Of course, most men who have garden land or an allotment, there is a walking tractor or tiller, and even Soviet-style — type “Mole”, “Bee”, “Ural”. About them will be discussed.

Of course, most men who have garden land or an allotment, there is a walking tractor or tiller, and even Soviet-style — type “Mole”, “Bee”, “Ural”. About them will be discussed.

Usually in the second year of operation of such lawn and gardening equipment after winter storage, there is a problem with starting the engine. And the next seasons of arable happens that stalled during spring work in the greenhouse already and will not start at all!

As in all other life situations, there are certain “internal” reasons.

So — to start the two-stroke engine after a long winter Parking is as follows:

1. Fill the gas tank at least half with fresh fuel mixture and a good monoklonale cultivator from side to side for mixing settled at the bottom of the automobile. Better yet, to completely drain the old and pour the new fuel mixture. The reason is simple — a few months of downtime of the unit of gasoline vaporized light fraction, and it does not ignite. Also polymerization of fuel molecules into a new substance resembling diesel fuel, zabryzgivaya the spark plug and even the piston chamber.

2. To drain from the float chamber of the carburettor from the fuel mixture. If there is a special bolt, then just twist it until fully drained, oily liquid. Then open the gasoline valve and fill with fresh fuel mixture carburetor. At the end of the procedure — close the fuel tap and the bolt.

In those designs where there is no special drain holes in the bottom of the float chamber, you have to remove the carb and flushed it out.

After these simple procedures your metaakrilat easy to wind up and be obedient in the future.

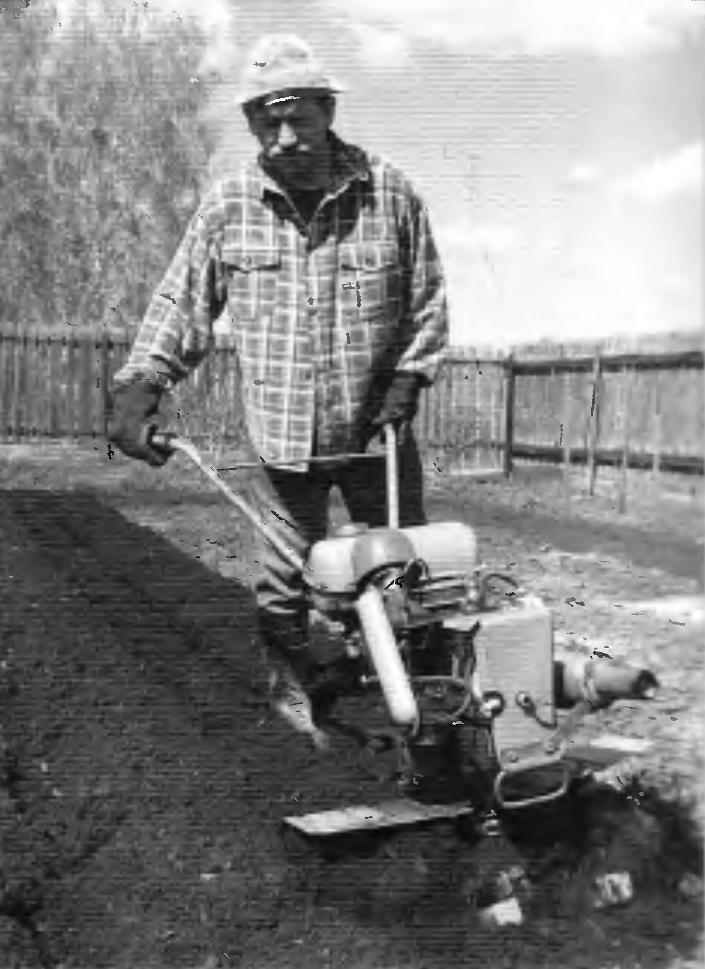

Modernization of the tiller:

1—nozzle on the muffler;

2—rubber damper;

3—wing;

4—supporting and regulating heel;

5—reference-guide ski (or wheel);

6—tiller

After several seasons of operation comes the need for deeper maintenance. Reasons will serve as a bad start “on hot”, increased fuel consumption and unexpected interruptions in the operation of the engine. So, the necessary maintenance are as follows:

1. To remove cylinder head, withdraw piston to the upper point and clean the surface of carbon. The cleanup can be done with a sharp knife, being careful not to scrape and then sand with fine sandpaper.

