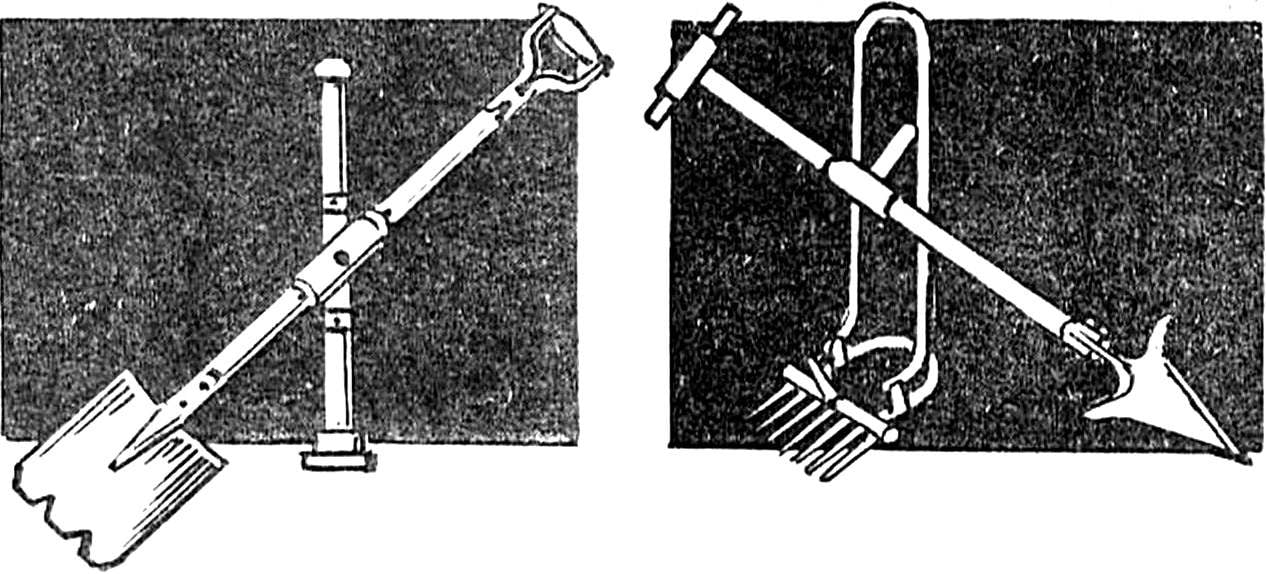

Fig. 1. Shovel-hoe:

1 — cropped the canvas digging sharp-rectangular shovel CPL (GOST 19596-87) with modified talakai, 2 — axle Ø 14 mm, 3 — coupler pipe, 4 — lock nut (for continuous operation), 5 — multi-segment water-gas supply pipes, 6 — screws Ø 6 mm, 7 — shaft, 8 is press-fitted into the stub of the finger.

As in the prior art, for rigid fixation of the bayonet in any of three positions is enough to turn the screw coupling until it stops at the corresponding ends of the cheeks.

Older people can recommend another tool. Using it, it is not necessary to continuously “bow” when digging the garden or garden plot. Helps out here, “shod” in rubber “Shoe” thrust stand with a bracket and a special rotating device, made of two sliding relative to each other clips from pipe sections with the appropriate parameters. So the bayonet was easier to bury in the ground, shovel with wooden handle in metal (of the separated tube segment) the holder and has a slightly modified plane of blade.

The basis for the design is, again, shovel CPL. Only the canvas it is not pruned. And to make it deeper and with less resistance were in the ground, not sliding off break roots brushwood on the site, the cutting end it is performed smoothly rounded, and trapezoidal. Moreover, the plane of the blade without affecting the edges of the spade, straighten with a hammer. The resulting rectangular in cross-section of the teeth is sharpened at the angle of 20 degrees and thermoablative to a hardness of 53 HRC 37…uh .

But to make such a shovel — even half the battle. It is important to learn to work. Taking the end of the cutting with the right hand, left leg bury the blade in the ground (at an angle of 70 degrees). Then stalk away … until the moment when he will stand perpendicular to the ground. And then, clutching a resistant stance to the ground, the shovel sharply pull (with rotation). As a result of another portion of the soil itself if thrown forward.

Fig. 2. Rotary shovel resistant resistant:

1 — multi-segment water and gas supply tube pipe arm holder, 2 — arm, 3 — shard, 4 — resistant rack, 5 — bracket, 6 — outer yoke — cut steel seamless tube (GOST 8734-75) with an external diameter of 50 mm and a wall thickness of 2.5 mm, 7 — inner race — a section of pipe (GOST 8734-75) with an outside diameter of 45 mm and a wall thickness of 2.5 mm and 8 screws Ø 6 mm, 9 — digging sharp-rectangular shovel (GOST 19596-87) with a modified canvas, 10 — rubber “Shoe”.

