engine; 2 — sprocket (z = 16); 3 — 203 bearing; 4 — driven sprocket (z = 48); 5 — additional gearbox; 6 — brake mechanism; 7 — power shaft; 8 — a gear-rear axle; 9 — bearing 10 — drive wheel

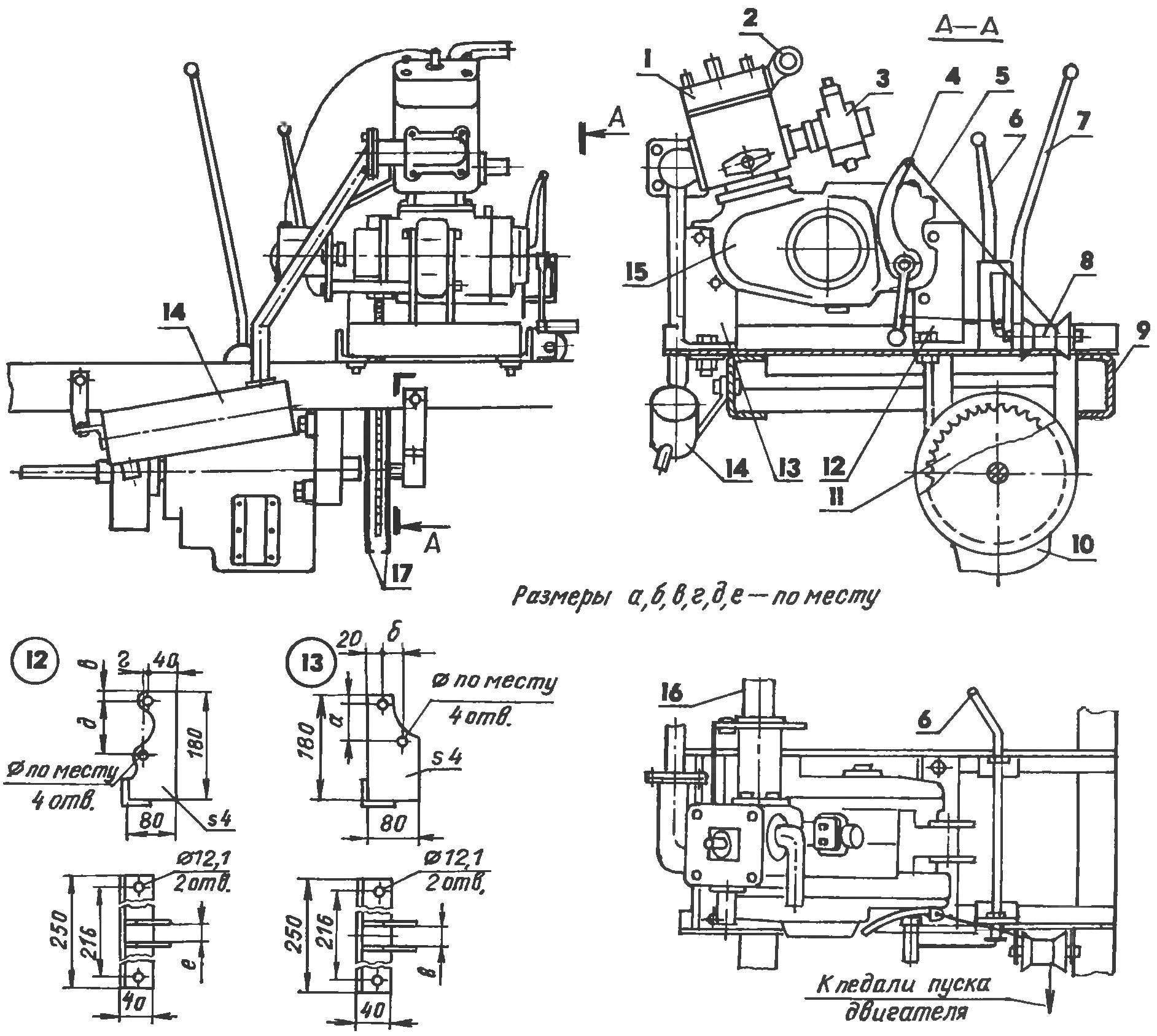

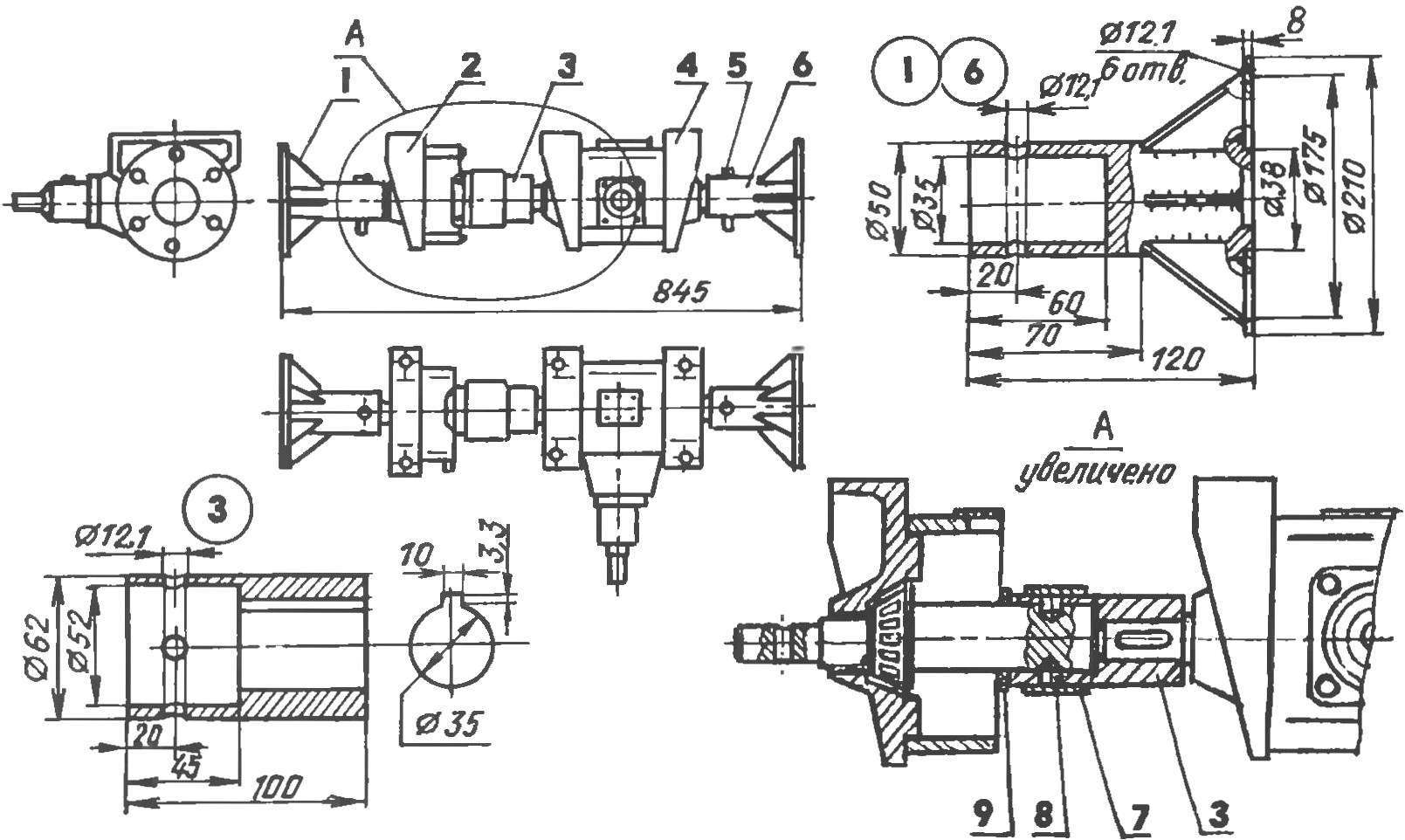

Location of the major components of the powertrain on the frame:

1 — frame; 2 — steering gear (GAZ-51; in the section a — A conventionally not shown); 3 — bracket bearing of the input shaft of the additional transmission; 4 — case input shaft