The proposed mini-farm is designed for breeding and keeping rabbits of any breed in both private and public subsidiary farms. Its basis is a two-tier cage-module (if necessary, there can be several of them, united by a common roof). The farm’s design and maintenance regime are thought out so that it can be used even by amateur rabbit breeders who can care for the animals only once a week—on their days off. It is with this frequency that feeders are filled with hay, root crops, or feed; no more often are the canister automatic drinkers with water heating. The slatted floor of the cages with funnel-shaped sloping shafts for manure makes unnecessary the constant cleaning and maintenance that would otherwise be required.

The cage design is simple, and construction costs are recouped in the first months of operation. Only two sheets of fiberboard, two sheets of three-layer plywood, four 60X100 mm beams, 50 picket planks, 4 m2 of roofing felt for trays, nails, and paint are needed. In addition, the equipment set will include two deep enameled bowls (approximately 220 mm in diameter), four canisters (for example, five-liter polyethylene ones from “Tosol”), a manure collection tank up to 300 mm high, two VPI-03 electric kettles (household, immersion type), and step-down transformers 220X127 V (four for 7—8 cages).

The design of each cage is calculated for strict orientation by cardinal directions: the blind, closed wall with boxes of hay racks and feeders faces north and shields the animals from cold winds; the roof overhangs 900 mm on the north side, 600 mm on the south, and is flush with the protruding beams on the west and east.

