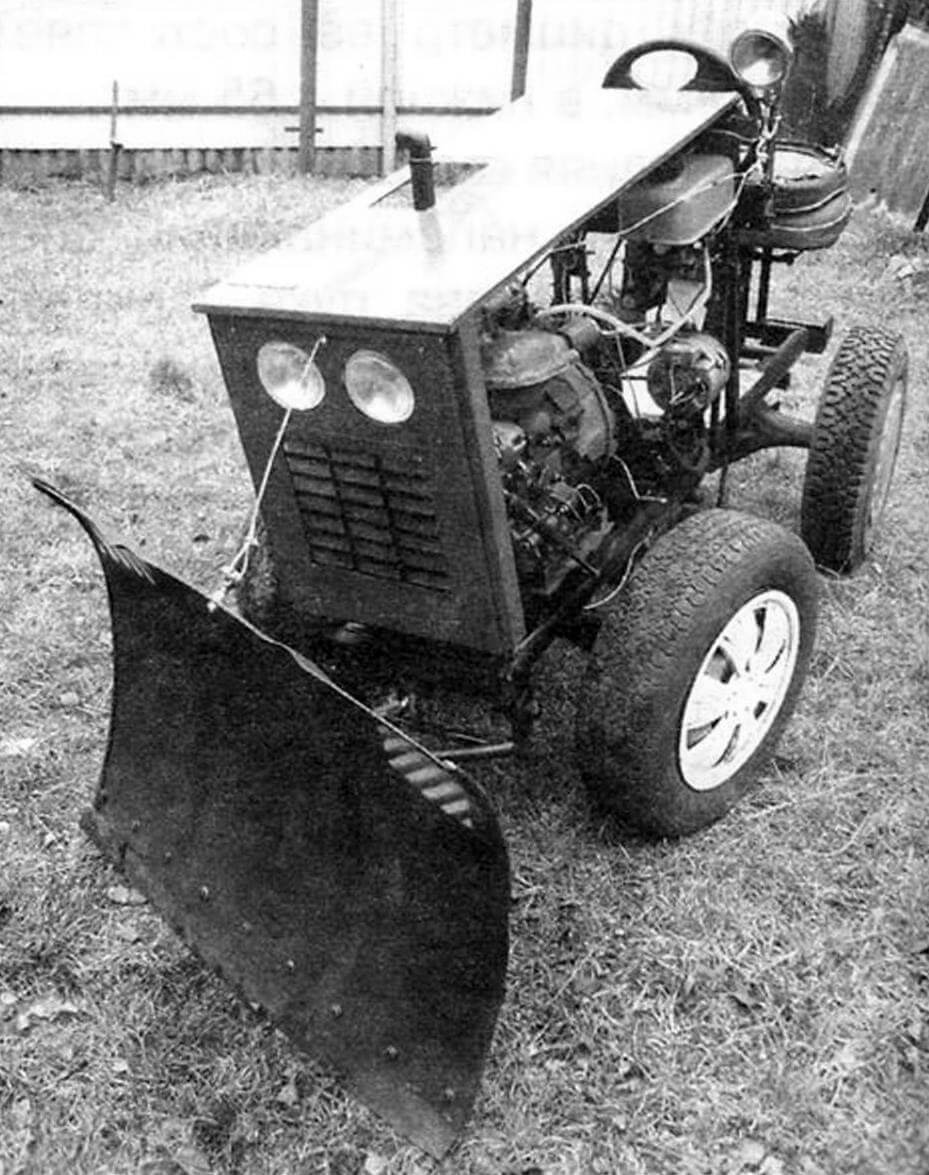

The idea to create a mechanical four-wheeled assistant came after several years of cultivating a summer cottage with a homemade walk-behind tractor, which turned out to be very heavy and difficult to control and was quite exhausting during the agricultural work season. And on top of that, I wanted to have a universal machine that would help both in summer and winter, and also did not take up much space and could easily fit into a car trailer for transportation on public roads.

I started by looking through the Modelist-Constructor magazines I had and searching for drawings. As a result, the basic layout of the mini-tractor was formed. Its dimensions determined the size of the trailer I had, and the track should be about 700 mm so that the beds could be processed without damaging the plants.