bearing; 5 — additional crossing (away from the car GAZ-51); 6 — a power shaft; 7 — coupling; 8 — front axle; 9 — tow hook

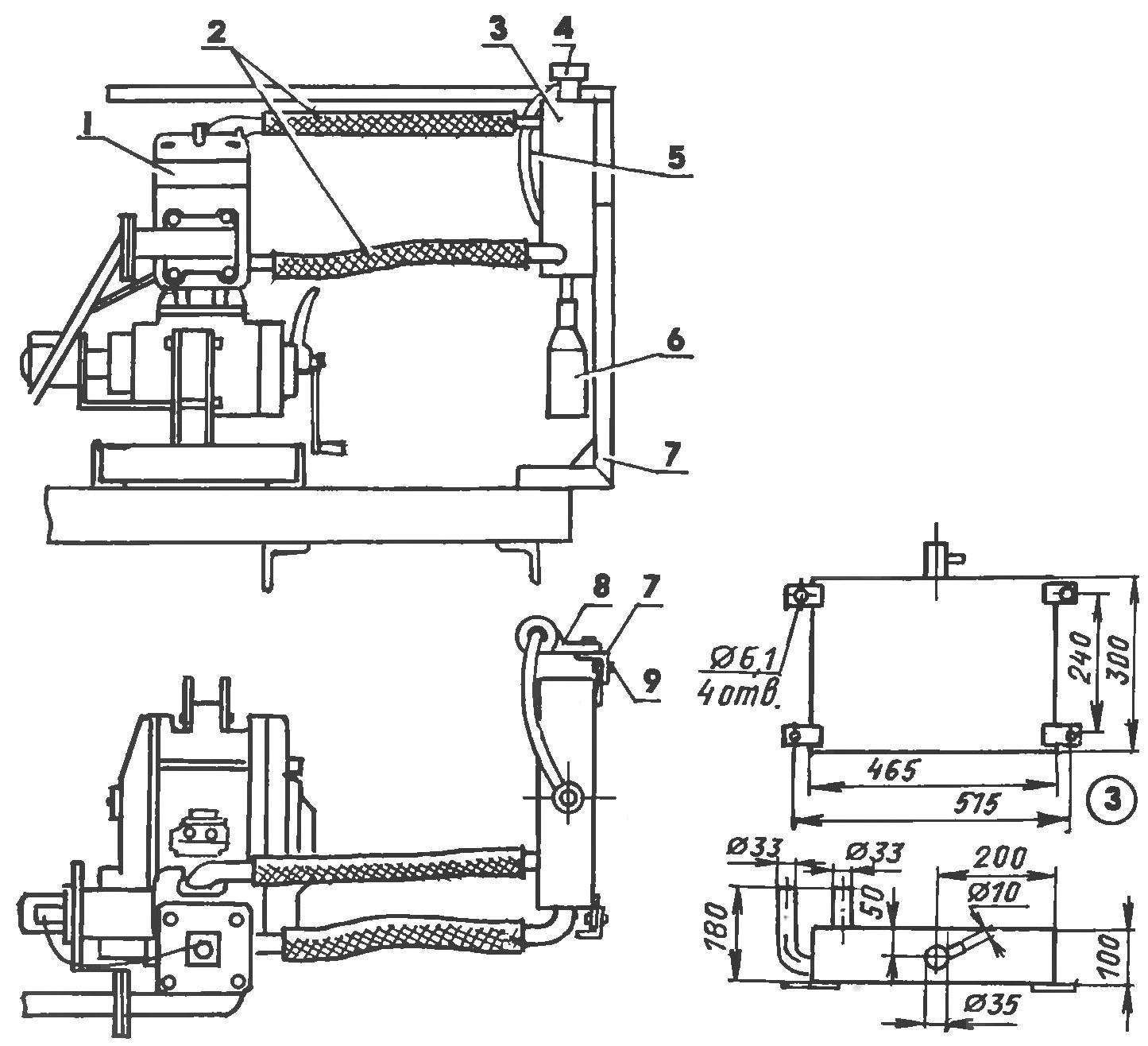

The thermosyphon cooling system:

1 — cylinder water cooling engine; 2 — rubber hoses; 3 — tank-radiator (sheet s3); 4 — filler cap tank of a radiator; 5 — a hose of a broad tank; 6 — expansion tank (plastic bottle); 7 supports of the front frame of the engine compartment; 8 — clamp-expansion tank; 9 — bolt M6 fixing tank of the radiator (4 PCs.)