Very comfortable this shovel when digging potatoes, other root crops. Will Zaglebie bayonet at a right angle next to the Bush plants. Then slightly slide the handle on and again sharply pull it forward to the position perpendicular to the ground. Now the left foot, press down hard counter and with a slight turn of the handle, throw the potatoes in the side of the removed row.

Help lightweight rake

Badly needed in the economy and a rake. Over the centuries of its existence, their design has undergone few changes. Modern rakes are essentially the same (for Dahl) “manual harrow consists of a ridge of the whetstone in the yard, through Dirhami, up to 12, in which impacted teeth pegs in the finger, and grabovymi akin to a stick in the height of a man, stuck in the middle of the range.”

However, the wooden rake is now almost never see. Instead, they usually use a welded, metallic. But I, for example, they are not always satisfied. Because the commercially available options are typically heavy. Even with light pressure they immediately deepened into the ground and can break up the surface roots of plants. Because of that I prefer to use a homemade rake, almost archaic wooden structures.

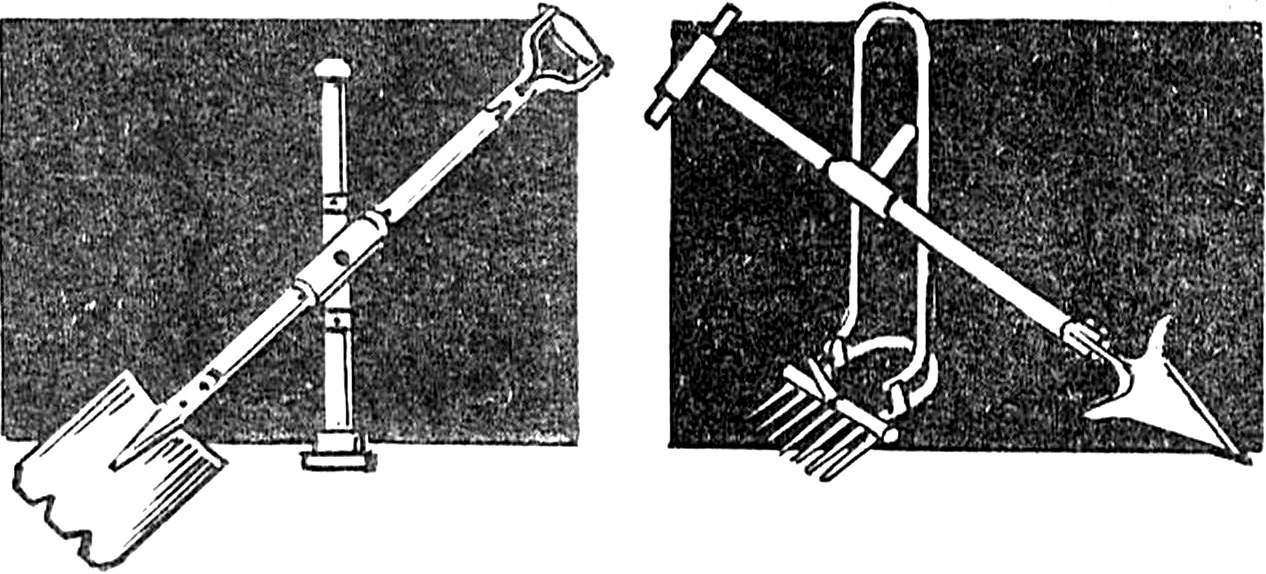

Fig. 3. Rake with tubular mount:

1 — shaft, 2 — screws Ø 4 mm, 3 — multi-segment water-gas supply pipe, 4 — screw Ø 6 mm, 5 — strap 35X40 mm, 6 teeth.

Mount — tubular. It is based on the same multi-segment water-gas supply pipes of the corresponding size. Preferably pipes with an outside diameter of 33.5 mm diameter (26.8 mm), successfully interfaced with cuttings Ø 40 (or Ø 30) mm and a length of 1300-1600 mm, coming to our trade network. In order to avoid undesirable cracking when wedging it is also necessary to foresee the technological holes in the nodes of possible stresses that threaten the appearance of cracks and breakage.

To the rake, and a special fixture, the design of which is so simple that in the explanatory drawings and drawings not needed. Is it a plate cut from an old saw cut, with the base of 570 mm, a height of the sidewalls for 35 mm and converging in the form of an isosceles triangle as a Central part. The apex of this triangle is separated from the base at 120 mm.

The fixture is attached to the rake teeth with the help of linings, screwed from the other side “lambs” M6. It serves to destroy weeds that appear in the beds soon after planting. While weeding, first cut using the installer weeds. And then, removing it from the teeth, are harvested with a rake all this “biomass” and loosen the surface layer of the earth.