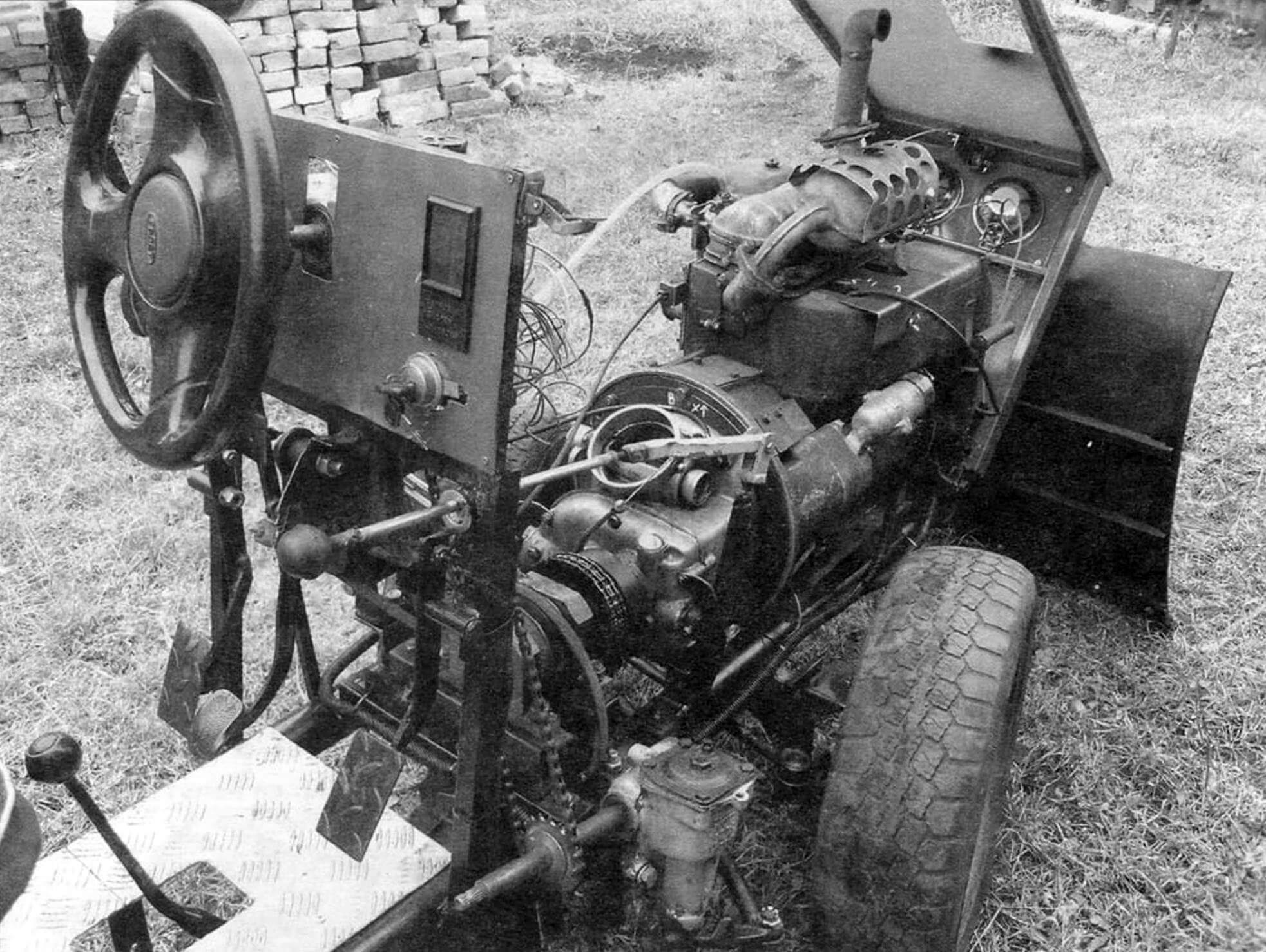

It all started with the search and purchase of a UD-25 motor, which I found through an advertisement in the newspaper, although options were considered using imported motors for walk-behind tractors, of which there are many in stores now. I liked the motor because it has sufficient power, its own cooling system and small dimensions. The only thing that was missing was an electric starter, but a friend helped me solve this problem; he gave me a starter from LUAZ, which fit perfectly after modifying the engine cooling casing.

