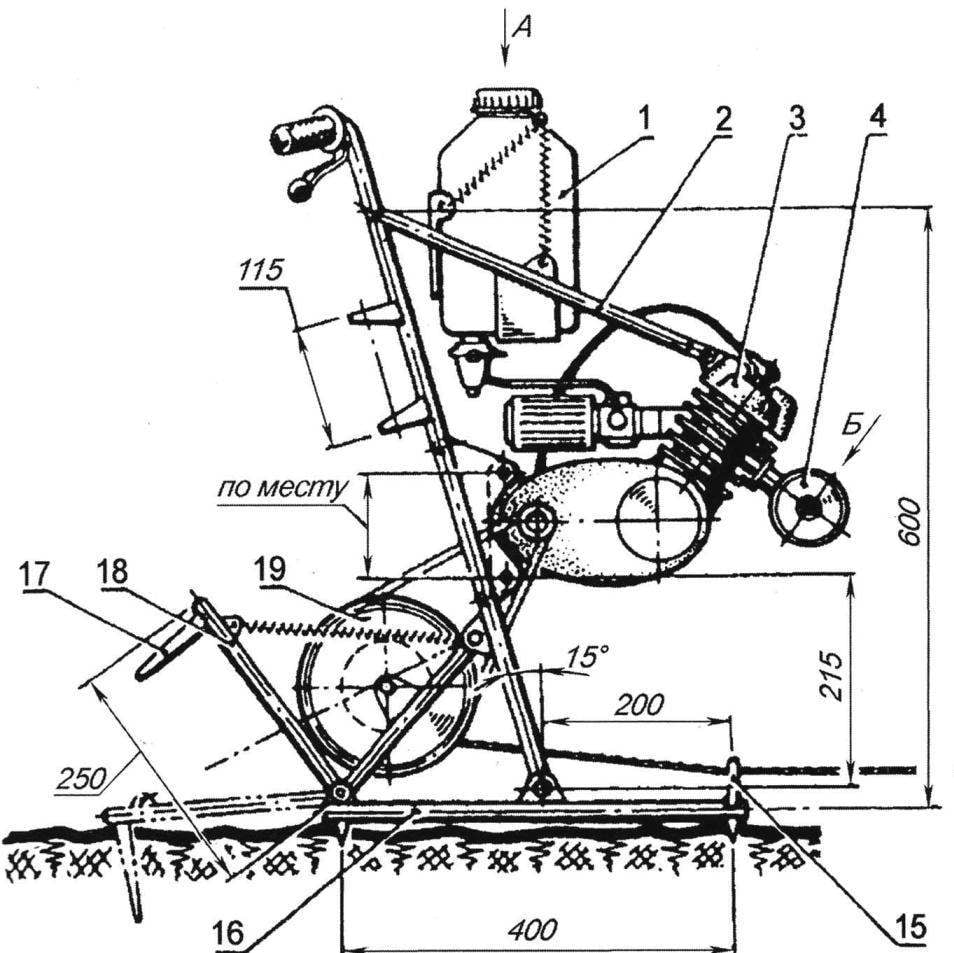

The basis of motoliberty developed by the Muscovite I. Sorokin, is the engine V-50 — at the time this engine power about 2 HP, equipped with “heavy” moped type “Riga” or “Karpaty” (and now a lot of stored in garages and sheds). The motor is installed on Motorama welded from lengths of steel pipes with a diameter of 30×2. 5 mm and sheet steel with a thickness of about 3 mm. from Top Motorama fixed wheel of a moped, on the bottom base area of the pipes of the drum and sprocket drive. Back on the supporting platform hinged anchor — P-shaped spring-assisted tubular frame with two welded to it with anchors from the steel tapered plates, similar to the blade of shovels.

As the drum winch used wheel hub moped (and fit the hub of any light motorcycle) is attached to dural cheek and sprocket driven — for example, a large gear wheel from a road bike.

If the gear ratio of the gear chain is insufficient, have to do driven sprockets with more teeth is best for this suitable sheet aluminum thickness 4 — 5 mm. to Calculate such a star is not too difficult. For this purpose the number of teeth of future stars (e.g., z = 80) is multiplied by 12.7 mm (step-chain), resulting in the length of the pitch circle (1016 mm). Next this value is divided by 3.14 (PI), and the result is the pitch diameter Dd = 323,6 mm).

outline on the workpiece the center of the sprocket, using a Vernier caliper to draw pitch circle, carefully divide it into 80 pieces (each — for 12.7 mm !), carefully stake the centers of the holes whose diameter should match the diameter of the bushings of the chain, and then drill out all the holes 80 (best on a drill press). Next you should pick up the rod, the diameter of which is equal to the diameter of the sleeve circuit, and, alternately inserting it into each of the holes and using a leading Bicycle sprocket as a template, draw on the workpiece a profile of each of the teeth. The complete conversion of the metal disc stars is carried out with a hacksaw and files.