The remnants of soot and abrasive dust wipe thoroughly with a clean oiled rag, gradually shifting the piston to the bottom. For reassembly, if necessary, replace the gasket under the head and evenly, without bias to reach the mounting nut.

Would suggest to apply the gasket under the cylinder head of soft sheet aluminum is paracetomol. This will increase the heat transfer from the cylinder to the fins of the heads and improve cooling of the engine.

2. Inspect the contacts of the plug, trim the contact surfaces and cleaned them with fine emery paper. Be sure to adjust the gap and the ignition timing according to the operating instructions of the engine! As a rule, the moment of disconnection of contacts of the plug should occur at 2 — 3 mm before top dead center of piston motion. Upon completion of the work necessary to install the cover plugs on the sealant gasket. No dust, no water or oil should not get into this area of the engine.

3. Strongly suggest to remove the cap-Naslednik. Many reasons of failure of operation of the engine, are rooted in it. Just strip the end of the high tension leads for 20 mm and twist the copper conductor in a loop the size of the threaded tip of the candle. To strengthen the wire on the candle conveniently an ordinary nut with an appropriate šajbočka. By the way, pick better sparking candle. It is best to buy several different candle patterns and choose the most appropriate during the work. Coming up with a good candle, the engine of the tiller will start hot and cold and does not stall in case of overheating.

4. Remove and inspect air filter. Usually it’s paper type. As a result, on the second season of agricultural work, such as worn piston rings, and engine loses the property of easy winding. Take note: air filter must be promisin special oil or at least simple avtolom! Otherwise, it passes the fine dust… to Make air filter maintenance easier is to put it in a double plastic bag and pour the usual benzopyrano fuel mixture. Shaking and shaking for five minutes, drain the dirty wash and pour a new one. For heavily soiled filter you can carry out the procedure three times. Then dry the filter in a natural way or, better blow it with a hose from the compressor.

5. Another disease, which affects Soviet ice — gapping the plane of attachment of the carburetor to the cylinder. Using a file or emery lapping, remove the original curvature and to bring it to the plane. Eliminating such a marriage, you eliminate the harmful “leak” and improve the operation of the internal combustion engine.