The second model was intended for a narrowly specialized task — the transport of heavy loads. This makes the car fairly stringent requirements: towing vehicle must have a large margin of safety — because transporting gives a huge load on each node on each shaft on each bolt. However, the “Ocarinas-2” works flawlessly.

The FRAME of the tractor is a rectangular structure, which is based on thin-walled steel channel No. 10, with relative ease and in the same time frame provide sufficient strength.

The channels are welded cradles and brackets from the corners of various sections, which are attached to almost all the transmission units and the frames of the engine compartment, floor and seats.

The HOOD motor compartment has a frame structure from the area 35x35x4 mm and a cladding made of steel sheet with a thickness of 0.5 mm. Sheets of skin attached to the corners with screws-tapping screws.

Thanks to the hood of a car type managed in the space of the engine compartment to place a units of the power plant: engine, tank the radiator, fuel tank, etc.

FRAMES floor and seats, as well as the frame of the engine compartment, assembled from segments of area 35x35x4 mm and constitute a single whole with it. Floor, seat and backrest are recruited from birch edged boards. In fact, seat and backrest made of plywood, foam and leatherette.

The ENGINE capacity of 20 HP on the tractor of the motorcycle “IZH-Planeta-5” with built-in transmission with four gears.

Regular cylinder air-cooled engine replaced with water-cooling cylinder from tractor Puscuta PD-10U, which have greatly improved the working conditions of the motor, as without the high-speed flow of air, it quickly overheated.

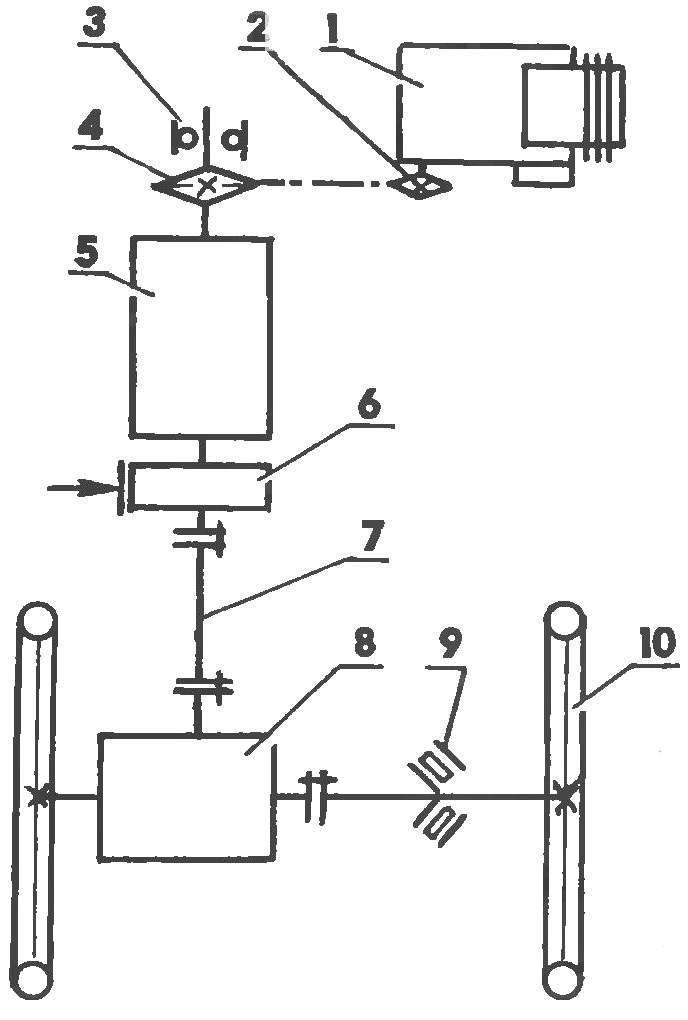

The power unit mini-tractor (on the top view of the additional transmission is not shown):

1 — cylinder, water-cooling (from the engine PD-10U); 2 — fittings for drainage and water supply; 3 carb; 4 — the lever of kick starter; 5 — the cable from the lever the kick starter pedal to start the engine; 6 — a gear lever. connected traction with the pedal transmission of the engine; 7 — the lever of additional transmission; 8 — block of the cable to the pedal starting the engine; 9 — spar frame; 10 — additional CPT; 11 — sprocket driven shaft for additional transmission; 12,13 — mounting bracket engine (area 40×40, steel sheet s4; sizes a,b,C,g—); 14 — muffler; 15 — engine (from a motorcycle “IZH-Planeta-5”); 16 — magneto (from the tractor); 17 — protective cheeks, driven sprocket (steel sheet s1)