Motoliberty (on the rear view and the view of the engine and the anchor device are not shown):

1—fuel tank; 2—the struts are the front mount of the engine; 3—engine type V-50; 4—damper; 5—clutch lever; 6—a gear shift lever; 7—the handle of the throttle of the carburettor; 8—the lever of a hand brake; 9—front engine mounts; 10—cheeks rear mount of the engine; 11—drum winch; 12 — crossmember motor; 13 — bridges plug; 14—steel wire rope Ø5; 15 — guide rail clamp (steel rod Ø8); 16—base area (pipe 22×2,5); 17—anchor; 18—paw anchor; 19—sprocket drive

The fuel tank is a plastic tank under the engine oil capacity 3 l; in its lower part with a standard motor a tap with a sump.

The winch controls are the same as any moped — right handlebar — grip throttle and hand brake lever (that with it slows down a bit later), left clutch lever and switch gear boxes.

The engine is equipped with a small motoliberty a homemade silencer made from thin-walled tubes with a diameter of 20 mm and 80 mm and a couple of caps from sheet steel with a thickness of 2 mm. Inside of the muffler — matted steel wire, or thin chips. The device is very simple, but very effective.

As a rule, the engine of this type can be quite long to operate without forced cooling, especially if it is blown by the wind. However, it is better to equip it with air cooling system. For this purpose the rotor-flywheel is fixed a pulley belt transmission and cylinder head — bracket with bearing housing in which establish a couple of ball bearings and shaft with pulley and fan.

A few words about how to use this motoliberty. First of all, it is placed on the edge of the area and lock the anchor device. The shift lever is transferred to the neutral position, and a working tool (plow, cultivator or Hiller) refers to the opposite end of the site. Work best in pairs: one controls the winch and the other is a plow.

So, let’s begin. Using the kick-starter which is started and warmed the engine, then squeeze the control lever grip and turn the first gear and smoothly release the clutch lever. The cable begins to be wound on the drum, and the plow — to move. That’s all.