Loosen will become easier

Loosen the soil in a garden or in the garden often. And manufactured for this purpose, the domestic industry equipment made often so that working have to and then bend over. Can you do without it?

Of course, you can. An example of this — two designs of rippers, who is successful to the same and additional functions.

Ripper-vegapamil made from strips of water-gas supply pipes with an outside diameter of 26.8 mm, swivel bonded with each other. The dimensions of the curved pedal, and swivel-handle — depending on the characteristics of the shape of the employee. You can even involve the performance of stand-handle sliding. For example, telescopically incoming one another of pipes. Teeth are made of steel of grade St. 3 according to the dimensions indicated in the figure and are strengthened in the holes of the cross member by clinching the back of the necks of a diameter of 8 mm. the abutment tooth is performed and is established in its place the same way. But the point of his knife deliberately for the convenience and safety of the working.

Fig. 4. Ripper-vegapamil (I):

1 — supporting tooth, 2 — cross member with working teeth, 3 — arched foot pedal, 4 — hinge joints, 5 — pivot strut-handle; II — penetration, III — loosening, IV — digging.

The method of using Ripper-vicariates not much different from working with the rotary shovel having a support rack. Clicking on a bent pedal, green thumb tip rack-a handle on yourself: the buried cross member with teeth easily turns another clod of earth.

For the manufacture of cultivator-lancomeparis also needed periods of water-gas supply pipes, but some other range. But the work on here is a kind of Bur, is made of paintings by old two-handed saws. Head shape — triangular, tip down. On the sides it has a small, curved in opposite side cutting edges with a sharpening angle of 20 degrees (not shown on the picture). And the top three appropriately curved wedge-shaped plot. Formed this trio cuts with subsequent reversals: Central — against the rest — clockwise. The side portions of the upper part of the work as the dumps guide for the cutting edges of the soil, and is Central to secure the head on the rivet in the eyelet, made on the lower end of the bar. Head termoobrabotki to the hardness of 37 HRC 53….

Fig. 5. Ripper-lancompiler:

1 is a drilling head, 2 — rivet, 3 — inner tube (GOST 8734-75) strut, 4 — bolt M8 with nut — lamb, 5 — outside pipe (GOST 8734-75) telescopic racks, 6 — telescopic handle made of seamless steel pipes (GOST 8734-75), 7 — holes with thread M8, 8 — a variant of the rack — arm swing.

Ripper-lancecorporal had a good performance planting potatoes. It can be used to perform the holes when planting flowers in onion family. Remember: depth of planting depends on the plant species, but on average follow the rule “three times” the height of the bulb.

Under the planting depth means the thickness of the layer above the bulb, not the distance from the bottom of the pits or grooves to the surface. On heavy clay soils it reduced to 2-3 cm, and on light, sandy, on the contrary, increase in those of 2-3 cm.

“Recoilless” scrap

Assuming that the ingenious is always simple, you should probably recognize all known typical design of a scrap sample of sverginamento. But there are other views on this matter.

The fact that ordinary scrap quite a significant impact, especially if the ground is rocky. Will work, as they say, their hands do not smell. And the issue we have “recoilless” the scrap industry is still somehow not been established, although various structures are proposed homebrew a lot. At the heart of their usually — closed tips with a pipe loose inside (one-third of the volume of the cavity) of the large lead shot. Last quenches occurring at the time of shock reflection. But it does so partly due to the friction of the pellets against each other and on the inner wall of the casing scrap. In addition, the pellets gradually lose their shape, wear out.

Fig. 6. “Recoilless” scrap:

1 conical tip, 2 — steel pipe (GOST 8734-75) with an outside diameter of 33.5 mm, 3 coarse lead shot, 4 — motor oil, 5 — rivet 6 — chisel tip.

In the proposed design of the scrap pellets have a diameter of 2-3 mm each and plentifully moistened with machine oil. On top of that form of tips for better matching arising in the process of working loads. And this is important. Because the force of the impact here has more than the normal scrap value.

Recommend to read RIPPER HIV In recent years, more and more supporters of progressive subsurface tillage. Individual gardeners produce it with a fork. One time there was a Ripper Berezutsky. In contrast, the... SNOWMOBILE: IDEAS AND DESIGNS Interest in snowmobiles as individual means of transportation on winter roads and sporty type motor vehicles manifested itself long ago. But as widespread as it is now, the hobby of...  Should show gumption, hard work, and — contrary to well-known saying — that could be from the waste pipe very good… gardening tools. And with minimal production costs. The published material of the candidate of agricultural Sciences S. Larkin from Moscow — proof.

Should show gumption, hard work, and — contrary to well-known saying — that could be from the waste pipe very good… gardening tools. And with minimal production costs. The published material of the candidate of agricultural Sciences S. Larkin from Moscow — proof.