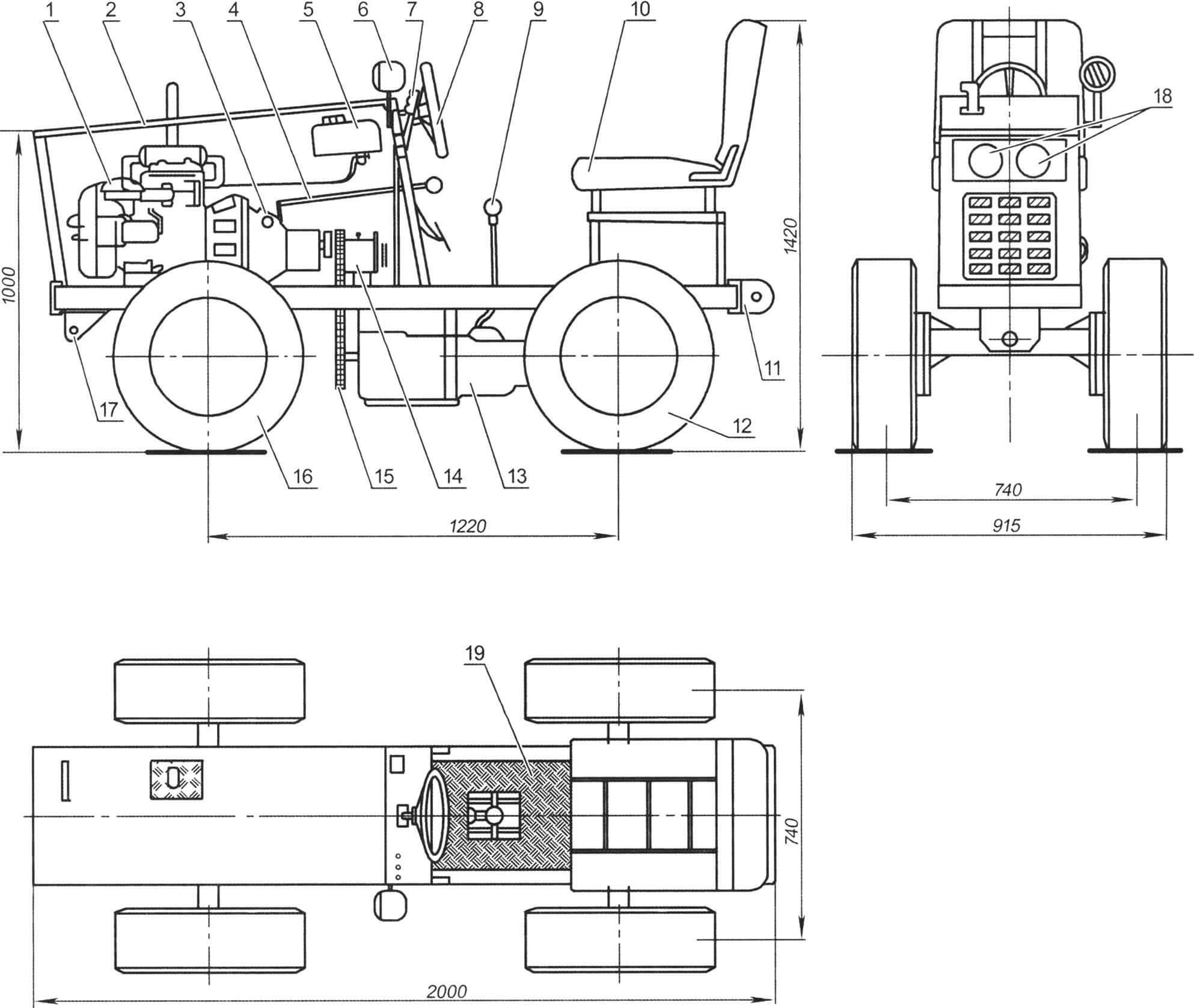

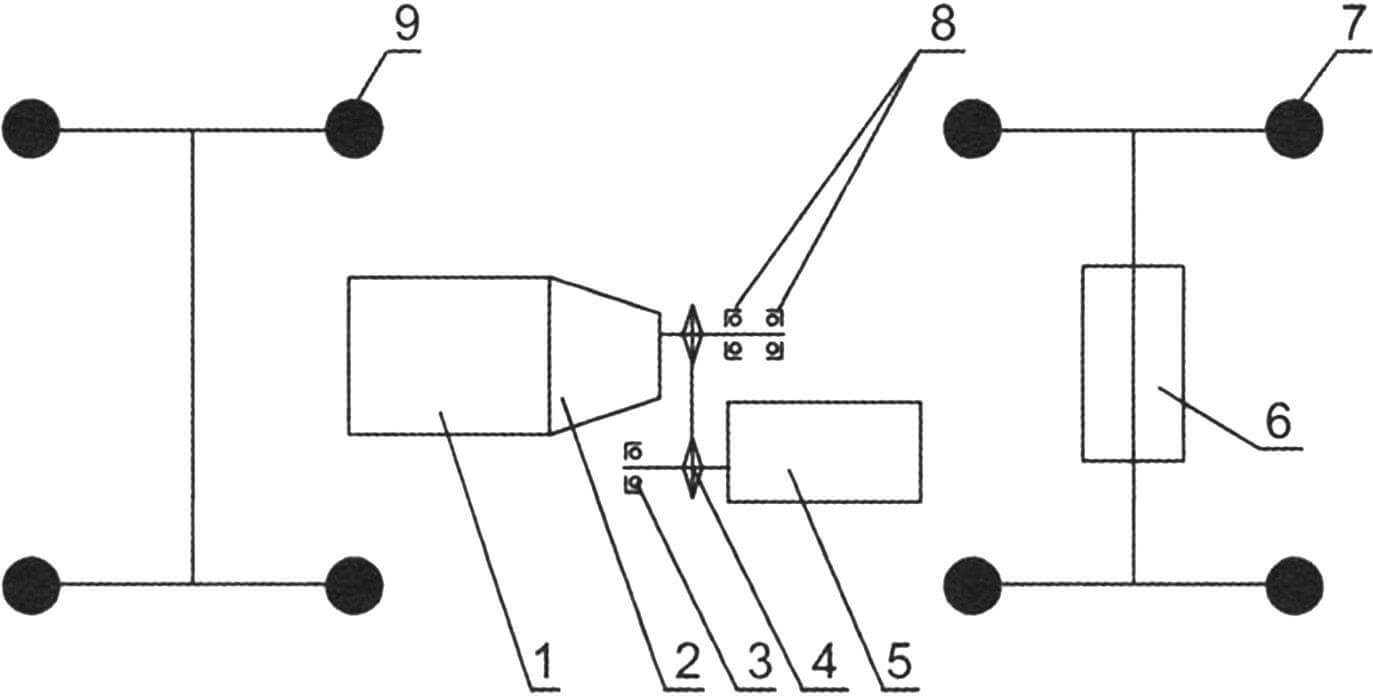

1 — power unit UD-25; 2 — hood; 3 — gearbox (from the Ural motorcycle); 4 — gear shift lever (for the gearbox from the Ural motorcycle); 5 — gas tank (from a Ural chainsaw); 6 — searchlight; 7 — lever for raising and lowering the blade (handbrake from a VAZ car); 8 — steering wheel (from a VAZ car); 9 — gear shift lever (from a VAZ car); 10 — seat (from a Kamaz vehicle); 11 — eye (steel s12, 2 pcs.); 12 — rear wheel (from the Moskvich car); 13 — gearbox (from a VAZ car); 14 — generator (from the Moskvich car); 15 — main chain drive (double-row chain with sprockets from the timing drive of a VAZ car); 16 — front steered wheels with hubs (from a VAZ car); 17 — eye (steel s12, 2 pcs); 18 — headlights; 19 – floor (aluminum corrugated sheet)