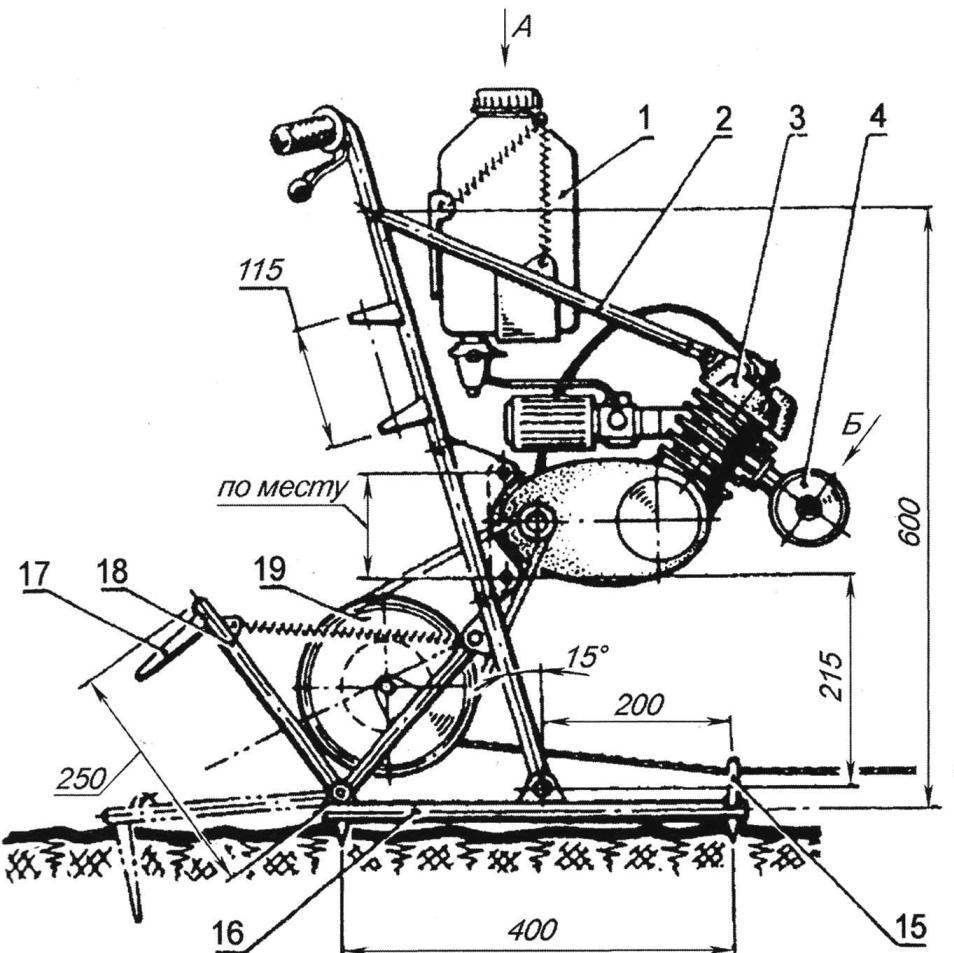

Malogruzovaja:

1—footboard (pipe 22×2,5); 2—bracket footrests; 3—steering column (tube 30×2,5); 4—axis of the steering column (bolt M12 with nut and washer); 5, 7 — gusset plate (steel, sheet E2,5); 6—pole (tube 40×2,5); 8 — bracket seat (50x50x3 channel); 9 — seat; 10 — front seat (tube 22×2,5); 11—a bolt of M6 with nut; 12, 14—the wall and the underside (plywood 12); 13—piping (area 40x40x2,5); 15 — bolt M8 with nut and washer; 16—the cradle body (wooden block 40×100 mm); 17, and 21 sites of the cradle body (steel, sheet s3); 18—brace (pipe 22×2,5 mm); 19, 22—wheels; 20—axle truck; 23—the drive sprocket front drive wheel

Of course, to use a convenient, compact power unit only for the treatment of the soil would be irrational. Meanwhile, it is virtually without alteration can be used to drive a truck trailer.

By using such “hybrid”, for example, perfectly solved the problem of delivery of motoliberty to and from work — it gets there on their own, bringing on himself the plow or cultivator, shovels and planting material. On the job malogruzovaja for half an hour turns into motoliberty, which produce the intended work.

And then the reverse transformation, and malogruzovaja brings home not only agricultural tools, but also, for example, the harvest of potatoes.

To turn the winch in the power unit malogruzovaja, it will be finalized. This is a reference platform on the frame, set the wheel-driven sprocket, and the cable from the hand brake lever on the right handlebar connected to the braking device on the wheel hub.

The Foundation of the cargo trailer is a welded frame, assembled from steel tubes of various diameters, which is installed a plywood body. With the engine fit in the frame with the drawbar, the front end of which ends on the steering column. The latter is a section of pipe with a diameter of 30×2. 5 mm with a pair of textolite or bronze bushings. The other end of the drawbar is welded to the bogie axle — cut steel pipe with a diameter of 30×2,5 mm, which is fixed by welding two half-axles, which is a step rollers with the thread on the external parts.

The frame of the trailer

The diameter of the axle shaft must match the diameter of the wheel bearing.

To the axis of the truck welded to the brace with two pads for fixing the locating blocks of the body, carved from a block of wood with a cross-section 40×100 mm. the Body is assembled from veneer pieces with a thickness of 12 mm and metal (steel or aluminum) parts on the nuts and bolts with M6 thread.

Before the body is installed the seat and T-shaped footrest for the driver. It should be noted that the steering angle is about 90 degrees right and left, so that malogruzovaja can turn literally on a dime.

If malogruzovaja will be used in the dark, it makes sense to equip it with headlights and rear “dimensions” with their food by low-voltage winding of the generator.

Recommend to read COMFORT BEGINS WITH A HANGER You enter into your apartment, whether to visit, the first thing that greets you when you walk through the door, the hallway or the front, as it is called. In modern homes it is usually... ACCURATE THERMOMETER Now appeared in the sale of electronic thermometers showing both the temperature in the room and outside the window, and very accurately thanks to the spaced sensors. However, ordinary... Scroll back to top

In this release, “M-K” we want to acquaint readers with one of the most effective tilling mechanisms, which has recently been gaining more and more popularity among Amateur designers. This motoliberty, the main advantage is that, unlike self-propelled tilling machines to create traction she uses all his power.

In this release, “M-K” we want to acquaint readers with one of the most effective tilling mechanisms, which has recently been gaining more and more popularity among Amateur designers. This motoliberty, the main advantage is that, unlike self-propelled tilling machines to create traction she uses all his power.