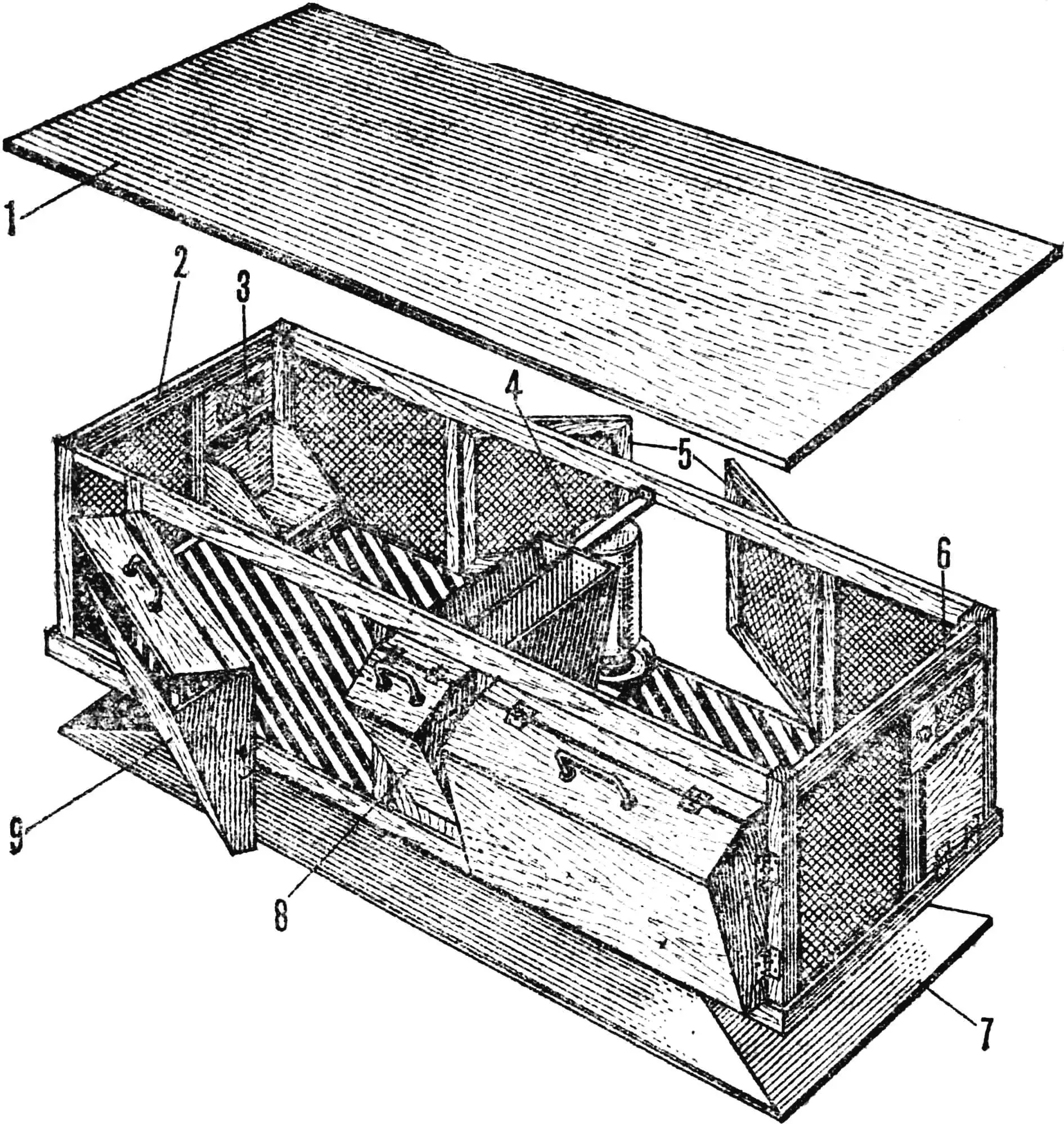

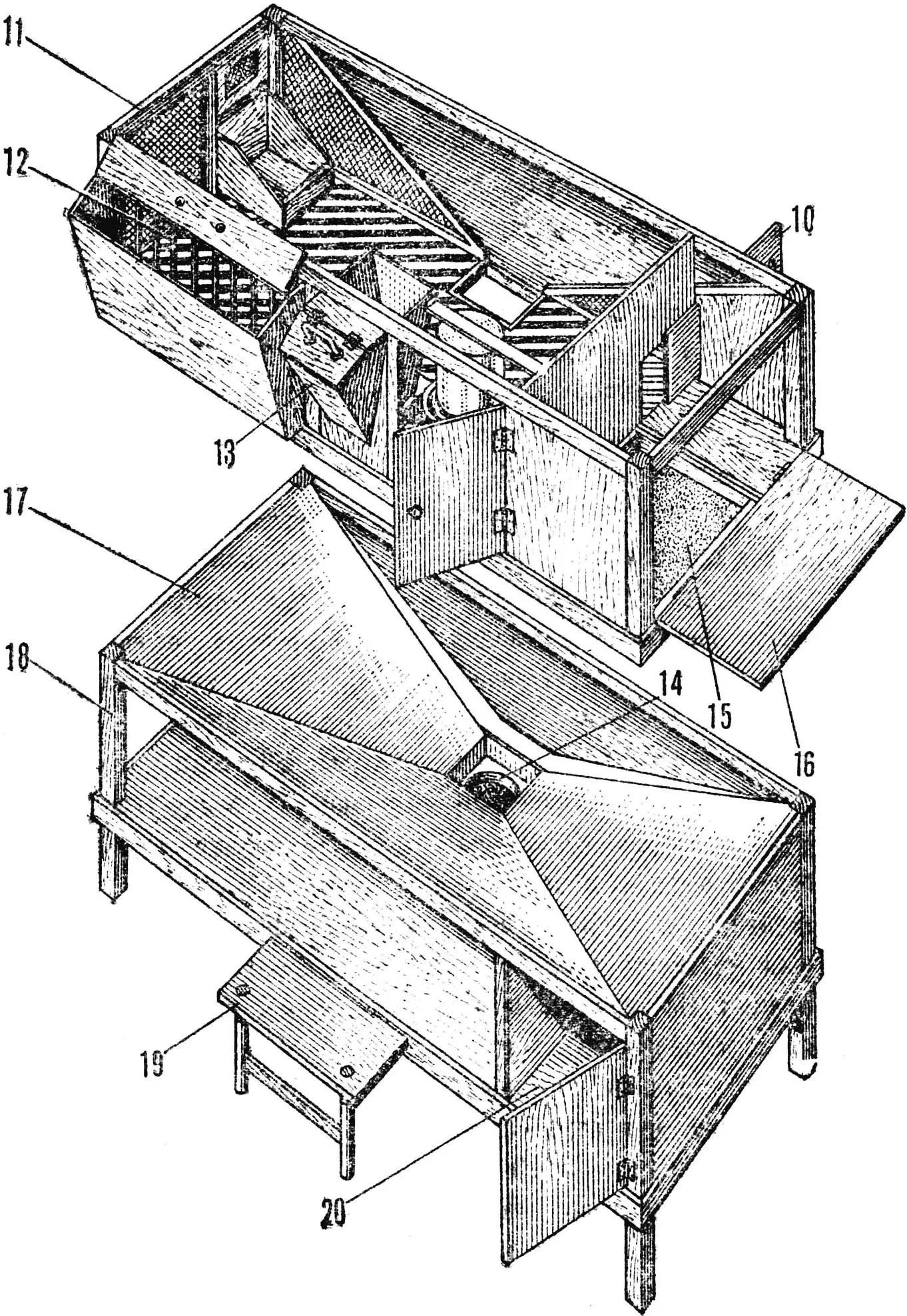

The cage consists of a base frame, lower and upper tiers. When installing the structure in an open area, it is equipped with a roof made of roofing material, preferably transparent or semi-transparent, or simply roofing felt as a last resort.