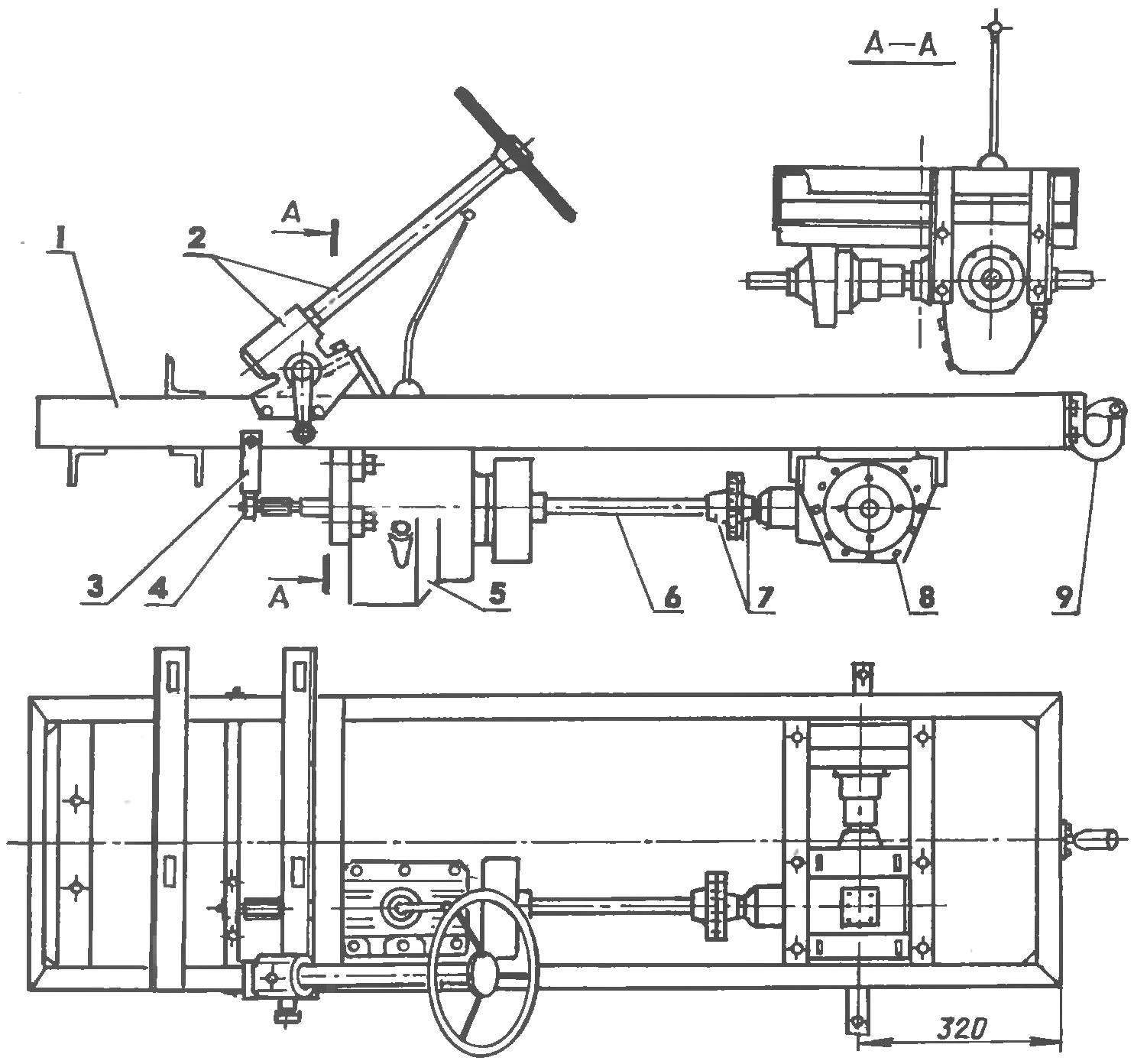

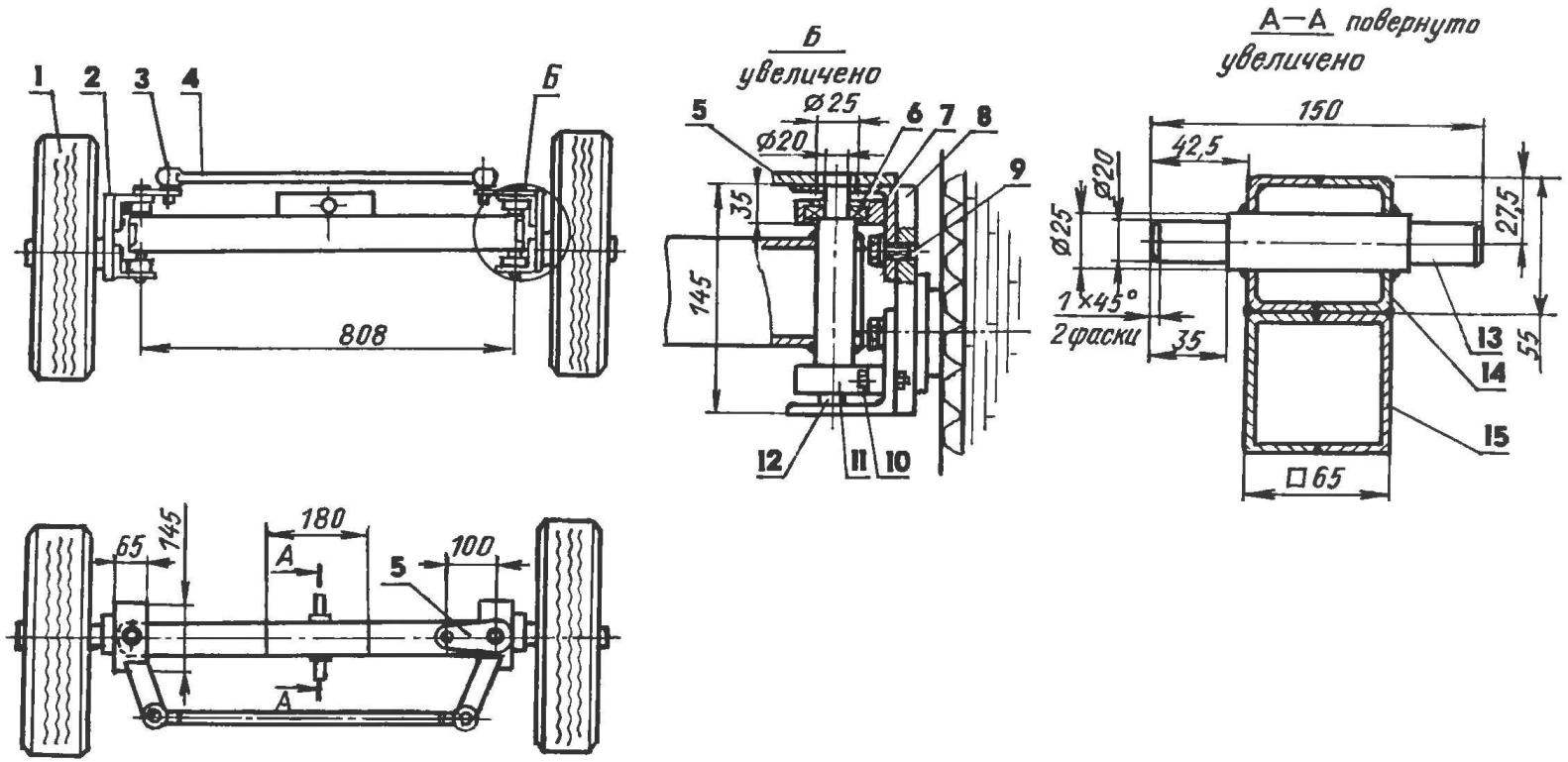

Front axle:

1 — wheel of 8.40-15′ with wheel hub; 2,8 — body knuckles (steel plate 145x80x16 and area 65x65x5); 3 — ball joint (ZIL-130); 4 — transverse thrust (from car ZIL-130, cropped); 5 — a Pitman arm (steel sheet sl0); 6 — bearing 204; 7 — top shelf knuckle (area 65x65x5); 9 — screw M12 top mount shelves (2 PCs.); 10— bolt M10 body mounting lower bearing (2 PCs); 11 — the case of the lower bearing; 12 — pin (rod Ø25); 13 — shaft swing of the axle beam (rod Ø25); 14 —shaft housing (steel channel from steel sheet s5); 15 — beam (channel 65×32,5×5)

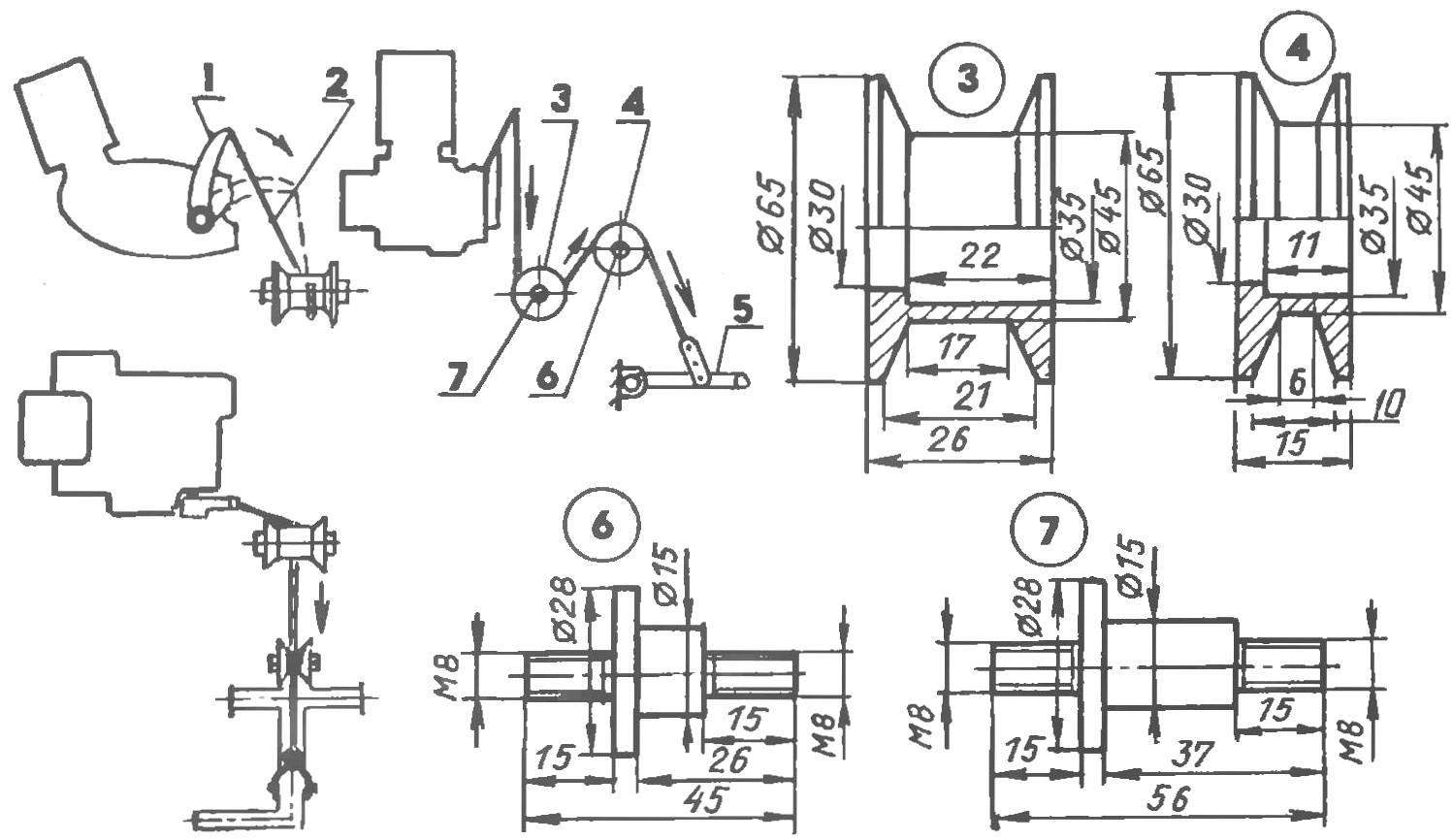

Diagram of the trigger mechanism of the engine:

