holiday cottages or dwelling houses of the manor type of water is generally pumped from wells or boreholes. Heat it for domestic use often in electrotechno (pass-through or cyclic action) is a relatively inexpensive and convenient thermal devices. However, offer the industry’s elektrolitny designed for “soft” water with low salt content. And well or borehole water is usually “hard” (and therefore delicious) because it dissolved salts of various elements, particularly potassium. When heated, this water (especially boiling), the Heaters (thermal heaters) in the titans quickly covers the gray “fur coat” — scale, which impedes the heat transfer.

holiday cottages or dwelling houses of the manor type of water is generally pumped from wells or boreholes. Heat it for domestic use often in electrotechno (pass-through or cyclic action) is a relatively inexpensive and convenient thermal devices. However, offer the industry’s elektrolitny designed for “soft” water with low salt content. And well or borehole water is usually “hard” (and therefore delicious) because it dissolved salts of various elements, particularly potassium. When heated, this water (especially boiling), the Heaters (thermal heaters) in the titans quickly covers the gray “fur coat” — scale, which impedes the heat transfer.

To remove the “fur” chemists have invented many means, but they are not quite as effective as telling them about advertising, and most importantly — not “harmless” — what is silent. After use, the Titan must be repeatedly washed, and the sheath Heaters these funds partially corrode. To split the scale by mechanical means is absolutely impossible to damage the heaters very easily.

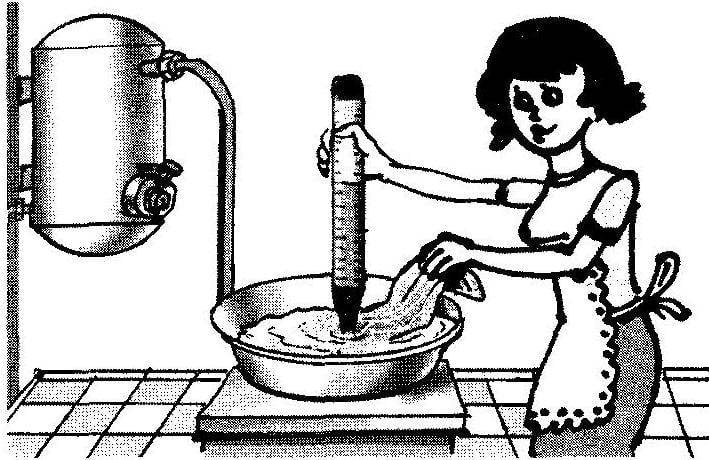

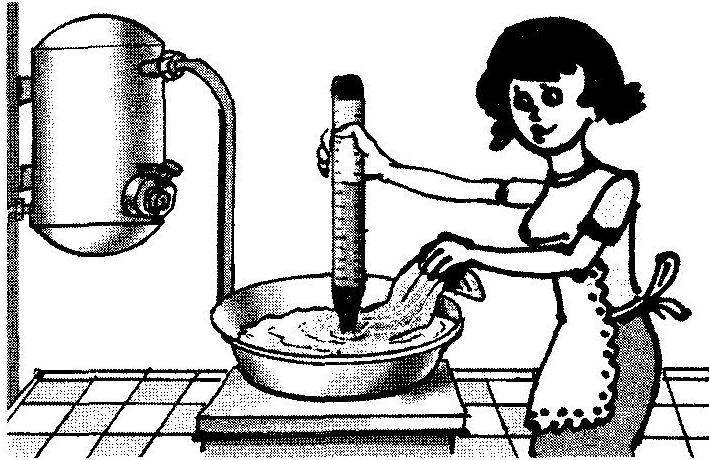

Offer the design of the heater with oil heat exchanger protects the heating elements from scale, — a kind of oil bath.

