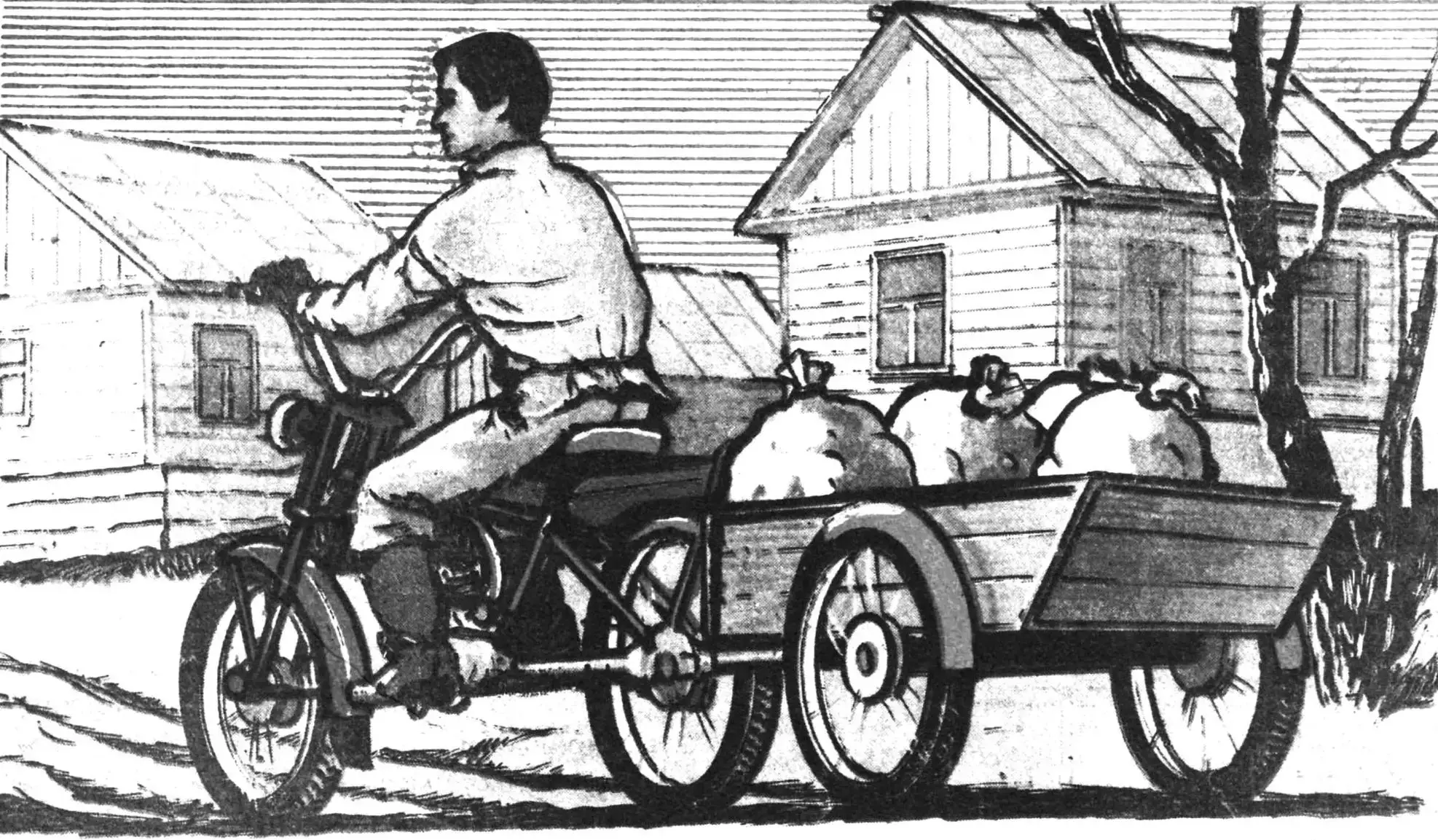

A moped is often considered an expensive toy for children. And in fact, a significant portion of these two-wheeled machines are purchased by young people for purely recreational purposes. And only a small share of mopeds are used as a means of transport for business trips. And what if suddenly there is a need to transport some cargo – for example, a gas cylinder, a couple of bags of cement or, finally, a bundle of hay? Is it really necessary to carry all this on a hand cart, while one and a half or two “horses” are lazing around in the barn?

If desired, any moped can be turned into a kind of truck-trailer, and the moped itself undergoes minimal modifications and retains the ability to perform its “standard” functions.