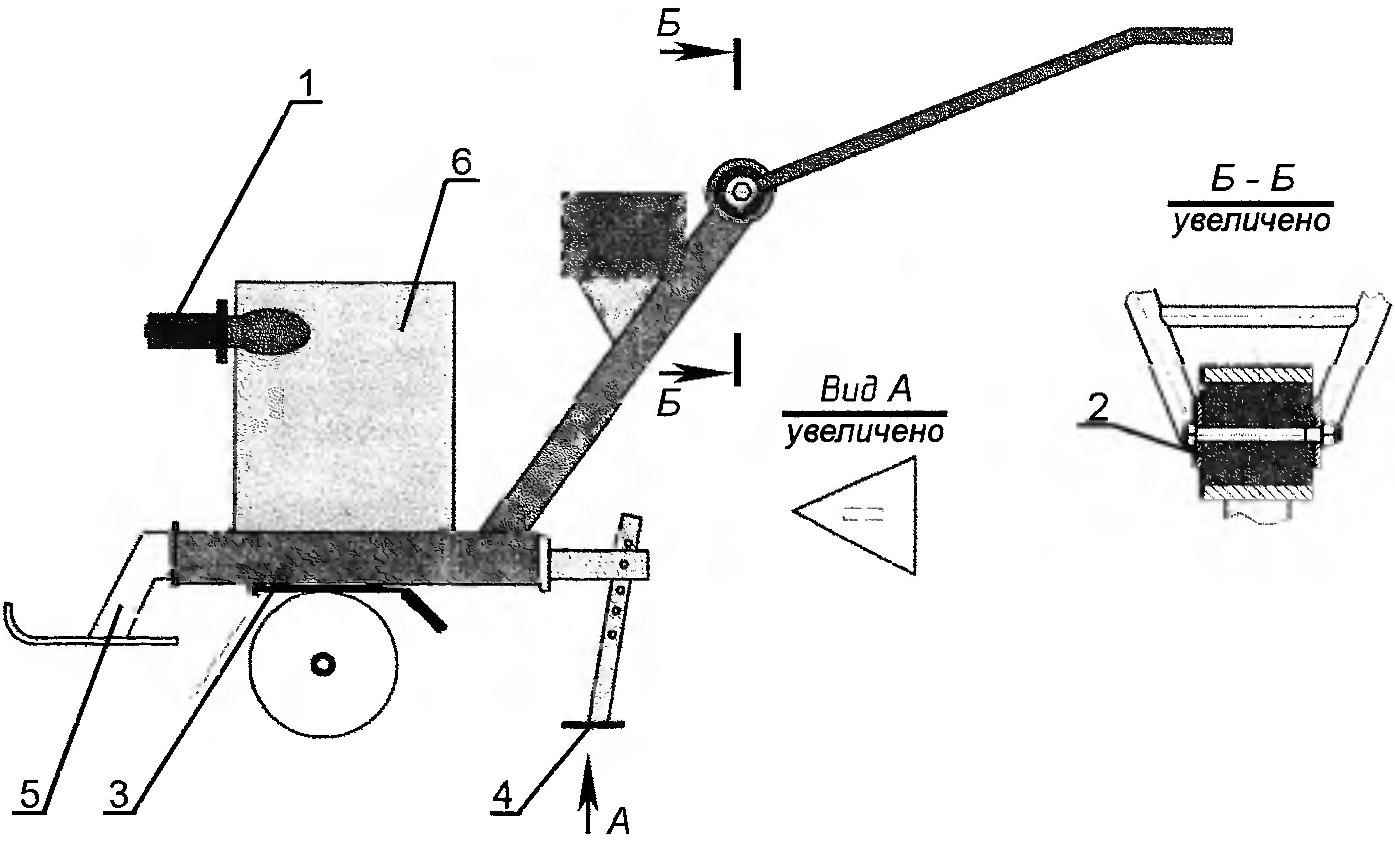

Head on regular muffler:

1—a flange of fastening of a nozzle to the silencer;

2—the outer casing;

3—silencing element;

4—pressing plate;

5—disk-partition;

6—securing housing to the silencing element (screw М8х25)

There is also a creative side to this topic is necessary to upgrade the purchase of motoagricola. Alterations, or rather, improvements not so much, but I think that they are important as they facilitate the work with a tiller:

1. Addition design wings over the mills if they were not. The material of the wings — sheet: galvanized steel about 1 mm thick, of aluminum alloy (1 — 2 mm), or even plastic. The level of arrangement of the wings is determined during a test spachek. They don’t have to lie on the ground with the full depth of plowing and duty to protect the farmer from flying lumps of the ground. It is possible to strengthen the factory mounts.

2. To improve the controllability of the tiller during tilling can be welded to the brake Fang base plate in the form of an equilateral triangle with dimensions of 80x80x80 mm 3-mm steel sheet. For heavy tillers are useful in supporting the front ski, which will not allow the technique to dig in the soft soil.

3. For repayment of the vibration loads on the joints of the hands is very desirable connecting the control arms to the frame of the cultivator through the rubber vibration damper in the form of rubber. The easier way to do this is in the use of vibration gloves with palms made of porous rubber. Veebruarini easy to make your own or buy in the store clothes (though they are, like the front leather).

It is useful application and both.

Loud exhaust of two-stroke engines, maybe not the main drawback of the Soviet motorcycles But it has a negative effect on hearing, and as a consequence the nervous system of the host. Neighbors crackle of the engine is also unpleasant.

Therefore, be sure a “loud” unit to provide additional “glushiteli” nozzle. In each case you will have to use ingenuity and skills together with plumbing tools and welding unit. The design of “handy” the owner will come up with it myself, but the importance of the fundamental approach — additional silencer should not inhibit the flow of exhaust gas to mute the sound by 20 — 30% is required. Otherwise there are problems when starting the engine, and lost power. The key thing to think about, calculate and provide minimum resistance to exhaust gases from the additional muffler. From personal experience I would advise to use single chamber nozzle of a silencer made in accordance with the attached drawing. It’s simple — the diameters of the flow tubes should be more exhaust ports are “native” to the muffler, and the sum of areas of through holes from chamber to chamber — twice.

Design, in General, simple in manufacture, and in operation, consisting of only a few parts: the internal “glushiteli” pipe with a disk partition and removable outer pipe-casing with the gland plate.

Nozzle is attached by four M6 bolts to a similar flange on the native silencer (option tiller “Bee”) through paronitovye gasket.