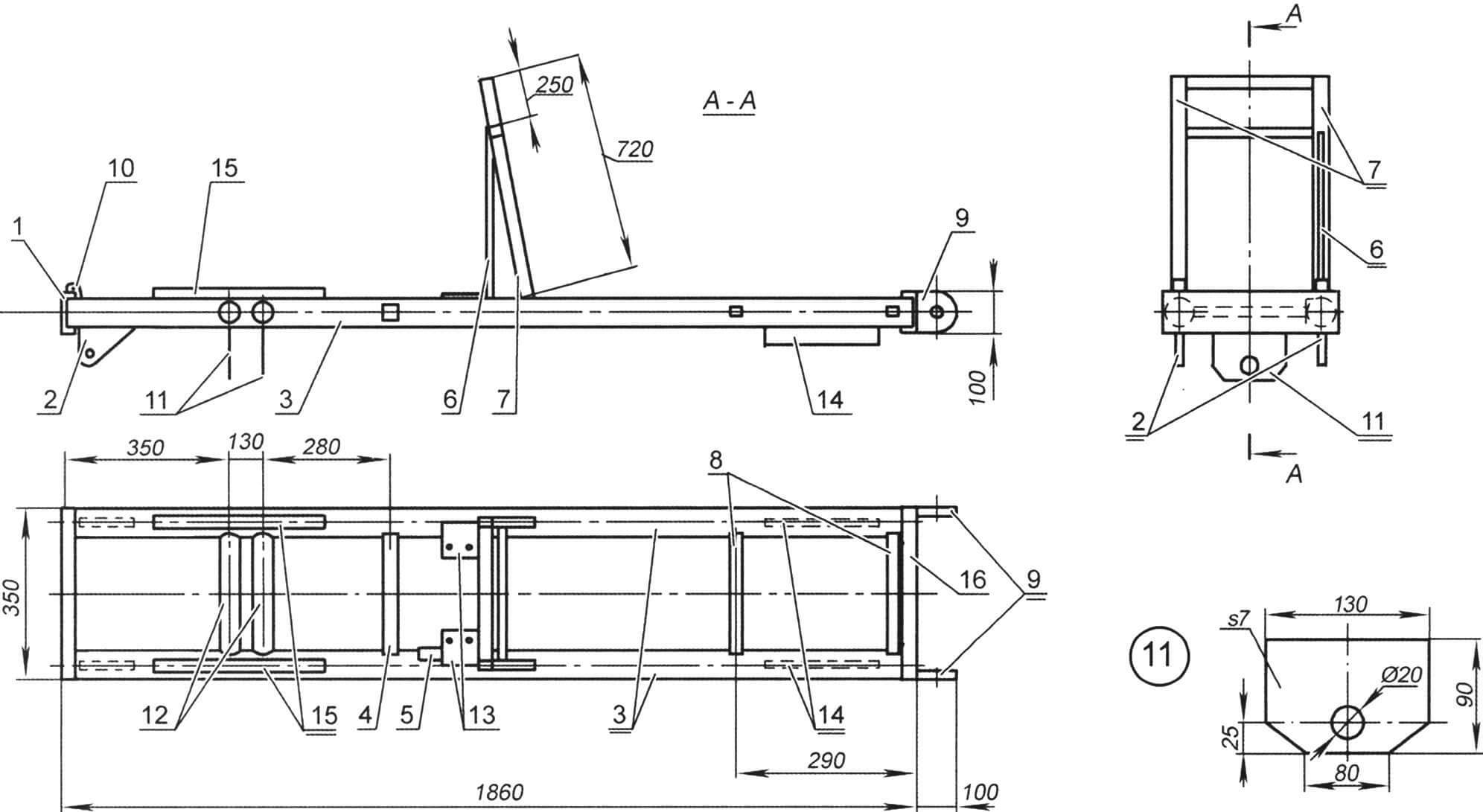

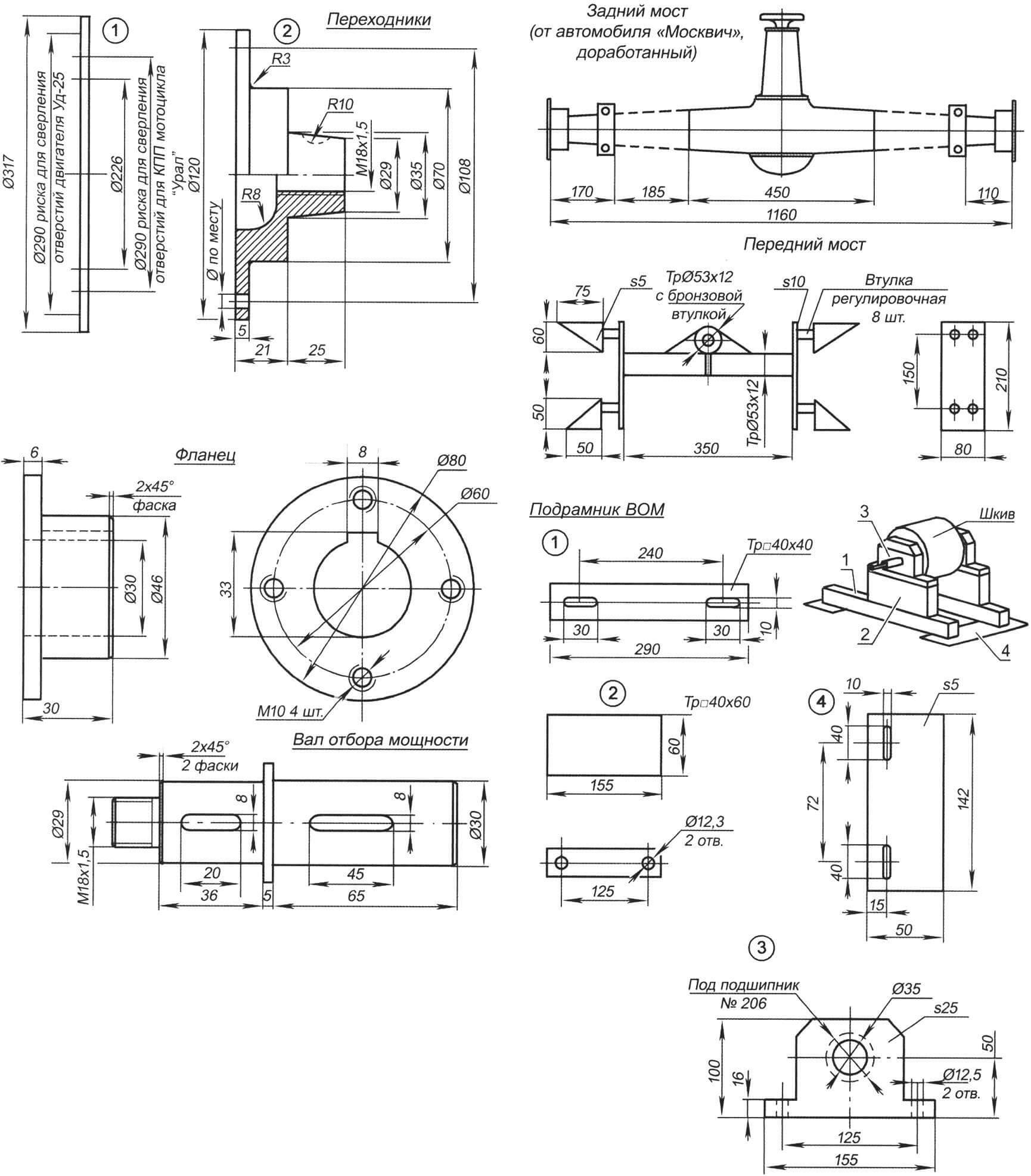

After the engine was overhauled and ready for use, work began on creating the frame, and this was very difficult since the dimensions of the tractor are small, and I did not want to raise the units high above the frame so that the tractor would not be prone to tipping over. The frame turned out to be rectangular in shape, it was welded from water pipes with a diameter of 57 mm and reinforced with cross members from a pipe with a diameter of 53 mm. Brackets for fastening axles, units and seats are welded to the frame, and a U-shaped stand for pedals, panels and steering wheels is installed.

