Have water pipes in homes, as in the system of cold and hot water, a so-called shut — off valves- the valves closing off the flow of water in taps. The design of such valves may be different.

Have water pipes in homes, as in the system of cold and hot water, a so-called shut — off valves- the valves closing off the flow of water in taps. The design of such valves may be different.

Until recently, the choice of valve was the valve screw housing ductile iron or brass. And if the latter have quite significant resource of health, the first not stand up to scrutiny. And only the cheapness of iron gate devices have attracted a buyer. In the apartments of mass developments and typical of the manor homes they have found wide application.

Actually, it should be noted that the tightening of the valves is rarely only when you need to turn off the water in need of repair or replacement of pipes, taps, installation of plumbing items.

But it is this fact (of rest) helps to ensure that over time, the valve steel valve stem, rusting, “fused” with a cast iron casing head so that they turn off the water at the right time is not possible. When you begin to use force, most often the stem breaks.

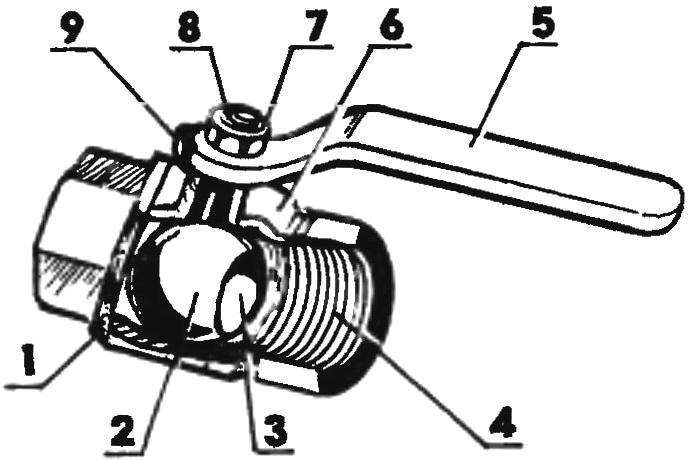

The construction of the ball valve:

1 — housing (stainless steel); 2 — ball valve (stainless steel); 3 — orifice; 4 — screw; 5 — handle; 6 — gasket (PTFE); 7 — a nut of fastening of the handle; 8 — stem (stainless steel); 9 — restrictive collar

In this case, you can try to turn the stock, pre-moistened “fused” parts of a special liquid or kerosene, heat the head with a blowtorch, a gas torch. But such events don’t always help.

Of course, it would be possible to replace the steel valve stem on the brass. However, it is better to solve the problem fundamentally — to put a new valve, not cast iron. Brass? Here’s something to consider. Yes, the brass valve will not rust. But it is not without other disadvantages: leakage of water through the stuffing box; wear rubber gaskets and, as a consequence, possible damage to the valve seat or breaking the threaded part of the rod with increased twisting.

Recently appeared in the sale of ball shut-off devices (in common parlance they are often called ball valves), both imported and domestic production. By design, they are much simpler (hence more reliable) than their listed predecessors, and at a cost comparable to brass.

Body and main parts of ball valves made of stainless steel. The locking element is a polished ball with a through hole, the diameter of which corresponds to the passage of the inlet pipe or less. In this regard, the valves are divided into full bore and semi -. The latter is usually installed where you do not need a high water consumption — for example, before the drain cisterns of toilets.