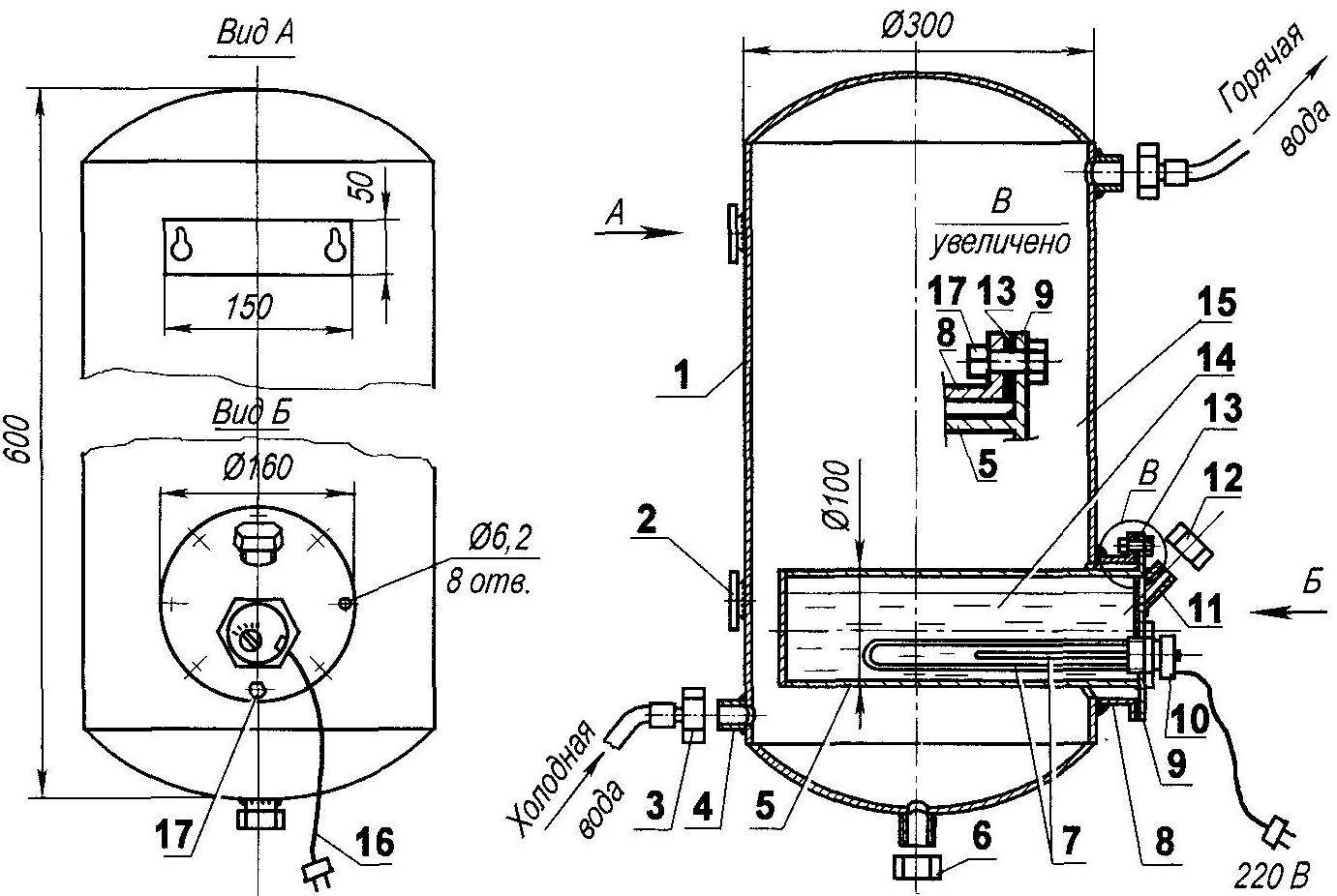

The body of the heater you can pick up any (for example, from the receiver of the compressor) or make a segment of steel pipe with diameter of 300 — 400 mm. from the Inside the body does not even need to paint very soon, its inner surface covered with a layer of scum and won’t rust.

In the case of three welded threaded fitting of the half-inch pipe (or 3/4″). One in the lower part (bottom) — it will provide for a complete emptying of the container if necessary. As usual, this fitting is plugged with a stopper. The other two are welded into the shell at its lower part, and the other at the top. The first is for depositing titanium cold water, one for hot water consumption.

The holes for the fittings can be cut with welding up to install fittings or after welding — drill drill bit, using the fitting as a template.

In the lower part of the shell cut a large opening sunroof to be installed in the titanium heat exchanger. For mounting of the heat exchanger of the shell welded neck flange. The diameter of the neck and the hatch slightly larger than the diameter of the heat exchanger.

Heater for hard water:

1 — titanium casing (the receiver of the compressor); 2 — mounting bracket of the heater to the wall (steel, sheet s3. 2); 3 — hose with two flare nuts (purchased product, 2); 4 — fitting (threaded pipe fitting 1/2″, 3 PCs.); 5 — exchanger casing (steel pipe O100); 6 — tube drain water (blind nut 1/2″); 7 — electric heaters (heating elements); 8 — filler hatch with flange (pipe O150, sheet s3); 9 — manhole cover (steel, sheet s3); 10 — the thermostat of the Heater (40 — 80°C), 11 — the oil fitting (threaded pipe fitting 1/2″); 12 — oil cap (blanking nut 1/2″) 13 — gasket (rubber, s2); 14 — the working fluid of the heat exchanger (transformer oil) 15 — heated liquid (water); 16 — power cord with plug (220 V); 17 — mount caps (bolt M6, 8 pieces)

The heat exchanger is a device consisting of a heating elements placed in a sealed housing. But because the air trapped between the heaters and the housing, is a poor conductor of heat, it “replaced the” transformer oil — electric current, the latter does not hold, and the coolant is good.

The exchanger casing is welded of ordinary steel pipe with a diameter of 100 — 150 mm. One side closes a round plate the same diameter as the pipe, and the other side flange. The flange is welded rezinovy half-inch fitting and run the hole under the fitting, Heaters and fasteners. Eight mounting holes for the M6 bolts are drilled in the flanges of the housing of the heat exchanger and of the neck of manhole under it.

Connection of electric heating elements in home network 220 is made via a thermostat that switches on when the coolant temperature is below 40°C and off at 80°C.

After filling the heat exchanger, transformer oil (to full volume) fitting overshadowed by a tube.

The connecting flange of the heat exchanger to the flange of the filler neck is made through the rubber gasket.

If the heater will be hung on the wall (which is the most rational way it was posted), then to the body are welded one or two brackets. Connecting the heater to the water system through flexible hoses.

On the outer surface of the heat exchanger in the process of operation will be the formation of scale, intensity of which depends on the water hardness. However, it can be removed by mechanical means and by removing the heat exchanger from titanium. After such cleaning remains only wash away the dust and the heated water can be used without fear even in the food.

A. MATVEICHUK