Fabrication and Assembly are performed in the following order:

- to cut hacksaw a piece of water pipe external diameter of 42 mm and a length of 140 mm. Then neverlet in its side walls 24 holes 08мм, trying to place them in a checkerboard pattern;

- to produce the flange, which may be square, and, having fitted it to a shared plate of the muffler of the cultivator, to lay out the holes. Then drill them with a positive tolerance, and a Central hole to modify to the desired diameter round file;

- cut with chisel disc-cover and cook all together: flange, inner glushiteli the tube and the disk partition;

- saw off nozhovkoj on metal from water pipe outer diameter 60 mm length 145 mm;

- cut the strip size 20×58 mm 3-mm steel sheet, drill a hole in it 08,5 mm and weld it to the outer pipe;

- last drilled hole 07,2 mm in the disk-partition, and it is cut with a tap thread M8;

- further, the nozzle is assembled and installed on the tiller.

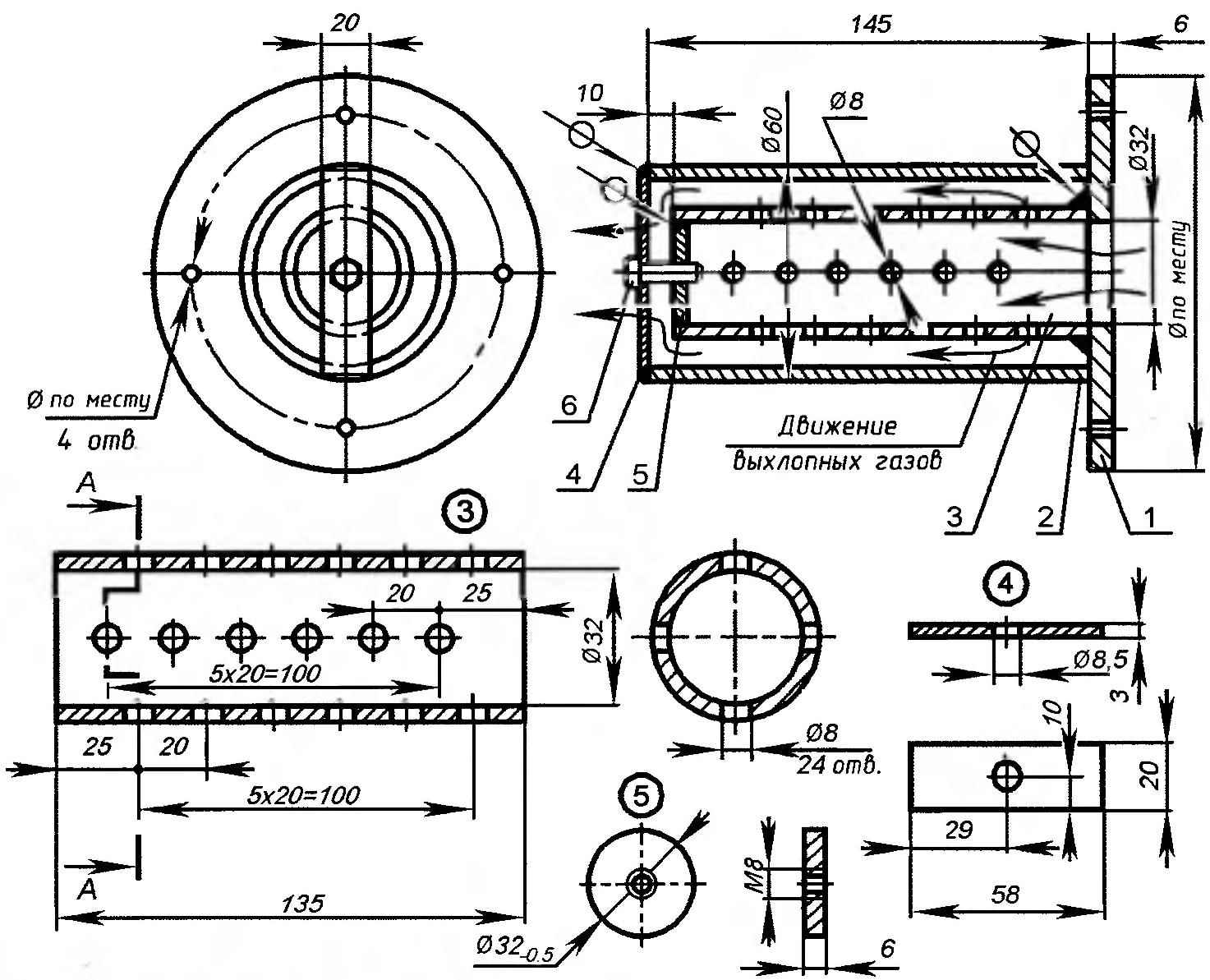

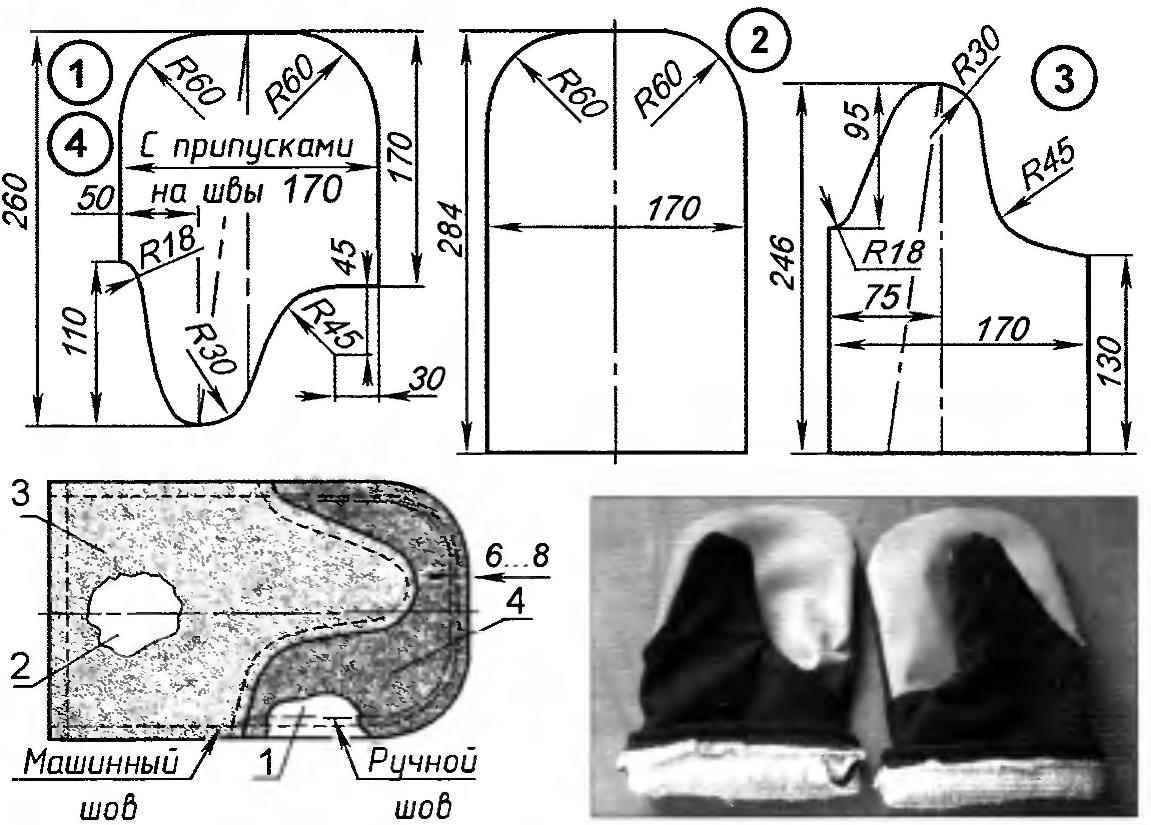

As earlier mentioned homemade “libraryalice”, will lead them pattern. Note that if the material from which gloves are made with clearly marked front and inside, patterns, components 1 and 3 should be performed mirrored for right / l left hand. Damping pads of foam rubber are cut by part 2, reduced only by the width of the seam allowance and sewn by hand darning needle with thick thread stitch with a big step.

“Vibro-gauntlets”:

1 —the inner part (“hand”);

2—outer part;

3—the inner part (“thumb”);

4—vibration-damping pad(porous rubber s5)

For this pattern you can make warm mittens (from an old blanket, drape, thick woolen fabric) for winter chores or regular gloves (canvas, denim) — for summer. After completing the internal part (“hand”) of synthetic non-woven material “thesis”, we get “Neprikasaemye” gloves for picking berries from prickly bushes.

It is desirable to do before the start of active plowing of household plots.

Here, perhaps, and all the user tips the cultivators with gasoline carbureted two-stroke engines.

I wish you, the hardworking men, soft plowing and the operation of motoagricola no problem!

A. MATVEICHUK, Zavodoukovsk, Tyumen region.