Mechanical saws produced by industry certainly make the work associated with preparing firewood for the winter easier. But most of them have one drawback: during operation, the entire unit along with the motor has to be held in your hands, which not everyone can do.

In the proposed homemade design, the entire power plant is stationary, hinged to the frame. Firewood is placed on special trestles located on the opposite side of the frame. To cut a log, you need to turn on the electric motor and use the control lever to lower the saw.

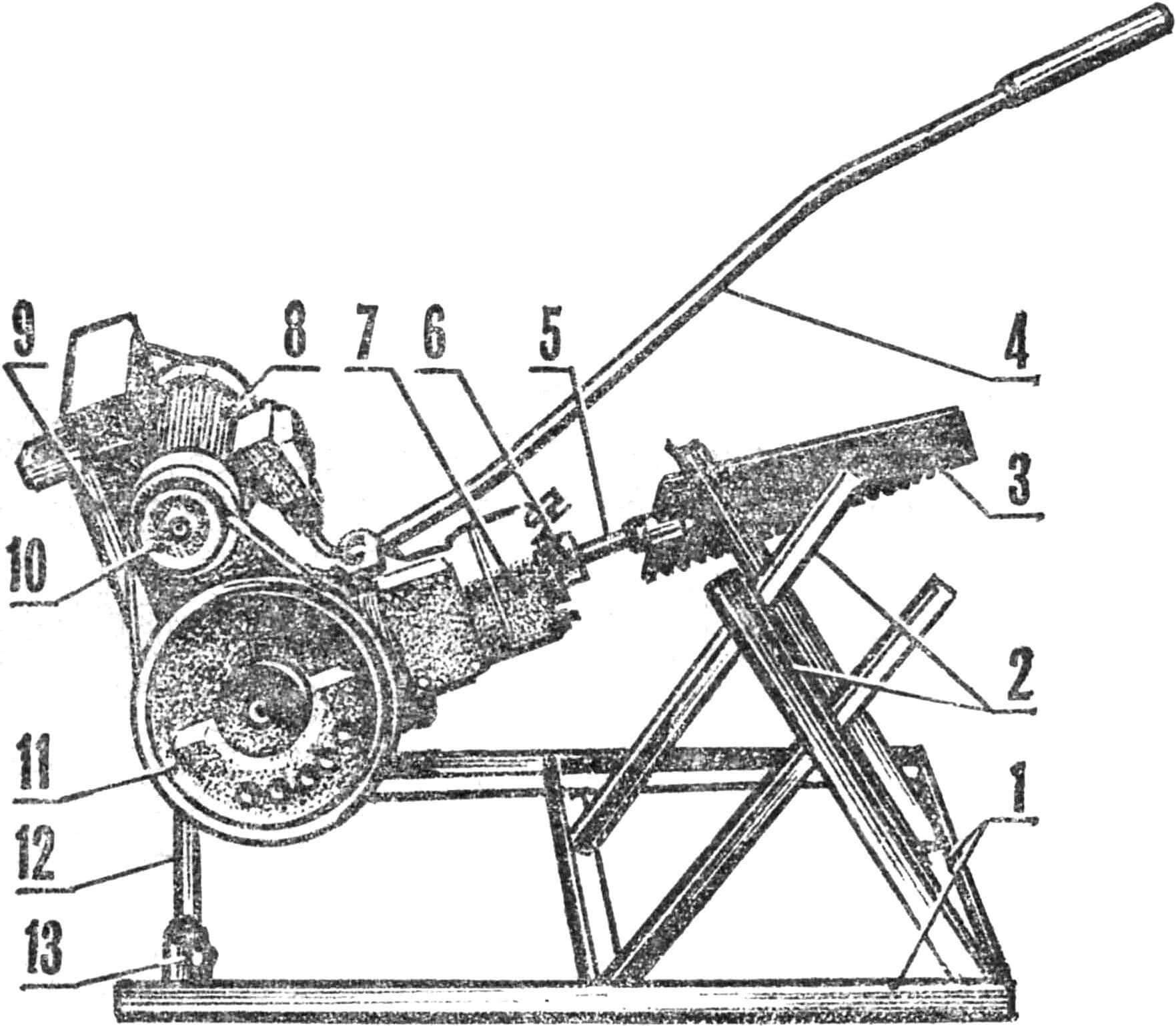

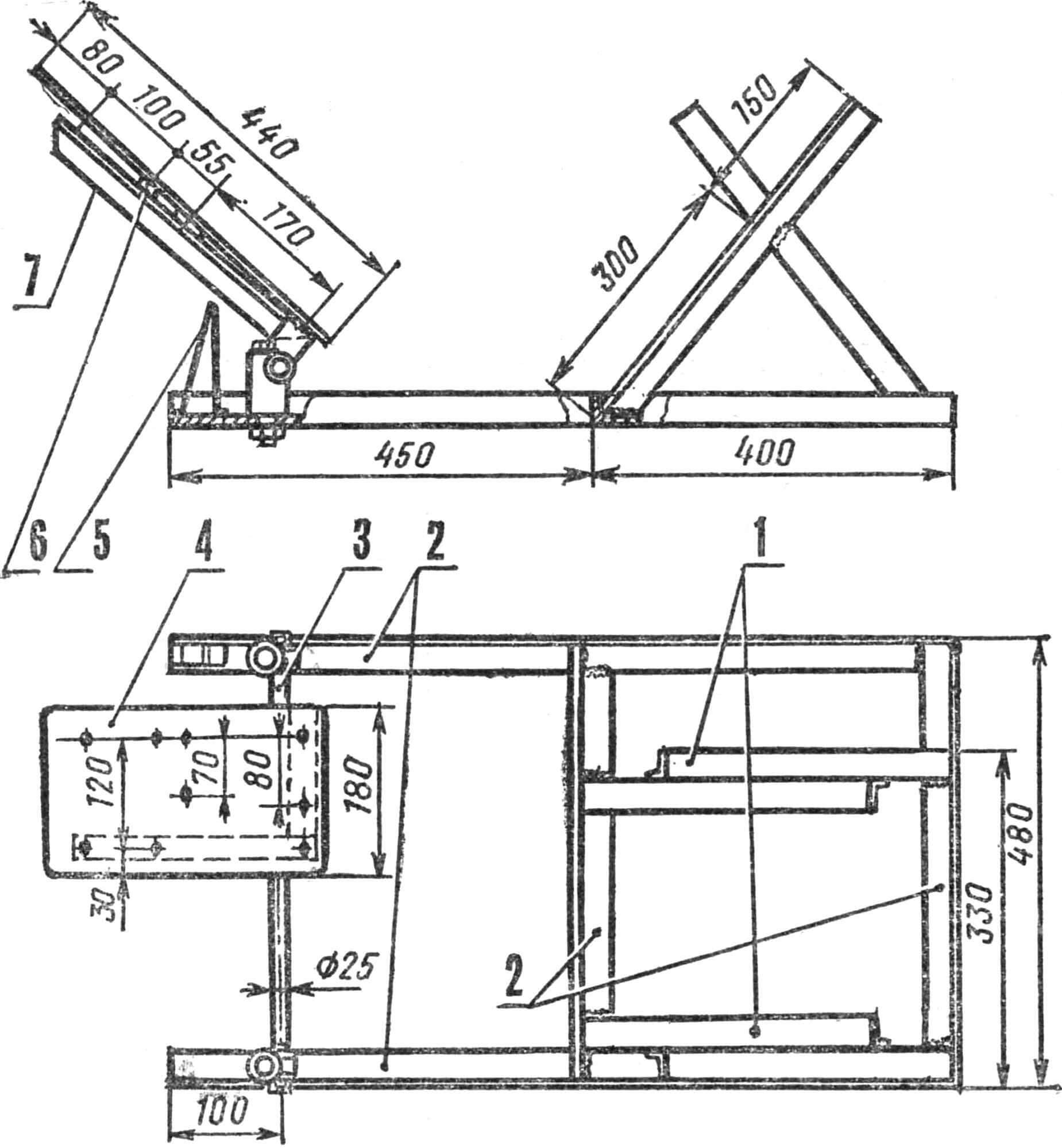

The design is simple to manufacture; all mechanical parts are used (with minor alterations) from old mechanisms. Its basis is a frame welded from corners No. 5. On one side, trestles for firewood are fixed, and on the other, an axle is installed on brackets. It serves as a hinge for the rotating plate – the base of the power plant. The plate – a steel sheet 3 mm thick – is attached to a corner welded to the axle. It has holes for fixing the electric motor and the drive mechanism of the saw. To give the plate longitudinal rigidity, a second corner is attached from below. A washer is placed between it and the plate along the axis of one of the motor mounting holes, thanks to which you can adjust the belt tension by tightening or loosening one of the motor screws and thereby changing the bending of the plate.

1 – support frame, 2 – trestles, 3 – saw, 4 – lever, 5 – rod, 6 – bushing, 7 – cylinder, 8 – electric motor, 9 – base plate, 10 – electric motor pulley, 11 – flywheel pulley, 12 – axle, 13 – bracket.