1 — the lever of kick starter, 2 – the cable to the pedal starting the engine; a 3.4 — pulleys (FT4); 5 — pedal start engine; 6,7 — shafts of the pulleys (FT4); on the main view of the pulley 4 and the pedal start conventionally not shown

Bearing front axle:

1 – housing support (sheet s5); 2 — bearing shaft swing

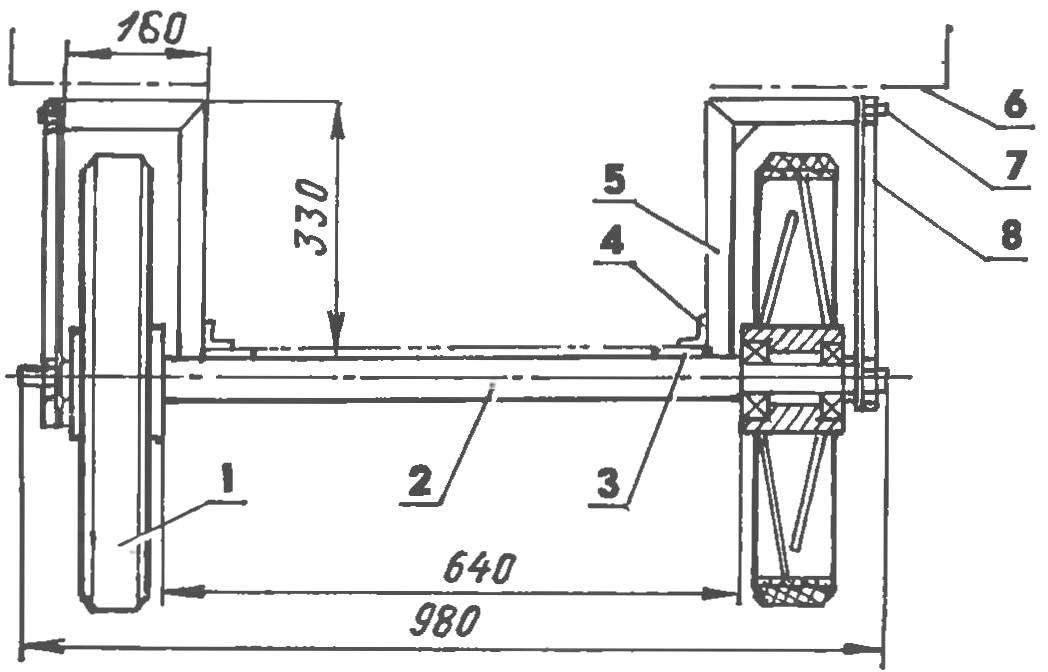

Rear axle:

1.6 — rear wheel hub; 2 — bearing; 3 — coupler; 4 — reducer (potato harvester); 5 end-to-end pin Ø12 (2); 7 – casing (steel s2); 8 — mortgage pin Ø12 (4x); 9 — boot

“Asoinca-2” selected a very simple scheme for water cooling — thermosyphon, which allows for the absence in the system of pump, fan and other such things. I’ve ruled out even the radiator of the automotive type, replacing it welded from sheet metal in a rectangular tank with a neck for filling water and pipes for connecting the hoses. The system works flawlessly! Even in extreme heat and in low gears there is no sign of engine overheating. The main thing is to occasionally check the water level in the tank is the radiator.

The ignition on the engine from a tractor magneto.

The engine is mounted across the frame of the tractor on the lodgment with the help of two brackets and four bolts. Torque from the output sprocket is transmitted to the input shaft of the additional transmission motorcycle chain.

The launch of the power plant is operated by a pedal connected by a cable (via a system of pulleys on bearings 202) with the kickstarter the engine. The result is a dense layout of nodes of the engine compartment, the pedal had to be located on the front crossmember of the frame. However, this system works reliably.

ADDITIONAL transmission with four forward gears and one back — from the GAZ-51. She shifted to the left of the axis of symmetry of the tractor and is attached with four bolts to the vertical corner brackets of the frame. This transmission lever on the driver workplace is located next to the lever, a thrust is controlled by the transmission built into the engine.

This transmission gives the tractor working speeds in the range of 3 to 30 km/h.

The Parking brake mechanism, available in more checkpoints, performs the function of a main brake of the tractor. He is driven by a pedal under the left foot of the driver (the clutch pedal is the right leg).

Homemade shaft brake mechanism connected with the rear axle of the tractor.

REAR AXLE — pestiferously composed of one conical reducer potato harvester and of the other gear. Such a device is well established mini-tractor “Ocarinas”, and I turned to this tried and tested mechanism. For extensions of gauge towing vehicle added another half of the same gear, cut from a simple hacksaw.

Rear axle is attached to its bracket under the frame with six screws. Wheel tractor — three-ton tractor truck. To thaw put them on the chains.

FRONT AXLE. His beam welded from two segments of area 65x65x5 mm in the form of a square pipe. From cuts the same corners and thick steel plate made and knuckles. To the upper shelves fists welded conical bushing bolt ball joints and the right — and even a Pitman arm. The ball joint and transverse link (shortened) from car ZIL — 130. Tie — rod- car GAS-53, the steering column is from the GAZ-51 (both of these details are also shortened).

The wheels of the front axle size 8,40-15′ — charged mobile sawmill (the same are used, usually on different machines for agricultural purposes). These wheels I got together with hubs and even with fasteners, which greatly facilitated their installation.