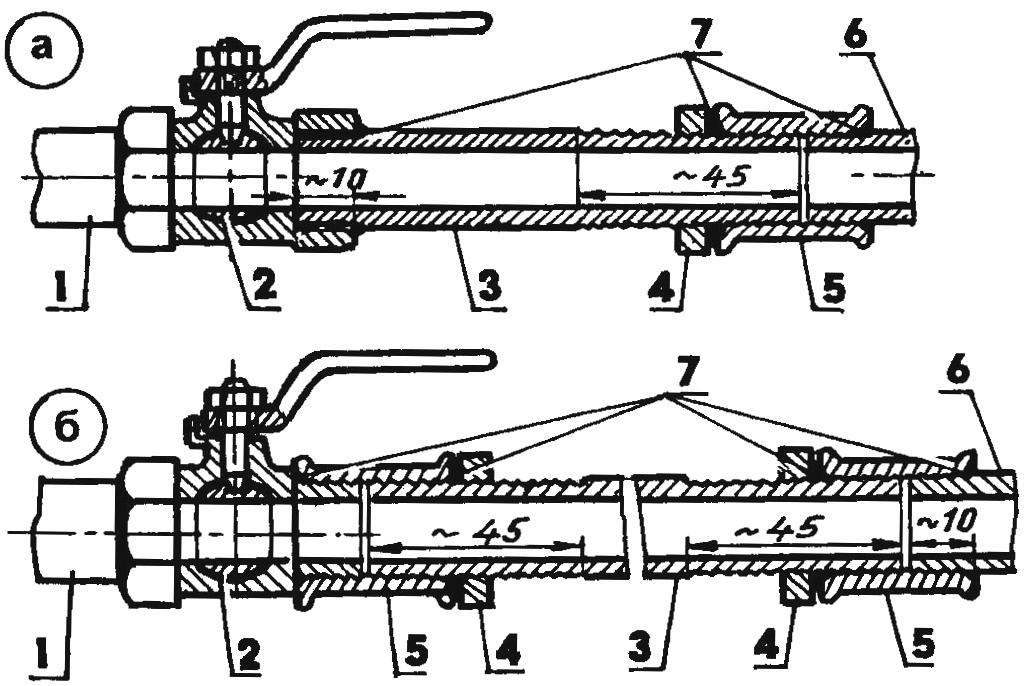

Joining the sleeves to the ball valve:

a — directly; — by means of couplings and nuts; 1 — pipe branch; 2 — ball valve; 3 — the eviction; 4 — nut; 5 — coupling; 6 — injection pipe; 7 — seal

The balloon inside the body is placed in Teflon o-shell with the corresponding through holes, in which it can be rotated. At the top of the ball has a socket in which is inserted the end of the rod. The other end of the rod through the holes in the seal and the housing comes out and to it is attached a handle by which the rotation of the ball (the opening and closing of valve) through 90°. To limit the rotation of the handle on the valve (or the handle) is molded collar.

Ball valves have a number of advantages over valve, both constructive and consumer.

The main thing — that the complete opening-closing ball valve is only a slight turn of the stem (and the ball), only 90°. This provides fast execution of operations, does not require the designated exit of the rod from the housing when opening the locking device and practically eliminates wear of the latter.

It is also important that the abrasion of the sealing sheath ball valve several orders of magnitude less than that of the rubber seals of the valve locking device.

The same range of ball valves is truly amazing. At the same time provides various connection pipelines: pipe connector-coupling, as in conventional valves, coupling and nipple and the other. This design allows you to attach to them not only pipes and hoses, and modern tubes, flexible hoses.

In addition, ball valves are very compact. They are available with short and long rods (or special extension brackets) different handles or without them — under a special key to avoid unauthorised opening and closing.

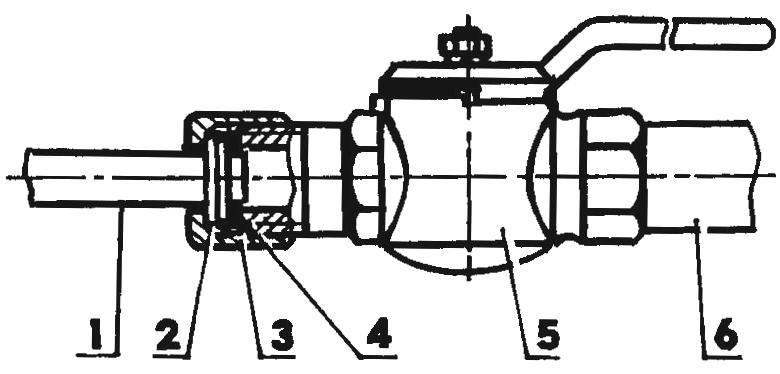

Joining ball valve flexible hoses:

1 — flexible tube; 2 — washer (brass); 3 — swivel nut (brass); 4 — rubber seal; 5 — ball valve; 6 — tube entry, or eviction

The obvious advantages it is worth adding that with the help of ball valves it is possible to accurately regulate the flow of water. In addition to that, there are special valves with an extra flywheel on the housing, which by means of friction transmission is very “finely” adjust the shaft rotation ball lock.

Replacement brass valve ball valve for no difficulty, as their length is approximately the same and alteration of piping is not required.

Cast iron the valve is longer than the ball, so after dismantling will have to extend to this size of tubing. This increase is possible in two ways: into the corresponding tap along the length of the tubular insert is threaded on both ends or replace the old spigot on other, more long.

Depending on the performance of the threaded parts of the valve (external, internal or combination) groans join the locking device either directly or using a coupling and nut.

A. POLIBIN