1 — front bumper (channel No. 6.5, L=350); 2 — eye (steel s12, 2 pcs.); 3 — spar (pipe Ø57); 4 — cross member (pipe 40×20); 5 — generator mounting bracket (angle 50×50, L=75); 6 — amplifier (pipe 15×15, L=450); 7 — stand (pipe 25×25, L=720); 8 — crossbars for fastening the seat (pipe 25×25); 9 — eyes (steel s12); 10 — hood mounting ear (steel s5, 2 pcs.); 11 — front axle mounting bracket (steel s5, 2 pcs.); 12 — cross member (pipe Ø53, 2 pcs.); 13 — PTO frame mounting bracket (steel s5, 2 pcs.); 14 — rear axle mounting bracket (steel s7, 2 pcs.); 15 — motor mounting bracket (pipe 50×25, L=245, 2 pcs.); 16 — rear bumper (channel No. 8, L=350)

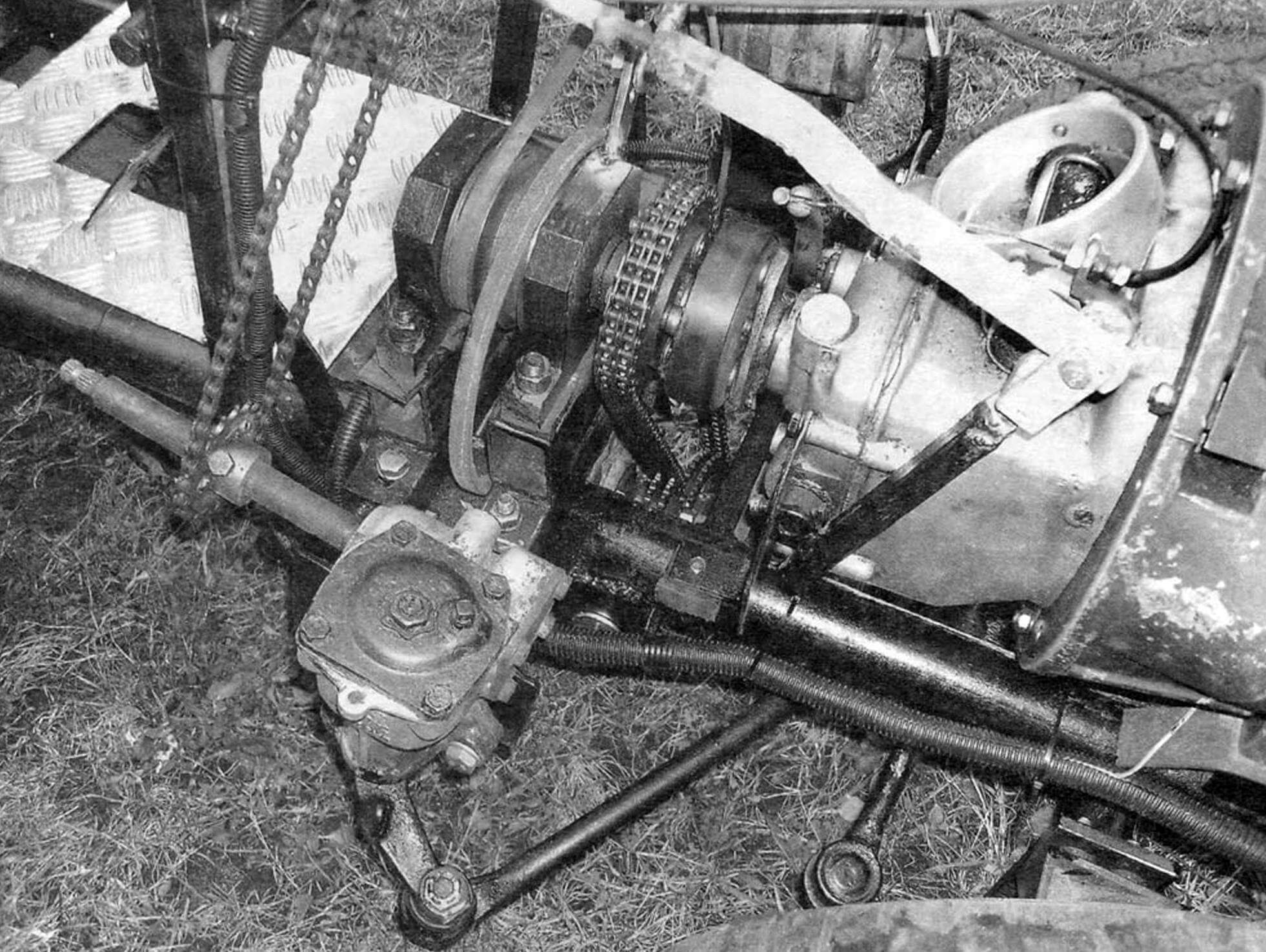

The front axle is welded from pipes and plates welded to the ends, to which the ball joint mounting brackets are screwed through adjusting bushings. The hub assembly with brake mechanisms and wheels are taken from a VAZ 2106 car. The steering components are also from it: gearbox, rods and steering wheel. The steering gear shaft is connected to the steering shaft with a chain from a bicycle, since the latter interfered with other units.