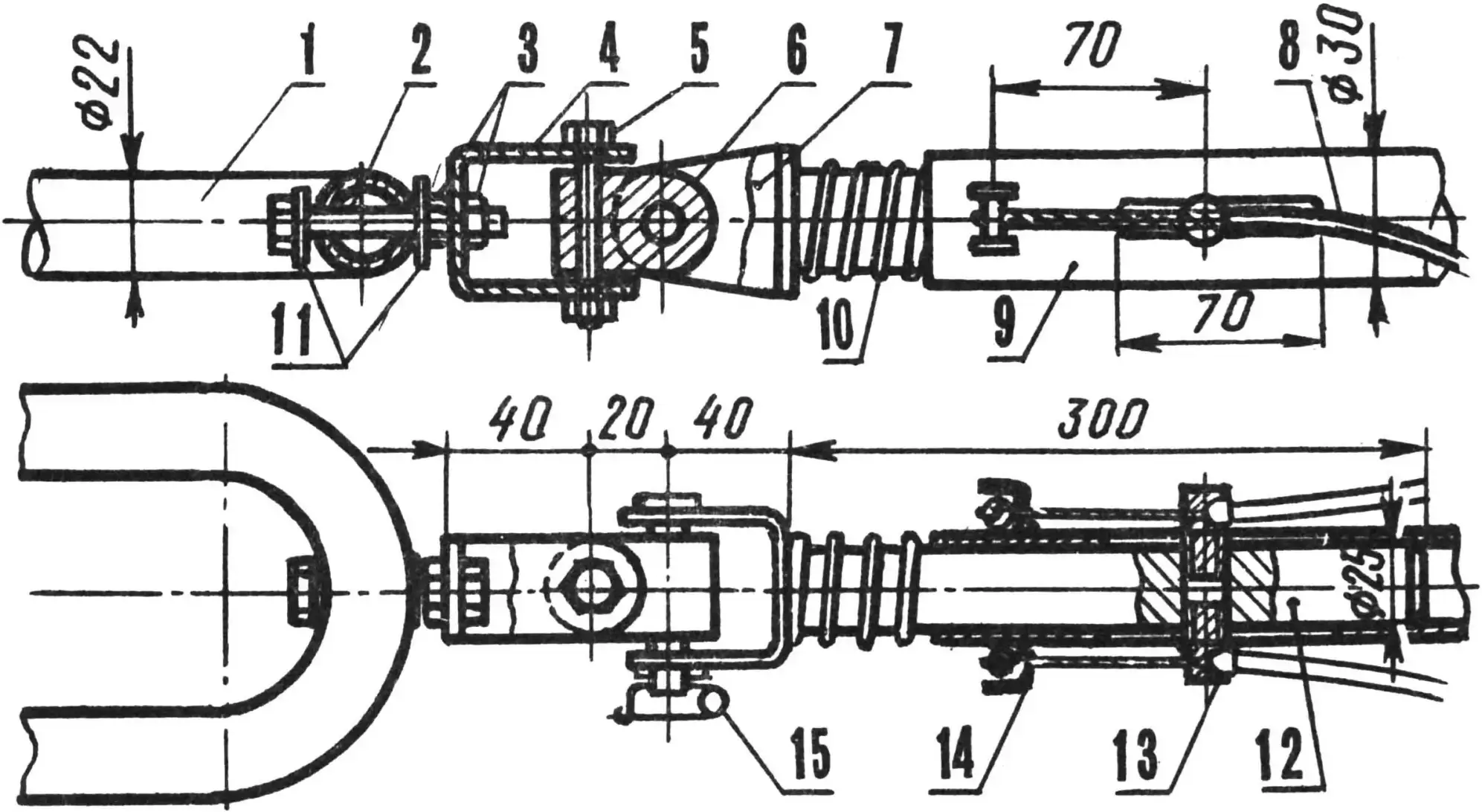

The conversion of a moped consists of hanging a towing device on it. It is an arc bent from a steel pipe with an external diameter of 22-25 mm and a wall thickness of 2-2.5 mm. It is best to bend the pipe in a pipe bender, having first filled it with dry, sifted sand and warming up the bending point with a blowtorch (or first in a forge) during the deformation process. The free ends of the pipe are flattened, and holes are drilled in them along the diameter of the rear axle of the moped. The towing arc is fixed on the moped axle with standard rear axle nuts and is additionally reinforced with two braces made of 3X20 mm steel strips, the ends of which are bent in the form of clamps and secured with screws and nuts with M5 threads. Finally, a hole of Ø 12.2 mm is drilled in the towing arc for the cardan shaft of the coupling device.