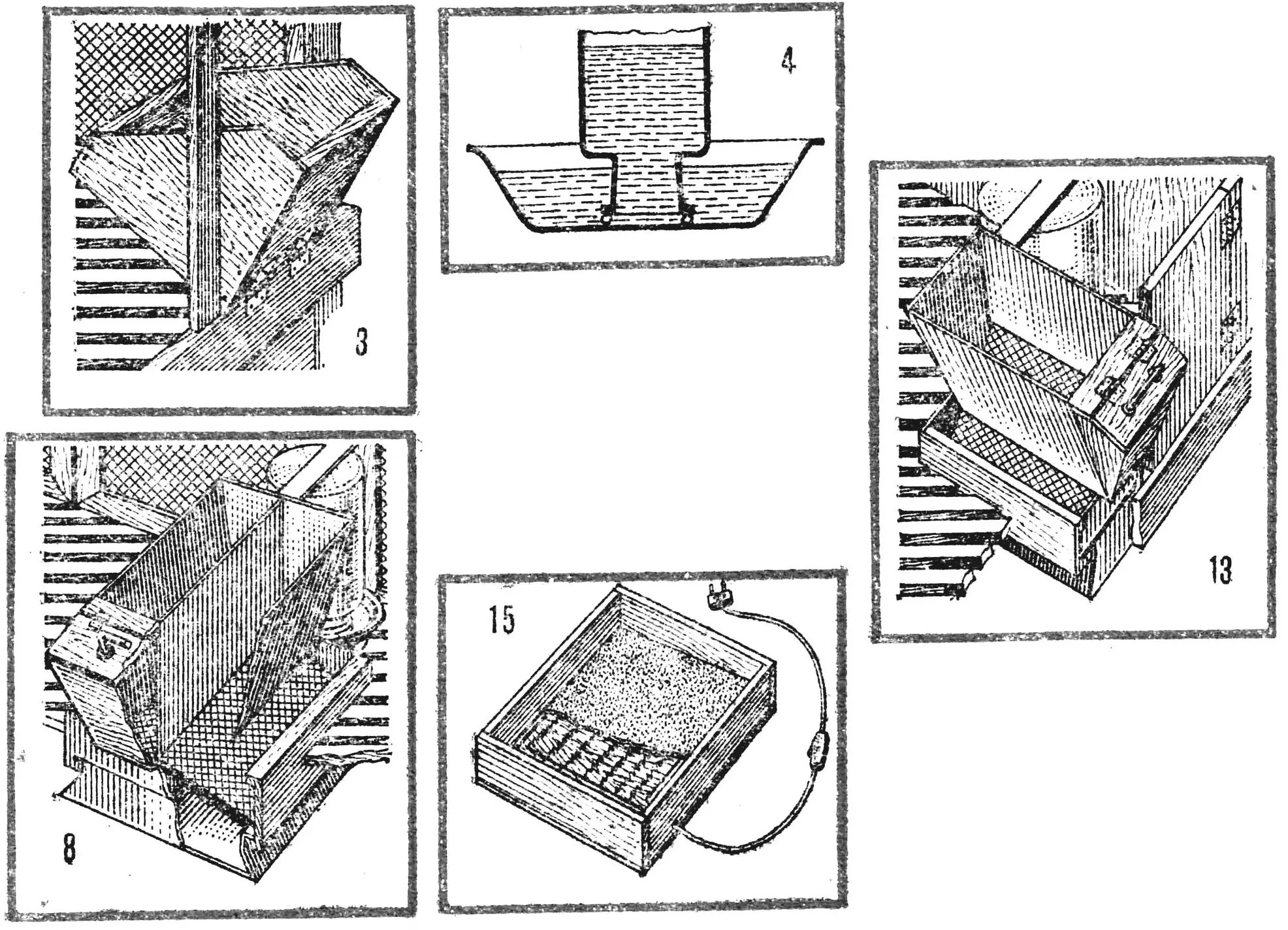

The upper tier in the main version is a weaning tier, serving for raising young rabbits after the suckling period. The space is made of cells of different floor areas: one of them extends beyond the frame dimensions. Males live in it; however, if the number of females in the litter predominates, the larger cell is given to them. The halves of the weaning tier are separated by a feed hopper working on both sides and a shared canister drinker. In addition, each compartment has a hinged feeder for root crops, as well as hay racks for grass and hay, made as an opening door; there is also a door to the automatic drinker. The tier floor is horizontal, made of wooden slats arranged at 45° so that young rabbits don’t injure their paws. The walls and doors (except the northern ones) are slatted.

1 — roof, 2 — upper tier frame, 3 — root crop feeder of weaning compartment, 4 — drinker, 5 — weaning compartment doors, 6 — root crop feeder door, 7, 17 — sloping shaft, 8, 13 — feed hopper, 9 — hay rack, 10 — nesting compartment shutter, 11 — lower tier frame, 12 — hay rack grid, 14 — manure collection tank, 15 — nest box, 16 — nest box door, 18 — base frame, 19 — folding bench, 20 — tool box.

The same elements make up the lower breeding tier of two—nesting and exercise—compartments. The first has a removable floor section located lower than the rest of the tier area: a nest box is placed here before kindling; the doe will move into it, obeying her burrowing instinct. The rest of the nesting compartment is stationary, equipped with a wall with an opening, covered with a shutter if necessary. The door to the nesting compartment has hinges at the bottom; when opening (folding down) the door, a platform is formed.

The exercise compartment also has a slatted floor, only with reverse slat arrangement, perpendicular to the direction of the upper tier assembly, which, by the way, achieves greater rigidity of the entire structure. The exercise area has a canister drinker, a hinged feeder for root crops, and a bunker feed hopper. The hay rack door is also hung on the post of the rear wall of the exercise area. In addition, there is a door for installing the automatic drinker.

An opening is made in the exercise floor under the conical end of the sloping shaft, reinforced under the upper tier floor. The sloping shaft of the lower tier connects to a bunker equipped with a removable door and a container for manure collection. Inspection and periodic cleaning of the shafts—through special doors. They also provide access to containers for disposal of feed meal, located under the inclined screens of the feed hoppers.

In the lower part of the cage frame is an electrical equipment compartment, which can also serve as a lockable room for separating rabbits or storing valuable tools. Nearby there is a shelf for auxiliary devices for cage care; in the middle is a folding base-bench, on which one stands when working with the upper tier or uses it for rest.

For convenience of loading feeders, they are made protruding or folding outward. Thus, root crop feeders open by turning toward you and are held in this position by the upper door; by folding it back, you can fully turn the feeder and turn it into a table.

Feed hoppers consist of a body with windows for feeding rabbits and a tray. The latter is a fine-mesh screen that passes meal to a pull-out container for subsequent disposal.

Folding elements of the cage are equipped with handles, hinges, shutters, and, if necessary, mortise locks. The side and front walls of the cage are covered with fine mesh, and the working side of the hay racks is large-mesh.

Up to 25 animals are kept in one cage simultaneously: in the lower tier—a doe with a new litter, in the upper tier—the previous offspring. When keeping ten females in eight cages (two cages have an upper breeding tier, one—a male tier), a daily output of one rabbit weighing 4.5 kg is achieved.

A mini-farm does not require a large area: one cage occupies only 1.4 m2; a two-row mini-shed of eight cages with a gap between them of 70 cm (by legs) and a passage of 110 cm—an area of less than 25 m2.

Experience and practice of operating two-tier cages for several years on an experimental farm have shown not only profitability but also high profitability of using the described design in amateur rabbit breeding, protected by author’s certificate No. 782773 with priority from November 20, 1978.

«M-K» 5’83, I. MIKHAILOV, inventor