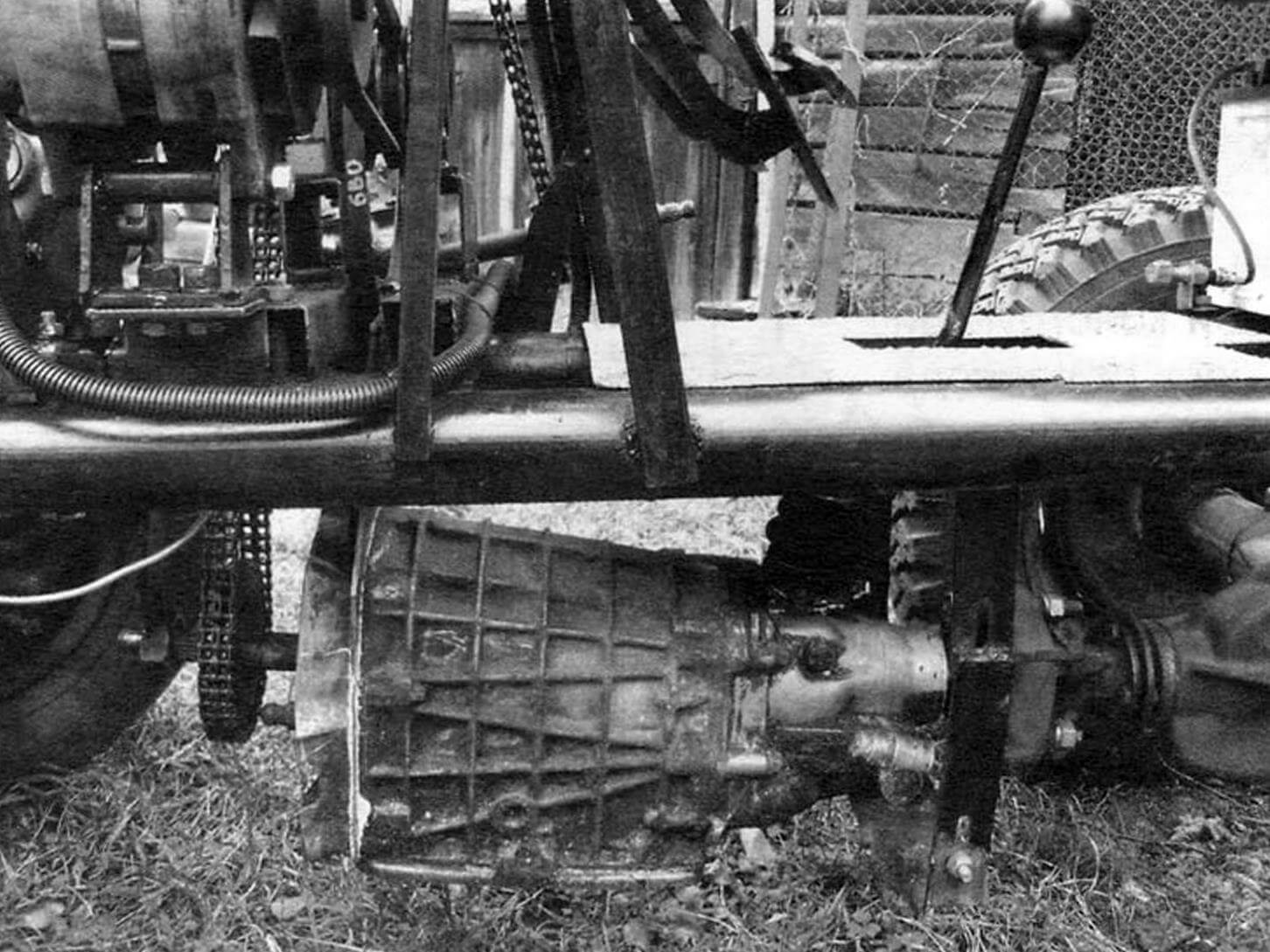

The mine tractor has two gearboxes. The first assembly with clutch was taken from a Ural motorcycle. It is connected to the motor via an adapter, then through a rubber coupling from the same motorcycle the box is connected to a sprocket and power take-off shaft of its own design and through a double-row chain from the Zhiguli timing drive it is connected to the box from a VAZ 2107 car. The box, in turn, is connected with a rear axle from Moskvich-408, which was shortened to a track size of 740 mm. The chain between the boxes is pulled by a small sprocket from the timing drive, mounted on the end of the screw.