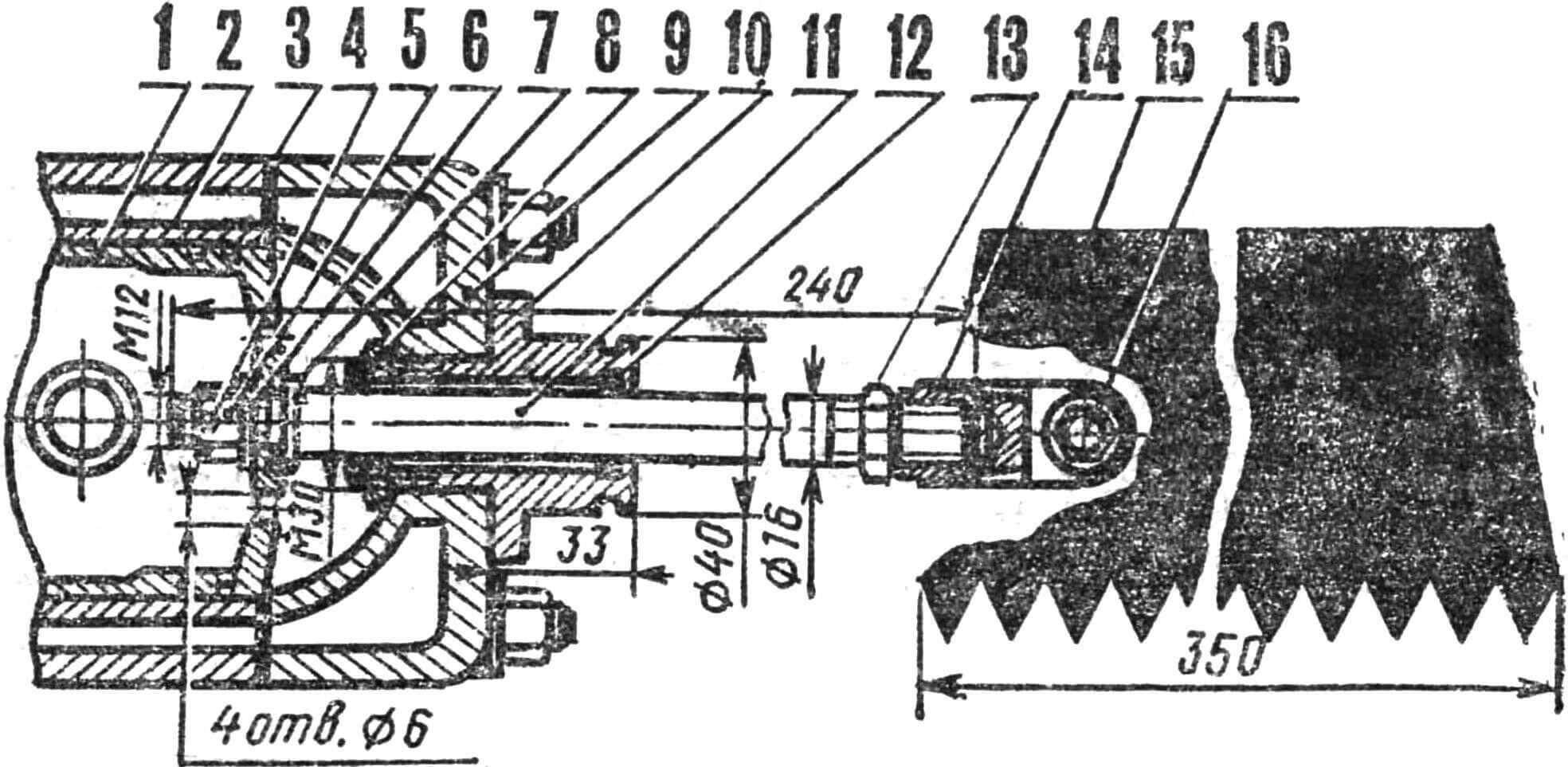

The starting engine of the PD-10 tractor is used as a drive mechanism for the saw, with minor improvements. First of all, it is necessary to replace the standard pulley with a larger one – Ø 260 mm. It is better to use it from a decommissioned D-37 tractor engine. It will act like a flywheel because it has a counterweight to compensate for the forward movement of the saw. The hole for the spark plug should be enlarged to 30 mm and a sleeve with an oil seal should be inserted into it, fixed in the cylinder head with an M30 nut. The engine piston is also subject to modification: a Ø 12 mm hole is drilled strictly in the center and four Ø 6 mm holes around it in order to get rid of compression. Next to the central hole, a 4 mm Ø recess is drilled to hold the lock washer, which is placed on the rod. The latter is a steel rod 240 mm long and Ø 16 mm. One end has an M16 thread, and the other has an M12 thread and a flat for a lock washer. The rod is fixed in the cylinder with an M12 nut. The saw holder is screwed onto the opposite end and secured with a lock nut in the required position.

1 – trestles, 2 – support frame, 3 – axle, 4 – base plate, 5 – limiter, 6 – washer, 7 – corner

As a saw, you can use a regular hand saw, cut to 350 mm. The most important thing is that when installing the working element, its cutting edge is strictly parallel to the stroke of the rod. Based on this, you should make a cutout for the holder.

1 – piston, 2 – cylinder, 3 – gasket, 4 – cotter pin, 5 – nut, 6 – washer, 7 – lock washer, 8 – nut, 9 – cylinder head, 10 – sleeve, 11 – rod, 12 – oil seal, 13 – lock nut, 14 – saw holder, 15 – saw, 16 – bolt with nut and washer.

From the engine pulley Ø 85 mm (from a car generator) to the crank mechanism, the drive is carried out by an A-800 V-belt, and the distance between the centers of the pulleys should be 205 mm.

The manufactured device has proven itself in operation. With its help, one person can easily cope with the preparation of firewood for the winter.

E. SYCHEV, Korsun-Shevchenkivsky, Cherkasy region.