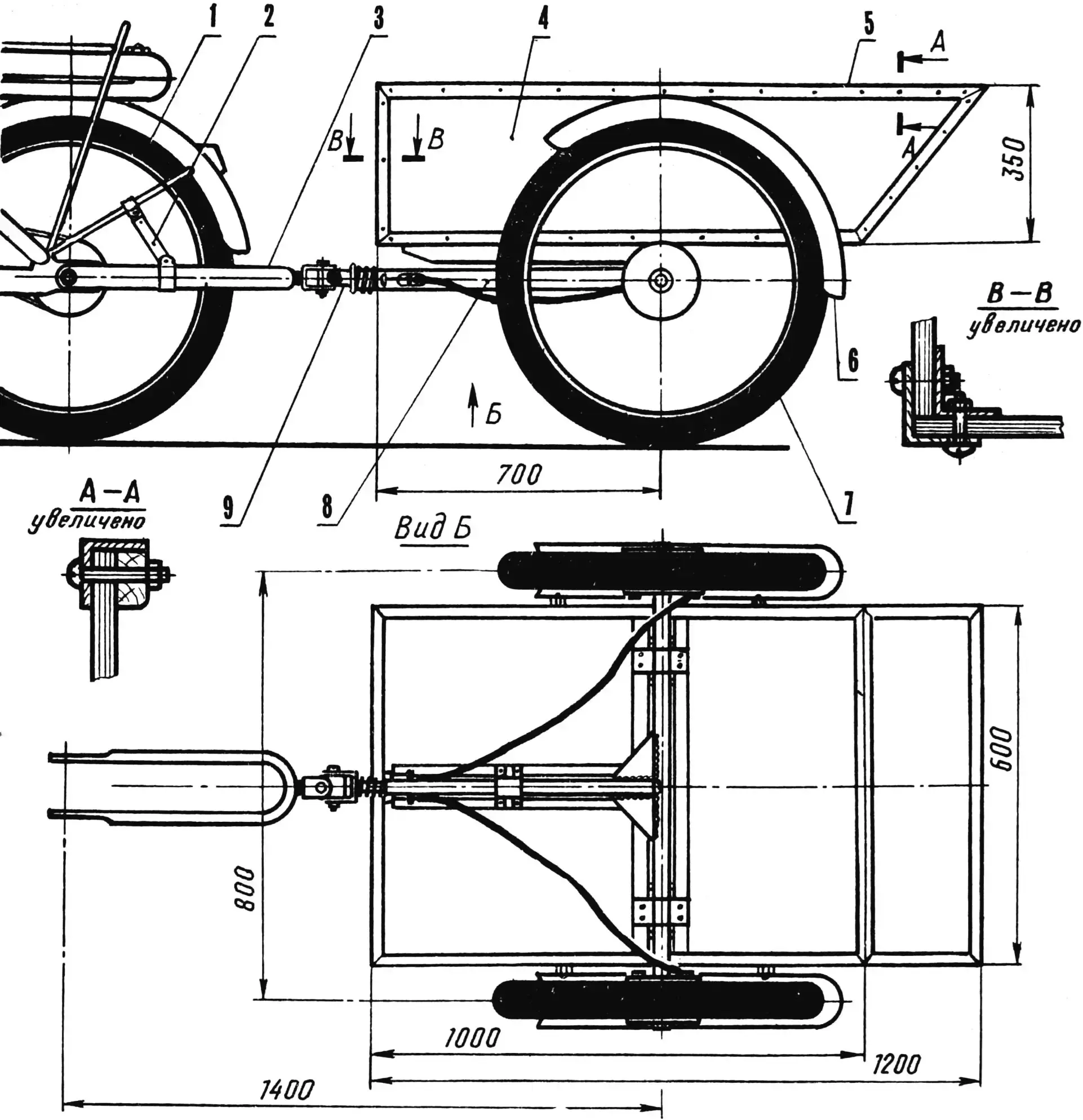

1 — moped type “Riga-11”, 2 — towing arc brace, 3 — towing arc, 4 — body panel, 5 — reinforcement, 6 — mudguard, 7 — wheel, 8 — T-shaped bogie frame, 9 — coupling cardan device.

The trailer itself is a two-wheeled cart equipped with moped wheels, a simple suspension system and an inertial braking device. The trailer body is plywood. Construction plywood with a thickness of 12 mm was used for the bottom and sides. The assembly was carried out using duralumin “corner” profiles 40X40 mm with a shelf thickness of 3 mm. The body is very strong, durable and beautiful, in which the “corners” are located both inside and outside; at the same time, the sides are tightly pulled together with each other and the base, forming a rigid box. The edges of the sides are also edged with a duralumin “corner” reinforced with a wooden lath of a section of 20X20 mm, as shown in the pictures.