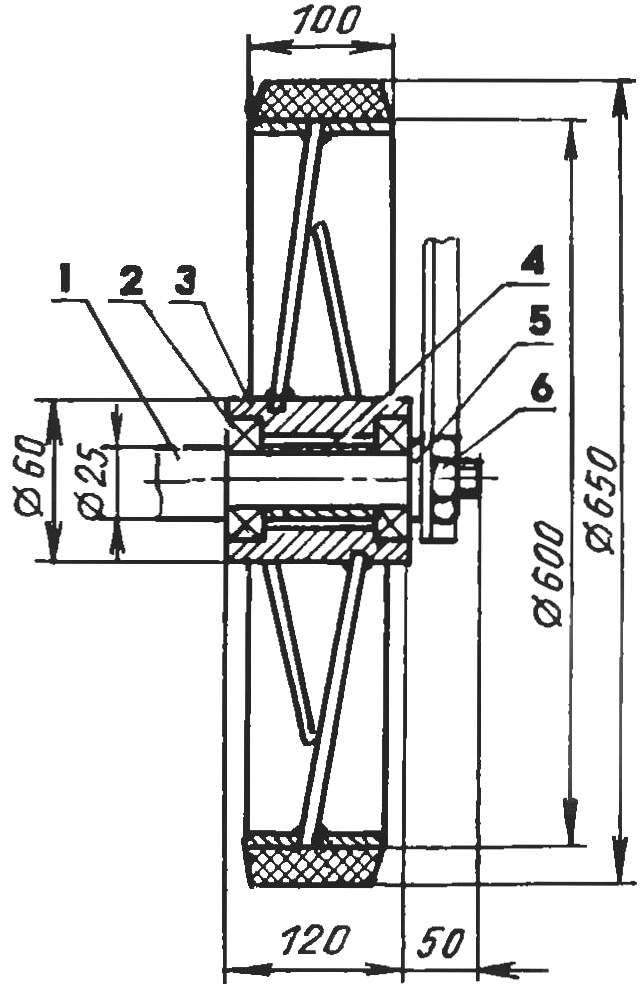

Trailer wheel and its position on the axis:

1 — wheel axle (steel, Ø25 rod); 2 — the bearing 204 (2); 3 — hub; 4 — spacer (tube 24×2); 5 — shaft; 6 — nut M18 x 1 5

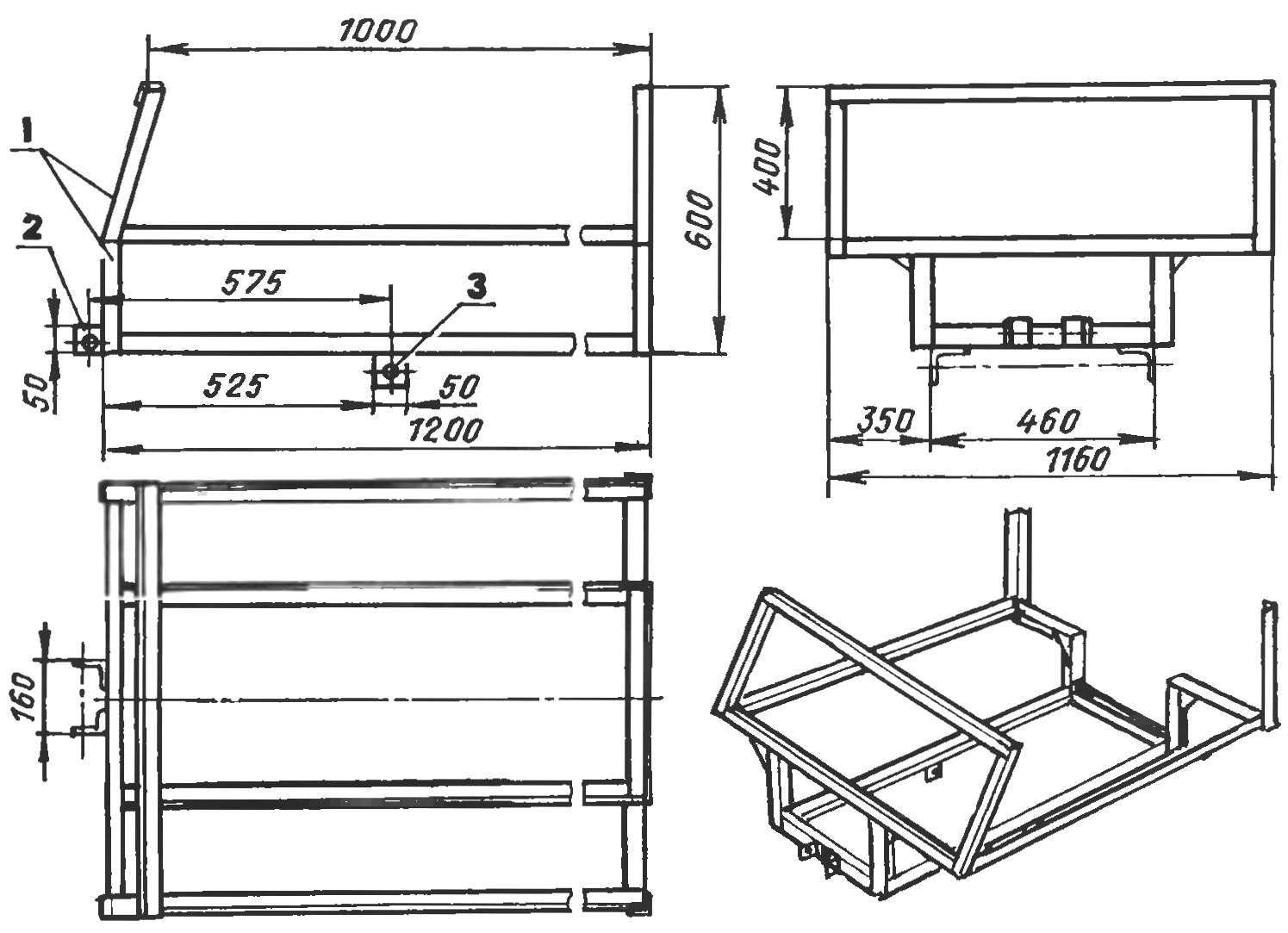

Body shell:

1 — the elements of the framework (area 40x40x4); 2 — front eyelet (area 50×50, 2); 3 — rear eyelet (area 50×50, 2 PCs.)