1 — power unit UD-25; 2 — gearbox with clutch from a Ural motorcycle; 3 — bearing No. 202; 4 — main chain drive; 5 – additional gearbox from a VAZ car; 6 — final drive from the Moskvich car; 7 — rear wheels from the Moskvich car; 8 — bearing No. 206, 2 pcs.); 9 — front wheels from a VAZ car

Separately, I would like to dwell on the power take-off shaft; it can simultaneously drive the shaft for connecting attachments, a generator (from a Moskvich-412 car) and an NSh-10 pump.

The front wheels are from a VAZ car, and the rear wheels are from a Moskvich car, shod with “toothy” tires for better traction.

The front brakes are hydraulic; a clutch cylinder from VAZ was used as a brake cylinder. The rear brakes are operated manually by a lever via a cable.

The driver’s seat is from a KAMAZ vehicle, it is foldable, which is very convenient when transporting a mini tractor.

After running tests, which confirmed the functionality of the design, a hood was made, which opens with a gas stop from the rear door of the Niva car. The hood was covered with panels from an old Biryusa refrigerator, which friends gave away. To work in the dark, I installed headlights.

I live in the city of Mtsensk, Oryol region. In honor of his native land, he named his mechanical assistant “Eaglet”.

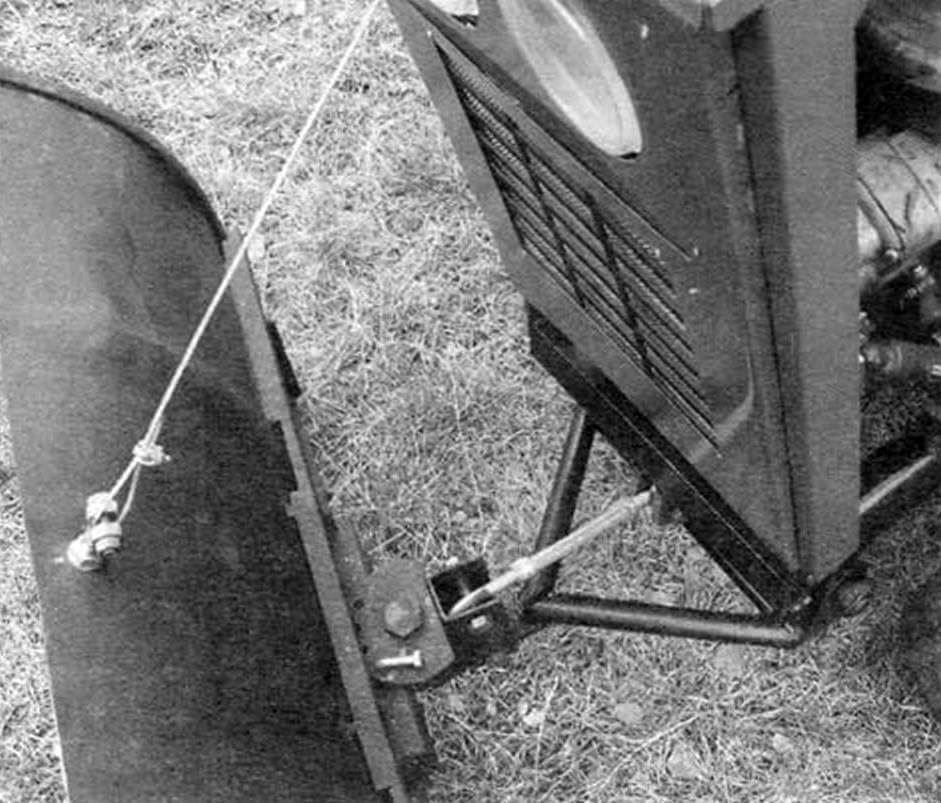

The mini-tractor turned out the way I wanted, small and maneuverable. It has 16 speeds, the average speed is about 40 km/h. For him, I made a blade and a mechanized shovel from an old 200-liter barrel with a wall thickness of 3 mm; the blade can be rotated left and right by 45° and is fixed with an M8 bolt. I purchased two plows and made the frame for them myself. The tractor also has a trailer ball, to which you can attach the same car trailer, in the back of which this assistant is placed.

Currently, work is underway to create a cultivator and harrow.

Relatives, friends and work colleagues helped in creating the mini-tractor, to whom I would like to say words of gratitude. And also a special thank you to the famous magazine “Modelist-Constructor”, which I have been reading since school: it helped me not only in creating the mini-tractor described, but also in solving many technical problems.

P.S. Of course, the UD-25 motor is not easy to find, but if you take an imported power plant from a walk-behind tractor (of sufficient power), then it is quite possible to use the entire structure of the mini-tractor, you just need to make an additional flange and drill holes for mounting the motor in place in the frame.

A. REPIN, Mtsensk, Oryol region.