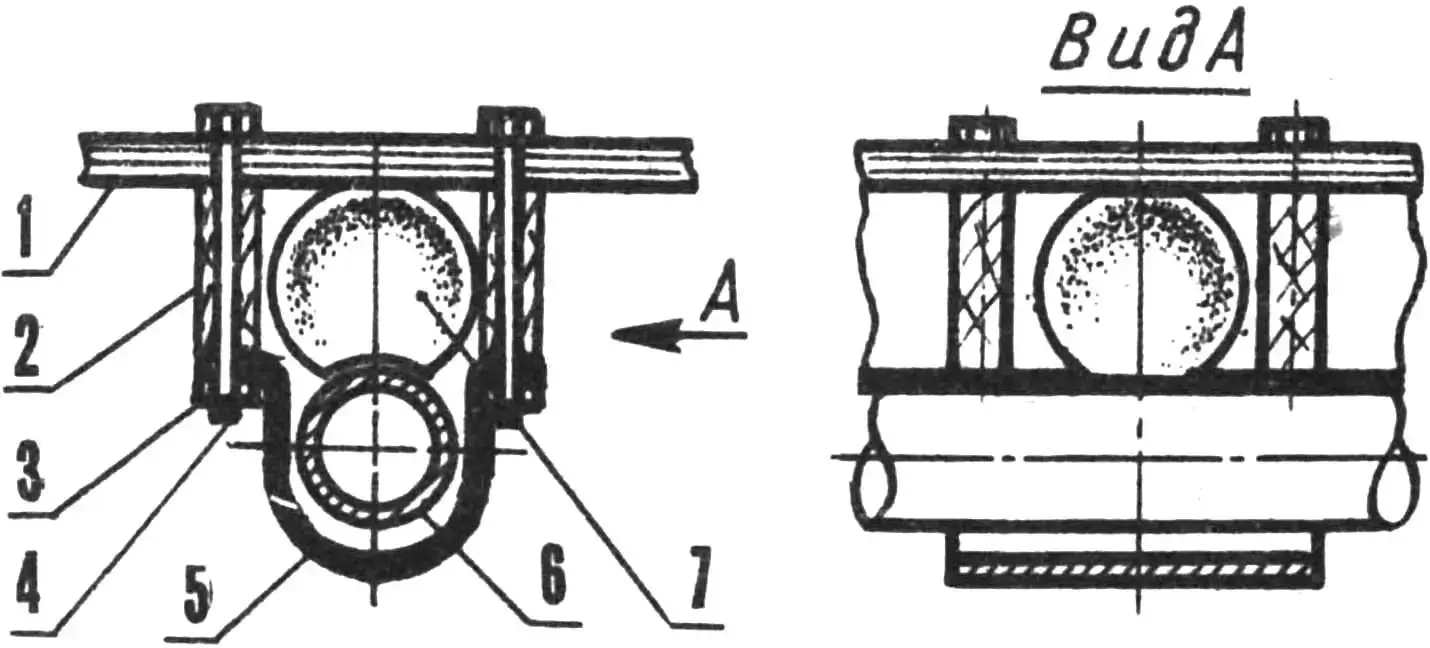

In the lower part of the body, on the base, two side members made of wooden planks with a cross-section of 30X75 mm are mounted – they are the bottom reinforcement; between them there are shock-absorbing elements – ordinary tennis balls. As practice has shown, they very reliably spring the body, withstand a fairly large load, and their service life is practically unlimited.

The trailer frame is very simple and is a T-shaped structure welded from two steel pipes Ø 30 mm and a wall thickness of 2.5 mm. In principle, it is quite possible to use water pipes here – the so-called “inch” ones. The joint of the pipes is reinforced with steel triangular gussets made of sheet steel 3 mm thick.

The axle shafts, on which the wheels are fixed, are the front axles of the moped. To install them in the frame cross member, adapter bushings welded into the pipe are used. The axle shafts are preliminarily connected by welding to the bushings. Of course, such a solution is forced, and if possible, it is better to use axle shafts made of good steel (for example, hardened 30KhGSA), turned in the form of a stepped roller with fixation in the frame cross member with a threaded stud or bolt.

And the last thing concerning the chassis is the brake drum stops. They are steel strips with a cross-section of 6X20 mm, welded in place to the crossbars.