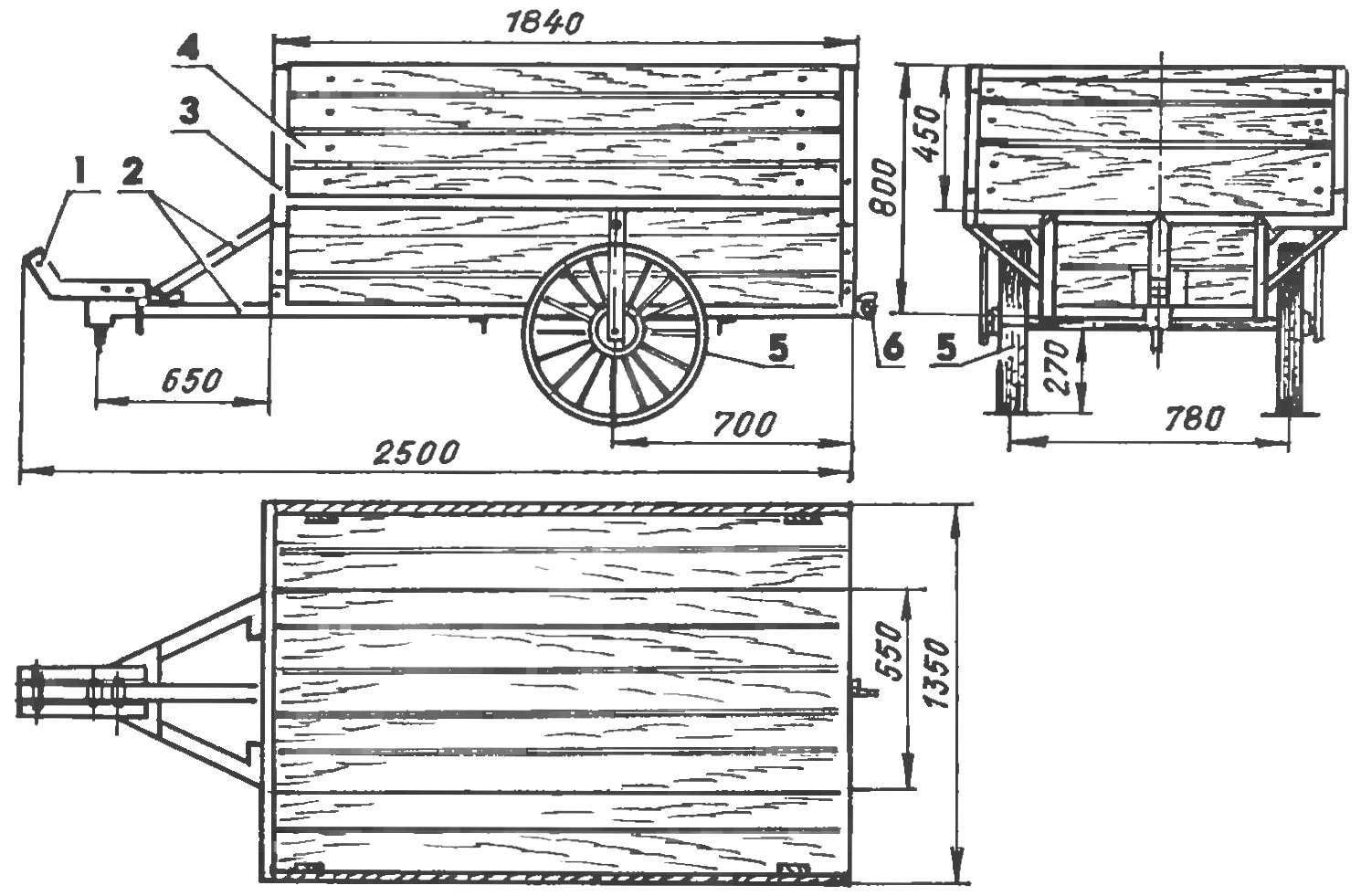

Tractor trailer:

1 — universal hitch; 2 — struts carrier (40×40 area); 3 — the frame of the trailer (the area 40x40x4); 4 — casing (birch edged Board s15…25); 5 — wheel; 6 — tow hook

Axle trailer:

1 steel — rubber coated wheel; 2 — axle; 3 — lining (steel strip s1…5, 2); 4 — frame element of the trailer (the area 40×40); 5 — clamp (area 40×40,2); 6 — contours of the side of the trailer; 7 — bolt M10 mounting rack to the bracket (2 pieces); 8 — (40×40 area, 2 PC.)

And rear, front axle is attached to the angle brackets under the frame. But not directly, but by means of two bearings, in the bearings that hold the axis of swing of the axle beam. Between the pillars and the brackets under the bolts to put the shims.

The BODY of the tractor designed to transport small loads of up to 250 kg, for those cases where the use of a tractor trailer is irrational.

The body frame is made of angle 40x40x4 mm birch and covered with edging Board. It is held on the frame by means of four lugs and bolts.

In the original version the body was able to tip over like a dump, but then is useless for this function was rigidly fixed. You have the option of folding the rear side.

TRAILER. Of course, Arsenal have a tractor and a cargo trailer. Design it provides a useful amount even in a niche between the wheels that are not often seen in makeshift trailers In comparison with analogues (same dimensions) but my trailer allows you to carry a lot of cargo on 20 — 25 percent more.

Frame structure of the trailer carrier, which minimized its mass. Like the exterior, the trailer is lined with birch edged Board 25 mm thick (floors) and 15 mm (wall). All wooden parts are painted with a sexual oil paint, diluted with linseed oil. Like the tractor, the trailer has rear hook for connection with the wheel console used for the carriage of long items. Trailer load capacity is one ton.

S. GORYACHEV, Rybinsk, Yaroslavl region.