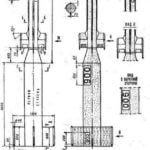

1 — towing arc, 2 — longitudinal joint, 3 — nuts, 4 — cardan joint fork, 5 — vertical joint (bolt with nut), 6 — cardan crosspiece, 7 — cardan fork, 8 — brake cable, 9 — drawbar, 10 — spring, 11 — washers, 12 — rod, 13 — stop, 14 — bracket, 15 — pin retainer.

The coupling device is a cardan joint, allowing the drawbar of the cart to freely deflect up and down, right and left, and rotate around its axis. This coupling system is quite reliable and much simpler in execution than a ball lock: it can even be made at home.

The universal joint consists of two forks – the easiest way to make them is from sections of a suitable steel channel or even a steel strip 3-4 mm thick and 40 mm wide. The cardan “crosspiece” is made of duralumin (a bar with a cross-section of 45X45 mm, 60 mm long, in which two mutually perpendicular holes of Ø 8 mm are drilled). The longitudinal hinge of the drawbar is a threaded stud Ø 12 mm, secured with two nuts on one of the forks and freely rotating in the towing arc. To prevent self-loosening, the nuts are counter-sealed by riveting the ends of the threaded stud protruding from them.

In one of the forks, the crosspiece is also secured with a threaded stud with the nuts locked by riveting. The other fork and the second hole in the crosspiece are connected with a quick-release lock – a pin secured in the fork with a special “pin”.

On the trailer drawbar, the cardan fork is mounted movably, for which purpose it is welded to a section of pipe that freely enters the drawbar. The ability of the fork to move freely in the drawbar is used to operate the brake inertial mechanism. It is not too complicated. When the towing moped itself is braking, the inertial forces possessed by the moving trailer tend to push the moped and, overcoming the elasticity of a not very stiff spring, move the drawbar relative to the fork, or more precisely, the section of pipe that is welded to it. The mutual movement of these design elements is used to operate the brakes of the trailer wheels. For this purpose, a longitudinal groove is sawn in the drawbar, and a rod with two stop grooves under the brake cable sheath is inserted into the section of pipe welded to the fork. Two L-shaped split brackets are installed on the drawbar, as shown in the figures. The brake cables are secured to the brake drum levers, run along the frame without sharp bends and are connected to the drive elements on the drawbar.

Braking adjustment is purely experimental. Several test drives will allow you to select both the initial moment of brake operation and their simultaneity on the right and left wheels. All this is carried out by the adjusting bolt on the brake drum of each wheel.

Installing the body on the frame is not particularly difficult. It is fixed using three steel clamps bent from 4X25 mm steel strips and serving as guides during body vibrations. The clamps are fastened to the side members on the bottom of the body with 6 mm bolts and nuts.

Of course, it is best to use ready-made mudguards (for example, from the front wheel of a moped), securing them with M5 threaded bolts and nuts on the sides of the body. In principle, it is not difficult to make plywood shields from individual elements connected with duralumin “corners”. Shields bent from plywood strips 4-5 mm thick look good.

1 — body bottom, 2 — side member bars, 3 — nut, 4 — bolt, 5 — guide clamp, 6 — frame, 7 — shock absorber ball.

There are no particular problems if you use a trailer with a two-speed moped such as “Riga”, “Karpaty”, “Verkhovyna”. However, less powerful mopeds equipped with engines such as D-6 – D-8 are too weak for this purpose. Therefore, I recommend slightly increasing the gear ratio of the chain drive by installing a sprocket with a larger number of teeth on the rear wheel. In principle, you can use the leading sprocket of a road bike, however, although the pitch of the bicycle chain and the diameter of its rollers coincide with similar parameters of the moped chain, the bicycle chain is much narrower than the moped chain. Therefore, it is better to cut a new one using the sample of the bicycle sprocket, as a template, for example, from sheet duralumin D16T 4-5 mm thick. This is not too difficult to do – use an electric drill and a drill of the appropriate diameter.

It is best to install two sprockets on the rear wheel of a moped at the same time, like on a sports bike. This allows you to “switch” the moped from towing mode to a regular, “passenger” mode. To do this, you need to have a piece of chain with a lock in reserve: installing or removing it is a matter of a few minutes.

If you plan to drive on the highway, you should equip the trailer with at least reflective lamps, or even better – a normal set of lighting devices. It is strictly forbidden to transport people in such trailers – this rule must be firmly learned. When switching from the “passenger” version to the “tow truck” version, try not to forget that the dimensions of the composite vehicle have increased significantly, and do not try to drive it, for example, through a gate. And the last thing. Do not overload the trailer – this can quickly disable the engine and transmission of your moped.

V. VORONOV